Principle of operation

any installation for spraying polyurethane foam is as follows: components A and B are poured into special tanks of the foam generator. The installation takes each of the components in the required quantity and supplies it to the spray gun. Under the influence of compressed air pumped by the compressor unit, the polyurethane foam fraction is mixed and released from the spray gun. When the mixture hits the surface, it foams and hardens, forming a thermal insulation coating of rigid polyurethane foam. Learn more about polyurethane foam spraying technology

To carry out work on spraying polyurethane foam, you need: - a foam generator - a spray gun - a compressor - foam spraying components - special clothing

Our specialists will help you choose equipment for spraying polyurethane foam that will best suit your needs.

By collaborating with us, you get a comprehensive solution to the issue of thermal insulation - information on technology, selection of raw materials and equipment, delivery.

FOAM GENERATOR NAST-2

- price

- how to choose a foam generator

Purpose: applying heat-insulating polyurethane foam coating to walls, ceilings, pipelines. For heat and cold insulation of equipment, tanks, and in the preparation of thermal vans. For sealing interpanel seams on buildings and roof repairs.

Contents: - foam generator - spray gun PR-6 - connecting hoses (5-10 m) - passport

Specifications:

| Foam capacity, kg/min | from 0.2 to 1.5 |

| Basic ratio of components A:B (can be changed as desired) | 1:1,1 |

| Pressure in the component supply system, MPa, no more | 0,5 |

| Pressure in the air supply system, MPa | 0,4-0,6 |

| Nominal compressed air consumption, m3/hour | 30 |

| Thermostat system | No |

| Supply voltage, V/power consumption, kW/hour | 220/0,45 |

| Hose length, m | 5-10 |

| Overall dimensions, mm | 520x240x505 |

| Weight, kg | 34 |

| Capacity volume | 24l x 2 |

| Warranty, months | 12 |

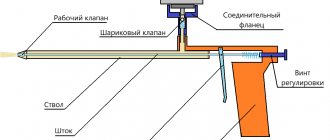

Features: The NAST-2 foam generator is a simplified modification of the NAST-3 installation with reduced productivity. As practice shows, for spraying vertical and horizontal surfaces from the “bottom” position, the optimal installation productivity is 1-1.5 kg/min. The device is equipped with the latest PR-6 spray gun, which differs from previous models in its simpler and shorter nozzle design. Thanks to this, the gun does not require special cleaning. The gun is distinguished by a new internal structure, which allows for a better mixing of liquid components.

What to consider when choosing an installation

- Choosing an installation for spraying high-pressure polyurethane foam is advisable only when it is necessary to spray not only polyurethane foam, but also other two-component polymer coatings: polyurea, polyurethane. The cost of such an installation is significantly higher than the cost of a low-pressure apparatus.

- The need for automatic heating of the starting material depends on the brand of the selected components to obtain the finished mixture. When using water-based raw materials, the mixing temperature should not be lower than +20 °C, since:

- The risk of a decrease in the adhesive properties of the finished polyurethane foam in relation to the treated surface increases;

- The pore size in the foam increases, it becomes “spongy”, which worsens the thermal insulation characteristics of the coating;

With a decrease in the temperature of the air, the surface being treated and the cooling of the components themselves, the activity of the foaming process decreases. The above leads to an increase in coating density and excessive consumption of raw materials. When using viscous components, it is difficult to achieve precise dosage compliance. Pumps may not be able to pump fluid that is too thick. As a result, the finished coating will be of poor quality. Heating reduces the viscosity of the starting material, and pump operation is stabilized. Automatic heating of supply tanks is used. If the installation is not equipped with them, and heating is required, use thermomats or thermal belts that are placed on the container and maintain the required temperature.

FOAM GENERATOR NAST-3

Purpose: applying heat-insulating polyurethane foam coating to walls, roofing, pipelines. For heat and cold insulation of equipment, tanks, and in the preparation of thermal vans. For sealing interpanel seams on buildings and roof repairs.

Contents: - foam generator - spray gun PR-6 - connecting hoses (5-10 m) - passport

Specifications:

| Foam generator type | low pressure |

| Foam capacity, kg/min | from 0.2 to 3.0 |

| Basic ratio of components A:B (can be changed as desired) | 1:1,1 |

| Pressure in the component supply system, MPa, no more | 0,5 |

| Pressure in the air supply system, MPa | 0,4-0,6 |

| Nominal compressed air consumption, m3/hour | 30 |

| Thermostat system | No |

| Supply voltage, V/power consumption, kW/hour | 220/0,45 |

| Hose length, m | 5-10 |

| Overall dimensions, mm | 520x240x505 |

| Weight, kg | 34 |

| Capacity volume | 24l x 2 |

| Warranty, months | 12 |

Features: The extremely simple design of the foam generator allows for high-quality thermal insulation work with polyurethane foam. It is equipped with a new type of spray gun that does not require cleaning with special compounds. The device is equipped with the latest PR-6 spray gun, which differs from previous models in its simpler and shorter nozzle design. Thanks to this, the gun does not require special cleaning. The gun is distinguished by a new internal structure, which allows for a better mixing of liquid components.

How to choose equipment for applying polyurethane foam thermal insulation?

When constructing or operating existing structures, we are often faced with the need for thermal insulation or searching for ways to save resources on heating and air conditioning. In a word, we think about saving our own funds. Any prudent and economical owner, after a long analysis of thermal insulation materials, will certainly come to the understanding that polyurethane foam (PPU) as a material for thermal insulation has no alternative. And here questions arise. The most important of them are which system of polyurethane foam components to use and how to choose a suitable installation for their application? Let us dwell on the task of choosing equipment.

Currently, the market offers a huge amount of various equipment, imported, domestic, expensive and not very expensive, simple and reliable and of unknown origin. By simple comparison it is not always possible to make the right choice. Experience in this field is also required. Having similar experience, we will try to help you with your choice. So that you, saving money, purchase exactly the installation that you specifically need.

FOAM GENERATOR NAST-5

Purpose: applying heat-insulating polyurethane foam coating to walls, roofing, pipelines. For heat and cold insulation of equipment, tanks, and in the preparation of thermal vans. For sealing interpanel seams on buildings and roof repairs. Possibility of spraying work in the cold season.

Contents: - foam generator - spray gun PR-6 - connecting hoses (5-10 m) - passport

Specifications:

| Foam generator type | low pressure |

| Foam capacity, kg/min | from 0.2 to 5.0 |

| Basic ratio of components A:B (can be changed as desired) | 1:1,1 |

| Pressure in the component supply system, MPa, no more | 0,5 |

| Pressure in the air supply system, MPa | 0,4-0,6 |

| Nominal compressed air consumption, m3/hour | 30 |

| Thermostat system | There is |

| Supply voltage, V/power consumption, kW/hour | 220/2,6 |

| Hose length, m | 5-10 |

| Overall dimensions, mm | 520x240x505 |

| Weight, kg | 34 |

| Capacity volume | 24l x 2 |

| Warranty, months | 12 |

Features: The most popular model for spraying work. It features increased productivity compared to NAST-3. It is equipped with a PR-5 spray gun, which greatly simplifies spraying work. There is built-in protection against power surges in the network. Comes with a digital display. The foam generator uses a thermostating system that allows it to work in the cold season due to the ability to heat the foam components to the optimum level. Due to the temperature control system, the consumption of raw materials is reduced. The device is equipped with the latest PR-6 spray gun, which differs from previous models in its simpler and shorter nozzle design. Thanks to this, the gun does not require special cleaning. The gun is distinguished by a new internal structure, which allows for a better mixing of liquid components.

High pressure installations for spraying polyurethane foam

The operating pressure of the high-pressure installation for spraying polyurethane foam is 10…12 MPa or 98.69…118.43 Atm.

The equipment is energy-intensive, requiring 10...35 kW to operate the installation itself, the heating system and the compressor.

Compressed air is not used to mix the components. Airless spraying of polyurethane foam. Compressed air is required to operate barrel pumps (if provided by the manufacturer for this model of PPU equipment) and to clean the mixing chamber of the sprayer.

Drum pumps (not plant pumps) take components from containers (usually 200L drums) and deliver liquids to the heating block. Liquids heated to the required temperature are supplied to the pumps of the installation, and the excess is returned through the recirculation system back to the barrels. The dosage of components on HP equipment is only 1 to 1.

The pumps increase the pressure of the liquids in the hoses to the parameters specified in the settings and subsequently maintain it throughout the entire spraying process. The polyol and isocyanate are fed into the atomizer under high pressure.

Pipelines are usually combined into a common hose with a heating system. This heated sleeve is heavy and rigid. Therefore, the last 3 meters, just before the sprayer, are removed from the hose to provide the operator with greater mobility, mobility and convenience.

For some models of high-pressure equipment, pipelines can be extended up to 93 m and applied from bottom to top over most of the length of the hose (attention, large mass!). In this case, there will be no problems with supply to the sprayer, nor problems with mixing in the mixer.

High-quality mixing is ensured due to the fact that liquids injected into the mixing chamber are transformed into a finely dispersed phase, almost into a fog. And then there is a mixing of, in fact, not two liquids, but two “foggy” flows on opposite courses.

High pressure guarantees mixing quality, accordingly:

- smooth and even layer on the surface;

- low thermal conductivity coefficient;

- minimal losses due to overconsolidation and rebound, i.e. if the declared density [free foam, factory, theoretical] of the foam is 30 kg/m3, then the actual density will be 35 kg/m3;

- ease of operation for the operator, who can stop repeatedly and at any time and then continue spraying PU foam.

The equipment requires competent and careful maintenance. The minimum cost of imported, “simple” equipment (only the main set) is about 700,000 rubles.

Such equipment requires: barrel pumps, recirculation system, compressor, generator, stabilizer, air dryer. Heated components and hoses are already included.

We can say that troubles with high-pressure foam spraying equipment begin when repairs are required, because branded [expensive] spare parts are required. In addition to repairs, routine maintenance also takes place, when only “original” components should be used.

Moreover, replacement is required many times more often than desired, and there are also many nodes where replacement is necessary. You should be prepared for this, because... You have to pay for the pleasure of working on high-pressure foam spraying equipment.

FOAM GENERATOR TMS-5

Purpose: the installation is intended for performing spraying work on thermal insulation of horizontal and vertical surfaces.

Contents: - foam generator - spray gun PR-6 - filling block - connecting hoses (5-10 m) - passport

Specifications:

| Foam generator type | low pressure |

| Foam capacity, kg/min | from 0.2 to 5.0 |

| Basic ratio of components A:B (can be changed as desired) | 1:1,1 |

| Pressure in the component supply system, MPa, no more | 0,5 |

| Pressure in the air supply system, MPa | 0,4-0,6 |

| Nominal compressed air consumption, m3/hour | 30 |

| Thermostat system | No |

| Supply voltage, V/power consumption, kW/hour | 220/2,5 |

| Hose length, m | 5-10 |

| Overall dimensions, mm | — |

| Weight, kg | — |

| Capacity volume | — |

| Warranty, months | 12 |

Features: The unit is equipped with a wheelbase. Components are collected from any consumable containers. The device can be equipped with a filling unit, which allows the production of molded products from polyurethane foam, as well as the filling of inter-wall spaces. There is built-in protection against power surges in the network. Equipped with a digital display. The device is equipped with the latest PR-6 spray gun, which differs from previous models in its simpler and shorter nozzle design. Thanks to this, the gun does not require special cleaning. The gun is distinguished by a new internal structure, which allows for a better mixing of liquid components.

FOAM GENERATOR NAST-7U

Purpose: applying heat-insulating polyurethane foam coating to walls, roofing, pipelines. For heat and cold insulation of equipment, tanks, and in the preparation of thermal vans. For sealing interpanel seams on buildings and roof repairs. Possibility of spraying work in the cold season. Pouring polyurethane foam products into molds (PPU shells, PPPU panels, clinker tiles, etc.) Pouring polyurethane foam into the inter-wall space for thermal insulation.

Contents: - foam generator - spray gun PR-6 - filling block - connecting hoses (5-10 m) - passport

Specifications:

| Foam generator type | low pressure |

| Foam capacity, kg/min | from 0.2 to 7.0 |

| Basic ratio of components A:B (can be changed as desired) | 1:1,1 |

| Pressure in the component supply system, MPa, no more | 0,5 |

| Pressure in the air supply system, MPa | 0,4-0,6 |

| Nominal compressed air consumption, m3/hour | 30 |

| Thermostat system | There is |

| Supply voltage, V/power consumption, kW/hour | 220/4,6 |

| Hose length, m | 5-10 |

| Overall dimensions, mm | 520x240x505 |

| Weight, kg | 34 |

| Capacity volume | 24l x 2 |

| Warranty, months | 12 |

Features: The NAST-7U foam generator allows you to both carry out work on spraying polyurethane foam and pour polyurethane foam components into a mold. It features increased productivity compared to NAST-5. It is equipped with a PR-6 spray gun and a filling block. The foam generator uses a thermostating system that allows it to work in the cold season due to the ability to heat the foam components to the optimum level. Due to the temperature control system, the consumption of raw materials is reduced. The foam generator is equipped with a protection system against power surges. NAST-7U has a digital pouring timer, which allows for extremely accurate dosing of components into the mold, which eliminates waste of raw materials. Like NAST-5, this unit is equipped with a digital display.

Select an installation for spraying polyurethane foam

The operating principle of polyurethane foam spraying equipment is as follows:

- pick up components from barrels;

- heat them to the recommended temperature;

- dose the polyol and isocyanate in the required ratio;

- feed the components under pressure into the pressure hoses;

- inject “A” and “B” into the mixing chamber of the sprayer;

- remove the PPU composition from the sprayer by spraying it onto the enclosing structure.

Without going into details, all installations work according to the above algorithm. But, as you know, The devil is in the detail. Let's talk about these details.

Let's start with how important it is to mix both ingredients completely and well. Then the reaction occurs 100% and the polyurethane foam is obtained with the declared characteristics and will serve for a long time.

If there is an imbalance (as the “sprayers” say) in the weight or volume ratio (regulated by the manufacturer in the specifications) of the components, then there is no need to talk about the quality of the foam.

If component A (polyol, in Russian terminology) is more than it should be, then, for example, hard closed-cell polyurethane foam turns out to be soft, short-lived and may have the smell of unreacted catalysts, the material loses volume, has poor (high) thermal conductivity and increased moisture absorption.

In the case of an excess of component B (isocyanate in Russian terminology), the foam turns out to be denser and more fragile, with a clearly noticeable smell of isocyanate. In terms of thermal conductivity and moisture absorption, foam plastic also does not meet standard values.

To mix and spray polyurethane foam components, low and high pressure equipment is used in conjunction with a set of auxiliary equipment: generators, compressors, compressed air dryers, liquid heaters, barrel pumps, etc.

FOAM GENERATOR PGS-3

Purpose: applying heat-insulating polyurethane foam coating to walls, roofing, pipelines. For heat and cold insulation of equipment, tanks, and in the preparation of thermal vans. For sealing interpanel seams on buildings and roof repairs.

Contents: - foam generator - spray gun PRS-011 - connecting hoses (5-10 m) - passport

Specifications:

| Foam generator type | low pressure |

| Foam capacity, kg/min | from 0.2 to 2.5 |

| Basic ratio of components A:B (can be changed as desired) | 1:1,1 |

| Pressure in the component supply system, MPa, no more | 0,5 |

| Pressure in the air supply system, MPa | 0,4-0,6 |

| Nominal compressed air consumption, m3/hour | 30 |

| Thermostat system | No |

| Supply voltage, V/power consumption, kW/hour | 220/0,45 |

| Hose length, m | 5-10 |

| Overall dimensions, mm | 520x240x505 |

| Weight, kg | 56 |

| Capacity volume | 24l x 2 |

| Warranty, months | 12 |

Features: The extremely simple design of the foam generator allows for high-quality thermal insulation work with polyurethane foam.

Functionality

Let's pay attention to the functionality of the equipment. Quite often it is believed that when thermally insulating buildings and structures it is necessary to “fill in” something. For example, people come to us with a request to “fill” the roof. Roofs, attics, floors and other horizontal surfaces are not filled with polyurethane foam; they are thermally insulated by spraying. As a rule, when thermal insulation of various construction projects there is no need for casting equipment. Almost all objects are thermally insulated by spraying. Sometimes in the process of thermal insulation it is rational to use polyurethane foam filling components. But it is still more convenient to process them using a spraying unit. The next functionality of the installations is the presence or absence of thermostatting systems. Spraying polyurethane foam insulation is largely a chemical reaction on a construction site. And for any chemical reaction to proceed, it is necessary to maintain certain parameters. In this case, we are interested in temperature. For the production of polyurethane foam, the optimal temperature is 20° C. Hence, the presence of a temperature control and heating system for components is highly desirable for polyurethane foam processing.