Icer

24709 1 0

Icer September 28, 2016Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

Many people, when it comes to attaching cornices to plasterboard ceilings or walls, for some reason think that it is impossible to do this and that they must reach a solid base to ensure reliability.

In fact, this is not so, you can perfectly fix the structure on the gypsum board itself, and it is this option of work that we will examine in today’s review. I'll tell you about three proven mounting methods, and you need to choose the one that suits your situation best.

In the photo: even massive cornices can be fixed to plasterboard without any problems

How to hang a curtain rod

Almost every owner of his own home strives to make it as cozy and comfortable as possible.

Using curtains on the windows helps solve this problem. In order for them to serve for a long time and reliably, it is necessary to correctly select and secure the cornice on which they are hung. Despite the apparent simplicity of the question of how to hang a cornice, there are quite a lot of pitfalls. Before starting work, you should decide on three questions:

- choose the type of curtain rod taking into account the size and weight of the curtains;

- determine the type of base on which it will be attached;

- choose the optimal mounting option.

We take into account the length of the pipe and the number of brackets

Sagging cornice

- this is a consequence of an imbalance in the thickness and length of the curtain rod with the weight of the curtains. A curtain rod that is too thin or a curtain rod that is too long, weighted down with curtains, and even with a large distance between the brackets, will cause sagging, regardless of the quality of the curtain rods (see picture below).

By taking measurements and assuming the dimensions of your cornice, you can easily calculate the optimal number of brackets for it.

The presented diagrams clearly show the required number of brackets for a wrought iron cornice of a certain length (see pictures below).

Here it is worth paying attention to the fact that if your cornice consists of two pipes, then an additional bracket must be installed at the junction. It will serve as an additional support point and increase the strength of the entire cornice.

Possible options for cornices

The market offers a significant selection of the mentioned products, differing in material of manufacture, mounting location (wall or ceiling ) and design features.

All realized models, according to the type of material used, can be divided into three main groups:

- wooden ones are the most popular for decorating residential interiors.

This is explained by a wide range, excellent compatibility with almost any interior and furniture, and the ability to form a complete and visually attractive ensemble.

Such models focus attention on the window opening and create a feeling of home comfort.

- metal – made of alloys based on aluminum or stainless steel.

Look great in Empire or Rococo style interiors. They add laconicism and rigor to the design. They are an excellent solution for decorating a study or office space.

Such models of cornices are often equipped with figured tips, forged elements, and other design solutions. Therefore, their installation will make your window opening visually attractive, memorable and unique.

- plastic ones are the most practical and budget-friendly versions of window design.

The multi-variant color palette allows them to organically fit into the range of any interior, including rooms decorated “under wood”. Easily and simply fixed on plasterboard walls.

According to their design, the following types are distinguished:

- single row;

- double row;

- three-row.

According to the configuration, manufactured cornices are divided into:

- telescopic;

- round;

- profile flexible

- strings (tension)

- tire (skid)

- baguette

- electronic

- integrated into the suspended ceiling (PK5 profile)

Material selection

The most expensive are cornices made of different types of wood and metal; such products not only perform their main function well, but are also decorative elements that add zest to the interior of the room.

Plastic and aluminum products are cheaper and simpler, most often hidden behind beautiful and expensive curtains, and used only for their main purpose.

In general, the choice of product depends on the style and design of the room, the type and number of curtains, and personal preferences.

Base type

Cornices can be installed on the ceiling, window opening or wall. The base for installation can be hard and durable (stone or wood materials) or fragile. For example, it is impossible to give the correct answer to the question of how to attach a cornice to drywall on a ceiling without special knowledge. The same can be said in cases where the final alignment of the walls is carried out with gypsum plasterboard sheets.

It is very difficult to attach a curtain or cornice to it. Such work requires the presence of a certain tool, special fasteners, knowledge of the intricacies and sequence of work.

Typical options for attaching a cornice to the ceiling or walls, in such cases, may not be suitable due to their insufficient functionality. But, if the above conditions are met, attaching the cornice to drywall becomes an operation that can be easily performed independently by persons without special training.

Preparatory stage

For those deciding how to attach cornice to drywall, the work must begin with preparation.

Having chosen the cornice and decided on the type of supporting surface, you should purchase all the necessary consumables, including fasteners for mounting your purchase on a plasterboard wall, and prepare the necessary tools.

To work you will need:

- ladder;

- perforator (drill) with auger (drill) of the required diameter;

You can use a universal solution, an impact drill.

- Goggles to protect your eyes from possible ingress of dust and crumbs;

- a hacksaw for wood or metal (depending on the material of the cornice and the chosen mounting option);

- hammer, Phillips screwdriver (screwdriver with bits), pliers;

- measuring and control tools (tape measure, square, building level);

- pencil or felt-tip pen for marking.

It is mandatory to purchase fasteners of the selected type, or materials for arranging the lining: wooden beams, ceiling profiles, hangers.

The procedure, in this case, takes a minimum of time. The sequence of operations is initially clear:

- marking;

- drilling holes (in a stone wall), followed by installation of plastic dowels of the required length and diameter (determined taking into account the weight of the curtains with curtains);

- installation at the location of the product being fixed;

- its fixation with self-tapping screws.

If the walls (ceilings) are wooden, then drilling and installation of dowels may not be carried out. After marking, the product is fixed in place with self-tapping screws.

Correct installation of structures

Before installing the curtain rod, you need to determine its weight. In order to secure heavy products, it is necessary to strengthen the structure. It is recommended to use additional elements and parts in this case. The design must be safe. After all, in addition to its own weight, it must also support curtains. The surface on which installation occurs must be reliable.

Layout of curtain rods.

For strong fastening you will need the following tools:

- screwdriver;

- perforator;

- building level;

- roulette;

- pencil;

- ladder;

- dowels, screws.

Before installation, you need to check the dimensions of the product. The cornice should not interfere with the opening of the window. And the curtain should fall freely. The window sill and other elements should not interfere. Therefore, the fasteners must be installed accordingly.

At the preparatory stage, you need to mark the surface for future fastening.

If the bracket is metal, it is recommended to strengthen it with three self-tapping screws. When marking, special attention should be paid to the protrusions. So, the edges of the cornice protruding beyond the window must be equal. To make the calculation accurate, you can outline the contours using a pencil and tape measure.

After marking, you need to drill a hole for the dowel and fix it. A special bracket is attached using self-tapping screws. Measure the distance and fix the second fastening element. The rings are attached to the rod in advance; after the work has been done, it is necessary to check the strength of the fastening and all connecting elements.

The process of attaching curtains can be made easier if you put on the hooks in advance. There are various decorative attributes for cornices. So, beautiful tips can be attached to a barbell. In addition, these elements will hold the curtain. Thus, the design will not only be beautiful, but also functional.

Return to contents

Mounting options for plasterboard surfaces

There are several possible technical solutions that will allow you to securely attach the cornice to gypsum board sheets (regardless of ceiling or wall installation), without damaging the latter.

In the event that the need for installation arose in a house whose construction and finishing have already been completed, there are several options for hanging a cornice on a plasterboard wall.

On glue

If you are going to attach a decorative cornice, you can use glue.

The procedure for performing the work is simple:

- The installed product is cut to size (if necessary).

In order to do this as accurately as possible, it is recommended to use a pre-made template (usually made if similar trims need to be made for several decorative cornices) or a miter box.

- GKL sheets are primed.

Types of fasteners

You can hang curtain rods on a plasterboard wall using the following types of fasteners:

Dowel "Butterfly"

It is the most popular solution for attaching cornices to sheets of plasterboard.

The product can have different geometric dimensions (diameter/length). For hanging a cornice, the 10*50 models are optimal.

It is offered in two varieties.

TNF – polypropylene expansion dowel.

Requires a hole with a diameter of 10 mm for installation and allows the installation of a screw with a diameter of (3.0-3.5) mm.

TNF-W – analogue complete with screw.

Allows fixation of a bracket (support angle) up to 5 mm thick. installed in a hole with a diameter of 10 mm. Allows screwing in a hook (screw) with diameters of (3.5-5.5) mm.

The product consists of 2 parts: static and spacer. The second is inserted into the prepared mounting hole. As a result of screwing, it expands and fits as tightly as possible to the back side of the gypsum board sheet, expanding the supporting surface. This increases the load-bearing capacity of such a fastening, and allows it to securely fix a light wall or ceiling cornice.

The material used to make the “Butterfly” is polyethylene, nylon or polypropylene.

For those who are deciding how to hang a cornice on a plasterboard wall, we suggest using this algorithm:

- the installation location of the brackets is determined;

- Markings are made for installation holes (under the level);

To drill interior wall trim made of plasterboard, it is better to use a screwdriver with a wood drill.

If you are drilling into a ceiling, it is advisable to put a disposable cup over the drill to collect debris.

- The dowel, before installation, is slightly compressed with your fingers.

Then it is inserted into the hole up to the cap. After this, the screw is screwed in. This mounting structure is designed for a weight of 17 kg.

- The element that performs the fixation is placed last.

The size is selected taking into account the thickness of the screw. A 3 mm dowel requires a 3.5 mm screw-in element.

- The screw must be screwed in until it stops. This will allow the spacer element to open as much as possible.

You can hang a cornice on drywall using a metal “Butterfly”. This is a Molli dowel. But their use for fastening cornices is impractical.

Driva dowel.

This product will be an excellent solution to the question of how to hang a curtain on drywall. It is intended for fastening products to soft and fragile materials, including gypsum boards. At the same time, the latter does not delaminate or crumble. The advantage of this fastener is that there is no need to pre-drill holes. It is screwed directly into the wall with a screwdriver or screwdriver (there is a cross-shaped hole in the head for this purpose).

The end of the rod may have a sharp tip that works similar to a screw, making it easier to screw the product into the wall.

The screw thread located on the surface provides the necessary strength of adhesion to the base and eliminates the possibility of it falling out.

Made from metal and plastic. Depending on the weight of your curtain rod (including curtains), both the first and second options can be used. Plastic varieties are designed to support a weight of 25 kg, metal ones up to 32 kg.

conclusions

This article discusses several different options for attaching cornices to walls or ceilings made of different materials.

Practice shows that wall placement of curtains is more reliable due to the greater thickness of the supporting surface. In addition, curtains designed for wall mounting, as a rule, look more status and attractive.

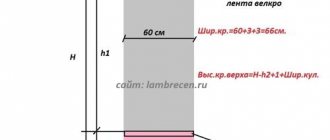

If you do not have the necessary financial resources to purchase them, you can hang the curtains on a curtain rod mounted on the ceiling. And cover the latter with a decorative panel (usually the width of the latter is taken to be 200 mm), which is spaced from the wall at a distance that ensures convenient use of the curtains. Another option is to put it in a specially equipped niche.

The main thing is that the niche and panel do not interfere with opening and closing the window sashes.

Which mounting option to choose is up to everyone to decide for themselves. we tried to talk about the main ones. If you have any questions, ask them in the comments. We will definitely give a detailed answer to everyone.

Shortening the slats

They will have to be shortened at the top; as mentioned above, the slats have small sewn-in weights at the lower end. Using a tape measure, measure the height from the curtain to the bottom end of the slats. There should be a gap of at least 2 cm between the floor and the slats. Trim each of them with scissors, so that there is room for lapels. Remove the plastic eyelet from the cut piece. To prevent synthetic fabric from fraying from cuts, treat it with a burning match or lighter. Fold the fabric left for the lapel, make a cut in the center, and insert an eyelet into it. Glue the edges of the strip using, for example, “Moment”. Follow the above procedure with each of the slats.