Specialists from Sweden have made a huge contribution to the insulation of wooden windows. The special production technology of insulation they developed is called Swedish.

Swedish building thermal insulation material has ideal quality characteristics, thanks to which heat is retained in the premises.

The peculiarity of its use is that it fits tightly to the surface, does not require gluing, is very quickly and easily installed, reliably fills joints, and can last more than 20 years. How to insulate wooden window structures using Swedish technology, and what nuances you need to know, read more in this article.

How window frames are insulated using Swedish technology

In the construction market, a service called “window insulation using Swedish technology” is becoming increasingly popular and in demand. But some people still have doubts - does such an operation as repairing wooden frames really allow you to get a modern window, reliable and of high quality, and at the same time not pay very much, or even do the work yourself?

This type of window insulation is called “Swedish technology” because it is performed using Swedish building materials. The tubular silicone seal, made of rubber, will not be afraid of either dirt or paint. Manufacturers claim that this material can last a couple of decades.

According to experts who insulate windows using Swedish technology, it will be quite difficult to perform all the necessary operations with your own hands. You will need not only the appropriate tool, but also certain professional skills.

Not every owner will be able to use his own hands to make a cut around the perimeter of the sash with a cutter to create a groove for rolling the seal into it - such an operation is necessary so that over time the material does not peel off or fall out.

Summing up

The Swedish method of insulating window systems has secrets and nuances. Let's look at some features:

- Frames can be varnished or painted only after completion of the thermal insulation work. Otherwise there will be damage on the surface. The paint is applied carefully, without touching the insulating material.

- Certain window structures are insulated from the inside due to separate sash. For example, frames in Stalinist houses.

- To install thermal insulation, a standard set of tools is not enough. Additional equipment will be required: a cutter for cutting a groove, a roller for pressing insulation.

- Thanks to Swedish technology, the room provides a high level of thermal insulation. You can save money on heating and purchasing expensive plastic window units. A long service life will eliminate the need for annual window insulation work using conventional methods.

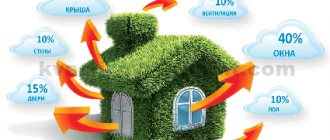

Thus, you can insulate window structures with your own hands. When selecting a sealant, they focus on its performance and quality. Thanks to Swedish technology, heat loss is reduced by 80%, noise insulation is increased to 75%, and dust ingress is eliminated.

Video about window insulation using Swedish technology

Is it expensive to repair wooden frames?

Prices for insulation and fitting of windows with standard dimensions - 1.5 * 1.2 (1.3) m - approximately 3000-3500 rubles. This includes dismantling the sashes, preparing a groove for the perimeter seal using a cutter, placing a tubular silicone seal there, if necessary, adjusting the sashes, sealing the glass to the window sash, the opening between the sashes - in cases where the sashes are paired.

Work with fittings is paid additionally - everything from repairs to replacement with new ones. Prices for them can be found when placing an order for work. If repairs to the window frame are required, this must also be paid for separately.

Important! In cases with separate type bindings, which are also called “Stalinist”, insulation is usually carried out for the internal sashes, and those on the outside are left as is. But if you order such work for external sashes, the price will be doubled.

The price lists of companies performing such work also include a painting service. Its price for a regular window will be approximately 6,000 rubles.

With such data, it is not difficult to calculate how much a full repair would cost for one ordinary window. The total cost can be compared with the cost of a standard double-glazed window.

Typically, a PVC structure of the same size, including double-glazed windows, window sills, ebb, slopes and a mosquito net, together with installation and dismantling, costs approximately 15 thousand rubles. Of course, if you decide to do all the necessary operations yourself, the costs will be completely different.

Finnish windows

Description and key differences

The closest and most familiar analogue of Finnish windows to domestic consumers is wooden window and balcony blocks manufactured in accordance with GOST 11214–86. The quality and reliability of these products varied greatly depending on the place of production, but some samples still serve well to this day.

Unlike Soviet wooden windows, Finnish ones are not designed for periodic adjustment of technological gaps during operation. The internal sashes and frame are made of multi-layer laminated timber, which undergoes bioprotective and water-repellent impregnation, becoming resistant to shrinkage due to fluctuations in temperature and humidity.

The outer sash is made of aluminum; the frame also has a protective aluminum screen that protects the wood from precipitation and frost. Thanks to this, the maintenance of technological gaps is guaranteed throughout the entire service life.

The most obvious feature of Finnish windows is the synchronous movement of both sashes when opened. Due to this, a high density of the vestibule is ensured with the formation of a sufficiently large sealed chamber between the outer and inner glazing.

The latter can be represented by single glasses; also, in the most modern window models, double-glazed windows with up to two chambers can be installed to increase energy efficiency in regions with cold climates.

The advantages of Finnish windows are their natural appearance and high-quality thermal protection due to the significant width of the window block - up to 220 mm. The manufacturability is also surprising: the wooden window is equipped with reliable modern fittings, ensuring tight locking and many years of operation.

Among the few shortcomings, the massiveness of the sashes, which reduces the luminous flux, as well as the high cost of products made from high-quality wood, especially stand out.

Fittings and window operating modes

Unlike the plastic windows that many are accustomed to, Finnish ones have only one opening mode - rotary. It may seem that this reduces ease of use, but this solution is fully justified by the increased reliability. Judge for yourself: instead of a complex swing-out mechanism, a pair of durable steel hinges is used, which do not need adjustment and require a minimum of maintenance (lubrication once a year).

The absence of a flap and micro-ventilation mode is compensated by various solutions depending on the window configuration: a classic window, a folding transom with lower hinges, or a supply valve with a built-in dust filter. The valve is adjustable and can be adjusted to different operating modes of climate control equipment and general house ventilation.

The locking mechanism of Finnish windows does not have a drive system located in a hidden groove along the contour of the sash. Instead, an ordinary window shutter is installed, and contour locking is not required due to the high rigidity of the wood and the use of fairly thick and soft seals around the perimeter of the frame.

Finnish windows are equipped with an inter-frame tie on the railing, which ensures synchronous movement of the racks. The screed can be separated, opening access to the space between the frames for washing glass and servicing the hinge group of the outer sash.

Another highlight of Finnish windows is the ability to install plastic blinds in the space between the frames, for adjusting and raising them there is a convenient handle on the inner sash.

Features of Continental windows

There is a variety of wooden windows, for example Skaala Continental, which is a hybrid of Finnish and modern plastic windows. In fact, this is a prototype of a modern system based on PVC profiles, however, instead of plastic frames, milled wooden frames are used.

Hybrid windows have gained high popularity mainly due to the ability to equip them with common contour fittings that provide four modes of operation. Also, such windows have a standard profile size of 78 mm thick, which facilitates their installation in apartment buildings made of concrete panels, where the installation of window blocks wider than 100 mm causes difficulties in attaching the window sill and finishing the slopes.

The main difference between Continental type windows can be found on the outside of the frame. Here, as in classic Finnish windows, an aluminum screen is used to protect the block from atmospheric influences. This is the calling card of all Finnish windows: the protective screen is part of the external finishing and is very technologically combined with the finishing of the slopes and rain ebb.

What would be better - choosing double-glazed windows or repairing old frames?

If problems with frames arise, the homeowner will have to make a choice which technology is more preferable for him.

In one case, the result is a well-repaired window that closes perfectly, with seals in place, and, of course, painted. Another case is a simple turnkey plastic window. Of course, you choose the option that is closest to you yourself. Despite the fact that the cost of both windows is almost the same, not everyone prefers double-glazed windows. There can be many reasons for this: from the personal preferences of homeowners to the reluctance to have plastic in the house. Meanwhile, reviews of Swedish technology are the most favorable.

Important! When choosing insulation for wooden windows, you should check that the frames are not rotten - replacing these elements will cost a tidy sum. First, you need to pay attention to the lower part of the sashes and window frames, where the water drains from the glass. If these elements are too rotten, restoration and subsequent thermal insulation of the window is almost pointless.

Technology for insulating wooden windows

If you decide to insulate windows in your home using Swedish technology, you should familiarize yourself with the essence of the insulation process. Some people can do the job with their own hands, but it’s better to trust the experts.

In wooden frames, a special groove is sawed on all sides. A tubular seal is embedded there, which is able to withstand temperature fluctuations from -50 to +80C. Conventional seals, which are sold in every store, will last no more than two seasons. With the use of professional materials, you will not need to worry about replacing them for 10-15 years; they do not peel off and take exactly the shape that is needed.

Repairing with a Swedish sealant is convenient because it has 5 sizes - 5, 6, 8, 10, 12 mm, which makes it possible to choose it for cracks of any thickness. In this way, complete tightness of the sashes is achieved when closing the windows.

After the seal is placed in place, both the window frame and the joints of the frames and glass are completely sealed, thereby completely eliminating possible blowing. As additional services, painting, replacement of drainage systems, glazing beads, and glass are provided. After the repair of wooden frames is completed, you get almost the same effect of double-glazed windows, but, according to reviews, with much greater advantages.

The advantages of carrying out work on the restoration of wooden frames:

- The total cost of repairs is 2-3 times lower than the price of a double-glazed window.

- The insulation process will not take more than 3 hours.

- You don't have to seal the frames for the winter with your own hands.

- All work is carried out outside the apartment, so there is no need to be afraid of spreading dirt into your home.

- The frames in your apartment will continue to be made of natural material.

- There will be a distance between the glasses three times greater than in double-glazed windows - due to this, heat transfer is reduced, and the appearance of condensation on the glass is eliminated.

Source: utepleniedoma.com/uteplenie/dveri-i-okna/kak-proisxodit-uteplenie-okonnyx-ram-s-ispolzovaniem-shvedskoj-texnologii

Advice from professionals

The choice of the original seal is carried out in accordance with the operating conditions, the diameter of the outer tube and who will do the work. Thus, thermoplastic elastomer (6-8 mm) is afraid of temperature changes, but is the cheapest in its segment. Rubber (6, 8, 10 mm) is hard, afraid of paint and can only be placed in an ideal groove. Silicone insulation (5, 8, 10, 12 mm) is more expensive than its analogues, but is completely worth the investment.

Manufacturers offer a choice of transparent and colored versions of Swedish insulation tape

It is worth paying special attention to the bottom bar. This is explained by the fact that the load from the sashes and condensate falls to a greater extent on it. As a rule, cracks appear from changes in humidity, worn areas from the movement of sagging windows. The latter are corrected before hanging, and the cracks are filled with putty and secured with a primer.

Mistakes are often made when threading sealing tape. It consists in the additional use of adhesive or sealing materials.

Attention! Only the mounting edge of the Swedish insulation should be located in clean grooves.

The original tapes have letter markings. It indicates the relevance of the product for a specific gap between the sash and the frame. So, E fills 2-3.5 mm, P - up to 5 mm, and D is intended for wide voids in the range of 3-12 mm. You can determine the width using plasticine wrapped in thin polyethylene.

How is window insulation performed using Swedish technology?

Insulating windows using Swedish technology allows you to restore old frames and extend their service life. At the same time, the appearance is improved, functionality and tightness are increased, and the design better protects from cold and wind.

Thanks to these features, it is not necessary to dismantle wooden frames for replacement. It is recommended to first compare the cost of updating an existing structure and purchasing a metal-plastic window. The complexity of implementing the technology is also taken into account.

Alternative option

Recently, there is another way to insulate windows, and this applies not only to wooden, but also to plastic structures. We are talking about an absolutely new product – heat-saving film.

Some manufacturers already install it on plastic double-glazed windows in the factory. And the “home” option for do-it-yourself use has appeared quite recently. At the same time, installation work is surprisingly simple:

- The film is cut to the size of the glass with an addition of 2 cm on each side - an overlap on the frame is required.

- Then, using a home hair dryer, it heats up and sticks to the glass, becoming almost invisible.

The manufacturer of this film guarantees an increase in the heat saving index of glass by almost 50%, which allows you to maintain a constant temperature in the room for 8 hours.

Advice! It is optimal to use both options: insulating windows using Swedish technology and sticking heat-saving film. This “double” insulation will allow you to achieve good heat savings even in the most severe frosts.

The considered methods of window insulation belong to modern energy-saving technologies, the use of which is becoming widespread. In addition, such methods make it possible to make repairs less frequently, in this case wooden frames due to their less wear. This is achieved by reducing operating loads caused by temperature changes.

Advantages and disadvantages of the technique

The effectiveness of insulation using this method is due to the fact that a seal made of rubber is added to the design and is characterized by excellent performance in reducing heat loss in the room.

This is Swedish material, hence the name of the technique. It is mounted in a special way, which makes it more difficult to carry out repairs yourself. Swedish window insulation technology is popular due to a number of positive qualities:

- The seal lasts a long time - about 20 years. For comparison: foam rubber and simple rubber require replacement after several seasons of use.

- Swedish material does not accumulate pollution.

- Tightness. The seal does not allow wind to pass through and significantly reduces heat loss.

- Thermal and sound insulation properties are improved.

- By reducing the intensity of heat outflow, heating costs are reduced.

- Time saving and practicality due to the absence of the need to repeat the procedure annually.

- The seal can withstand significant temperature fluctuations: from -50°C to +80°C,

- Creating a barrier to dust and other contaminants that often penetrate from the street into the room.

- Improving the appearance of the window frame and sashes, because Before installing the Swedish sealant, the wood is restored.

- There is no need for additional window insulation.

- Reduces the risk of condensation.

- The window frame retains the ability to “breathe”.

If we compare the Swedish method with the Finnish one, there is another advantage: it is not necessary to install insulation on all sashes (only on the internal ones), because The window is a prefabricated structure (double sashes are twisted together).

There are also disadvantages to this method. If you plan to use Swedish technology for insulating wooden windows with your own hands, you may encounter difficulties. We are talking about the need to use special equipment. So, to install the rubber seal, you need to make a groove around the perimeter of the sashes. The material will be placed in it.

Another disadvantage is the relatively high cost of performing the work. In addition, if you make mistakes during installation or use low-quality material, the service life will be shortened, and the sound and heat insulation properties will be weakened.

For this reason, it is recommended to use the Swedish method in two cases:

- it is not possible to dismantle the window and replace it with a metal-plastic one;

- there is confidence in the professionalism of the worker who will restore the window frame.

Possible difficulties

Working with Swedish insulation is so simple that there simply shouldn’t be any difficulties. Errors can only appear if :

- Low-quality counterfeit material was purchased (the cord itself and the sealant), without markings or accompanying documents.

- The insulation process occurred with technical violations - the surface was not cleaned and prepared.

- The work was carried out at very low temperatures, which is why the sealant did not “grab” the silicone cord.

- In some cases, to create grooves, special equipment is needed, which only professional companies have.

Despite the high cost of the insulation itself, and the desire to carry out the work yourself, it is best to trust professional builders.

Necessary tools and cost of consumables

To restore old wooden windows, use the following set of tools:

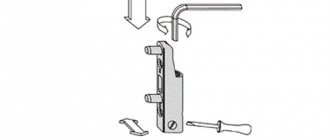

- roller walker, through which the rubber seal is placed in the grooves;

- screwdriver;

- milling tool - it is used to make grooves.

The cost of the material depends on its type and cross-section configuration. Available options:

- thermoplastic elastomer, or TPE, costs less than its analogues (from 11 rubles/linear meter and more), because does not last long due to exposure to temperature changes;

- rubber material is made from rubber and represents an average price category;

- silicone rubber - a material for sealing windows, representing a high price category (25 rubles / linear meter) - is distinguished by a convenient cross-sectional shape (round with a herringbone fastening) and is characterized by elasticity.

In order for the structure to serve for a long time, it is not recommended to choose cheap material. The best option for insulation using Swedish technology is a silicone seal.

Stages of work

To repair wooden windows, you should first select insulation. It differs in cross-section configuration:

- W-shaped;

- P-shaped;

- V-shaped;

- round;

- in the form of a semicircle;

- tubular material with internal fins.

The diameter of the Swedish seal also differs. The market offers a large number of options, but the material is selected taking into account the size of the leaks in the frame: 2-12 mm. When the sealant has been selected, we proceed to window repair using Swedish technology:

Preparatory stage. Restoration can be carried out provided that the window unit is suitable for the work. Check the condition of the lower part of the frame. Also, there should be no obvious defects or large cracks on the sashes.

The area of wood where the hinges are installed is also examined. The material gradually wears out, which can lead to sagging of the sashes. If there are defects, they are eliminated using putty and the painting method. Worn out structural elements are replaced.

Before insulating wooden windows using Swedish technology, it is recommended to dismantle the main structural elements and carry out restoration. The sashes are removed from the awnings. Frame removal may be required.

If necessary, the glass is also removed. All elements of the window block are cleaned of old coating and defects are eliminated. If during the inspection phase it is discovered that there are still leaks when closing, grinding may be required. If the gap is significant, the surface is increased using a lath.

Window insulation using Swedish technology is performed after preparing the groove for the rubber seal. It needs to be done around the perimeter of the sash at an angle of 45°. Moreover, it is important to immediately remove the chips and further clean them. Groove dimensions: 3x5 mm or 3x7 mm.

A Swedish seal is placed inside. If a silicone product is used, it has a herringbone-shaped mount. This makes it possible to fit the material tightly into the groove. A special tool is used.

If you plan to insulate windows using Swedish technology yourself, you should know that it is necessary to eliminate all sources of draft. This means that, along with installing the silicone material around the perimeter of the sash, sealant is applied to the areas where the wood and glass join.

Where the hinges are installed, no seal is installed. Here it is recommended to make a small indent from the hinge area (10-15 mm).

After laying the seal, the sash is returned to its place.

If you plan to insulate windows using Swedish technology, then gluing silicone material to the sash is not recommended. At the same time, it loses its elasticity. In addition, in cases where the moving elements of the window unit are opened separately, the seal is secured only from the inside.

You should know that the Swedish repair method is also suitable for thermal insulation of plastic windows.

Renewal of rotten areas

If the wooden frames are in good condition and you don’t want to change them completely, but there are rotten areas, then they can be restored. This is absolutely easy to do.

Epoxy putty

Epoxy putty allows you to remove small rotten areas of the frame in the shortest possible time. It is very good if it contains fiberglass, which can increase the rigidity of the frame. Restoration begins with the damaged area of the frame being thoroughly cleaned of paint. Then all the dust is removed. After this, the putty is mixed and applied to the prepared area. It is necessary to apply it so that it fills all the cracks and crevices.

In this case, the damaged area must be recreated so that it is more voluminous than the entire plane of the frame. This is necessary so that further grinding can be done. The putty hardens at room temperature for at least 24 hours. When the putty area has dried, it must be sanded using sandpaper (it is better to attach it to a block) or a sanding machine. After sanding, the entire surface of the frame should be smooth. After such a restoration, the appearance of the window becomes like new, but there is no guarantee of sufficient density in places that are actively used.

Replacing a frame part

Replacing part of the frame also allows you to remove rotten areas. This method begins with inspecting the frame for damage and marking them. After all of them are found, you need to remove them with a mallet or chisels. A replacement is being prepared in their place, and the new frame part must completely match the size and shape of the removed part.

When the required part of the frame is ready, it is installed in place and fixed with glue and clamps. The frame will dry completely after 24 hours, then the clamps can be removed. After this, the junction of the new part with the frame is carefully sanded. This is necessary to avoid any differences in height.

Antiseptic

Another important point is treating problem areas with an antiseptic composition. After applying it, the frame should be dried. To increase the service life of old wooden windows, it is best to cover them with drying oil. This will prevent the appearance of new rot and partially restore the structure of the wood. Drying oil is applied in 3-4 layers using a brush, and each new layer is done only after the previous one has been completely absorbed. Such impregnation protects for 2–3 years.

If you want to protect your windows for decades, you need to impregnate them in a different way.

- To do this, take a metal pipe 10 centimeters thick, with one end sealed. It is installed at an angle of 30 degrees, three-quarters filled with drying oil and heated from below using a hair dryer or hotplate.

- Impregnation with drying oil begins after the bubbles disappear on its surface.

- Next, you will need an iron hook with a built-in end. The part is placed in the pipe and pressed down with a hook for 5 minutes. Then they hook the bar with the tip of the hook, remove it and dry it.

- You cannot touch the parts with your hands, since the temperature of the hot drying oil is more than +130 degrees. Moreover, this entire procedure must be carried out exclusively on the street and away from residential buildings. As a result of this treatment, the service life of wooden window frames can increase to 100 years.

How much will it cost to insulate windows using Swedish technology when you call a specialist to your home?

First, the cost of materials that will be used in the process of restoration of the valves is calculated. If it is not possible to use the necessary tools, a specialist is invited. The cost of repairing wooden window frames is calculated separately.

The degree of complexity and scale of the work should be taken into account. The average price is 100 rubles/linear meter. Directly laying Swedish insulation in the grooves costs more - 200 rubles / linear meter.

In addition, a fee may be charged for filling out and processing the application, as well as the initial call to the specialist and consultation (300-500 rubles). The announced prices are not final, because may vary depending on which repair company you contact. The cost of restoring a large window using this technology corresponds to the price of a plastic window block from the middle price category. However, wooden structures look more attractive.

Source: uteplix.com/obyekty/okna/uteplenie-po-shvedskoj-tehnologii.html

Features of the technology

Swedish window insulation allows you to get a modern, reliable and high-quality window from an old structure. At the same time, the costs of this procedure are minimal, especially if the work is done independently.

This type of insulation is called “Swedish technology” because it was invented by thrifty Swedes for the purpose of energy saving. In addition, insulation is carried out using Swedish building materials, in particular Swedish silicone sealant.

This material can withstand temperatures from -50 to +80 degrees Celsius, while being able to take any shape and maintain elasticity. According to manufacturers, such a seal will last a couple of decades, while conventional insulation needs to be changed after two or three seasons.

Unlike the traditional and thorough sealing of windows, insulation in this way will allow you to open and close windows without hindrance throughout the year. However, it should be said right away that Swedish insulation is a relatively complex procedure that requires certain skills and the availability of the necessary tools.

In particular, not every home craftsman will be able to make a cut around the perimeter of the sash with a milling cutter in order to obtain a groove for rolling the seal there. And without performing this operation, the material can quickly peel off and fall out. Also, insulation involves replacing all fittings so that the structure functions as expected.

Therefore, if you are not confident in your abilities, then it is better to entrust this work to qualified specialists. The price for their services will be justified by the quality of the insulation and the guarantee for the work done.

New product on the construction market

The relative novelty of the repair work raises doubts among many who decide to replace the window - the financial side of the issue allows you to significantly save on installing new windows, but will the cheaper method be worth it? Experts confidently state the difficulty of performing this type of dismantling on their own. Not everyone can make a selection along the sash, creating a groove for the seal. But having examined the process in detail, it seems possible to perform it yourself if you have the tools and materials.

Swedish insulation or double glazing

Often, homeowners are faced with a choice - to insulate a window using Swedish technology or install a new double-glazed window. In the first case, you will get a wooden window that is well sealed and opens and closes perfectly in winter and summer. In the second case, a turnkey plastic window will be installed.

Many people prefer wooden windows, and not only for reasons of economy. The fact is that wood is a more environmentally friendly material; its ability to “breathe” provides a favorable indoor microclimate. In addition, this technology receives the most positive reviews from the owners of such windows.

Note! Before making a choice in favor of insulating windows, you need to make sure that the frames are not rotten, since replacing these elements will cost a decent amount, so insulating them will be pointless.

How to understand where it's blowing from?

Before you begin work on insulating a window, you should make sure that it is actually blowing from it. Very often, a room “freezes” for other reasons; the air circulation in it is disrupted - a cold flow moves near the windows, which creates the illusion of a draft.

There are several ways to determine the source of window ventilation:

- Tactile - in case of a strong draft, it is enough to move your palm along the perimeter of the window to feel the air movement;

- With the help of a lit match or candle, the light will begin to oscillate at the slightest movement of air;

- Using a paper sheet pressed by a closed sash - if the sheet moves easily between the sections of the glass unit, then the problem is in the seal.

It is necessary to check the window along the entire perimeter, as well as in the area under the window sill. It is also worth paying attention to specific details on the window, which most often cause drafts - the bead holding the glass unit, the rubber seal, fittings (hinges, handles).

Insulation technology

Window repair

So, the instructions for performing repairs and insulation are as follows:

- First of all, you need to dismantle all the fittings - hinges, locks, latches, etc.

- Then the structure must be cleaned of old paint. The easiest way is to use a hair dryer and a scraper. You can also remove the old coating using a special chemical solution called a stripper.

- After this, the structure should be treated with a primer composition, which will have an antiseptic effect and also improve adhesion between the wood and the new paintwork.

- Then the most complex procedure is performed - a groove is selected along the perimeter of the wooden frames, in which the seal is subsequently fixed.

- Next, the wooden structure is painted. To do this, you can use a spray bottle or spray bottle.

- After the paint layer has dried, a sealant is glued into the grooves. Due to the fact that it has 5 sizes, you can choose the right material for any cracks. This allows you to achieve complete tightness when closing the doors.

- Next, you need to completely seal the window frame, as well as the joints of the frames and glass. To do this, it is best to use silicone sealant.

- Then the installation and adjustment of hinges, latches, etc. is carried out.

Advice! If sealant gets on the glass during work, you need to wait until it dries, after which you can scrape it off with a knife.

As a result, Swedish window insulation technology creates the same double-glazed window effect, but with even greater advantages than metal-plastic windows.

Executing the slope

To achieve the maximum effect from window repairs, it is necessary to pay attention to the insulation of slopes.

The window opening can be finished with the following materials:

- Plasterboard;

- Plastic;

- Sandwich panels.

The installation technology for all these materials is very similar and looks like this:

- First of all, the old coating is removed, especially if it is crumbling and falling off.

- Then the window opening must be treated with an antiseptic that will prevent the occurrence of fungus and mold. (See also the article How to cover a window with siding: features.)

- Next, starting profiles are mounted around the perimeter of the frame. Before fixing them with self-tapping screws, you need to check the position with a building level.

- After this, panels for slopes of the required size are cut from sheets of plasterboard or plastic, taking into account the layout.

- Then, thermal insulation material is placed in the space between the wall and the slope. As a rule, mineral wool is used for these purposes.

- Next, the cut slopes are inserted with one edge into the starting profile, and attached to the wall with the other. For these purposes, you can also use a special profile or glue. Drywall is usually glued with gypsum mortar.

- After this, the corners are trimmed using plastic or metal profiles.

- If plasterboard is chosen as the material for the slopes, then it needs further puttying and painting. (See also the article Painting the facade: features.)

Advice! If, after insulating the window frames using the Swedish method, the windows begin to fog up, then it is necessary to provide ventilation in the room.

This phenomenon occurs due to disruption of natural ventilation through cracks.

How to insulate wooden windows from the inside for the winter with your own hands for a long time

To eliminate cracks, use window putty. This method provides excellent tightness. As a result, the house will be warm and quiet. But you will have to work hard to clean the window after it has been depressurized.

The cracks should be sealed at the junction of the sash with the glass or frame and on the frame itself. Wood inevitably acquires these defects due to temperature fluctuations. To eliminate them, the following materials are used:

- wood putty;

- paraffin melted in a water bath (cracks are filled by squeezing the mixture out of a syringe; it takes about an hour to harden);

- sealant (ideally if it matches the color of the wood);

- putty made from a mixture of gypsum and chalk.

A fairly durable insulation option is a sealing cord with a tubular cross-section. It is used for several seasons and does not limit the freedom of movement of the sash. You can choose an option with a self-adhesive base. But for greater reliability, it is recommended to select the sealant and glue separately. To fix the material, you can use silicone sealant, which allows you to extend the service life of such insulation up to 5 years.

Sealant

Using silicone sealant, cracks in the area where the frame meets the glass are eliminated. This is a labor-intensive but effective method. The frame is freed from glass, cleaned of dirt and old paint, insulated with silicone, the glass is inserted back, and an additional layer of sealant is applied. Glazing beads are used to secure glass.

Thermal insulation film

If the windows become covered with condensation or a layer of ice, there is nothing better than insulating them with thermal insulation film. It is applied to the inside of the glass. This surface is pre-cleaned, degreased, and covered with double-sided tape. The fabric heated with a hairdryer is stretched and carefully straightened.

Polyurethane foam allows you to qualitatively fill cracks and mask defects (cracks, chips). This is a universal, practical and affordable material. After drying, excess foam is removed with a mounting knife. To avoid crumbling and getting wet of the porous polyurethane foam sealant, the cut on the outside of the window is painted or plastered.