Modern construction, renovation and energy saving. Myths and reality

In the vast majority of cases, construction and finishing companies try to create for the client an ideal picture of the work they perform, in which, after installing windows, doors, roofing, etc. Comfort and coziness will reign in your home for many years. However, it is worth understanding that this is not the case.

In reality, the worst enemy of any structure is temperature. Temperature fluctuations entail changes in the volumes of substances and products made from them. If we talk about windows or doors, then you shouldn’t be surprised that cracks that were carefully sealed in summer will appear again in winter. And you should be aware that there is no escape from this. The gap is a condenser of moisture, fungus, a source of draft and a “thief” of your money at the same time. And one of the possible ways to combat it is the use of sealing elements that have a special set of characteristics, the main ones of which are compensation of the resulting temperature gap, protection from moisture and provision of ventilation. Such a seal is PSUL.

PSUL - what is it?

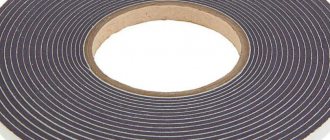

PSUL is a pre-compressed self-expanding sealing tape. The essence of this tape is that it is placed in a joint or seam, and it expands and fills all the gaps and cracks, including the smallest ones, thereby protecting the seams from weather influences. Its functional purpose is to create a ventilated assembly seam when installing windows, doors and balconies. It is made from a special polyurethane film with the addition of acrylic. This combination of materials provides better thermal insulation and moisture resistance. In addition, the material is resistant to aging. On the one hand, the tape has an adhesive backing, which makes working with it more convenient.

Scope of application and advantages of PSUL

Depending on the specifics of the product in combination with which the PSUL will be used, and the tasks assigned, there are tapes for waterproofing, tapes for heat, water and noise insulation, tapes for vapor and waterproofing.

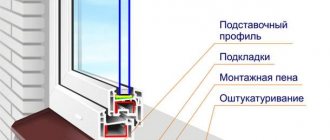

Today, replacing old wooden windows with new metal-plastic ones is quite a popular and advisable procedure. Such windows protect the house from cold, wind, moisture and noise, are simple and easy to use, durable, and also fit perfectly into any interior. A plastic window is a complex product. However, the installation process is also difficult to call easy. Often, when choosing windows, a gross mistake occurs - the client selects only the profile manufacturer, color and, at most, the type of fittings. However, in addition to the quality of the profile itself and the double-glazed window, the process of installing the window, as well as the execution of the seam, is of great importance: sealing, sealing, fastening. The weakest point in the window opening is at the junction of the window and the wall, which is filled with polyurethane foam. The polyurethane foam itself quickly collapses when exposed to moisture and ultraviolet radiation (sunlight). To fill all remaining gaps during window installation, a special PSUL tape for windows is used, protecting the foam from the specified climatic influences.

The next area of application of PSULs are balcony blocks. In this case, tapes with heat, water and noise insulation properties, or butyl tapes with vapor and waterproofing functions are most often used.

In some cases and under certain conditions, PSUL can be used when working with roofing. For roofing, it is advisable to use a tape that has waterproofing characteristics. Possible areas of application include sealing gutters, slate joints, tiles, metal tiles, roof windows, etc.

The advantages of PSUL over other materials are:

- ease of installation (pasting the tape is done in one motion, the tape bends and cuts easily);

- compatibility with most materials and types of surfaces (plastic, metal, concrete, stone, etc.);

- high level of shear resistance;

- high environmental performance;

- fire safety;

- optimal insulation quality regardless of weather conditions;

- durability;

- convenient packaging.

Application area

Pre-compressed sealing tape is used to protect the installation seam from moisture ingress and accumulation, as well as from room heat loss. The use of PSUL when installing windows is not just desirable, but necessary and regulated by the relevant quality and safety requirements of the technology. Installing PSUL can significantly increase the service life of the assembly seam and the window unit as a whole. In addition to maintaining the integrity of the foam, the tape also gives the seam a more aesthetic appearance. At the same time, PSUL can be used in concrete structures, roofing work, processing of log joints, and even when equipping a ventilation system.

pros

- Simple and convenient installation;

- No need for additional processing;

- Complete filling of free space;

- Weather resistance;

- Vapor permeability;

- Moisture resistance;

- Durability;

- Inert to the formation of mold and mildew;

- Compatibility with other building materials;

- High adhesion to the surface;

- Fire safety.

Minuses

The only disadvantages include the cost of the material. The use of PSUL tape involves additional material and time costs, however, all these disadvantages are easily compensated for by the resulting comfort and high performance characteristics.

Technical characteristics of PSUL

Among the main technical characteristics of self-expanding tapes are:

- vapor permeability coefficient;

- adhesive bond strength;

- degree of waterproofness;

- operating temperature;

- conditional durability.

Vapor permeability is the ability of a material to pass or retain water vapor. Measured in (m2*h*Pa)/mg. In accordance with GOST 30971-2002, this indicator should be no more than 0.15.

Adhesive bond strength is the ability of a material to resist chipping or peeling. Measured in MPa (kgf/cm2). In accordance with GOST 30971-2002, this indicator must be at least 0.3 MPa (3.0 kgf/cm2).

The degree of water resistance is the level of resistance of a material to the transmission of water droplets. Measured in Pa. According to GOST 30971-2002, this indicator should be at least 600.

Operating temperature - shows the temperature limits within which the material is capable of performing its functions. Measured in degrees Celsius. For each PSUL it is individual, but not less than -36°C and not less than +70°C (according to GOST 30971-2002).

Conditional durability is the number of years during which the material stably maintains its passport characteristics (subject to compliance with the installation rules). It is measured in years and, in accordance with GOST 30971-2002, must be at least 20 years.

Pre-compressed sealing tape (PSUL) “Favor Fast”

| PSUL is a self-expanding tape made of elastic polyurethane foam, impregnated with a special mixture of modified acrylic. Acrylic impregnation significantly increases the service life of polyurethane seals. The tape is coated with glue on one side, which simplifies its installation. The tape is supplied compressed and rolled into rollers. Hermetically packed in shrink film. |

Description of PSUL tapes “Favor Fast”

PSUL FF is a universal multifunctional tape, it can be used with all building materials: concrete, brick, steel, wood, plastic and other materials. The tape is used to protect moving and fixed joints from water, noise, cold, dust penetration and other unfavorable factors. Has the ability to pass vapor.

| The scope of application of PSUL tapes in construction is very diverse. I would like to emphasize that the use of PSUL tapes when installing windows as the outer layer of the installation seam along GOST 30971 – 2002 is mandatory. As can be seen from the figure, PSUL prevents water, snow and dust from entering the window opening structure, ensures the release of water vapor from the structure into the atmosphere, and protects the mounting foam from harmful UV rays. See: GOST 30971 – 2002… |

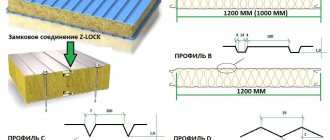

| Currently, PSUL FF has also become widely used when installing roofs as a seal between metal tiles and the ridge, metal tiles and eaves strips. As a sealant for corrugated sheets: under a straight ridge and for junctions. The presence of an adhesive layer makes the installation of PSUL FF tape as convenient as possible, and its “self-expansion” allows you to fill all the unevenness and gaps of the seam. |

PSUL “Favor Fast” tapes are produced in the following assortment:

PSUL tapes, density 50 kg/m3

| Size, mm* | Width, mm | Thickness, mm | Roller length, m.p. | Number of rollers per pack. | Photo | |

| Before expansion | After expansion | |||||

| PSUL 8*4/20 | 8 | 4 | 20 | 8 | 25 | |

| PSUL 8*4/20 | 8 | 4 | 20 | 16 | 25 | |

| PSUL 10*3/15 | 10 | 3 | 15 | 10 | 20 | |

| PSUL 10*4/20 | 10 | 4 | 20 | 8 | 20 | |

| PSUL 10*4/20 | 10 | 4 | 20 | 16 | 20 | |

| PSUL 12*6/30 | 12 | 6 | 30 | 5,6 | 16 | |

| PSUL 12*6/30 | 12 | 6 | 30 | 11,2 | 16 | |

| PSUL 15*4/20 | 15 | 4 | 20 | 8 | 13 | |

| PSUL 15*4/20 | 15 | 4 | 20 | 16 | 13 | |

| PSUL 15*6/30 | 15 | 6 | 30 | 5,6 | 13 | |

| PSUL 15*6/30 | 15 | 6 | 30 | 11,2 | 13 | |

| PSUL 15*8/40 | 15 | 8 | 40 | 4 | 13 | |

| PSUL 15*8/40 | 15 | 8 | 40 | 8 | 13 | |

| PSUL 20*6/30 | 20 | 6 | 30 | 5,6 | 10 | |

| PSUL 20*6/30 | 20 | 6 | 30 | 11,2 | 10 | |

| PSUL 20*8/40 | 20 | 8 | 40 | 4 | 10 | |

| PSUL 20*8/40 | 20 | 8 | 40 | 8 | 10 | |

| PSUL 20*10/50 | 20 | 10 | 50 | 3,3 | 10 | |

| PSUL 30*10/50 | 30 | 10 | 50 | 3,3 | 7 | |

* bold – PSUL with double winding of the roller

PSUL tapes, density 30 kg/m3

| Size, mm* | Width, mm | Thickness, mm | Roller length, m.p. | Number of rollers per pack. | Photo | |

| Before expansion | After expansion | |||||

| PSUL 10*3/15 | 10 | 3 | 15 | 10 | 20 | |

| PSUL 10*4/20 | 10 | 4 | 20 | 8 | 20 | |

| PSUL 12*6/30 | 12 | 6 | 30 | 5,6 | 16 | |

| PSUL 15*4/20 | 15 | 4 | 20 | 8 | 13 | |

| PSUL 15*6/30 | 15 | 6 | 30 | 5,6 | 13 | |

| PSUL 15*8/40 | 15 | 8 | 40 | 4 | 13 | |

| PSUL 20*6/30 | 20 | 6 | 30 | 5,6 | 10 | |

| PSUL 20*8/40 | 20 | 8 | 40 | 4 | 10 | |

| PSUL 20*10/50 | 20 | 10 | 50 | 3,3 | 10 | |

| PSUL 30*10/50 | 30 | 10 | 50 | 3,3 | 7 | |

Attention:

PSUL can be manufactured in different widths according to the customer's order!

The time for complete expansion (5 times) is from 2 to 24 hours.

Minimum installation temperature 5 C°, operating temperature limits: from –50 C° to +95 C°.

The minimum service life (according to the manufacturer) is 20 years.

According to our technical experts, high-quality sealing and protection of the seam is provided by the Favor Fast PSUL with acrylic impregnation with a density of at least 50 kg/m3.

Watch: Tech. PSUL characteristics...

The declared technical characteristics of the PSUL “Favor Fast” manufactured according to TU 5775-002-26699569-2015 correlate well with the requirements of GOST 30971-2002.

Watch: Comparison of tech. characteristics of PSUL “Favor Fast” and GOST 30971-2002...

Advantages of pre-compressed sealing tape (PSUL) "Favor Fast":

|

Scope of application of pre-compressed sealing tape (PSUL) “Favor Fast”:

- sealing of roof elements: junctions of tiles and corrugated sheets;

- when installing windows, as the outer layer of the construction seam;

- insulation of seams and joints during the construction of buildings and structures made of reinforced concrete slabs;

- when assembling structures from sandwich panels and any prefabricated building structures;

- sealing the seams of ventilation ducts;

- sealing joints of non-pressure pipelines: storm and fecal sewers;

- sealing the gaps between the door frame and the opening in the wall.

Important!

The use of PSUL tapes with obviously less expansion than necessary in a particular case can lead to undesirable consequences: the occurrence of leaks, blowing out of the PSUL by a strong wind, as well as squeezing out the PSUL with foam. High-quality sealing and protection of the seam is ensured only by correctly sized tapes.

The most frequently asked question is “how much should the PSUL expand after installation?”

This is the most popular question and complaint to the manufacturer, so we answer it in detail directly on the website. Using the example of PSUL Favor Fast 20*8/40 (4 m.p.) material, which was tested at the EUROSTAN LLC IC. Test report No. 1 ST-05/2015 dated 05/06/2015

Watch: Protocol PSUL FavorFast...

PSUL Favor Fast 20*8/40 (4 m.p.)

The initial thickness of polyurethane foam is 40 mm.

The thickness in the compressed state (before expansion) is 8 mm.

The declared thickness after expansion is 37 mm, the actual thickness according to test results is 38.24 mm. Page 4, Table 2 of test report No. 1 ST-05/2015 dated 05/06/2015

Which more than meets the requirements of the TU 5775-002-26699569-2015 developed by us.

The difference in the initial thickness of polyurethane foam and its thickness after expansion is 2-3 mm (depending on the initial thickness of the PSUL). This difference is due to the impregnation of the material with a special mixture of modified acrylic.

Acrylic impregnation significantly increases the service life of polyurethane seals. But!!! Reduces the effective size of the material during secondary expansion after compression into rollers by 2-3 mm!!!

When impregnated with acrylic, the so-called “sticking” of polyurethane pores occurs. Acrylic prevents the polyurethane pores from expanding to their original thickness. This is normal, it means that the material is indeed fully impregnated with a special mixture of modified acrylic, which means it will be resistant to UV rays and will provide the declared characteristics for a long time (minimum service life 20 years).

Remember!!! If the PSUL expands to its original thickness, most likely there is simply no acrylic in it. In order not to offend our economical competitors, we can put it mildly - the amount of acrylic does not correspond to the norm. This means that when installing windows, it is NOT recommended to use such material as the outer layer of the installation joint.

All products are certified in accordance with Russian legislation.

See also: •Profile seals •Universal seal •Self-adhesive PPE tape •Sealant for sandwich panels

" Return

Installation dimensions PSUL. Features of choice.

After installing metal-plastic windows, doors or balcony sections, it is important to choose the right sealing tape. If you are sealing joints yourself, without resorting to the services or consultations of installation companies, you should adhere to the following basic recommendations.

First you need to pay attention to the width of the adhesive layer. This indicator is determined based on the gap between the mounting foam and the outer part of the quarter window opening and can range from 10 to 20 mm (in other cases, the size of the adhesive layer is selected individually). The next important parameter of the tape is its maximum expansion. To ensure maximum efficiency, the gap should exceed the value of the tape in the compressed state by no more than 20 percent (critical value - 50 percent). Otherwise, the performance of the PSUL will be unsatisfactory. For example, if the gap between the window and the wall is 13 mm, you should choose a tape with a rolled thickness of 10 mm. If, however, a tape with a maximum expansion of 20 mm is installed in a gap of 17 mm, its efficiency indicators will be lower than that of a tape 12 mm thick with an expansion of up to 30 mm.

How to choose?

When choosing pre-compressed sealing tape, the first thing to consider is its width. After installation, the tape should fill all the free space, which is why it is important to calculate the distance from the top of the opening to the seam of the polyurethane foam. It is also important to know the expansion coefficient. The most effective indicator is no more than 30%. A higher percentage indicates a low density of the material, which leads to poor sealing. To make the calculations more clear, let us give an example: for a seam 1.3 cm wide, a PSUL with a width of 1 cm (folded) is suitable, and the expansion coefficient should be 3 cm.

Price PSUL. Manufacturers

The main pricing factors for sealing tapes are:

- Overall dimensions, mm;

- roll length, m;

- composition and functional features;

- country of origin and level of delivery complexity;

- number of resellers.

The first three items on the list practically do not change over time and do not have a significant impact on price changes. The last two points affect the cost of the product to a much greater extent for the end consumer. Therefore, it is more advisable to buy PSUL from a regional representative of the manufacturer. This will definitely allow you to save on insulating your home. The next thing to pay attention to is the brand name. You should not give preference to companies that you have not heard of. Reviews from real buyers of the products you are interested in, which can be found on the Internet and in print publications, will help you avoid getting into trouble. You can also seek advice from relatives, friends and acquaintances.

Among the sealing materials from domestic and foreign manufacturers on the market, it would not be out of place to mention such an eminent domestic manufacturer of sealing tapes as the Robiband company. Today, thanks to the use of advanced technological solutions, flexible pricing policy and successful management, Robiband is the leader in the segment of polymer sealing tapes, producing products of the highest quality in accordance with European and world standards. The company's products are in demand both in Russia and abroad.

Purchase and installation of PSUL

You can buy PSUL wholesale and retail by placing an order online, by phone or by visiting a store in person. As for installation, everything is extremely simple. The surface on which the tape will be applied must be dry, cleaned of dust and degreased. The last operation is optional, but provides higher adhesion of the tape to the surface. After preparing the surface, everything must be done quickly so that the tape does not have time to expand. Using a tape measure or other tool, measure the dimensions of a window, door or roofing sheet, quickly unwind, cut and glue the appropriate piece of tape. Ready. Now your home is insulated and reliably protected from climatic influences.

Installation

Before opening the tape and gluing it in the right place, it is imperative to prepare the opening, namely, clean it of dust and construction debris, and also prime the surface. The protective film is removed from the window, and the surface is cleaned and degreased. Do not leave the protective film on. Firstly, it is necessary only to protect the frame during the installation process, secondly, under the influence of ultraviolet radiation it clings more strongly to the material, which subsequently causes great difficulties in removing it, and finally, thirdly, if you remove the film after installing the PSUL, then part of it will remain on the profile, which will cause aesthetic discomfort. Please note that the edge of the tape is not suitable for gluing. This remainder is cut off. The gluing should be carried out carefully, gradually removing the protection from the adhesive layer. After processing the entire perimeter, the tape is cut evenly into the seam. As a rule, the top seam is glued first, then the side seams. Full expansion of the tape occurs within half an hour at a temperature of 20 degrees. At lower rates the process may take 2-3 times longer. Often, if work takes place in winter, installers use a heat gun to speed up the expansion process.