home

> Glazing of facades

> Glazing systems

> Mullion-transom glazing

Advantages Examples Calculation Application Our work Bonuses Prices Guarantees

Calculate the project

Stroitelnaya offers design and installation services for mullion-transom glazing systems with a 7-year warranty. The company's staff consists of highly qualified employees with extensive experience in implementing projects of any complexity. We guarantee high quality work, strict adherence to construction deadlines and contractual obligations.

Types of post-transom structures

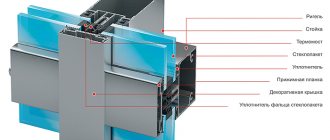

Classic post-transom system

Consists of an aluminum supporting frame and clamping profiles. On the outside, horizontal and vertical fixing strips are covered with decorative overlays.

Structural glazing

The translucent filling is fixed without using visible clamping strips: the double-glazed windows are attached to the frame in a hidden way, from the end side. External seams, the thickness of which is 1-2 cm, are insulated with a special sealant. Externally, the facade looks like a solid wall of glass.

Read more →

Semi-structural glazing

It is a synthesis of elements of structural and traditional mullion-transom glazing of facades. Fixation of double-glazed windows to the supporting mullion-transom frame is carried out using a spacer frame of the double-glazed window and a connecting profile. Narrow clamping bars installed horizontally or vertically can also be used.

Read more →

Do you have questions about mullion-transom glazing?

If you find it difficult to choose a facade glazing technology, contact construction experts for a free consultation. Together we will find the optimal solution!

To get a consultation

Question answer

What are the features of post-transom installations?

The systems consist of a metal frame into which laminated, tempered glass or double-glazed windows are mounted.

This is how they do it:

- stained glass windows and doors;

- glazing of facades of shopping centers, shops, offices;

- installation of office partitions;

- glass roofs;

- glazing of country private houses;

- skylights on the roof of buildings;

- entrance groups;

- panoramic glazing of balconies and loggias to the full height of the opening;

- construction of winter gardens;

- cottages with terraces and verandas.

The frame of the post-transom system is made of aluminum profile. Aluminum is characterized by high strength, reliability, durability and is not inferior in its parameters to PVC frames.

When glazing facades using the mullion-transom method, vertical mullions and horizontal crossbars are installed. Pressing frames are used to secure translucent fillers. Decorative covers are installed on top of the frames. This is the classic and most popular method of facade glazing, easy to install and convenient to use. Alternative methods of installing facade systems are frameless structural, semi-structural, spider, modular.

Aluminum profile can be cold or warm. Cold glazing of facades does not retain heat. The temperature difference between outside and inside the room will be small. This type of glazing is economical and costs less than warm modules. It is a system made of lightweight hollow aluminum profile without a thermal bridge. The filling includes one layer of tempered glass. The main element of warm facade systems is an aluminum profile for 2-4 chambers with a polyamide insert, energy-saving transparent glazing panels. Such façade glazing provides a high level of thermal insulation. Thick impact-resistant glass, double-glazed windows with energy-saving properties, and triplex with a special heat-insulating coating are used as fillers. The use of sealants and seals also reduces heat loss and prevents the possibility of moisture penetrating into aluminum structures.

The appearance of aluminum windows, doors, and frames can be matched to the building’s finishing design thanks to the following technologies:

- powder coating offers a wide choice of colors from the RAL palette;

- Anodizing the aluminum surface gives a beautiful metallic shine and creates a durable protective film;

- To create wood-like frames, natural stone can be laminated.

Advantages of mullion-transom aluminum facade structures:

- tightness of the internal space - protection of the facade from wind and precipitation;

- reliability and durability;

- Fire safety;

- good profile resistance to corrosion and mechanical stress;

- ability to withstand the load of its own weight, wind pressure, snow.

- glazing installation is quick and can be done at any time of the year;

- you can design facades with glass of any size;

- suitable for buildings with complex architectural solutions;

- allow in a large amount of natural light;

- give a fairly wide view of the street;

- create a visual effect of lightness of the structure;

- look attractive;

- are easy to maintain;

- warm profiles provide energy savings;

- For repairs, you only need to replace the failed glazing element.

Compared to wooden or plastic systems, aluminum mullion-transom facades have greater strength, functionality, and increased performance characteristics. Such facade systems are characterized by the absence of harmful impurities. They protect better from the effects of adverse weather conditions and last for many years.

What do you need to know about design options?

The glass facade can be continuous or include:

- aluminum windows;

- entrance groups with conventional hinged or sliding doors;

- blind or opening stained glass windows.

You can install backlighting to illuminate the facades at night. Automatic systems may include various sensors and fire-fighting technologies. Sliding doors can be opened using a code pad, magnetic card, facial recognition or fingerprint technology.

Various options for connecting racks and crossbars allow you to create inclined surfaces and structures of various shapes. As a rule, windows are installed on mullion-transom supports. The frameless installation method in this case is less practical and is suitable for installing hidden sashes instead of windows.

In addition to the design, mullion-transom systems can include different filling materials: opaque or transparent panels. Durable sheets of glass or double-glazed windows can be tinted, matted, covered with solar control film, or sandblasted.

Features of the mullion-transom glazing system for facades

Performing bends of SPC in any planes. Popular in construction, the mullion-transom facade glazing system can provide absolutely feasible opportunities in modern facade design. This high-tech system has helped change the face of cities around the world. If you choose structural glazing, you will get a complete absence of glass unit fastening elements on the outside of the building.

Use of modern sealants Translucent structures are securely fixed to the facade of the building using silicone sealant, which in fact acts as a load-bearing element. Covering opaque areas, stained glass windows based on aluminum profiles will serve as a design decoration for the building.

Versatility of fastening and joining of profiles The mullion-transom glazing system, produced according to the exact dimensions of the customer, has a distinctive feature in that it is possible to build in hidden sashes for external opening.

In semi-structural glazing, mechanical (using a clamping strip) fastening of double-glazed windows is used. Visually, the plank will not be visible on the surface of the facade, because it has significantly smaller dimensions than standard “clamps”. In addition, it is possible to install conventional double-glazed windows, which will reduce the final cost of the SPC.

Main technical characteristics of TP-78 EF

- The width of the front part of the profile is 78 mm;

- The presence of two types of thermal bridge, the width of which is 22 and 34 mm;

- The filling that is used is: deaf and also translucent, their thickness varies in the range of 6 - 50 mm;

- The presence of three sealing contours in the sashes and between the blocks;

- The maximum moment of inertia of the frame is 322 cm4, the impost is 524 cm4.

The TP-78 EF system was created specifically for high-rise construction in difficult climatic conditions. In this case, there is no need to install scaffolding during the installation of structures.

The installation of the facade is carried out using ready-made blocks assembled in the workshop. Due to the fact that the production of elements takes place in a factory environment, high quality assembly work is guaranteed.

Compensation for temperature deformations is carried out using a rubber seal between the elements.

The block is fastened to the building using steel and aluminum mounting units. The design of the units makes it possible to adjust in three directions.

The main feature is that both options cannot be distinguished from the front side of the facade - the sash is invisible. The fittings used are top-hung for external opening (with friction hinges) and parallel-retractable (drive - manual or automated).

Fittings from well-known European manufacturers are used: ESCO, GIESSE, SOBINCO.

The mullion-transom system is used in the following types of facade glazing

- Panoramic glazing - a translucent structure is installed to the full height of the room, from floor to ceiling.

- Continuous glazing - the façade of the building consists exclusively of glass and metal throughout the entire area.

- Strip glazing is glazing in the form of a glass strip in which translucent elements are located without visual separation.

- Double Skin (double glazing) - the façade of the building is a multilayer structure of two glass contours with an air gap between them.

- Jumbo glazing is glazing using massive large-area float glass.

- Fire resistant glazing – glazing using fire-resistant translucent façade systems.

Description of technology

Crossbar glazing of facades is a proven classic. It consists of vertical and horizontal steel or aluminum profiles, the space between which is filled with single glass in a cold facade and multilayer glass in a warm one.

Typically the visible width of the profiles is 50 mm. This is quite enough to ensure design rigidity. The external metal parts of the facade can be painted in any color to create a complete design.

Thanks to sealing strips and thermal inserts of various thicknesses, a classic translucent façade can be made from double-glazed windows of various thicknesses.

“Cold” façade”

The mullion-transom glazing system for “cold” facades is characterized by the use of single glass in an aluminum profile without thermal inserts. At the same time, the temperature inside the buildings remains at an acceptable level.

The supporting function is performed by the racks, and the crossbars prevent the structure from deforming. In addition to the classic post-crossbar, there is another version of the crossbar-transom. It uses crossbars as racks, and the remains of the racks act as spacer crossbars. Thus, the cost per square meter is reduced.

The façade elements are connected to each other in different ways. This can be a butt or overlap fastening, as well as an “anchor” or “cracker”.

"Warm facade"

The mullion-transom system of “warm” facade glazing is characterized by the use of multilayer double-glazed windows. The number of glasses can reach 5-6 pieces. The external profile width can reach 70 mm. This is due to the mass of filling elements. The weight of one double-glazed window can reach 700 kg, which in total puts a significant load on the frame.

The Russian climate leaves its mark on the number and width of thermal inserts. In addition to them, the profile can be equipped with special foamed additional elements. For high-rise buildings this is not so important, since at high altitudes in different climatic zones the temperature is the same.

Price for mullion-transom glazing per m2

This system is rightfully considered the most popular on the market, due to the successful combination of the minimum cost of the entire structure, as well as high functionality and attractive appearance. In practical implementation, mullion-transom glazing of facades at affordable prices per m2 is a frame of crossbars and mullions, to which other glazing elements are attached.

| Name | Unit. | Price |

| Cold translucent design without openings | per m2 | from 5,200 rub. |

| Warm translucent design without openings | per m2 | from 7,100 rub. |

| Cold translucent design with openings (windows/doors) | per m2 | from 6,400 rub. |

| Warm translucent design with openings (windows/doors) | per m2 | from 8,050 rub. |

Main technical characteristics

- The width of the front surface of the profiles reaches 50 mm;

- Profile section height values: 56 - 240 mm - for racks, 34 - 169 mm - for crossbars;

- The filling is solid and transparent, the thickness varies from 4 to 48 mm;

- The maximum permissible filling weight does not exceed 600 kg;

- The value of the maximum moment of inertia of the TP strut is 1420 cm4, the same parameter of the EK strut is 137 cm4.

The TP-50300 series is designed for the manufacture of vertical structures, as well as inclined

translucent.

Advantages and disadvantages

Any system has a number of positive and negative properties, knowledge of which allows you to avoid making mistakes when choosing glazing for a particular object.

Advantages

- Frame installation technologies. Unlike other systems, a mullion-transom facade, or rather its vertical and horizontal load-bearing profiles, can be connected to each other in several ways. This allows you to select a connection node for a specific facade. The classic facade glazing system has a variant when only crossbars are used for installation. In this case, one type of profile is used for racks and lintels. Material costs are reduced due to the use of a profile without residue or trimmings.

- Tightness. Dense and high-quality joints between glass and metal do not allow moisture and air to pass through from the external environment.

- Interchangeability. The racks and crossbars are made from the same profile, which allows you to use all the material without residue. This property is convenient to use at the design stage, when you can cut factory profiles to zero, significantly saving money.

- A mullion-transom façade can be compared to plasticine. A large selection of fastening and additional elements, as well as glass and double-glazed windows allows you to install facades of fancy shapes. These are sloping roofs, “spiral-screw facades”, various connections to buildings, domed and arched glazing, breaks and transitions from one plane to another.

- Energy efficiency. The glass façade allows enough sunlight to pass through to save electricity. Double-glazed windows and a frame with thermal breaks and thermal inserts, as well as foam insulation, make it possible to maintain the temperature of internal visits at an acceptable level of +19-21. °C.

- Versatility. Post-transom facades are suitable for both cottages and high-rise buildings.

The facade of a private house is glazed using a mullion-transom design

Sources

- https://BazaFasada.ru/fasad-zdanij/stoechno-rigelnaya-sistema-ostekleniya.html

- https://www.alpicagroup.ru/osteklenie_fasadov/sistemy_osteklenija_fasadov/stoechno_rigelnoe_osteklenie.html

- https://AnkorOkna.ru/info/stoechno-rigelnaya-sistema-ostekleniya-fasadov.html

- https://priorglass.ru/stoechno-rigelnoe-osteklenie/

- https://www.facade.ru/services/fasadnoe-osteklenie/stoechno-rigelnoe-osteklenie/

- https://climb-g.ru/alyuminievoe-osteklenie/306-fasadnoe-osteklenie.html

- https://nord-glass.ru/poleznye-stati/stoechno-rigelnogo-ostekleniya-fasadov/

- https://al-solution.ru/information/rack-and-crossbar-facades

Integrated “hidden sash” window with improved thermal characteristics

In the updated solution, the glass unit is glued to the sash using the middle glass (this solution is patented by ALUTECH Group of Companies), and not behind the outer glass, as in most domestic and foreign systems.

In double-glazed windows, the main heat loss occurs through the spacer frame. The use of a new method of gluing the filling made it possible to break the continuous cold bridge, which, in turn, made it possible to significantly improve the thermal characteristics of the new hidden sash.

The thermal conductivity of a typical frame-sash section is reduced to Uf=1.15 W/(m2*K), which is significantly better than similar systems of domestic and European production. This design assumes the use of double-chamber double-glazed windows with a thickness of up to 62 mm.

In addition, the new version of the sash has higher aesthetic qualities. Gluing the outer chamber of a double-glazed window allows you to completely preserve the decorative properties of the outer glass and hide the profile of the sash as much as possible.

This system provides the possibility of using top-hung and parallel-sliding outward opening. Additionally, Giesse offers hardware kits for this opening option.

Also, at your request, the necessary set of components and drives for organizing automatic opening of windows can be selected and supplied.