Mulwatt

18974 0 9

Mullvatt September 7, 2016Specialization: Capital construction work (laying a foundation, erecting walls, constructing a roof, etc.). Internal construction work (laying internal communications, rough and fine finishing). Hobbies: mobile communications, high technology, computer equipment, programming.

Drywall allows you to quickly and effortlessly level the walls on the balcony.

As a finishing material, plasterboard on the balcony is not so common, as some believe that it will not withstand specific operating conditions.

This is fundamentally wrong. I recently finished finishing the loggia with plasterboard and insulation. I spent a minimum of time, effort and not a lot of money on everything. Therefore, I consider this technology one of the most effective. But I was able to simultaneously insulate the room and protect it from moisture.

I will now tell you how to cover a balcony with plasterboard sheets. I think many readers will be inspired by the idea and will decorate the mentioned premises in exactly this way.

Which gypsum board to choose for installation on a balcony

Determining which type of plasterboard sheet on a loggia or balcony is more acceptable should take into account its basic classification.

Let us immediately note that its weight and strength depend on the thickness of the sheet; accordingly, these parameters partially determine the scope of its application. The largest manufacturers of gypsum boards distinguish the following types:

- Ordinary drywall, without adding special additives, can be used in dry, heated rooms with a natural level of humidity.

- Moisture-resistant plasterboard is recommended for use in rooms with high humidity, as well as where condensation can form, for example, slopes, balconies, bathrooms, kitchens.

- Fire-resistant gypsum board contains additives in its coating that inhibit direct fire. It can be used near fireplaces, stoves and other sources of high temperatures.

As you can see, from this classification, the most suitable for installation on a balcony or loggia is moisture-resistant plasterboard. For installation on walls, it is recommended to use thicker sheets (from 8 mm), and on the ceiling you can use thin 6 mm gypsum board.

Finishing

After all puttying work, the plasterboard surface must be treated with a primer. This composition will not only improve the adhesive properties of a wall finished with gypsum board sheets, but also significantly reduce the consumption of glue and paint.

If ultimately the surface will be painted, then it is better to apply the water-based emulsion in several layers. Alternatively, you can use wallpaper, tiles, or mosaics for finishing.

Plasterboard sheets for interior decoration of a balcony are quite the best option, the main thing is to know which type to choose and the basic rules for its use. By performing all installation work taking into account a certain technology, you can create a reliable and durable structure.

Subscribe

Sequence of work when covering a balcony with plasterboard

Installation work is not particularly difficult if you carry it out together with a partner. It would also be a good idea to study the algorithm of actions in advance so that the final result of the repair will please you with its quality.

Preparatory work

Before finishing the loggia with plasterboard begins, the installation of all necessary communications must be completed. If possible, it is necessary to install new double-glazed windows, as well as carefully prepare the walls for finishing.

The surface of the wall on which the plasterboard structure will be attached must be inspected for cracks and possible areas of mold or mildew. If this moment is missed, then it will be very difficult to correct such shortcomings in the future.

The cleaned walls and ceiling of the balcony must be primed. Among the variety of primers, it is better to choose one that contains PVA glue. After its application, a very stable film is formed on the surface, which can become reliable protection for many years.

We select materials and tools

In order not to waste time searching for the right tool during the installation of drywall, it is better to prepare everything in advance. To install plasterboard structures you may need:

- water or laser level;

- waterproofing, heat-insulating and vapor barrier material;

- tape measure, ruler;

- fasteners (dowel - screw or dowel - nail);

- metal hacksaw, jigsaw;

- hammer;

- guides and metal profile;

- perforator;

- screwdriver;

- polyurethane foam;

- putty;

- drywall.

Installation of guide profiles and frame

Finishing a balcony or loggia with sheets of plasterboard begins with the installation of a frame onto which the finishing material will later be attached. This process is quite complex, labor-intensive, requiring accuracy and attention. But the quality of the work performed determines how the finishing will proceed in the future and the final result of the repair. For the frame, you can use either wooden slats or a metal profile.

After the area of the surface to be finished has been measured, profiles or slats of the required size are cut. The ceiling and walls are marked and the center line is marked in the center. The remaining lines are drawn perpendicular to the axis. The frequency of marks is every 30-40 cm. Guide profiles or wooden slats are attached to the surface of the walls. To do this, we make holes with a hammer drill and attach the profile to the wall or ceiling using dowels.

Initially, the planks are not fully fixed. Before firmly fixing the guides, use a level to check the horizontal and vertical of the frame and only after that all the guides are firmly fixed.

We insulate a balcony or loggia

The best option for insulating a balcony is polystyrene foam. Having a small thickness, this heat-insulating material retains heat well. It is also worth noting its low cost. An alternative to expanded polystyrene will be polystyrene foam. Sheets of this material are easy to cut and insert into the sheathing. The insulation is fixed with special plastic dowels “umbrellas”. The fasteners must be placed at the corners of the sheet. A small gap should be left between the insulation and the frame guides, which is filled with foam.

After the installation of the heat-insulating material is completed, the entire structure is covered with foil vapor barrier. It is attached to the frame with a stapler. Vapor barrier roll foil protects walls from exposure to steam and moisture, which is very important when arranging a balcony.

Fastening sheets of drywall

We prepare the material. We cut out the sheets of the required sizes. If necessary, make holes in the drywall for the lamp. On a sheet of drywall, cut the chamfer at an angle. This will prevent further deformation of the sheets and improve the quality of the finish.

Drywall sheets are attached to the frame with self-tapping screws. The fasteners are fixed in increments of 20cm. The screw head must be hidden in the thickness of the plasterboard sheet.

Finishing work

The assembled plasterboard structure is prepared for painting. To do this, the surface is impregnated with a primer, and the seams between the panels are puttied. All plasterboard finishing is covered first with starting and then finishing putty.

Having studied in detail the stages of finishing a balcony with plasterboard and the features of the material, you can not only save money, but also quickly create a cozy, beautiful room for relaxation with your own hands.

What are the main steps to follow?

Let's briefly look at what step-by-step instructions for finishing a loggia with plasterboard look like. Obviously, it can also be applied to the balcony.

- Surface preparation. At this stage, it is necessary to dismantle the current finishing so that it does not interfere with us. You need to make sure that the base is strong and the old plaster is not crumbling.

- Carrying out markings. Using a level, plumb line, tape measure and other auxiliary tools, markings are made for the future frame.

- Frame assembly. Using properly selected profiles, a sheathing is made to which the drywall will be attached.

- Heat and vapor insulation. Thermal insulation material is inserted into the frame, and then a vapor barrier is made. Some believe that it is possible to insulate a balcony with plasterboard, but polystyrene foam, mineral wool or other insulation will give an even greater effect. Therefore, they need to be used in conjunction, and not rely on gypsum board alone.

- Installation of drywall. At this stage, it is necessary to cut the gypsum board to the required size and attach it to the sheathing.

- Finishing work includes priming and puttying of previously laid sheets.

This is what the main stages of work look like. Next we will look at them in more detail so that there are no more questions about the process.

Choosing drywall

To cover a loggia or balcony, you can use only moisture-resistant plasterboard. Anyone else will get damp in a fairly short time. Moisture-resistant drywall is much more resistant to moisture and is also treated with special substances that prevent the formation of fungus.

Is it possible to cover a balcony with poor quality plasterboard? This finishing material, like any other, can be manufactured in violation of production technology, so an inexperienced craftsman is not always able to choose high-quality material. As a rule, such finishing will need to be redone as soon as possible after completion of the work. Before you go to the store for drywall, you need to get comprehensive information on how to choose the right drywall for finishing a balcony or loggia. Which drywall is best for loggias and balconies is not difficult to figure out

When choosing this material, you should pay attention to the following points:

- If it is possible to purchase gypsum boards at a large retail outlet, then this should definitely be done. Such trade organizations value their reputation and take goods for sale in large quantities from trusted manufacturers

- It is advisable to inspect each sheet of drywall for abrasions, scratches and bends. If there is even minor mechanical damage, the plasterboard sheet must be put aside and a perfectly flat one selected

- You should not purchase drywall, the price of which is significantly lower than the average. Trying to save money, you can lose significantly more money by purchasing a low-quality product, which may not look different from good material, but during operation the plasterboard wall may bend or the plaster between the cardboard layers will begin to crumble. The easiest way to protect yourself from low-quality purchases is to purchase material from well-known manufacturers. Among plasterboard manufacturers, the most famous and popular are Knauf, Rigips and Lafarge. The products of these companies will cost much more, but you don’t have to worry about the quality of the plasterboard material

Pros and cons of drywall

Drywall is a layer of gypsum covered on the outside with cardboard. It is used for covering the ceiling and walls in the house. The flexibility of the material allows you to create wall and ceiling structures of almost any complexity based on it. Covering a balcony with plasterboard has the following advantages:

- Leveling surfaces of any degree of curvature. While with plaster (the main “competitor” of drywall) you can level a maximum wall with a 1.5-centimeter thickness of curvature;

- The cleanliness of the work, which is why this material is also called “dry plaster”;

- The ability to hide small pipes and electrical wiring under the interior finishing with plasterboard;

- Soundproofing;

- Simplicity and speed of work, the ability to create multi-tiered suspended ceilings;

- Possibility of placement on the balcony under plasterboard sheathing for steam and thermal insulation;

- Hygroscopicity, due to which air exchange is maintained between the wall and the balcony;

- Availability due to low price;

- Multiple lighting options: use of built-in lamps, ice lighting.

Covering a balcony with plasterboard has many advantages.

But, like all materials, drywall is not without its drawbacks. These include low resistance to mechanical stress.

Also, the cladding is located at a certain distance from the wall, which as a result reduces the volume of an already small room. Well, ordinary drywall is not resistant to moisture. But this minus is easy to fix. It is enough to choose waterproof plasterboard for covering the balcony. How is it different from the usual one? We'll find out now.

How to properly insulate a loggia with mineral wool

Loggias and balconies have long ceased to function as storage rooms. Now more and more owners are seeking to increase the usable area of their apartments by combining a room with a loggia, or by arranging a small room directly on the balcony. In both cases, before proceeding with the design of the room, it must be insulated, since the developer did not initially envisage the role of the loggia as a living room. And the best raw material for insulating walls, floors and even ceilings is mineral wool.

The use of such material to ensure the preservation of room temperature has both a lot of advantages and disadvantages. It is important to take into account both the pros and cons of mineral wool, as well as the features of insulation technology, even before starting repair work.

Work order

For the most effective finishing of the balcony, follow the following instructions:

- remove old peeling trim;

- Fill all the cracks well with polyurethane foam;

- if necessary, remove all fungal infestations and prime the walls;

- apply markings for the frame. We must not forget about level control and the need to install a sufficient number of fasteners (profiles or bars along the edge of the sheet under the ceiling and near the floor);

- secure the frame elements to the walls. It is recommended to make the lathing with horizontal strips in increments of 40 - 60 cm for reliable fastening of the thermal insulation inside the frame;

- lay the thermal insulation so that it fits tightly into the frame, without creating voids, but also without sticking out;

- cover the frame with a layer of vapor barrier, seal the joints with tape (the foil side should be directed inside the room);

- fasten the drywall as tightly as possible at the junction with the window sill, wall, corners, etc., leaving about 1 mm for possible movement of the sheets due to temperature changes;

- Scroll the gypsum boards with self-tapping screws every 15 - 20 cm; you also need to monitor the depth of their screwing. The durability of the plasterboard structure largely depends on this;

- putty joints, screws and corners of the structure;

- After applying the primer and allowing it to dry completely, you can begin finishing.

Drywall on the balcony is installed on a frame made of wood or metal and lined with sound and heat insulation.

Ceiling and wall cladding work

Just as in the case of floor insulation, a frame of logs is installed on the ceiling and walls to evenly and firmly secure the mineral wool. A wooden beam measuring 0.5x0.4 cm is suitable for such purposes.

The logs are installed with the same frequency - half a meter, and are connected by transverse strips, and installation begins from the junction of the ceiling and wall. If insulation is carried out for the purpose of further arranging a separate room with your own hands, after forming a frame from beams, electrical wiring is carried out.

Next, using a special mounting adhesive, mineral wool is glued into the cells formed on the surface of the ceiling and walls, just like in the case of the floor, cut into pieces. In this case, you should be careful and ensure that the insulation layer is not pressed through. This way the side walls, parapet and ceiling of the loggia are insulated. The wall bordering the living space does not need insulation and is best suited for installing electrical sockets and switches.

It is important to securely fasten the mineral wool to the walls

Which is better: heated floors or radiators?

Warm floorBatteries

The final stage of insulating a loggia with your own hands is the formation of insulation from steam and condensation, which are destructive for both mineral wool and timber. For this, sheets of polyethylene are used, which, using a construction stapler, are attached to the frame of the ceiling and then the walls.

The insulation has been completed, now finishing work awaits, which will give the room a more comfortable and habitable look. It is worth starting the finishing from the ceiling - it can be sheathed with clapboard, plasterboard or other finishing material. Then the final covering is laid on the floor, and, lastly, the walls are covered. When working with wall decoration, it is important to remember the need to leave holes in the places where sockets and switches are installed.

Resistance to wet environments

Plasterboard walls also have their pros and cons when installed in wet areas

It is important to choose the right material here. There are at least 3 types of drywall available for sale, depending on possible operating conditions:

Moisture-resistant drywall

- moisture resistant;

- refractory;

- ordinary.

Each of them has its own advantages, as do the designs made from it. If the sheet does not burn from fire, then from direct exposure to water and gypsum board it will become completely unusable. But this will only happen to a lesser extent than with conventional material for dry rooms. Gypsum is gypsum, you can add hardeners and hydrophobic components to it, but it will not change its main property - hygroscopicity, as a result of which it swells.

This is another of the few disadvantages of drywall and structures made from it. Therefore, due to the possibility of flooding by neighbors above, it is not recommended to build partitions and ceilings from ordinary plasterboard. This can lead to additional financial and nervous waste. It is better to use materials that are more moisture-resistant, for example, foam blocks, and it is better to make the ceiling suspended or suspended without the use of plasterboard.

Drywall walls also have pros and cons in terms of versatility and practicality. By creating a structure from this material using frame technology, it is possible to perfectly hide communication elements without much difficulty. Pipes, wiring, ventilation ducts. But again, if there is a threat of flooding, it is better to use gypsum board sheets. They have a distinctive feature - green cardboard.

Decorative plasterboard partitions

But the main advantage of drywall is that only from it can you make entire works of art and unique compositions:

- arches;

- bar counters;

- decorative designs in Art Nouveau style;

- huge massive columns.

Advantages and disadvantages of mineral wool

The advantages of mineral wool include the characteristics that an ideal insulation should have. Namely:

- Absolutely harmless to humans (no toxins are released, safe in contact with the body).

- It has an optimal ratio of light weight and thermal protection.

- Fire resistant.

- Easy to install.

- Creates sound insulation.

- Unpretentious to climatic conditions (insulation work can be carried out in the winter season).

As for the shortcomings of the material, the list includes such characteristics as minimal moisture resistance, pliability when wet and a high degree of crumbling. Therefore, when working with mineral wool, it is important to ensure high-quality waterproofing, as well as control the pressure on the material during installation in order to avoid deformation and destruction.

Do-it-yourself finishing of the loggia with moisture-resistant plasterboard

Have you decided to cover your balcony with plasterboard yourself? Pay attention to moisture-resistant drywall. The most suitable material for a balcony

There will be no mold or mildew, and you won’t be afraid of a fire either.

The light green sheet consists of a couple of layers of cardboard, with gypsum filler inside. Impregnated with a composition that repels moisture.

Don't want to overpay? Let's correctly calculate the amount of drywall. Measure all the walls, subtract the area above the railings, but feel free to include the window and balcony door in the calculations. But calculate the required amount of insulation without windows and doors.

One sheet of drywall requires 70 self-tapping screws, and a dowel - nails - 5 pieces per block.

See what you need to repair your balcony yourself. Perhaps you have something at home or can borrow from a neighbor.

Moisture-resistant drywall has a green tint

We purchase the following materials in the store:

- Drywall;

- profile or block for sheathing;

- self-tapping screws for drywall;

- insulation;

- putty;

- primer;

- paint.

You will need the following tools:

Screwdriver

Stationery knife

Building level

Hammer

Roulette Pencil

Hacksaw

First, get rid of the old plaster, all cracks, and apply waterproof putty. Treat the balcony walls with primer a couple of times and you won’t think about mold for a very long time. The preparatory work is left behind and you can begin installing the sheathing.

The metal sheathing will serve you for a very long time, but the wooden version is also not bad, and is easier to work with.

Install the sheathing horizontally and secure it with dowels, maintaining a distance of 60 centimeters. Use a grinder to remove unnecessary parts.

The insulation has already been selected, lay it evenly and without gaps. Rolled foil is laid on top of the insulation. This is necessary for vapor barrier and will not be difficult. Secure with a mounting stapler and proceed to the most interesting part - covering the balcony with plasterboard.

Useful video:

Start with the largest wall to save material and spend less time cutting. Drywall can be easily cut with a knife, just place a hard and even object, such as a level, along the cutting line.

Attach the sheets to self-tapping screws every 20 centimeters, press the caps into the sheet, then it will be easier to plaster. Form a wall by adjusting the second sheet to the level.

The main work on finishing the balcony is behind us, but it’s too early to relax. Prime the walls well and seal seams and joints. Now the surface needs to be puttied, then proceed to grouting. Prime again and exhale. The best part remains - painting it in the chosen color. This article will help you with this.

In short, we spent more time preparing than we did. Now only you have such a cozy balcony with smooth walls and original design.

Types of drywall and frame profiles

Today, the finishing materials market offers a wide range of different types of plasterboard sheets and frame profiles.

Drywall marking

Types of drywall

Certain types of gypsum boards differ in their technical characteristics and scope of application

Therefore, when choosing the material you need, you should pay attention to the markings of the sheets:

- GKL is an ordinary plasterboard sheet consisting of a layer of gypsum, covered on both sides with layers of cardboard;

- GKLV – moisture-resistant sheet. It includes hydrophobic additives that repel moisture, and is created specifically for finishing work in rooms with high humidity - bathrooms and toilets, kitchens, etc.;

- GKLO – fire-resistant sheet. It consists of a mixture of plaster and asbestos, held together by fiberglass mesh instead of cardboard;

- laminated gypsum board - differs from a regular sheet in its coating of polyvinyl chloride film. Such drywall, installed on a wall or ceiling, does not require additional finishing with putty - it is already ready for painting with any composition, for wallpapering or for applying decorative plaster;

- arched gypsum board is a thin and flexible sheet, specially designed for creating curved structures (arches, niches and multi-level semicircular ceilings).

In addition to the area of application, plasterboard sheets vary in thickness. The most massive of them, up to 50 mm thick, can be used as load-bearing wall panels, and they can also be used to finish floors. The thinnest modifications have a thickness of only 4 mm - this is the so-called “ceiling” plasterboard. It is used to create structures that do not experience heavy physical stress during operation: for suspended ceilings and other decorative interior elements. Sheet sizes can vary in length - from 2 to 4 m, in width - from 60 cm to 120 cm.

Types of frame profile

Profile types

The popularity of gypsum boards is largely due to the simplicity and speed of their installation. This is achieved by using standardized frame elements - metal profiles. Before covering the balcony with plasterboard, a frame of such profiles is mounted.

They come in two main types - wall and partition. Each of these types consists of guides and load-bearing elements:

- Wall profile. It is used when covering load-bearing elements - walls and ceilings, to which it is attached using standard fastening fittings (hangers, “crabs”, etc.). Guide wall elements (UD marking) should be installed along the perimeter of the future structure. Along the walls when installing suspended ceiling structures; or along the ceiling and floor, when covering walls. The load-bearing elements of the wall profile (CD marking) are intended for direct fastening of gypsum plasterboard sheets to them. They are inserted into guide elements and attached to the walls using frame reinforcement.

- Partition profile. It is designed to create load-bearing frames for wall partitions. When finishing a loggia with plaster, this profile is used relatively rarely, since it does not seem practical to divide the limited balcony space with partitions. It is possible to install a partition here only if there are two separate entrances to the loggia, say from the hall and the kitchen.

Installation technology

Well, now you can tell us how to decorate a balcony with plasterboard yourself. The technology consists of several stages, presented in the diagram below:

Diagram of installation of drywall on the balcony.

Now I will tell you about each stage in more detail.

Preparatory stage

As is usual with good craftsmen (of which I dare to include myself), let's start with preparing the room. Here's what I do:

- I am dismantling the old finish. If the balcony was wallpapered or tiled, they should be completely removed and the surfaces should be cleaned with a spatula. In the case where the walls were painted with facade paint, it is enough to simply clean off the peeling pieces, and the layer of paint that adheres firmly can be left. Since we will use EPS for insulation, it will not bring us any harm.

Before starting work, you need to dismantle the old finish.

- I clean surfaces from dust and debris . To do this, I first clear the balcony of foreign objects, after which I use an industrial vacuum cleaner (you can use a regular household one) to clean the concrete walls from dust. This promotes better adhesion of adhesives and makes work easier.

The walls can be cleaned with a grinder.

- I carry out repairs of defects in enclosing structures. We are talking about cracks, depressions and protrusions that may be present on the walls or parapet. Through them, water can penetrate to the drywall, which will lead to damage to the finish. There are several repair methods:

- Small cracks need to be slightly sawed with the disk of an angle grinder, and then filled with foam using a gun. After this, the protruding parts of the foam should be trimmed so that there are no problems with gluing the extruded polystyrene foam.

- Large cracks must be freed from crumbling concrete using a chisel and a hammer drill, and then filled with a specially prepared cement repair mortar.

- Recesses in which the reinforcement is visible should be sealed with special care. First, metal parts should be cleaned of traces of corrosion and coated with a rust converter. And then fill the defect with a solution.

Cracks and defects need to be repaired.

- I am waterproofing balcony surfaces. This can be done using mastic or pasting material (the easiest way is roofing felt). Not long ago I devoted a separate article to this topic. If you are interested, you can contact her for the missing information.

Waterproofing the balcony floor.

- I prime the surface. Those surfaces (usually walls and ceilings) that have not been waterproofed must be primed. For this I use a primer for mineral surfaces with antiseptic properties. The active substance included in such a liquid prevents the appearance and development of mold and mildew on the enclosing surfaces of the balcony.

The walls and ceiling are primed with an antiseptic primer.

- I insulate the balcony using penoplex.You can, of course, use another building material for this, but I prefer this due to the ease of working with it. The EPS installation diagram is as follows:

- I glue pre-cut foam sheets onto the walls and ceiling using cement glue. If work is carried out in the cold season, it is better to replace cement adhesive with polyurethane adhesive.

- I seal the seams of the insulating material with polyurethane glue or polyurethane foam. If this is not done, islands of cold may form in the insulating layer, which will negate the effectiveness of thermal insulation.

- I additionally fasten the insulation using plastic “fungi” dowels with wide caps (I described the entire process of insulation using penoplex in more detail in one of the articles, which you can read before starting work).

The balcony must first be insulated with extruded polystyrene foam.

- I install foil reflective insulation. The material, as you already understood, will be penofol - foamed polyethylene with aluminum foil. It is attached to the penoplex using self-tapping screws, staples or double-sided tape. The joints are sealed with metallized adhesive tape to ensure maximum tightness.

Balcony after installation of penofol.

This is how simple and easy it is to prepare the walls and ceiling of a balcony. However, I will be fixing the drywall to the sheathing, so the next stage is its construction.

Lathing construction

To achieve complete mutual understanding, I want to explain why I install drywall on the sheathing rather than gluing it to the wall:

- in this case, there is no need to make significant efforts to level the walls; all unevenness can be leveled by correctly placing galvanized profiles on the brackets;

- Heat and sound insulation can be easily installed under the lathing layer, which you could verify for yourself if you studied the previous section in detail;

- a false plasterboard wall allows you to hide utility lines that would otherwise have to be laid in pre-made grooves;

- profiles allow you to create walls of any shape (but it’s up to you, here I will describe the simplest technology).

I see only one downside - a slight reduction in the usable area of the room. However, the advantages, in my opinion, outweigh this disadvantage.

I'll tell you how to install the sheathing:

- I install the upper UD profile. To do this, I draw a line on the ceiling in such a way that there is a gap of at least 4-5 cm between the penofol and the drywall, which will help remove moisture from the insulating layer. After this, I secure the profile with plastic dowels and screws, making holes with a puncher directly through the insulating pie.

Installing a UD profile.

- I'm installing the lower UD profile. To do this, using a plumb line, I tap out landmarks on the floor (to create a vertical line), along which I draw a line and secure the galvanized part. In this case, you will be 100% sure that the rack profiles will stand strictly vertically. The parts are secured with screws, the distance between which should be no more than 30 cm.

More detailed profile fastening diagram.

- I install guide profiles at the corners of the balcony. You need to act in the same way. By the way, a laser construction level, which can be rented at a construction supermarket, greatly simplifies the work of installing the frame. Ceiling, floor and wall profiles are connected using a cutter.

- Installing rack CD profiles. They serve to strengthen the plasterboard structure. The distance between adjacent parts is no more than 60 cm. They are screwed to the ceiling and floor guides using small self-tapping screws.

Profile connection diagram.

- I am installing additional brackets for the guides. They are screwed to the wall using screws and dowels, after which the side legs are bent and screwed to the profile. Be careful not to bend the guide piece in one direction or another, tilting it away from the vertical. The pitch between fasteners is from 40 to 50 cm.

Installation of perforated brackets.

- I install the cross members. These are galvanized parts mounted between adjacent guides at a distance of 40 cm from each other. This is done with the help of “crabs” - special fittings for arranging cross joints.

After securing all the parts of the sheathing, you need to take care of the utilities. In the simplest case, we are talking about electrical wiring, which is needed to illuminate the room, as well as connect heating and household appliances.

I prepared a separate article dedicated to balcony lighting, so you can get detailed information from there. Here I would like to remind you of a few important points:

- for a balcony it is necessary to use special equipment (sockets, switches, lamps) that can be used in a room with a high level of humidity;

- All electrical wires should be laid in polymer cable ducts, which prevent fire in the event of a short circuit in the system.

General view of the sheathing with utility lines inside (there is no insulating layer in the photo, as the illustration is from another object).

Instead of galvanized sheathing parts, you can use wooden beams. However, it is susceptible to destruction in humid air, so I still recommend choosing the technology described above.

Well, now you can move on to installing drywall.

Installation of plasterboard sheets

The process of installing gypsum boards on the sheathing is as follows:

- I mark and cut slabs. To cut a sheet of drywall, you can use a regular carpenter's knife. First, a cut is made on one side (more than half of the sheet), after which the product is broken and cut on the reverse side.

Cutting drywall using a utility knife.

- I cut holes for installing electrical appliances. To do this carefully, you can use a drill, into which a special skirt is inserted instead of a drill.

Making a hole for the socket.

- Installing sheets of drywall. There is nothing complicated here, you just need to follow a few important nuances:

- The wall panel should be raised above the floor level by a distance of 1 cm to avoid moisture getting into the cladding.

- The drywall is secured using self-tapping screws, which are screwed into the galvanized profile at a distance of 20 cm from each other. The caps need to be recessed into the material so that they do not protrude later and interfere with the puttying.

- The truncated (cut) edges of the drywall must be installed against the walls and close to each other. If for some reason a gap more than 4 mm thick has formed between them, it should be sealed with cement adhesive for gypsum boards.

- The rounded edges of the drywall should be spaced about 5 mm apart from each other.

Installation diagram of plasterboard sheets.

- I am processing the seams between sheets of drywall. To do this, you will need putty and serpyanka - fiberglass tape, which is used to reinforce the seams. The sequence of actions is as follows:

- I'm preparing putty. To do this, I rush the dry construction mixture with water and mix the solution with a mixer until smooth. The finished composition must stand for several minutes so that the additives and plasticizers included in it are activated.

- I fill the seam with putty, then glue the serpyanka onto it, and then apply a new layer of putty on top. Then all this needs to be leveled, and then left until completely dry (the exact time is indicated on the package with the putty).

You need to additionally apply sickle tape to the seams.

- I putty the recesses formed by the heads of the screws. This is done using the same putty composition and a small spatula. Do not apply too much solution so that bumps do not form on the surface of the gypsum board.

- I putty the balcony surfaces with finishing putty. This way I prepare the room for final painting or wallpapering. After the putty has dried, the surface is sanded with floats until it is perfectly smooth.

Finishing

Painted drywall.

I won’t talk long about the finishing touches. If only because I don’t know what decorative material you will use.

If we are talking about paint and wallpaper, then the scheme is as follows:

- puttyed drywall is coated with a primer, which improves the adhesion of the surface, removes dust and reduces the consumption of glue or paint;

- the surface is painted in several layers with water-based emulsion or covered with wallpaper.

Finishing balconies and loggias with plasterboard

Covering a balcony with plasterboard is mainly used in cases where the surface is subsequently painted - the paints have very good adhesion to the paper gypsum board coating and provide additional protection against moisture penetration and mechanical stress. Drywall is not designed for other types of finishing: tiles, natural and artificial stone are cheaper and easier to lay directly on the walls, just like applying decorative plaster.

Installation of plasterboard sheets on any surface can be done in two ways: by gluing the sheet or screwing it to a special profile.

An ordinary balcony or loggia has small overall dimensions, so in cases where insulation is not required, it is better to glue gypsum boards to the walls. In addition to saving usable space, this will reduce costs (you won’t have to buy an installation profile and fastening fittings), and will significantly reduce the time it takes to complete the work.

Gluing drywall to walls or ceilings

If you need to level a balcony wall with plasterboard yourself, you can use several types of adhesives. Quite well-known are Knauf Perlfix, polyurethane glue Polymin, and Fugenfüller putty. If the walls are uneven less than 10 mm. To apply the glue, you can use a notched trowel; if you come across deep holes, they can be covered with an adhesive solution, and the protruding bumps can be knocked down or cut off.

Rice. 5 Finishing balconies with plasterboard by gluing

The procedure for gluing sheets to the wall is as follows:

- Preparing the surface. We clean the wall from sagging and then prime it with Ceresit ST17 using a roller.

- We dilute the glue in a container with water according to the instructions and spread it over the surface of the sheet with a toothed comb.

- We fasten the sheet, leaning it against the wall vertically (the length of 2500 mm should be enough for the entire height of the ceiling) and press it with an even beam or rule.

Rice. 6 Insulation of the loggia with Penolplex

Insulation and covering of the balcony parapet with plasterboard

If we use rigid Penoplex or foam plastic as insulation for parapet walls, then the easiest way to attach a plasterboard sheet to the insulation is by gluing it using the above technology.

When deciding whether it is possible to insulate a loggia with safer materials, many choose environmentally friendly basalt wool as a heat insulator. In this case, plasterboard cladding is carried out as follows:

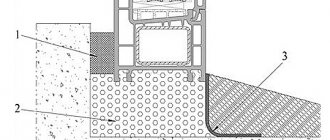

- We attach self-adhesive Penofol to the wall for vapor barrier with the foil facing out. We screw the PU guides to the floor and under the window sill using dowels with self-tapping screws.

- We cut out vertical posts from PS with dimensions of 5 – 10 mm. less than the height, we install them vertically according to the level in increments of up to 60 cm. Without fastening them to horizontal guides, we mark the location of the profiles on the floor and window sill.

- We insert insulation between the profiles and screw the cut-to-size sheets with self-tapping screws along the vertical marks.

Rice. 7 Balcony insulation with mineral wool under gypsum plasterboard

Finishing a loggia with plasterboard is overwhelmingly used in cases where the further decorative coating is painting. On balcony walls, it is more rational to install a plasterboard sheet with glue; to insulate the parapet, you can use mineral wool and frame installation of gypsum boards on a fixed profile. A more economical option for covering a loggia with plasterboard with insulation is to fasten polystyrene foam or Penoplex with dowels or glue, followed by covering its surface with glued plasterboard sheets.

Surface preparation and marking

Everything that disappears must be removed.

This work can be done quickly or efficiently. In the first case, nothing is cleaned, and the installation of profiles is carried out according to the previous coating. The surface is not prepared at all, because it will be hidden by drywall, so who cares if there is old wallpaper or peeling paint.

Obviously, before starting work, you need to remove all objects from the balcony. Skirting boards and baguettes, if any, are also torn off.

By removing the old finish, you can make sure there are no defects on the wall. We are talking about a balcony, where there may well be cracks through which air blows in from the street. Therefore, it is recommended to clean the wall to the base. If there are cracks, they need to be filled with foam. Small cracks are sealed with sealant.

If you do not get rid of all wall defects, then finishing the balcony with plasterboard will not be of high quality. It is on the balcony that defects such as cracks and crevices occur most often. Before correcting the builders' mistake, you need to clean the base from grease and dust particles.

The prepared base must be marked for attaching the frame. You need to draw lines on the floor along which the guides will be attached. These lines can be made either with a pencil or with a paint cord. In most cases, a rectangle will be drawn on the floor of the balcony along its walls. Similar lines are made on the ceiling, where guides will also be installed. Markings are also made on the bottom of the window sill in those places where the drywall will be attached under the window.

There is no need to make any markings on the walls themselves to attach the hangers.

Material calculation

For a balcony, it is better to choose moisture-resistant plasterboard. Usually it is marked GKLV, and its back part is green

Correct calculation of materials will help to sheathe the walls with plaster and save money. The drywall itself is calculated based on the total area of the walls; it is not customary to subtract windows and doors from here. Thus, the necessary supply of material is formed. In the case of a balcony, it is worth subtracting the area above the railing, but not subtracting the door and window of the room.

Insulation is calculated minus all windows and doors.

Fasteners are calculated depending on the fastening pitch. Typically, a sheet of drywall takes 60-70 screws with a lathing pitch of 40 cm.

Dowel-nails are purchased at the rate of 10 pieces per profile or 5 per bar.

Metal self-tapping screws with a press washer require 10 pieces per profile.

The calculation is quite simple, but you need to pay attention to it

Installation of metal sheathing

First, a steel frame is installed on the ceiling, but first you need to determine the parallels on the vertical bases around the perimeter:

- Lines for the location of metal profiles are outlined;

- The lowest point is located and recedes 4 cm;

- A horizontal line is drawn according to the readings of the laser level;

- The line is transferred to other walls.

Now you should mark the installation of ceiling hardware:

- Retreat from the corner 10-25 cm;

- Mark points with a distance of 60 cm on opposite walls and connect with construction cord;

- Using the stretched markings, outline the location of the longitudinal and transverse profiles in 60 cm increments for the installation of “crabs”;

- Suspensions will be installed in the resulting gaps.

After measurements and preparation of steel structures, PN 28/27 guides are attached to the walls, and suspensions are attached to the ceiling. PP 60/27 is inserted into the guide strips and fixed to the hangers. The jumpers are connected to the “crabs”, with longitudinal products.