The reinforcing profile for plastic windows is an important element, thanks to which the window acquires the necessary rigidity, can withstand various mechanical loads, and withstand the weight of its own sashes. The profile extends the service life of the structure, allows you to create it of the required size, and not be limited to a small one that does not sag without reinforcement.

Why do you need PVC window reinforcement?

As you know, plastic has a low elasticity index, so a reinforcing profile is used to give it additional rigidity. Consequently, this design allows plastic windows to be more stable and, accordingly, resist wind loads. During strong winds, the windows must stop the strong flow of air, and this will be difficult to do without a reinforcing liner. The second and no less important purpose of reinforcement is the ability to avoid various deformations that can occur due to temperature expansion. This is especially true for those regions where there are very sharp and significant temperature changes throughout the year. This effect is possible due to the fact that plastic and steel react completely differently to temperature changes. If reinforcement is not used, then the plastic structure, consisting of a large number of components, will change its shape. For example, in the summer, windows will expand, which will lead to poor closing and opening of the sashes. In winter, on the contrary, they will narrow and, therefore, the formation of large cracks cannot be avoided.

Rice. 2. Features of the reinforcing profile.

What options are there?

The technology for reinforcing a window structure must not only meet general requirements, but also be in full compliance with the individual characteristics of the window opening for which the profile will be made. One of the basic parameters when choosing a profile is its thickness, which is determined by the following factors:

- Floor. The higher the floor, the more strength is required in the structure for reinforcement, because as the height increases, the wind load also increases significantly.

- Window size. If the width and height of the sashes exceed the standard, then such a window is subject to compaction of the reinforcement walls.

- Color. Oddly enough, but this indicator also plays a big role. The profile thickness for colored structures should exceed 2 mm, and for white ones 1.3 mm. A thickness of 2 mm is also relevant for those window options that are large. For them, the thickness can be further increased so that they can withstand higher wind loads and operation in difficult conditions.

Requirements for amplifier inserts

The basic requirements for reinforcing inserts are provided for by GOST, so compliance with them is mandatory for everyone without exception. These include the following:

- steel liners must be coated with anti-corrosion coating;

- they must fit tightly into the internal chambers of PVC profiles and only by hand, since the use of special devices in this case is prohibited;

- they do not need to be installed in product parts if their length is at least 700 mm, provided that a white profile is used;

- when using colored profiles, their installation in all parts of the product is mandatory; the same requirement also applies to parts of frost-resistant window blocks;

- from the liner to the reinforced part of the profiles, the distance should be from 10-30 mm;

- if the weight of the double-glazed windows is more than 60 kg, then it is worth using liners that will be trimmed at an angle of 450.

Please note that all characteristics of reinforcing inserts must be established in the technical documentation for the manufacture of parts. Such characteristics include thickness indicators, the provided shape and size of the valves.

Rice. 3. Possible forms of reinforcing profile.

Alternative PVC window reinforcement systems

Despite the fact that the metal profile is perhaps the most popular in use, it is increasingly subject to criticism. And it cannot be said that it is not justified, because the main disadvantage of such profiles is the low thermal performance indicator. This can be explained quite simply - metal conducts heat well. So profiles made from it greatly reduce such properties of windows as thermal insulation. Therefore, active work is underway to search for various kinds of alternatives.

Amplifiers made of glass composite materials are now being introduced into production. They have already been successfully tested in laboratory conditions and are beginning to win more and more customers.

An alternative system from the REHAU concern is aimed at completely eliminating metal liners. It offers an amplifier based on the innovative RAU-FIPRO fiber material. So far, the manufacturer is limiting itself to producing only an experimental series.

Now you can see a general trend of gradually abandoning metal amplifiers and replacing them with thermal inserts made of durable materials. So we can expect that in the near future, reinforcement will still give way to other types.

Rice. 4. Repair GENEO.

Manufacturing of reinforcing profiles for PVC windows

Making a high-quality profile is not so easy. Firstly, it is complicated by the need to use special equipment, including a rolling mill, a receiving device and electromechanical shears.

Rice. 5. Ready-made reinforcing profile.

To ensure a high-quality profile, rolled steel is taken with a thickness specified by GOST (1.2 mm). It also must be galvanized, and the galvanizing layer must be at least 8 microns. As for the grade of stainless steel that is used for such cases, most often it is ST 2 or ST 3.

Another feature is the calculation of the size, since it must correspond to the parameters of the central chamber of the PVC profile. Any inaccuracy in the figures may render the metal profiles unusable. Universal reinforcement is often used. Although there may be cases when it may only be suitable for certain brands of plastic profiles.

As for the shape, it is created using the cold bending method on roll forming equipment.

Closed reinforcement: stability and burglary resistance

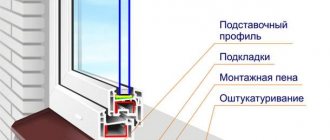

For long-term operation of a window, it is very important that its structure is stable, and that the window itself is firmly fixed in the wall opening.

It is the closed steel core located inside the window frame (it is called reinforcement) that allows you to firmly fix the window in the opening and transfer all the loads acting on the window during operation to the load-bearing frame of the building.

In addition, only a closed section of the frame and impost, i.e. those window elements into which the counterparts of the locking mechanisms are attached, allows the production of anti-burglary windows.

Thus, a closed reinforcement section, which is installed by default in all frames and mullions of the VEKA and WHS by VEKA profile systems, is the key to the stability and safety of window structures for your home!

Closed reinforcement provides more stable fastening of the window structure in the wall opening

The window can be fastened through anchor plates or through. But, regardless of the type of fastener, when using closed reinforcement in the frame, the fastening will be simpler, more stable and reliable.

Pay attention to the illustration: if the dowel goes through only one wall, the frame may play, but if the dowel goes through two walls, the frame is stable. The same applies to an anchor plate fixed to a U-shaped metal - one dangling metal wall and a closed one. As they say, feel the difference.

The second aspect is anti-burglary

Closed metal is a mandatory condition, without which the window will not be burglar-resistant.

The counter strips must be fixed into the metal, but in the case of U-shaped reinforcement this is impossible.

When attaching a striker plate to a frame with closed reinforcement, the screw passes through two walls, including the metal wall of the reinforcing liner. Do I need to clarify which option is more reliable?

Types of reinforcing profiles for PVC windows

Today there are no clear requirements for what type of reinforcement should be used. Each brand that produces plastic profiles independently sets the shape, and therefore the appearance. In general, the following types can be distinguished:

- closed loop – O-shaped reinforcement;

- open contour – U-shaped reinforcement.

Their difference is as follows. The metal cools faster, so in a closed structure, where there is more of it, more cooling will occur. Accordingly, if it is not closed, the cooling level will be lower.

Since window systems are different, for example Proplex, Rehau, VEKA, it is worth considering their features regarding reinforcement.

Rice. 6. Types of reinforcing profiles.

KBE

This is a German brand that began its development in the 80s of the last century. It offers its consumers 4 types of window systems:

- 58 mm;

- 70 mm;

- 76 mm;

- 88 mm.

Moreover, each of the systems has several varieties. Their main feature is that the thickness of the walls of the reinforcing profile is not always the same. It all depends on the types offered.

Rice. 7. KBE window profiles.

Schuco

Using the products of this company, you can not only replace all the windows in your home, but also install a high-quality door. A distinctive feature is the use of an original metal amplifier of standard sizes. This means that the wall thickness corresponds to all technological indicators, namely 1.5 mm.

Rice. 8. Schuco profile.

VEKA

This company, with more than forty years of experience, offers its customers A class products. It produces seven lines of windows, which differ in the number of cameras, design and installation width. As for the metal amplifier, it has the shape of a closed circuit. Note that Veka also specializes in the production of high-quality door systems.

Rice. 9. Features of the VEKA PROLINE 70mm profile.

Rehau

Its distinctive feature is the use of a steel profile with wall thicknesses of 1.2, 1.5, 2 mm. She is also the active inventor of an alternative reinforcement system. Let us remind you that for the Rehau GENEO window system, RAU-FIPRO fiber material is used. Its main advantage can be considered the ability to save energy up to 76%.

Rice. 10. Rehau profile.

Wintech

This company uses an innovative method of reinforcement. Its main advantages are that it does not corrode, enhances heat and sound insulation, is made from composite materials and is much lighter than the metal version. Moreover, its thickness is almost twice that of conventional profiles, which makes the structure stronger.

Rice. 11. Wintech profile.

Montblanc

The window system from this manufacturer is characterized by the use of a unified reinforcing liner. Its size is 35-28 cm, which makes it possible to avoid any errors during assembly. The wall thickness is slightly greater than required by the standards, namely 2 mm. These characteristics, together with others, make it possible for such windows to serve for more than 60 years.

Rice. 12. Montblanc profiles.

LG

This design is characterized by open reinforcement, which increases the thermal insulation rate. At the same time, different models provide wall thicknesses from 1 to 1.5 mm. This is somewhat substandard, but makes it possible to make such windows somewhat cheaper. The dimensions of the walls can also be different, for example, for LG-1 systems this is provided - 31x26 mm.

Rice. 13. LG profile.

Plafen

The company has been operating since the early 90s and has already managed to develop 5 unique window systems, each of which has its own characteristics. The reinforcement liner comes in different sizes, such as 32x25mm, 25x32mm, 35x25mm, 25x35mm. As for the wall thickness, regardless of the size, they are standard and meet the requirements of the State Standard - 1.5 mm.

Rice. 14. Plafen profiles.

Weltplast

This brand is characterized by the use of only a closed circuit, which allows for increased heat and sound insulation. By size, you can select a 20×30 profile. In this case, different thicknesses are provided - 1.2 mm, 1.5 mm, 2 mm. In any case, these indicators comply with the established standards, so the strength of the window systems is guaranteed.

Rice. 15. Weltplast profile.

Thussen

A profile with both closed and open contour is used. The thickness of its walls is standard 1.5 mm, but there are options with a larger value, namely 2 mm. There is also a good choice in terms of sizes, ranging from small 15x30mm, 20x30mm and up to things like 35x50mm. So you can choose the right option without any problems.

Rice. 16. Thussen profile.

Salamander

A distinctive feature of this brand is quality. This is achieved through the use of a U-shaped contour. There are several options available in terms of size and wall thickness. The latter can be either 1.5 mm or 2 mm. Such indicators can significantly increase the stability of the window structure.

Rice. 17. Salamander profile.

Deceuninck

Metal-plastic windows from Deceuninck are not much different in their characteristics from the previous ones. They are characterized by the use of both U-shaped and O-shaped. But regardless of this, the wall thickness is -1.5 mm. Distinctive aspects are only in size, for example, models with the following parameters are presented - 31 × 28.5 mm, 25.5 × 33 mm, 25 × 31 × 28 mm.

Rice. 18. Deceuninck profile.

Artec

The reinforcing profile from this manufacturer is also presented in closed and open form. There are no comments on the thickness parameters, since they are within the normal range - 1.5 - 2 mm. As for the mass, it depends on the size indicators and can be from 0.89 kg/m to 1.97 kg/m. This element of the window system provides good wind resistance, and therefore reliability.

Rice. 19. Artec profile.

Aluplast

The company is rightfully recognized as an expert in the production of PVC window systems. Their main feature is their high energy-saving property, which ultimately allows you to save on air conditioning and heating. This effect is achieved through the use of a reinforcing liner with a wall thickness of 1.5 to 2 mm. In this case, U-shaped and O-shaped shapes are possible.

Rice. 20. Aluplast profile.

Brugmann

He has extensive experience in this field, since he has been dealing with PVC profiles for windows and doors since the middle of the last century. Window systems from Brugmann are characterized by the same reinforcement for both frame and sash. A distinctive feature is the comparatively small weight of the profiles - 0.99 kg/m. The standard wall thickness is from 1.5 mm to 2 mm.

Rice. 21. Brugmann profile.

Gealan

This manufacturer is a German leader in the field of glazing. And this is not surprising, since its products meet all recognized standards. So, the wall thickness is only from 1.5 to 2 mm, so the buyer, of course, will pay a little more, but will be confident in the quality. The use of different profile shapes can also be considered a positive point.

Rice. 22. Gealan profile.

Plustec

Such a window element as a reinforcing profile from this company is characterized by a U-shape. Manufactured traditionally from galvanized steel, and thanks to good parameters, the weight indicator in certain models can be minimal 0.88-1 kg/m. At the same time, the wall thickness is standard – 1.5 mm.

Rice. 23. Galvanized steel profile.

Truba

The reinforcement liner from the Truba brand, like many others, performs the function of ensuring strength. This is possible thanks to its parameters, namely thickness and shape. In the first case, the indicator is 1.5 mm; as for the shape, it can be either U-shaped or O-shaped. Moreover, the mass of such a product is relatively small, and in some cases it can reach 0.89 sq. m.

Rice. 24. Use of profiles of different shapes.

Dimex

Steel reinforcing profiles from Dimex always comply with all GOST requirements. Firstly, the wall thickness is 1.5 mm. Secondly, models of different shapes have been developed, which allows buyers to choose the one that will satisfy all requirements. The weight of the product is no less important for the final result. In this case, several options are also presented, ranging from the minimum 0.95 kg/m to the large ones - 2.30 kg/m.

Rice. 25. Windows from Dimex.

How to choose the best option for such reinforcement?

To choose the optimal solution, you should definitely choose one of several high-quality options, including:

- Window design. Of great importance is the preliminary consideration of the number of sashes in the window, the shape, as well as the functionality. The denser the profile, the more load it can withstand, so you should definitely take care of this.

- Thermal characteristics. Harsh climatic conditions necessarily require energy-saving profile systems that are reinforced. They also help keep out excess noise. To ensure a sufficient level of tightness and the ability to hold double-glazed windows, additional reinforcement is used.

In general, when choosing this type of profile, you should definitely use all the initial data: from the size of a particular window to its desired appearance and parameters for thermal insulation and sound insulation. With the right choice of a high-quality solution, it will be possible to achieve a positive result and obtain a structure that will serve for many years without the need for replacement or repair.