The high demand for PVC windows makes their production highly profitable.

This is caused not only by large volumes of construction in the regions of the country, but also by the need to reconstruct outdated and deteriorating wooden windows located in the old housing stock.

It is not surprising that many novice entrepreneurs are interested in such a business, for whom it is important to understand the complexity of the process of legalizing production, to know the size of the initial investment in business development and to calculate the profitability indicators of a small enterprise producing PVC windows.

Is it possible to organize a successful business?

Although such a production process is quite complex and requires the manager to go through many preparatory stages, it is quite feasible even for novice entrepreneurs. In order to make the right decision on organizing such a business, it is necessary to take into account a number of factors:

The competition is quite fierce; today there are quite a few window companies represented in regional markets.

The struggle for customers is serious; it will be difficult for start-up companies to compete with large companies; they will need to produce not only high-quality products, but also seriously engage in product promotion.- Seasonality of business : in the autumn-winter period there is a decline in production, which can be explained by a drop in construction volumes during this period of the year. In order to reduce costs during downtime, it will be necessary to organize additional production, for example, repair or establish the production of all-season types of products, for example, the production of internal doors.

Which plastic windows are still better to install?

And in the end, the main thing is that a careless window manufacturer or a handsless installer can turn the best profile into disgusting trash. Therefore, before ordering windows, consult with neighbors, friends or just acquaintances who have already contacted the company you have chosen. Remember that a profile is just a piece of plastic, which, although it is an important component of a window unit, its choice must still be justified in combination with such factors as reliable fittings, a good double-glazed window and the conscientiousness of the craftsmen.

Manufacturing Process Requirements

Before you open your own production of PVC windows, you need to choose the organizational and legal form of the enterprise, for example, LLC with 2 founders, with taxation according to the simplified tax system - 15% of profits. To legalize an enterprise, you need to obtain permits from the municipal authorities where the enterprise will operate in order to officially employ employees.

In addition, an application is submitted to the Unified State Register of Individual Entrepreneurs indicating the OKVED codes. Most often, for such an enterprise, codes for work in construction are chosen: 25.23 45.44.1 and 45.42, production of plastic products, glass and carpentry. After this, an application for registration of a UTII payer is submitted to the tax office at the place of production.

Important! For enterprises that will independently engage in wholesale sales of products, the application will additionally indicate the types of activities according to OKVED code 51.53.24.

In order for products to be used for the construction of residential, public or industrial buildings, they must pass certified tests according to the declaration procedure.

To sell PVC windows in Russia, they must meet the requirements of Russian government regulations, and if the products are planned to be exported, then comply with the regulatory requirements of the relevant country , for example, for EU countries according to DIN standards and RAL colors.

Also, for the production of PVC windows, the manager must have a license from the State Construction Committee, permission from the fire department and labor protection, as well as the sanitary-epidemiological department and municipal departments in the field of employment of employees.

What should the workshop be like?

The basic requirements for the premises are sufficient space, the presence of storage facilities and cabins for staff, equipped with electricity, water supply, drainage, ventilation, heating and hot water.

The general power supply of the workshop must be three-phase 380V in order for the machines to operate, the wiring must provide the declared power of the machine equipment.

The premises must be equipped with an entrance for loading and unloading consumables.

The workshop area is selected according to the volume of production, for example, to produce 20 standard double-hung windows 1400x1200 mm per shift, 200 m2 of free space with a height of at least 3 m will be required.

Advice. The easiest way to find such premises is in an industrial zone, on the outskirts of cities and regions; usually the rent for such premises is not very high, approximately 15,000-30,000 rubles. per month.

Advantages

Our production gives us the opportunity to control the quality of manufactured products at each site. Our customers can be confident in the reliability of their windows and doors. We exclude deformation, breakage, and defects. We provide a guarantee of up to 15 years depending on the type of product or service.

The advantages of our doors and windows include:

- Diversity. Wide selection of configurations, dimensions and profile shades. Our specialists develop and produce non-standard systems - in the shape of a circle, trapezoid, triangle, arch. We cover plastic with decorative protective film in shades of the RAL palette. We paint.

- Comprehensive service from one contractor. We carry out all types of glazing and insulation work. Our craftsmen glaze houses, apartments, offices, shopping centers, institutions, turnkey enterprises, and finish balconies.

- Affordable price for glazing. We often offer discounts and regularly organize promotions. We always take free measurements of openings before completing an order.

To consult with our manager and make an accurate order calculation, call us or leave a request on the website. You can call a surveyor right now.

What is needed for production?

In order to produce windows in accordance with current standards, special equipment, qualified personnel and high-quality consumables will be required.

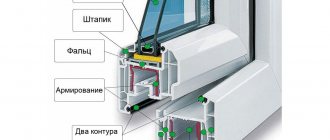

Composition of PVC structures: what plastic?

The main materials for windows are polyvinyl chloride (PVC) and reinforcing steel profile. PVC in powder form is produced from a mixture of ethylene and chlorine, from ordinary table salt. For the manufacture of window profiles, the following are added to the starting material: stabilizers, pigment materials and modifiers in order to give additional characteristics to the products:

- protection from fire and atmospheric influences;

- light resistance;

- fast welding process.

The resulting PVC profile is sent to the assembly line, where a steel frame is integrated into it using special equipment. This process is fully automated on modern CNC machines.

Basic materials and components:

Polyvinyl chloride (PVC) - 84,500 rub. per ton.- U-shaped profile 6 m reinforced, RUB 15.93/l.m.

- Glazing beads 44.1 rub./l.m.

- Rebated insert for KBE 58 mm, 1.94 rub./l.m.

- Window opening limiters, comb, RUB 23.57/piece.

- Profile for slopes 12.87 rub. /m.p.

- U-shaped reinforcing profile, 110.97 RUR/m.p.

- Closed reinforcing profile, RUB 159. /m.p.

- Regular double-glazed windows, 905 rub./m2.

- Multifunctional double glazed window, 1810 RUR/m2.

- Self-cleaning glass unit, 1950 RUR/m2.

- Soundproof double glazed window, 2250 RUR/m2.

- Children's castle from RUB 1,820.

- Combs for windows from 260 rub.

- Drainage, galvanized, 650 RUR/m2.

- Drainage, aluminum, 1690 RUR/m2.

- Window sill wood, 1820 rub./m2.

- PVC window sill, 970 RUR/m2.

Equipment

In order to select the right equipment, it is advisable to use the production line of one company. The most popular are machines from Turkish manufacturers: Yilmaz, Kaban and Nikmak.

List of equipment for setting up a workshop for the production of PVC structures:

saws for cutting PVC profiles and reinforcement elements: single- and double-head;- welding machines for PVC frames;

- roller conveyors;

- angle-cleaning machines and for milling the ends of imposts;

- copy-milling machines;

- saws for cutting: glazing beads and reinforced profiles, as well as punching and bending machines;

- stand for glazing and assembly;

- exhaust ventilation;

- washing, demineralizers and extruders;

- lifts.

Criteria for choosing a profile

Country of origin of the profile

Any company that recycles a window profile indicates its origin. At the same time, you can very often find the word “German” in the descriptive part. We recommend that you clarify what is meant by this word, because... Sellers like to use it to justify the high price of a finished window. The lion's share of this profile is produced in Russia using German technology. In this case, relatively cheap energy resources and labor are used, therefore, the cost of the product should differ from the profile produced in Germany.

Number of thermal insulation chambers

Of course, the most important criterion. It is believed that the more chambers, the better the thermal insulation. However, do not forget that an excessively large number of chambers can lead to the fact that the thermal conductivity coefficient can, on the contrary, increase due to the plastic partitions, which will act as a cooling radiator. Therefore, we definitely pay attention to the following criterion.

Profile width

When choosing a profile for a living room, it is better not to skimp on this parameter. Everything is simple here, the wider, the warmer. It is only worth noting that small-chamber wide profiles can be easily deformed, because have few stiffeners.

Number of double-glazed window chambers

We advise you to choose only two-chamber ones, even for glazing loggias - do not forget, the miser pays twice. However, choosing a double-glazed window is a topic for a separate article.

Reinforcing steel insert

It comes with an open or solid contour. If there are no restrictions on strength, then we advise you to choose an open one, it is warmer.

ISO 9001 Certificate

Provides a guarantee of control over the production of window profiles according to the quality management system.

Approximate costs and prices

The costs of organizing the production of PVC windows depend on the volume of production, which is calculated by the number of products per 8-hour shift, the cost of equipment and its delivery, the cost of materials, wages to workers, costs of water, electricity, fuel and lubricants and rental of premises

Equipment

This is the most expensive part of the project. In order to reduce the amount of initial investment in the project, they start by equipping a semi-automatic line or purchase working machines, but used ones.

Costs for installing a new semi-automatic line for the production of PVC structures, 20 products per shift:

double-head front saw - RUB 382,000;- Yilmaz automatic angle cleaning machine - RUB 235,000;

- Yilmaz end milling machine - 35,000 rubles;

- double-head welding machine - 421,000 rubles;

- device for cutting reinforcement - 9000 rubles;

- Yilmaz copy-milling machine - 108,000 rubles;

- compressor unit - 28,000 rubles;

- mechanism for forming drainage technological holes - 88,000 rubles;

- saw for making PVC glazing beads, automatic - 109,000 rubles;

- total cost of equipment -

- costs for transportation and installation of equipment - 60,000 rubles;

- other organizational expenses and obtaining permits to begin work - 80,000 rubles;

- total capital costs: RUB 1,555,000.

Materials

In order to determine the actual cost of materials for the production of PVC glass, they are calculated for 1 m2 of the finished product:

- glass, 2 sides per 2m2 - 620 rubles;

- shell, 4 m - 440 rub.;

- butyl for 0.1 kg/m2 - 4 rubles;

- other consumables - 210 rubles;

- PVC profile 0.5 m/m2 - 520 rub.;

- rolled metal - 592 rubles;

- components - 2100 rub.

- total 4486 rub./m2.

Total costs

Next, you can calculate all the costs for a month with 22 shifts for a standard window of 1.68 m2:

materials costs: 22x20x1.68x4486 rubles = 3316051.2 rubles;- monthly income at a window cost of 10,250 rubles: 22 x20 x10,250 = 4,510,000 rubles;

- rent - 35,000 rubles;

- housing and communal services payments - 29,000 rubles;

- salary of 10 specialists - 10 x 35,000 = 350,000 rubles;

- total monthly expenses: RUB 3,730,051;

- income tax (20%) - 155,980 rubles;

- net profit: 4510000 - 3730051 - 155980 = 623969 rubles;

- payback period with a profitability of 20%, 1555000:155000 = 10 months.

Double-glazed windows with "Spy" type glass

Such double-glazed windows are made using “mirror” glass “Spy”, the use of which allows you to limit visibility from the street during daylight hours, as well as to observe a more illuminated room from a less illuminated room, while remaining invisible through the glass. In the case of external glazing, such glass is tempered.

In addition, special glass of other types can be used in the production of double-glazed windows, including painted and reflective glass for glazing facades from such manufacturers as San Gobain, Pilkington, Guardian, Glaverbel, Euroglass, Saratov Institute of Glass.

is one of the few companies producing double-glazed windows with such glass. Their maximum dimensions are 2400 x 1500 mm.

| Name | Price, rub./m2 | Notes |

| Vacuum spraying | Product prices | 1-room / 2-room max 2 500x1 600 arr. No. M 2-5; “Shp” + 50 rubles to the price |

| Bronze | 1-room / 2-room max 2500x1600 mm, Russia | |

| Sputtered bronze | 1-room / 2-room max 2 500x1 600 arr. TM Br No. M 2-5 | |

| Tinting film | 1-room / 2-room Film made in USA |