A modern window sill can be used not only as a stand for flower pots or a work area, but also aesthetically pleasing to the eye, being a decorative element for both a separate room and an entire apartment or private house as a whole. Wooden window sills look especially elegant, the production of which can be made from different types of wood as a single piece or by gluing individual wooden planks. The model is suitable for a plastic window profile covered with film, color and texture reminiscent of natural wood, as well as a wooden window frame.

Manufacturing technology for wooden window sills

There are two technologies for manufacturing window sill countertops:

- Array;

- Plywood.

To make an array, one solid board is taken. Most often, such products are not very wide and quite expensive, especially if the choice falls on valuable varieties of wood.

Rice. 2. example of making plywood

A glued window sill board is several narrow slats that are glued together under pressure and temperature using a press. The slats are glued together in two layers, but each layer consists of several narrow slats. Due to this, the tabletop loses its appearance due to noticeable joints. Manufacturers can remove this defect by gluing with veneer.

Plywood and solid wood require drying. Poorly dried timber, even with proper use, will quickly reveal defects. The wood begins to deform and crack. The first signs of improper drying after installation will appear within a month.

Drying is followed by polishing, which grinds off excess parts. The tabletop is polished almost smooth

In this case, special attention is paid to the upper side. Plywood also goes through this stage, but if the product will be covered with veneer, such attention to detail during sanding is not required

When making plywood, different types of wood are usually used. The most valuable ones are taken for the top layer, as well as for the “visor”. In the middle, pine slats are usually used as the optimal material.

The treated tabletop is cut to fit the window. In this case, the corner should go into the grooves in the walls, and the “visor” itself should stick out at least 6 cm further than the window slope.

REFERENCE! Measurements for the window sill play an important role. An array that is too thick can cause poor heating of the window glass and condensation. For reliability

Dimensions

The correctly selected size of the window sill block will not only simplify its installation, but will also significantly extend its service life. The standard sizes of a wooden window sill block include products with a width from ten to eighty centimeters, a length of up to six meters and a thickness of two centimeters. It is necessary to calculate the distance from the stand profile to the edge of the wall.

It is not difficult to calculate the size of the window sill yourself. To do this, it is necessary to determine the length of the window opening and add six to ten centimeters to the resulting value, so that the protruding sides of the window sill protrude beyond the slope by no less than three centimeters. For example, for a window opening one meter wide, you will need a window sill block of one hundred and ten centimeters.

Two centimeters from the entire length will serve for the light reversal of the slopes, and eight centimeters - for allowances on the sides. The product intended for the balcony is fixed into the wall on one side, and protrudes 1 cm from the doorway side.

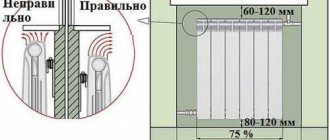

The width of the window sill is calculated even easier. First of all, it is worth mentioning that the window sill block is placed two centimeters under the window opening, but do not forget that a protrusion of five to seven centimeters must be maintained. This is because a protrusion that is too long will prevent the spread of heat emanating from the battery. In this regard, the circulation of warm air throughout the living space will be disrupted.

The appearance of condensation on the surface of the window glass will provoke freezing of the wooden covering of the window sill. Therefore, the sum of the three values will be the width of the required window sill.

For non-standard window sill designs that involve a rounded wall or the use of a window sill as a tabletop, it is recommended to make an accurate template using a tape measure and a sheet of paper. Due to the fact that the width of the window sill will be uneven, you may have difficulty determining the width of the product. In this situation, it is recommended to use the services of specialists or resort to the help of a precise geodetic device called a tacheometer. It is able to measure the required distance, as well as horizontal and vertical angles.

Box

Pine is the most popular material for making boxes among middle-class consumers. It is affordable and practical to use.

An oak window will be of better quality. But this material is quite expensive, so experts do not recommend making a window structure from it for the first time. Also, do not use soft wood.

The pine boards that will be used for the box must be properly dried.

If you have chosen laminated veneer lumber, then, subject to high-quality installation, you are guaranteed to receive a window of high strength; it will not change its parameters during operation.

To avoid subsequent deformation, the window block should be a couple of centimeters smaller than the opening.

Depending on the thickness of the window, a timber of a certain size is selected. The minimum value is 6*4 cm.

Grooves in the timber can be made using a router or electric planer. Before carrying out this stage of work, it is best to practice on a separate piece of the board.

First you need to take measurements, according to which the box can be made. In the blanks for it, grooves in the shape of the letter G should be made to a depth of 1.5 cm. The ends of the bars are sawed off at an angle of 45˚. After this, all the elements of the window frame must be connected with wood glue, holes must be made in them, through which wooden rods 3 cm long must be inserted.

Thus, the resulting structure will become motionless and rigidly fixed at a right angle.

The opening into which the box will be installed must first be prepared: cleaned of debris and dirt, leveled. Holes should be drilled in the walls (in increments of no more than 80 cm) into which dowels should be driven. The box is secured with self-tapping screws.

After this, using polyurethane foam, you need to seal all the gaps between the walls and the box. The advantage of this fixation is the following: the design does not depend on temperature changes.

It must be remembered that the geometry of the window must be strictly observed: angles - 90˚, difference in diagonals - no more than 10 mm, deviations in evenness - no more than 1 mm per 1 m of window block length.

Sealing and securing

Sealing

After the above steps, in principle, you can do without additional measures, but to achieve the best effect, additional fixation of the window sill will not be superfluous. In the case when not only the window sills are made of wood, but also the frames of the window blocks, you can proceed as follows.

On the back side of the window, directly through the frame, you need to screw a couple of self-tapping screws into the window sill.

The length of additional fasteners should be chosen so that the screws enter the window sill by at least 5 cm. Such measures will not be superfluous and will allow you not to worry about the strength of the window sill. This is especially important if this element of window decoration will be used to place bowls with flowers or other decorative elements on it. Polished

You should also not forget that all the cracks remaining after work must be sealed with polyurethane foam or silicone sealants. In this case, you won’t have to worry about blowing from under the windowsill.

Installing a window sill with your own hands, how to install a window sill

Installing any type of window sill comes down to three operations:

- preparing the seat,

- installation of the structure

- and securing the structure.

However, depending on the material from which the window sill is made, there are some subtleties.

First, general points.

- Preparation consists of clearing the sinuses from dust and debris, beating off interfering influxes of mortar and plaster. If the window sill needs to be replaced, the old board will need to be removed.

- Installation of the structure - the window sill board is placed in its place, leveled using a level and temporarily fixed with wedges.

Now the details.

How to install a plastic window sill

The simplest option is to install a plastic window sill with your own hands. First, the plastic window sill is leveled and fixed in the desired position, placing pieces of drywall, wood or any other pads between the opening and the lower part of the window sill. When the window sill is exposed, the voids under the board and the board itself are moistened with water using a spray bottle and filled with polyurethane foam.

Installation of a plastic window sill

To prevent the window sill from being squeezed out by a “hump” in the middle, it is strengthened with spacers, which are inserted with emphasis into the upper slope. The spacers can be replaced with a load, which can be used as a five-liter PET container with water.

How to install a wooden window sill with your own hands

To reliably strengthen a wooden window sill, anchors made of steel plates bent at right angles are used. One edge of the plate is screwed with screws from the bottom of the board, the other is attached to the wall using dowels. Usually two fastenings are enough, for large windows - three.

The voids under the board are filled with foam and subsequently plastered. The layer of plaster also hides the part of the anchors that is attached to the wall.

How to install a window sill made of natural or artificial stone with your own hands

Working with stone window sill structures is difficult due to their significant weight. In addition, despite all their strength, stone (especially natural or artificial marble) window sills are quite fragile. Even a small impact can leave a noticeable mark on the polished surface or break off a piece.

To securely fasten a stone window sill, cement-based adhesives are usually used.

Usually, the window sill board is first placed in place “dry”, the necessary markings are made, removed, an adhesive solution is applied to the seat and installed again according to a permanent pattern.

Stone window sill

If dimensions allow, then in order to avoid such “fitting”, the adhesive composition can be pumped into the gap between the edge of the window opening and the window sill board using a mounting syringe.

If there is a window sill radiator niche and (or) a significant size of the stone window sill, its fastening is additionally reinforced with brackets. The fastening anchors in the window sill are installed in pre-drilled sockets using glue.

Installation recommendations

If the width of the windows is more than 1.5 m, then the lower part of the window sill should be additionally strengthened using metal or thick wooden pins. They are attached to the surface of the wall. This allows the window sill to withstand a certain load. After the installation of the wooden board is completed, it is necessary to install galvanized steel roofing flashings on the outside of the window. Its upper edge is placed in the slot of the window frame.

You need to carefully bend the edges of the drain and attach a drip at the bottom.

Wooden window sills have numerous advantages; they are not only more durable and attractive, but also fit perfectly into any interior. They can be made in different styles, but it is best to varnish them after installation or impregnate them with special oils. This will protect the surface from damage, excess moisture, and temperature changes. Installing window sills is not that difficult; you can do it yourself, especially if you have experience working with tools and wood. They look presentable and stylish.

Distinctive features of plastic window sills

Plastic window sills have almost ideal geometry. The sizes can be selected to suit almost all types of window openings, since the designs are available with a width of 10-60 cm and a length of up to 600 cm. Glossy or matte surfaces are available, as well as a wide selection of colors.

Unlike window sills made from other materials, plastic ones are not made of solid thickness, but in the form of partitions connecting two planes. On the one hand, this design has minimal weight, and on the other hand, it can withstand significant loads without deformation or damage. The presence of voids between the internal partitions also improves the thermal insulation properties.

Many manufacturers produce various additional elements that make the window sill look complete and aesthetically attractive.

Advantages

Among the advantages of plastic window sills are the following:

- maintaining strength and performance characteristics throughout the entire service life;

- resistance to high humidity, fungus and mold, as well as some chemically active substances;

- ease of care;

- the same service life with windows, slopes and decorative elements;

- a wide range of colors not available for window sills made of other materials;

- low cost compared to wooden or stone counterparts;

- simple installation technology.

Flaws

The disadvantages of plastic window sills include:

- fading under the influence of direct sunlight: the color shade changes, becomes duller and less attractive;

- over time, plastic loses its properties of strength and ductility, so under certain loads a part of the structure may crack or break off;

- window sills without a heat-resistant coating melt on contact with heated objects: a pan with a recently prepared dish, an iron, a soldering iron, etc.;

- low resistance to mechanical damage: impacts, scratches.

Miracles made of paper

Paper, white or colored, is found in every home. By using any bright paper - old postcards, glossy magazines, purchased colored leaves, decorated white paper or wallpaper with a small cheerful print, you can make a lot of interesting things to decorate the windowsill.

Decor for a window sill made of paper includes all kinds of origami balls, boxes, trees, and flowers.

With the help of glue, it is easy to build a three-dimensional figure or an entire staged scene from flat figures, copying theatrical scenery in miniature.

If you add correctly installed lighting, the scenery from the street will have a mesmerizing effect.

Few people can pass by without stopping and admiring the original idea for decorating a window sill.

Features of installing wooden window sills

Depending on the size of the product, grooves are made from the bottom, and the end parts are carefully polished and ground.

When calculating the size of the window sill, you need to keep in mind that the two sides and the front side are placed in the wall with a recess of at least 4 cm, and on the opposite side it should extend beyond the boundaries of the wall by 6 cm.

To increase the service life, wood material should be painted or varnished. To prevent the appearance of mold, fungi and insects, treat the bottom with a disinfectant.

To minimize heat loss in the future, it is worth insulating the lower part with felt. They need to be secured with nails. Pre-prepared boards are placed on a brick surface filled with a mixture of gypsum and lime. At the window, recesses are made in the wall where these boards are installed.

First, the window sill is installed sequentially under the lower surface of the beam, and secured with ten-centimeter nails without heads. To make it easier, you can first drive in a nail and then place the window sill on it.

When installing it, no tilt is expected. If this happens, then using several wedges mounted in the appropriate place, they are filled with cement mortar. After fixing the window sill, excess mortar is removed and the cracks are filled with foam. After some time, the slopes and scars are plastered, and the window sill is prepared for installation, which can be done immediately after the cement has dried.

Step-by-step instructions: installation and installation

Installation instructions:

- You need to prepare the base for the wooden slab. The brickwork is covered with lime-gypsum mortar, and the wood is covered with an antiseptic. Window joints are treated with polyurethane foam.

- The wooden block is installed in the prepared socket. The plane must be horizontal, this can be checked with a level. The maximum deviation is a slope of 1 degree into the room.

- It is fixed on the outside with self-tapping screws, and on the inside with polyurethane foam. To strengthen the wide window sill, metal corners are installed on the slopes.

Methods for installing window sills

Installation is included in the price of a plastic window and is carried out by experienced specialists. They have a rich list of tools and the necessary skills, but if desired, this procedure can be performed independently. To do this, you should choose an installation method, which depends on the characteristics of the room and the configuration of the window system. In the past, a special solution was used to attach a plastic window sill, but this technology has been replaced by more advanced methods.

Mounting on polyurethane foam

Polyurethane foam can absorb moisture, which leads to its destruction. Before installing a window sill, it is necessary to consider a system of hydro- and thermal insulation. Corrugated cardboard or polyethylene foam is suitable for this. On the window side, a sealant is applied to the end of the strip, which contains substances against fungus and mold. The product is fixed at a slight angle and supported by wooden blocks 40x50 mm.

The bars are positioned sideways, occupying the space between the auxiliary board and the slope. Then wedges are driven under the edges of the bars. If the window sill is made of wood or MDF, then polyethylene foam pads are placed at the points of contact with the wall. After plastering the slopes, the excess parts are cut off. All cavities under the window sill are sealed with polyurethane foam. When the substance hardens, beacons, spacers and other additional devices are removed.

Using fasteners or mounting strips

Fastening a window sill using this method is characterized by a long implementation time, but a high level of reliability. To perform the work you must have some knowledge and skills. First of all, the difficulty arises with counting the clamps and determining their correct location.

Attaching a window sill to a plastic window in a regular room and on a loggia or balcony is practically no different. In an apartment on a high floor, you need to use additional thermal insulation materials that are resistant to strong gusts of wind.

Using Brackets

The bracket is a spring bracket for reliable fastening of window sills. The element is made of polymer materials, the possibility of bending guarantees tight fastening. The plate is attached with a self-tapping screw, which fits into the hole made.

Installation sequence for window sill anchors:

- The bracket is secured to the stand profile with a self-tapping screw.

- The number of plates is determined by the geometric features of the product. On average, 5-7 pieces per 1300 mm length are enough. If the length is greater, then the structure must be reinforced with additional brackets.

- The space under the window sill is filled with a uniform layer of polyurethane foam.

- The window sill is brought into place and snaps into place after light pressure.

- The level is adjusted.

Thanks to the use of anchor plates, the likelihood of errors when performing work is minimized. Plus, attaching a PVC window sill with brackets takes a little time and takes a small amount of effort and money.

Expert advice

Recommendations for correct installation:

- The slope should only be towards the room; this must be monitored using a level.

- The wooden surface should be smooth, without cracks or gaps.

- The wood must be well dried, the amount of moisture should not exceed 10–20%.

- When mounting on self-tapping screws, it is recommended to use washers.

- Use an antiseptic solution to treat the surface.

You don’t need to be a craftsman with ten years of experience to install a wooden window sill at home yourself. It is important to choose the source material correctly and follow the installation rules. High-quality installation will allow you to effectively use the surface and ensure a long service life.

Procedure for replacing a plastic window sill

The procedure for replacing plastic window sills depends on the type of slopes and frame material, so in order not to damage the window and reduce the number of installation problems, you should choose the appropriate option.

In the apartment

Replacing a window sill in an apartment is done as follows:

- Remove the plastic plugs from both sides of the plate.

- The polyurethane foam is removed from under the bottom. The area adjacent to the wall is cleaned.

- Plaster is removed from slopes by trimming with a grinder and scraping with a knife.

- Using a grinder, the plane of the wall is carefully trimmed to the depth of the window sill protrusion on both sides.

- Using a jigsaw, the slab is cut into pieces of 30 cm, which are removed step by step so as not to damage the frame.

- Preparatory work for installing a new window sill.

- Level installation without fastening to the frame.

In a wooden house

In a wooden house, to replace plastic window sills you need:

- Remove the plugs from the end parts of the plate.

- Remove sealant from the side of the slopes and the bottom.

- From the street side, unscrew the ebb and find out whether the window sill is attached to the spacer profile.

- Unscrew the screws from the holders and spacers for the frame, remove the brackets.

- Remove the window sill.

- Carry out preparatory work.

- Install a new window sill.

Main functions, varieties and photos

Useful features:

- Protects the room from cold and drafts.

- Can be used as a shelf for storing flower pots, books, and interior items.

- A place to relax. If the width allows, you can arrange a seating area on it.

- Winter Garden. It can be created by placing decorative vases with flowers on the surface.

- Workplace. With a width of 30 cm or more, you can place a laptop or table lamp on it.

Attention

Methods of use in the room depend on what type and shape it will be.

Varieties:

- Wide - these include elements with a width of 40 cm or more. They are installed only if there are wide supporting walls. They hide the battery well.

- Narrow - no more than 10 cm wide. They have little functionality, so they are often replaced with wider ones.

- Formal - in fact, it is practically absent, its role is played by a small internal slope (how to install a slope?).

- Window sill running onto the wall . The launch width is 15–20 cm.

- Without launching onto the wall - this option allows you to save money by reducing the length.

Wood is an environmentally friendly material , so all elements made from it can be used in apartments where people with allergies, small children and people with problems with the respiratory system live.

You can diversify the look of the interior by choosing a non-standard shape of such an element. It can be straight, which can be seen in every apartment, or arched. Such window elements have curved lines in the form of an arc.

The photo shows examples of wooden structures.

Which plastic window sill to choose: product types

Choosing a plastic window sill is a responsible task, since this will determine how long it will last and retain its decorative properties. The following products are available:

- Plastic with PVC film glued on. An economical option that does not have protection against dirt or temperature changes.

- Multilayer plastic with CPL coating. It has high heat resistance and can come into contact with chemically active substances.

- EPL coated plastic. It has high strength and maximum service life compared to other types of products.

The more reliable and durable the protective film, the higher the quality of the plastic used, the higher the cost of the product. Therefore, you need to choose based on operating conditions and requirements for maintaining the decorative appearance and basic characteristics. In most cases, the choice is made in favor of window sills made in the same way as plastic windows, so that after the end of their service life they can be completely replaced.

Texture, color and design of plastic window sill

Plastic window sills are available with glossy, matte or laminated finishes.

The gloss looks stylish and attractive, as its surface reflects the interior or the environment outside the window. It has antistatic properties, so it is not prone to dust accumulation, but fingerprints, traces of moisture and other types of dirt are visible on it. Cleaning is simple, so visible stains are easily removed. In case of damage, restoration is impossible - the window sill must be replaced.

The glossy finish of the window sills looks stylish, dynamic, and modern. Can easily fit into any interior design style.

The matte coating has a unique texture, it is pleasant to the touch, and reflections and glare are not visible on it, as on a glossy one. It can be painted in any color and look very attractive at any level of lighting. However, the surface is prone to stains that are difficult to remove. If damaged, restoration is possible.

Matte surfaces of window sills look less aesthetically pleasing and cheaper than glossy ones. At the same time, stains and traces of finger touch are not visible on them.

Laminate coating can be one- or two-layer. It has high strength and durability. In a two-layer configuration, a special dye can be applied, which significantly improves the decorative properties of the window sill. Texture films that imitate natural materials are also available.

Laminate coverings on window sills allow you to create true masterpieces in interior design. They are able to naturally imitate various materials. If necessary, the coatings can be changed and restored at minimal cost, without changing the window sill itself.

Components needed when installing window sills and slopes with your own hands

To install the window sill you will need to purchase a number of components:

- side plugs;

- fasteners.

Side plugs are designed for installation on the ends of the windowsill parts protruding further than the wall. They are easily adjusted to specific sizes and are attached with latches.

Connecting elements are used to form window sill joints at an angle. For example, for attic or veranda windows that have several transitions of vertical planes. That is, such elements are designed to hide the joining seams of the structure.

Repair work

Like any other product, wooden window sills require compliance with its operating rules, otherwise urgent repairs will be required. When using it, you should limit the ingress of moisture onto its surface, and when cleaning you can only use special polishes and cleaning agents. But sometimes inspiration appears to update the window sill and completely change the design of the room or be forced to renovate it. Repairs may be caused by the following reasons: the formation of dents, cracks, chips or cracked paint on the surface. By the way, in the latter case, you will only need to update the surface of the window sill, removing the old paint layer and applying a new one.

Repairing a wooden window sill with your own hands is also possible in more severe cases. To do this, after removing the varnish or paint from the surface, apply a layer of putty to the place of cracks, chips or gouges. After drying, go over the surface with sandpaper.

Next, remove the dust using a vacuum cleaner, degrease the surface, and then apply a new layer of coating. This will complete the repair. The algorithm for how to repair a wooden window sill yourself is quite simple.

How much the repair will cost you will depend on the materials used. At the moment, it has become fashionable to choose window sills made of natural material, and wood is ideal for this. The absence of chemical emissions when heated from the sun, noble texture, reliability and durability - all this distinguishes this type of product from its polymer analogues. In the absence of fashion for curtains and curtains, the window will look perfect, and the first thing that will catch your eye is the window sill. This is the reason why window sill models made of larch or oak are so valued, because they fill the room with the aroma of pine needles or natural wood.

What wood is best to make a window sill from?

To make a canvas for a window sill, you can use any type of wood, but take into account the intended purpose of the structure, as well as in which room it will be installed. Hardwood is suitable for rooms where frequent changes in temperature and humidity are acceptable. This product will last a long time. The only negative is the high price of the material. An oak board will be a reliable stand for pots of indoor flowers.

Larch is a cheap material, but it has a number of advantages:

- the wood of this species has a pleasant shade corresponding to hard varieties;

- has all the properties obtained from coniferous trees and does not need to be treated with antiseptic substances.

Thanks to all these qualities, larch material is in high demand in the building materials market.

The board for a window sill in a wooden house is selected according to the following indicators:

- Material integrity. When examined from all sides of the board, there should be no chipping of wood, cracks or knots. In addition, there must be no signs of pest damage.

- Select tree species that have a strong wood structure. The best material would be a board made of oak, beech or hornbeam. The second place in hardness is deservedly occupied by larch, pine, chestnut, and cedar. Boards made from these types of wood have an original pattern.

- Wood texture and color. Each type of wood has an individual structure and color. Only the buyer decides which option to choose.

Window sill made of oak boards

The oak material for the window sill is made from a single board. Oak sawdust is used to make laminated wood, chipboard and MDF

Despite the fact that glued material is much cheaper than solid material, it has an important advantage, which is its resistance to deformation under the influence of moisture. Chipboard and MDF have the same qualities, but are even cheaper

To produce budget versions of the product, the wood is crushed, pressed and covered with a laminate. By creating such material, the manufacturer increases the amount of texture and color range. Thanks to this, the window sill can be imitated like marble or stone. The surface will be both matte and glossy.

When choosing a material for a structure, you need to determine the purpose for which it will be used. In addition, the canvas must fit into the overall design of the room.

How to seal foam under a windowsill

Foam not only degrades the aesthetic qualities of the window system, but also requires additional protection. The material shows excellent thermal insulation properties, but is destroyed by moisture. You can seal the foam using two methods:

- The trimmed foam is covered with tile adhesive. Before painting the walls, the area treated with glue must be sealed with putty. If there is wallpaper on the walls, then it is better to treat the surface with an acrylic-type primer.

- The second method involves the use of vapor-permeable tape. The product must be cut according to the required dimensions and secured in free space. A decorative cover made of wood, aluminum or PVC is mounted on top of the system.

Each technology has a number of undoubted advantages, but their combination will give the maximum result. The cost of consumables is insignificant, so you can easily use two methods at the same time.

Installing a window sill is a complex process that requires a set of tools, supplies and special skills. Many home craftsmen fix the window sill correctly on their own, and the quality of the result is excellent.

Preparation

First of all, surface preparation must be carried out. The point is that whether it’s a new house or a major renovation, after installing the window blocks there will probably be construction debris left that needs to be removed.

Wedges

Also at this stage it is necessary to level the surface intended for installing the window sill as much as possible. If even slight distortions are observed, they must be removed using wooden wedges. The only distortion that is allowed is a slight tilt of the window sill plane towards the room, but here we are talking about a few millimeters.

How to install?

All types of window sill structures are installed according to the general principle. Since plastic windows with plastic window sills are the most popular option, the work algorithm was compiled based on their example.

Measurements, purchase and dismantling

The first thing you need to do is to correctly measure all the necessary values. To determine the length of the window sill board, you need to measure the width of the window opening itself in the place closest to the space of the room. Add 1–2 cm to this value on both sides to hide the raw edges with slopes. Then the width of the wall to the window is measured and a few centimeters are added to the value in order to deepen the product into the special groove of the window.

The resulting value is the width for installation flush with the wall. In the event that the window sill protrudes, it is necessary to add another 6–8 cm to the resulting value, and the length of the eyelets is added to the resulting length.

In accordance with the measurements, the material is purchased and the window sill board is made with your own hands or a ready-made version is ordered from a craftsman.

Renewing an old wood frame seam

According to technology, glass wool should not lie inside the seam for 10, much less 20 years. Many of us have had windows for 30 or 40 years. During this time, the material has already begun to actively release harmful substances, and glass dust is floating in the apartment. This is bad. When working with glass wool, you must use personal protective equipment.

Old wooden window

We have already discussed the problem of finishing an old wooden window with ecowool, so we will only briefly present the conclusions. This material is relatively safe and lasts for centuries. If, of course, it was purchased from a good company. A vapor barrier membrane must be placed along the boundaries of the seam, external and internal, to protect the inside from moisture, and the surfaces of the window opening are treated with waterproofing.

We consider all this clear from a series of previous reviews, and therefore, as promised, we move on to the window sill. The main problem will be what to make a new one from. But we believe that everything can be solved.