Sandwich panels for slopes have recently appeared in the construction industry as an alternative to plaster and plasterboard finishing.

The panels have a layered structure, which is why they are called “sandwich”. The outer surfaces are made of polyvinyl chloride with a thickness of 1-2 mm, the inner layer is made of extruded or foamed polystyrene. Produced in sheet form. Can be one-sided, i.e. have only one layer of plastic. The dimensions of the sandwich panels for slopes are 3x1.5 m, 3x2 m..

Sandwich panels for slopes are the most suitable material for finishing windows. Its installation is devoid of all the disadvantages associated with plaster. There are no splashes or pollution of the environment. The use of drywall is more complex and time-consuming.

RECOMMENDED ON THE TOPIC

- The project of the Aseria cottage in the form of...

- Types of finishing of internal window slopes

PVC performs moisture-proof and decorative functions. The surface can be smooth and matte, white and colored, stylized as wood, metal or stone. It is easy to clean, does not fade and is not destroyed by the sun.

Recommendations for use

Finishing with sandwich panels is possible in any conditions, but installation during rain is not recommended. Mineral wool insulation can get wet, and this will reduce the quality characteristics of the products.

When using sandwich panels, periodic inspection of the appearance of the products is necessary. Shaped parts and fastenings must be sealed. If this is not the case, then the inside of the panels can be additionally glued. It is better to clean dirty external surfaces with a soft brush. If the top coating of the panels is lamination, the use of abrasive cleaning agents is prohibited.

Possible damage can be cut off and replaced with new ones, or can be restored using suitable repair paint if the type of polymer coating on the panel is known. Paint coating options include alkyd enamel or latex acrylate paint.

How to choose slopes: the best finishing option

There are several options for finishing slopes. Materials such as plaster, plasterboard, gypsum fiber, plastic panels and sandwich panels can be used for this. The price for window slopes of the latter type of material is the highest compared to other options.

The traditional way to finish slopes is to plaster the side and top niches of the window frame. The technology consists of leveling the surface by applying several layers of plaster, followed by priming and painting the surface. This method is characterized by a number of distinctive advantages. First of all, it is distinguished by its versatility. You can plaster the slope in a room with any humidity and temperature conditions. The mixture itself is an inexpensive material.

Plaster slopes are characterized by resistance to mechanical stress, ultraviolet radiation and moisture. This finish does not contain seams or joints. The surface is perfectly flat and smooth. In the event of a decrease in aesthetics, such slopes can easily be updated or repaired.

For slopes, plasterboard, plastic and sandwich panels, as well as gypsum fiber are used

Despite its many advantages, this method of finishing slopes has its drawbacks. Plastering side niches is a long and labor-intensive process that requires breaks in work to dry each new layer. In addition, to get a good result you need to have the appropriate skills. Plaster slopes are characterized by low thermal insulation properties. They are prone to freezing and condensation.

Sandwich panels

PVC sandwich panels look beautiful and come with ready-made insulation (if you are interested in this point, pay attention). This helps reduce the amount of work during installation and improves the quality of thermal insulation. For additional insulation and improved adhesion quality of working surfaces, polyurethane foam is used (this is optional).

Reasons to choose a plastic window slope sandwich

Sandwich panels for PVC windows are lightweight, easy to install, and durable. They retain moisture, heat and noise and are not prone to rotting. Maintenance is easy - wipe the sandwich material with a cloth (dry or damp) to remove dirt. Plastic elements have no disadvantages, except for one. With constant contact with UV, moisture, and high temperatures, products lose their original appearance and turn yellow.

The structure of sandwich panels includes the following layers:

- Fiberboard or metal;

- PVC directly;

- insulation (fiberglass, mineral wool, polyurethane foam).

A hot press is used to connect them. The surfaces of the panels are made decoratively profiled, smooth, a profiled version is available (decoration is provided only on the outside). The finishing sandwich material is easy to maintain. Sandwich panels are installed in rooms with any conditions, including high humidity.

Advantages

- Environmental friendliness, safety - the primary raw materials for window slopes are of high quality, so the solutions can be used without restrictions in schools, medical centers, and children's rooms. The safety of products is confirmed by certificates.

- Thermal insulation - due to the channel structure of the panels, the absence of gaps between the elements.

- Finishing of openings of all configurations - panels can have dimensions up to 600 m. There are locks on both sides, this simplifies installation and fixation, and allows you to create solutions of optimal width.

- Choice of decors – painting, lamination, UV printing (choose an option to suit any interior).

- High-tech installation - for assembling a sandwich structure, latches and sealant are provided, no glue is required. You can dismantle the slopes yourself during finishing, and then put them back.

- Affordable price – you can buy a window finishing solution inexpensively.

Other Features

Available types of coatings are matte or glossy. Gloss has a pronounced shine, but it tends to attract dust and fingerprints remain on it. If the window is constantly touched, opened and closed, you should choose a matte sandwich type option.

There is no need to additionally paint decorative PVC slopes. Factory products come with a film coating; it cannot be touched. The film protects the panel from damage, masks scratches, and increases resistance to mechanical stress. The material is not prone to fading and does not lose its original shape during the period of operation.

We recommend purchasing additional elements needed for decoration and installation directly with sandwich panels. This will help save time and money. It's cheaper to order in sets.

Our offer

We sell skirting boards, accessories, window sills at competitive prices, you can buy them with delivery throughout Moscow. We guarantee quality and affordable prices. Sandwich panels are available in different colors, see the product card for dimensions. Prices from 1000 rubles per piece.

We are ready to answer your questions, help you choose, and organize fast delivery. The environmental friendliness and safety of sandwich panels are confirmed by certificates. At the buyer's request, we provide the services of professional installers (they will select and install the panel). Please check with the manager for details (cost of service, time, place of departure, availability of technicians) when placing an order.

- PVC panels

- Profiles

- Sandwich panels

- Universal

If for some reason you were unable to reach us by phone, leave your contact information and our operators will contact you as soon as possible.

Features of plasterboard slopes for window openings

Many people prefer plasterboard slopes. The method is based on gluing or screwing sheets of material of the required size to the side niches, followed by priming, puttying and painting. This option attracts with its simple and quick installation, which even a novice master can handle. The material is also characterized by an acceptable cost.

Installation of plasterboard slopes - a quick and easy finishing option

Using strips of plasterboard, you can create perfectly smooth sides of the window. The space between the drywall and the wall is filled with mounting foam, which serves as a seal for the window. This surface is suitable for numerous paintings.

However, this method is not without drawbacks. The material is susceptible to moisture, so it can be used exclusively for finishing internal slopes. Condensation forms on the surface, which will soon lead to swelling and destruction of the structure. Such defects can be eliminated by completely redoing the slopes.

Drywall, like plaster slopes, is not able to interact firmly with the plastic frame. This contributes to the formation of cracks at the joints. The material is quite fragile, which does not exclude the possibility of it being pressed through and bending during installation.

After installing drywall, you will need to prime, putty and paint the surface to give it a finished appearance, which is not required when using sandwich panels for window slopes. It will take a few more days to complete all the work.

The installation of such slopes is carried out in two ways: frameless and framed.

Sequence of installation of plasterboard slopes

Installation of plasterboard slopes can be carried out in two ways: framed and frameless. With the frame installation method, at the initial stage you should screw the starting profile using self-tapping screws, as in the case of using sandwich panels for window slopes. It is fixed on the line of joining of the plasterboard sheet and the window frame in the groove. The original frame is ready, after which you can begin installation.

A feature of plasterboard slopes is that the strips of material do not fit tightly to the window frame. A gap is formed, which negatively affects the thermal insulation properties of the opening. This space should be filled with mounting foam or mineral wool.

Fastening drywall can be done using liquid nails

At the junction of plasterboard panels, perforated corners are installed. The finished surface is primed and puttied. After the composition has completely dried, the coating is rubbed with sandpaper to obtain a smooth base, which can be painted in any color with water-based paint.

Installation of slopes. Slope construction

The most common materials for finishing plastic windows: plaster, drywall, plastic. In this case, after installing plastic windows, slopes can be made using any of them, but it is advisable to strive to ensure that the service life of the slope is comparable to the service life of the window.

Next, we will consider technologies and materials, methods and order of implementation. And the preparatory work is the same for the installation of any type of slopes:

- If necessary, protect the window and window sill. Even if the protective film has not been removed from the block and window sashes, it is better to cover them with masking tape before dismantling the old slope, as well as before plastering begins. It’s good to seal the glass with polyethylene. The window sill also needs protection; for convenience, you can remove the end caps.

- If necessary, knock down old window slopes indoors. Since quite often plastic windows are installed instead of wooden ones, the frame of which is much wider. Therefore, without any problems, it allows you to install a new window without completely dismantling the old plaster slopes.

- Make markings. To do this, place perpendiculars from the edges of the window onto the window sill, assess how much you can expand not only the sides, but also the top. Choose the optimal, identical value for all sides. For the sides - mark on the windowsill, set aside the vertical and make marks at the top. For the upper side of the slope, also make horizontal markings on the wall. All this will greatly simplify subsequent installation.

Installation subtleties

You can install multilayer PVC panels yourself, the main thing is to follow all the rules and instructions for installing such materials. Using window slopes as an example, we will consider the technique of installing plastic panels at home.

Required tools for installation:

- self-tapping screws, liquid nails, sealant;

- mounting profiles;

- polyurethane foam;

- sandwich panels;

- mounting level;

- knife-cutter, electric jigsaw, scissors for cutting metal materials;

- electric drill;

- in some cases, experienced craftsmen use a grinder to cut panels.

Beginning builders need to use such a tool with caution, because if you apply too much pressure, the material will break. Before you start laying the sheets, you need to get rid of dirt (dust, paint, foam)

Sandwich materials are laid only on a clean base. If there is mold, it must be eliminated and the surface treated with a special impregnation.

Before you start laying the sheets, you need to get rid of dirt (dust, paint, foam). Sandwich materials are laid only on a clean base. If mold exists, it must be eliminated and the surface treated with a special impregnation.

- Preparation and measurement of slopes. Using a tape measure, measure the length and width of the slopes in order to cut the panels to fit the slope.

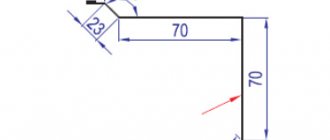

- Installation of profiles. The initial U-shaped profiles (starting profiles) are cut and fastened with self-tapping screws, which are installed along the edges of the profiles, leaving a gap of 15 cm between them.

- The side sections and the top PVC panel are installed in the plastic profile. The sections are fixed to the wall with liquid nails or foam.

- The areas adjacent to the walls are covered with cladding material made from an L-shaped profile. The border profile is installed using liquid nails.

- Finally, the junction areas are treated with white silicone sealant.

You need to use polyurethane foam with extreme caution, because when it comes out it doubles in volume. Otherwise, large gaps will form between the layered sheets and the wall, and the entire work will have to be redone

Slopes on balconies and loggias made of sandwich slabs are made similarly to the slopes of metal-plastic windows in an apartment.

Do-it-yourself installation of PVC slopes

Like all construction work, the installation of plastic slopes begins with preliminary preparation, during which the materials and tools necessary for this work are purchased.

What materials and tools are needed:

- Plastic for slopes with a thickness of at least 8 mm.

- U-shaped starting strip made of plastic.

- F-shaped plastic profile.

- Insulation material: mineral wool, polyurethane foam.

- Wooden slats.

- Drill for self-tapping screws.

- Building level.

- Roulette.

- Putty knife.

- Cement mortar.

- Long screws - 95 mm, self-tapping screws - 4.5 mm.

- Painting knife.

- Silicone sealant.

- Metal scissors.

- Construction stapler.

Next, the working surface is prepared: the remains of wallpaper or old plaster are removed from the old slopes, and the surface is treated with an antifungal agent.

If, during the installation of a metal-plastic window, cracks appear on the street side, they need to be sealed with cement mortar. This procedure is necessary to protect the polyurethane foam from harmful sun rays and seal the external assembly seams.

Source: balkonsami.ru

Peculiarities

Unlike old wooden frames, modern plastic windows are equipped with special ventilation equipment. For this purpose, the upper part of the window frame is tilted, forming a narrow opening for the flow of fresh air. As a result, air turbulence occurs with sharp changes in temperature conditions.

Drywall is often used for this purpose, but such building material can freeze in winter, and caring for it requires a lot of effort.

If the room is built of brick or reinforced concrete blocks, only sandwich panels can be used for maximum insulation of the slopes.

The advantages of using sandwich panels are as follows:

- additional noise and thermal insulation is performed. Additional insulation is carried out using polyurethane foam to better connect the material to the slope;

- does not require constant care and maintenance. Any type of contaminant can be easily washed off with a cleaning solution without damaging the structure;

- high vapor permeability. Unlike plasterboard material, sandwich panels do not get wet or crack when exposed to moisture;

- low weight of the structure (the weight of 1 m² with a product thickness of 24 mm is 3.9 kg);

- highly resistant to mechanical damage;

- resistance to ultraviolet radiation;

- stylish design appearance;

- resistance to mold and mildew;

- reasonable cost of the product;

- do not require additional registration. The surface of the panels has a structure similar to the surface of plastic windows;

- environmentally friendly material. It does not emit harmful substances, thereby causing no harm to living organisms during operation.

Despite the fact that multilayer panels have many advantages, some consumers have negative reviews about this building material, such as:

- under the influence of high temperatures the product turns yellow and becomes deformed;

- improper installation of the material can lead to the formation of gaps and cracks;

- Slopes cannot be finished using sandwich panels if the distance between the hinge and the wall is small. Otherwise, the structure will walk around the perimeter;

- Only low quality materials have such disadvantages.

Application options

The areas of use of multilayer products are quite diverse. Depending on its size and thickness, such material can be used for a variety of purposes:

- Typically, PVC sandwich panels of 8mm, 10mm and 24mm are used in the production of windows. This material is used to fill opaque fragments of balcony doors;

- In addition, multilayer PVC boards make it possible to correct mistakes made during construction work and too large tolerances on unplastered, rough surfaces;

- In addition, such PVC boards, as in the following photo, are also used for the production of advertising signs, banners and billboards of different sizes;

- Also, products of this nature are quite often used by qualified builders for the construction of wall partitions inside buildings if their prompt installation, perfect parallelism and low thickness are required;

- PVC sandwich panels for slopes are a very convenient option for those who want to decorate their windows and balcony doors very beautifully, but for reasonable money. It is important to note that in many respects, slopes equipped with such slabs are superior to alternatives in terms of durability and external aesthetics. Plastic structures can provide high levels of thermal insulation of a room, increasing the positive effect of installing new windows. PVC sandwich panels for windows demonstrate high resistance to mechanical damage and various types of contamination, and at the same time they do not require careful maintenance. Look at the following photo to understand what a window opening looks like, designed using multilayer slabs;

- Due to the fact that sandwich-type panels have excellent moisture resistance, they are actively used when performing finishing work in bathrooms.

In practice, PVC panels demonstrate high versatility. Judge for yourself: they are used in construction work in many countries with completely different climatic conditions. I would especially like to highlight the fact that PVC material of this nature can be installed in any weather conditions and at any time of the year. This means that construction work will not stop, no matter what. This not only significantly speeds up the time required to equip the facade of a building for various purposes, but can also provide significant savings in money.

Therefore, if you need a really high-quality material that will demonstrate high technical characteristics and last for quite a long time, you should definitely turn your attention to PVC sandwich panels.

Let's sum it up

According to consumer reviews, PVC sandwich panels 10 mm, 24 mm are an excellent option that provide reliable heat, steam, noise and sound insulation. Such a facade acts as an excellent protective mechanism for the walls of a building, and also gives structures for various purposes a complete, aesthetically attractive and original look.

Sandwich panels for slopes technical characteristics

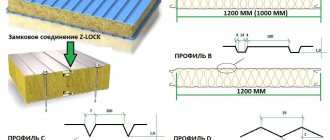

Sandwich panels are multilayer frameless building structures. The word “sandwich” (from the English sandwich – layer) means the “layered” structure of a building structure.

Properties and applications of PVC sandwich panels

The panels are assembled together into wall blocks using a profiled locking connection located in the body of the panel. Sandwich panels belong to a range of lightweight enclosing structures.

PVC sandwich panel is a three-layer structure: two rigid PVC sheets between which there is insulation (expanded polystyrene (pressed or foamed (PSV), extruded - ST, XPS), or in rare cases - polyurethane foam - FPU).

Figure 1PVC sandwich panel

PVC sandwich panels with polyurethane foam filling have the best heat-saving characteristics. Polyurethane foam is the most environmentally friendly material. Allowed for use in residential premises. Has minimal hygroscopicity and longest service life.

Expanded polystyrene is characterized by high strength, chemical resistance, durability, and high thermal insulation properties.

Depending on the climatic conditions and the purpose of the facility under construction (reconstruction), one or another type of insulation material is used.

Various materials can be used as the outer layer of a plastic sandwich panel:

• Rigid PVC sheet • Foam PVC sheet • HPL

Rigid PVC sheet is the most commonly used material in plastic sandwich panels used for slopes. For the production of sandwich panels with rigid PVC, white sheet material is most often used, the thickness of which varies from 0.8 - 2 mm; the surface of the sheet can be either glossy or matte. The density of such material is 1.4 g/cm3.

Foamed PVC sheets received this name because of the porous internal structure, which is specially obtained during the extrusion production of sheets. Foaming of the plastic occurs at the exit from the extrusion head, and a fine-cellular structure is obtained along the thickness of the sheet, containing a large percentage of tiny closed air bubbles. Therefore, in addition to the above properties, PVC sheets have low density (0.6 g/cm3) and good thermal insulation. Foamed PVC sheets, like rigid PVC sheets, have good moisture resistance. At negative temperatures, the impact strength of foamed plastics decreases.

The term HPL means a method of producing the material: a “pack” of papers is assembled (kraft paper for the inner layers, decorative paper for the surface, overlay for protecting the surface), impregnated with phenol-formaldehyde and amino-formaldehyde resins and pressed in a floor press under a pressure of 90 to 110 kg/cm2. When pressing, technological equipment is used, which determines the surface texture. For this purpose, special spacer metal sheets and matrices are used, the surface of which represents relief images imitating the pores of wood, the surface of stone, etc. These reliefs are transferred to the surface of a sheet of plastic, which allows you to obtain various types of surface: gloss, “satin”, wood pores, “asphalt”, etc. HPL is produced only in sheets. The thickness of sheet laminated plastic for the production of sandwich panels is most often 2 mm. Of all the plastics described above for lining the insulation in a sandwich panel, HPL is the most durable and reliable material, and sandwich panels with HPL can be used in operating conditions that involve the greatest loads on the material.

Any of the above-described facing plastics can be covered with a renolit film, which will make it more suitable for decoration. Most often, sandwich panels with HPL are used for decoration purposes. For slopes and windows, a simple hard matte or glossy white PVC sheet is most often used. Panels with foamed PVC are used less frequently.

What it is?

The insulation inside the panel may vary:

- polyurethane foam;

- extruded polystyrene;

- free foam plastic.

External coating options also vary. It can be made from:

- Rigid PVC (installation of PVC slopes is discussed here). It has a high density (1.4 g/m³). The sheet is always white, but depending on the coating it can be matte or glossy.

- Foamed PVC . Used for the inside of the panel. It has a low density (0.6 g/m³) and insulates well.

- Laminated plastic . It consists of several layers of plastic and decorative kraft paper, which are compressed and impregnated with resins.

Depending on the number of layers, sandwich panels are:

- Unilateral . One side is the rough side, the other, with greater thickness, is the front side.

- Double-sided . Both sides are obverse.

Properties and structure: are there any disadvantages?

The outer layer of the structure can be made of different materials.

- Made from rigid PVC sheet. For the production of multilayer material, white sheet material is used. Thickness ranges from 0.8 to 2 mm. The coating of such a sheet can be glossy or matte. The leaf density is 1.4 g/cm3.

- Made from foamed PVC sheet. The internal part of the structure has a porous structure. Foamed sheets have a low material density (0.6 g/cm3) and good thermal insulation.

- Made from laminated plastic, which is created by impregnating a pack of decorative, overlay or craft paper with resins and then pressing it.

Multilayer panels can be supplied as ready-made systems that do not require preparatory work for assembling the material. Finished structures are attached to the facing material using glue. The second design variation is that such panels are assembled using self-tapping screws before installation technology.

Advantages of plastic slopes

- Excellent aesthetic appearance;

- Installation is quick and mess-free;

- Relieves you from fogging up your windows;

- There is no overpayment for waste that may remain during the installation process;

- Long service life;

- They consist of solid strips and have a minimum of joints;

- Excellent sound insulation, thanks to such slopes your home will be much quieter;

- Not affected by water and steam;

- Easy maintenance, no painting required;

- Easy to clean with modern detergents;

- Windows and slopes made of the same material create a monolithic structure;

If handled correctly, these slopes will serve you for many years. Regarding the myths about the harmfulness of plastic products, I would like to say that by painting metal batteries, you will get much more harm.

Features of the material

It is important to purchase high-quality material, as otherwise, when exposed to direct sunlight, the panels may lose their shape and turn yellow.

When working with this material, care should be taken when performing mechanical impacts on it, for example, cutting. The material is quite fragile and the sheet can be damaged if you do not calculate the effort

The material is quite fragile and the sheet can be damaged if you do not calculate the effort

When working with this material, care should be taken when performing mechanical impacts on it, for example, cutting. The material is quite fragile and the sheet can be damaged if you do not calculate the effort

Working with sandwich panels should be carried out with care to avoid damage to the material

If there is not enough space between the window hinge and the wall, it will not be possible to install this material.

It is important to consider that the window opening when using this material will decrease on both sides by the thickness of the panels

Transporting products can be difficult since the sheets are large. However, in some stores they are cut into smaller pieces.

Dimensions

The parameters of sandwich panels depend on the equipment used by the manufacturer. However, there are standardized sizes. The maximum length of panels can be from 12 to 16 meters. The large size of the product can lead to fracture of the product under the load of its own weight during installation, and it will also be difficult to transport the material. The width is 100, 115 and 119–120 centimeters, and the thickness can vary from 5 cm to 35 centimeters.

In some cases, panels are made according to customer preferences. There are sandwich panels, the technical characteristics of which allow them to be used for finishing the slopes of windows and doors. The parameters of such panels are 3000 mm in length, 1150, 1300 or 1500 mm in width, and 10 mm in thickness. In rare cases, the thickness of products can be 24, 32, 40 mm.

Installation

Installation work of window slopes is carried out quite quickly. You can install the panels in just one day. Finishing slopes with sandwich panels is not a difficult task and you can do all the installation work yourself without much experience.

List of tools required for installation:

If necessary, you can further insulate the slopes by installing thermal insulation material on them. They can also be used as polyurethane foam. Liquid plastic can serve as a sealant between the slopes and the window - it is PVC-based glue. Its advantage is that over time it does not darken and does not spoil the appearance of the window. It is necessary that at least 24 hours pass after installing the window - this is the time for the polyurethane foam to dry.

Seven times measure cut once. So, we begin the installation work by measuring the slopes in order to accurately adjust the material to the size of the window. Taking into account the measurements, it is necessary to cut three strips, the top one parallel to the window sill and two side strips.

First we attach the starting profile, which in its shape resembles the letter “P”. Initially, the top one is fixed. There should be no gaps between the profiles. We fasten them using self-tapping screws 8-8.5 mm long, the distance between them should be no more than 15 cm.

Using polyurethane foam, we fill cracks and voids in the slopes. After the foam has dried, carefully trim and level it using a cutter. We insert the panel into the already installed upper profile. The side profiles are attached to the top board using self-tapping screws. Also, these profiles are fixed to the wall in increments of 150 mm. And we attach the last P-profiles to the window sill. We fill the gaps between the starting strips with liquid plastic. It is not recommended to use ordinary sealant, as it turns black over time, and this spoils the appearance of the window. After the liquid plastic in the gaps has dried, install two side panels.

The next final stage is the installation of finishing profiles. We take measurements and cut off the three necessary strips: one top and two side ones. It is recommended to cut the finishing strips with a margin of approximately 2-3 cm, and subsequently shorten them to the required size.

Then we snap the profiles onto the sandwich panel. In the corners the strips will overlap and need to be trimmed. On the profiles at the junction we mark the edges with a pencil and carefully cut them at an angle of 45 degrees. The void between the wall and the structure is filled with mounting foam. This will increase the degree of thermal insulation of the window. The junction of the finishing strips can also be covered with PVC glue for a more durable fixation.

Let's start installation

Finishing window slopes with sandwich panels

It will be quite easy to make slopes with sandwich panels if you follow the rules and sequence of actions. Even if you don’t have experience finishing slopes with your own hands, you don’t need to be afraid of this work. Before starting installation, you need to prepare tools and materials, you will need:

- Sandwich panel – you choose what material to buy from yourself

- Start profile

- F profile

- Liquid plastic – used as desired

- Tape measure and knife

- A screwdriver with self-tapping screws, a screwdriver and a drill - probably every home has the latter.

Slopes made of sandwich panels in a panel house

I have already said that installation should be done at least 24 hours after installing new windows. Using a tape measure, you need to take measurements and cut out panels for the side and top slopes. Use a knife to remove unnecessary pieces of polyurethane foam and begin installing the starting U profile using self-tapping screws for fastening. They need to be screwed in with a gap of 10-15 cm. Do not forget that the top profile is attached first, and only then the side ones should fit tightly with the top one. Next, we proceed to install the slopes using a sandwich panel; it is inserted into the grooves of the profile. Using the same scheme, we start from the upper slope.

Finishing of plastic slopes

Then there are two options:

- The first is to insert pieces of the starting profile into the vertical bar from above and below, and then the side panels fit into these grooves.

- The second is to simply attach the panel end-to-end with the window sill and the upper slope, after which the gaps are closed using liquid plastic.

When this stage is completed, all that remains is to give the slopes a finished look. To do this, use the f profile; it needs to be secured to the edges of the sandwich fabric. For additional thermal insulation, the voids between the sandwich sheet and the wall are filled with polyurethane foam - this process does not bring any inconvenience, since it is very easy to dismantle the profile. After filling the voids, the bar is returned to its place.

Plastic slopes made of sandwich panels for a balcony block

One more tip! It is better to trim the f profile after installation - to do this, it is attached with an overlap and then a cutting line is outlined using a pencil. In this way, maximum joining of the planks can be achieved.

We also recommend reading:

Convenient finishing of slopes with a PVC profile Beautiful and convenient do-it-yourself slopes made of PVC panels, wood or simply plastered Practical and easy installation of plastic slopes on windows Features of using plastic corners on slopes Arrangement and installation of metal slopes for windows

What requirements must the slope material meet?

Regardless of the technology for protective and decorative finishing of a window opening, finished slopes must meet certain requirements. The design must withstand various mechanical impacts without loss of operational and aesthetic characteristics. It is necessary that the slopes are moisture resistant. This especially applies to outdoor structures. The material must be characterized by wear resistance, immunity to ultraviolet rays and high humidity, and temperature changes.

Slopes must be moisture-resistant, wear-resistant, and have low thermal conductivity

The protective structure of the window should not deform over time. It must be distinguished by a long period of operation without loss of original properties. Due to the fact that the slope panel closes the installation gap, this is the main source of heat loss. It is necessary that the material has low thermal conductivity, which will provide a good level of heat and sound insulation in the room.