Contents of the article:

- Technologies for manufacturing spacer frames for double-glazed windows Raw materials for spacer frames

- Types of spacers

- Float glass

- Shprosy

- Types of double glazed windows

A double-glazed window is a translucent structure of two or more glasses, fastened together along the contour using spacer frames and sealants. The quality, tightness and service life of the entire window depend on compliance with technology and GOST standards.

The main materials used in the manufacture of double-glazed windows:

- glass;

- sealant;

- adsorbent;

- distance frame.

The technological process involves several rather complex stages, each of which requires attention and strict quality control. Only in this case can we talk about a high quality final product.

Technologies for manufacturing spacer frames for double-glazed windows

The spacer frame, by its purpose, belongs to the frame of the double-glazed window. It serves to separate the glasses from each other to the required distance. The quality of the spacer frame determines whether condensation will appear on the surface of the glass.

To prevent this from happening, an adsorbent is poured inside the part. It will absorb moisture that accumulates inside the chamber. This stops the process of condensation. The entire perimeter of the frame is perforated on the outside.

Raw materials for spacers

The following materials are used in production:

- aluminum;

- galvanizing;

- PVC.

Aluminum is the most widely used. The shape of the frame resembles a profile with perforations made in two rows. By type they are divided into:

- rigid, they are cut and connected to each other with steel or plastic corners, cutting is done on a machine;

- flexible, have a more elastic structure, they can be easily laid out around the perimeter by hand or using equipment.

Although this technology is considered outdated, it has been tested over the years and has proven its practicality.

Galvanized steel, compared to aluminum, has several advantages. The first is that there is no cold bridge. The phenomenon is observed when glass is fastened together with frames made of material with high thermal conductivity. Galvanized steel has the lowest. Therefore, the risk caused by temperature differences between the outer and inner glass is minimized. An important role in the design is given to the rubber seal.

The elasticity of the material makes it flexible, the angle can reach 90 degrees. With such a frame, condensation appears much less frequently.

Manufacturers have recently introduced plastic frames. One of the main advantages of the material is its reduced thermal conductivity. Plastic virtually eliminates the possibility of moisture appearing inside the glass unit. Sudden temperature changes do not affect the material. It retains its characteristics for a long time.

Distance frames perform the following functions:

- maintain the required space inside the chamber;

- protects it from excess moisture;

- creates a protective layer.

The quality of the product as a whole depends on the type of frame.

Types of spacers

There are several types based on the production method:

- thermoplastic;

- PVC;

- TGI;

- Swingle Strip.

Let's talk about each variety separately. Thermoplastic frames have a second name - TPS. Their production completely eliminates the use of metal. Instead, they are made from polyisobutylene, but the main advantage is low heat conductivity. At the same time, a similar sealant is applied. It minimizes the possibility of condensation.

Advantages of the technology:

- low scrap rate due to complete automation of the process;

- tightness;

- elasticity, due to which resistance to mechanical stress, temperature fluctuations and other influencing factors is manifested;

- suitable for all types of double-glazed windows;

- securely connects to the glass surface.

The next technology is Swingle Strip. It uses an elastic tape with an adhesive, an aluminum bridge and a desiccant as a sealant. This simplifies the process of insulation from moisture and condensation to a minimum. The tape combines the functions of several elements, namely the spacer frame, sealant and adsorbent. Fastening is quick and easy.

Swingle Strip speeds up sealing, makes windows resistant to moisture penetration and sudden temperature changes, and prevents condensation.

TGI is made from polypropylene foam and stainless steel tape. Foampropylene increases thermal insulation properties and protects against mechanical damage. Stainless steel does not allow gas to pass through. Together, the materials create a warm edge. The design includes an adsorbent. It fills the hollow part. Materials include molecular sieves or silica gel. In the first case, condensation appears at temperatures below -60 degrees, and in the second - at -45.

Among the advantages are:

- low heat loss;

- insulation of the room from the inside;

- no effect of “crying windows”;

- resistance to ultraviolet radiation.

PVC frames are similar to aluminum ones. They provide low thermal conductivity and do not allow sunlight to pass through. Even with a large temperature difference, the likelihood of condensation is reduced to zero. They use polyurethane sealant. It retains moisture well and adheres to PVC as much as possible.

Another technology is Super Spacer, used mainly in America. The frames are made of foam-like polymer, which has minimal thermal conductivity. As a result, they turn out to be very flexible and can be given any shape. The temperature of the glass surface increases by an average of 80 percent. Heat is perfectly retained in the apartment, and therefore heating bills become smaller.

The distance frames are fully responsible for the integrity and thermal efficiency of the package. At its core, each type has similar and at the same time different properties. Therefore, when choosing, pay attention to your further operating conditions for the windows.

How to choose the right one?

A good double-glazed window ensures 90% of the efficiency of a PVC window, so those buyers who carefully study its characteristics before purchasing do the right thing.

In order to choose a reliable double-glazed window according to the recommendations of European and domestic experts, you need to pay attention to the following characteristics :

- For average climatic regions at temperatures up to -15 C, a “warm” double-glazed window is required for 2 chambers, and for temperatures below -30 C, at least three-chamber ones.

- Sheet glass must be from 4 to 8 mm, modifications I and K.

- Triplex glass will be required to protect against small pieces in case of window damage, especially important for houses where children live and those located along the highway.

- For increased sound insulation, glass from 6 mm is installed. Triplex structures are also suitable.

- The gap between the glasses is from 6 to 16 mm.

- The air chambers can be filled with a special gas.

- Distance frames are better than steel ones.

- Sealants: thiokol and butyl.

- There should be no chips upon inspection.

- The evenness of the glass is checked with a rack.

- The discrepancy between the glass diagonals should not exceed 4 mm.

Types of glass for double-glazed windows

Modern production involves the use of a large number of varieties of glass. This allows you to carry out almost any individual orders, but at the same time not particularly inflate prices. Different types allow you to solve many problems that are set before the manufacturer:

- maximize energy efficiency;

- retain and reflect light in different spectrums;

- ensure strength and therefore safety;

- create an aesthetic appearance.

Sometimes in terminology there is a substitution of the terms species and variety. The latter directly indicates the brand of glass, which can indicate the quality of the product. Glass is manufactured in accordance with GOST 111-90, which specifies tolerances for the following parameters:

- optical distortions;

- thickness;

- the presence of non-destructive defects;

- plane deviations.

According to the standard, there are 8 categories. They are marked from M0 to M7. The table below shows the characteristics according to GOST:

| Glass category | Main characteristics |

| M0 | material used to make precision products, such as watches |

| M1 | Mainly used for mirror production |

| M2 | used for translucent structures and glass for vehicles |

| M3 | scope of application: household and artistic products |

| M4 | used in the production of windows, glass furniture and similar structures |

| M5-7 | They are of low quality and are most often taken as a budget option for partitions and glazing in production. |

All categories except the last three are polished. In addition to the indicated markings, TS and HS are also used. The first are heat-resistant, from which structures are made where resistance to prolonged exposure to flame is required. Some impact resistant glasses are processed at high temperatures, but this does not mean they are heat resistant. Chemically resistant (CR) varieties are used to make glassware for laboratories where chemical compounds are used.

Depending on the type of glass, the properties may vary, but there is a basis that is always the same. The only exceptions may be hardened or painted surfaces. They differ in thermal conductivity, strength and bending tests. Basically, the composition of glass from all manufacturers is the same - it is 75-80% SiO2, 10-15% CaO, the rest is Na2O. The main characteristics and their permissible values are given in the table:

| Characteristics | Range of values |

| thermal conductivity (conducts heat well and has low losses) | 0.4 - 0.82 W/m*Co |

| degree of light transmittance | up to 92% |

| chemical resistance | for washing it is possible to use non-aggressive chemicals |

| refraction of light rays | 1,46 — 1,53 |

| impact strength | 0.2 MPa |

| electrical conductivity | the material is safe to use |

Not all parameters meet current requirements for double-glazed windows. Therefore, manufacturers are trying to improve the properties and apply various coatings. This is how the following types of glass appeared:

Float glass

The most popular type. These are glass sheets with a thickness of about 0.4 - 25 mm, which are made from molten tin. Thanks to this technology, there is no need to perform additional grinding and polishing of the surface. They get a fairly smooth surface and can sell it at a reasonable price. Float glass is available in two versions: tinted and clear. For tinting, special mineral substances are used that help to obtain different colors. Mostly it is red, blue, green or bronze.

The main production is aimed at producing transparent float glass with a thickness of 4 mm. It is used for various types of double-glazed windows. The easiest way to improve the characteristics of such a stele is to cover it with a polymer film, this way you can reduce heat loss and improve sound insulation.

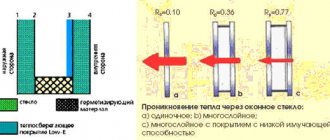

Energy efficient glass

To make so-called “warm windows”, glass with a special coating is used. A thin metallized layer is applied to the surface, which performs two functions:

- lets light in;

- blocks heat rays.

Thus, the ability to transmit light is completely preserved, and heat loss is significantly reduced. There are two types of coating: soft and hard. The properties of energy-efficient glass are also useful in summer, because they allow you to maintain a pleasant coolness and prevent the room from overheating. The properties of such glass are similar to a two-chamber package, but its use helps reduce the weight of the entire structure.

Triplex

Conventional float glass has a significant drawback - it breaks relatively easily. To increase safety, a variety called triplex appeared. This is an impact-resistant material that retains all light transmission properties.

The technology for producing triplex is based on alternating conventional material and polymer film. The first layer is a glass sheet, then film and glass again on top. Thus, the strength is significantly increased, and therefore safety is increased. Another plus is that if the window breaks, then due to the use of film it will not fly into pieces. Three layers is the minimum combination for triplex. The more layers, the higher the impact resistance of the finished product. The maximum thickness reaches 32 mm and allows for the use of up to four layers of film.

Wired glass

The second way to increase the strength of a glass surface is through reinforcement. It consists in the fact that a metal mesh is placed into the silicate mass during casting. Typically one of three types of wire is used:

- chrome plated;

- nickel plated;

- annealed.

During production, the method of manufacturing the mesh is important - welded or twisted, as well as the shape of the cells and their size. In terms of safety, it is worth noting that such glass does not become stronger, but if broken, it will not shatter into fragments. The metal mesh is an additional barrier for robbers. The structure of the sheets can be transparent, matte or colored. And the surface itself is smooth or has a slight relief.

Tempered glass

Hardening technology is based on a sharp change in temperature. First, float glass is heated to 650-680 degrees, after which it must be immediately cooled on both sides. Tempered glass is much stronger. It is more thermally stable. Regarding safety, it should be noted that the fragments of such a sheet are blunt, and therefore the possibility of cutting yourself is minimal. The easiest way to break them is to hit them on the end. This must be taken into account when designing.

Self-cleaning surfaces

When glazing large areas, there may be places that are difficult to clean, even with the help of industrial climbers. In this case, it is worth turning to a new technology - self-cleaning glass. Its essence is that a special coating is applied to the glass. Due to it and sunlight, organic matter easily decomposes without outside influence. Residues are easily washed off by rain. The water flows evenly and there are no marks or streaks on the surface.

Reflective glass

The properties of glass are similar to energy-saving ones, but their purpose is different. They are designed to reflect the sun's rays. The metallized coating, which is applied to the surface as protection, is called reflective. It can be either soft or hard. The difference is in the degree of resistance to external factors. Such windows can be installed on the sunny side of the house. They will help protect against overheating while still letting in natural light as usual.

Their peculiarity is that the surface looks like a mirror. Therefore, this type of window is used to maintain privacy.

Tinting

With its help, they usually darken the room, protect against overheating and, in some cases, reduce heat loss. There are four modifications of coatings:

- uniform toning throughout the mass;

- pyrolysis;

- polymer films;

- from oxides of various metals, which is applied exclusively in a vacuum chamber.

The main characteristics and rules of their operation depend on the type. The most durable ones are tinted throughout the entire mass. But they have a drawback - they attract light and heat up.

Given such a number of varieties, when choosing, you must rely on the requirements of the client.

Dimensions for plastic windows

The package sizes are set at the building design stage. For standard residential and industrial buildings, these dimensions are standardized; they must comply with state architectural and construction standards, and the maximum window size is 6 m2.

All packages with an area of more than 2.5 m2 and a door weight of more than 75 kg are not standard and must have a special certificate for additional safety testing.

A door with a three-chamber package of 3 sheets of 4 mm each, with an area of 2.5 m2, weighs approximately 75 kg.

Standard sizes of double-glazed windows are installed in houses of a certain type:

- Khrushchevka:

- with 1st leaf - 1150*1900/850*1150 mm;

- with 2 – 1.150*1.900/1.300*2.200 m;

- with 3 – 2.400*2.100/2.040*1.500 m;

- balcony – 1.350*1.340 /0.680*2.070 m.

- Stalinka:

- 2 doors – 1.080*1.080/1.250*1.800/1.500*1.900 m;

- balcony – 1.500*2.700 m.

- Panel house:

- 2 doors – 1.150*1.420/1.410*1.450/1.450*1.410 m;

- 3-leaf – 1.700*1.420/2.030*1.410/2.050*1.410 m;

- balcony – 0.400*1.410/0.680*2.140, as well as 0.500*1.410/0.680*2.140/1.200*1.410/0.680*2.140 and 1.700*1.410/0.680*2.140 mm.

Modern technology for the production of double-glazed windows allows them to be produced in any size, shape and level of complexity.

More information about sizes in the article at the link.

Types of decorative layouts for double-glazed windows

Modern windows are a complete structure. But manufacturers offer to give them an even more aesthetic appearance and use various decorative layouts. There are two main types: sprockets and false bindings.

Shprosy

These are elements that allow you to divide a large glass surface into segments. Today this design is not popular due to the fact that:

- the double-glazed window becomes heavier, for the same reason the load on the balcony partitions increases;

- high cost, which increases due to materials and their consumption;

- the presence of decor leads to large heat losses;

- Production needs specialists with experience in this particular field.

More often, decorative layouts are used, which are built into the package in advance and are internal. Another advantage is that when washing windows you do not need to wash additional parts.

The decor is made of plastic or aluminum.

False binding

This element can be attached to any side of the window, both internal and external. There is a frame applied on both sides. The structure is attached with glue or double-sided tape.

This is an exclusively decorative element that does not affect the functional parameters of the double-glazed window.

False binding is qualified according to several characteristics:

- material - usually metal, plastic and wood;

- color - white, colored or structure repeating natural materials;

- overall dimensions, the main one is the width, the value directly depends on the similar parameter of the double-glazed window.

Simply by shape, straight and curved edges are distinguished.

Venetian layout

The easiest way to change the appearance of a window. The decor is attached to the outside; for symmetry, it can be attached to the inside. Be careful, this window element prevents sunlight from entering the room.

Among the advantages:

- ease of installation;

- affordability;

- can be used at any time;

- helps create an incredible and unique style.

The disadvantage is that the service life of the decorative layout is short. If necessary, simply replace it.

Among the shortcomings, it should be noted that there are minor difficulties during cleaning. There is no point in removing the layout and then attaching it back to wash the window.

The layout is not only a lattice weave, it can also have a more interesting fancy shape.

Dismantling

Dismantling a package in a PVC window is not always associated with a defect or mechanical damage; very often it is replaced with a higher quality and energy efficient one. Dismantling is also carried out in case of mechanical damage to the glass, poor-quality assembly of the PVC window, fogging due to loss of tightness. The technology for dismantling the package is not complicated, but it requires precision execution, the use of protective equipment, and the work is performed in a team of at least 2 people.

The main stages of dismantling double-glazed PVC windows:

Remove the window sash, pull out the retaining rod from the top hinge, and disconnect the sash from the PVC frame.- Carefully lower the sash and move it to a safe place.

- A knife or spatula is placed on the vertical seam between the PVC frame and the bead.

- Carefully move the bead along its entire length.

- Remove the glazing bead from the frame, moving parallel along the glass.

- In the same way, the glazing beads are removed in order according to the scheme: the bottom horizontal, the second vertical, and the removal is completed with the top horizontal, at this moment you need to hold the glass unit with your hands.

- It is better to use special suction cups to remove the glass unit from the frame.

- If there are no suction cups, then dismantling is carried out with gloves, while carefully grasping the top with your fingers, carefully tilting it towards you, moving your hands, and taking the bag by the sides.

More information here.

Crack repair

Cracks form on the window under the influence of various factors. The most common ones are mechanical damage or the structure, when installed in a window opening, is not installed horizontally/vertically.

If the crack is small, located indoors, and the cold season has already arrived outside, then such a crack can be sealed with transparent tape until spring as a temporary measure.

There are several other options for simple temporary repair of a small crack in the glass of a PVC window:

- Silicone transparent glue is injected with a syringe into the gap, the surface of which is previously degreased. If the crack is small, then silicone is simply rubbed into it. After 24 hours, the silicone dries and the sash can be opened/closed.

- Epoxy glue is also applied to the crack, the surface of which is previously degreased, and paper tape is glued as close to the crack as possible so as not to stain the glass surface.

Full information about double-glazed window repairs can be found here.

When is replacement required?

If the crack is large, cold air enters through the window, condensation forms inside the package and on the glass, the seal of the package is broken and street noise enters the room, the glass in the package will need to be replaced.

Experts believe that, despite the apparent simplicity of this operation, it is almost impossible to qualitatively replace glass in modern double-glazed windows at home. This is due to the fact that the seal of the package will be broken. Such work must be performed on special factory equipment.

When replacing the entire glass unit, the above problems are eliminated. An on-site technician determines the characteristics of the package and selects the best replacement option.

If, nevertheless, the owner decides to independently remove the glass from the bag, it will be necessary to carefully trim the top layer of sealant with a knife, then remove the remaining layers to the aluminum frame, after which the glass can be easily removed.

Read more about replacement in this article.

Types of double-glazed windows

A double-glazed window is the transparent part of a window. Through it, natural light enters the room. It is inserted into a PVC frame. Several glasses are hermetically connected to each other with a given technological sequence. The glass unit performs the following functions:

- increasing the thermal insulation of the room;

- reduction of heat losses, you stop heating the street;

- increased sound insulation;

- reliably protects from all weather conditions; wind does not blow through the sealed structure.

The design consists of several glasses, which are located at a short distance from each other. Along the edge they are hermetically connected to each other using a frame in which manufacturers place granules along the perimeter of the air space. Their task is to collect excess moisture that passes through the glass. On the other hand, the adsorbent strip has perforations, which helps to effectively remove excess moisture. This way the glass unit is protected from the formation of condensation.

The technology provides for a certain degree of penetration, which is obtained through sealants. The multi-chamber bag is filled with dry air or any substance with inert gas properties.

According to technical characteristics, the latter is better than air, but after a few years additional gas injection may be necessary, since even with the most reliable sealing it tends to evaporate.

Types of double glazed windows

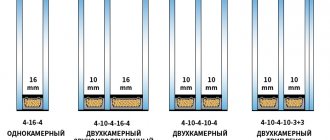

The main classification is the number of cameras that are present in the design:

- Single chamber. These are two glasses that are connected to each other into one chamber. The main characteristics are determined by the thickness of the glass, the presence of different types of coatings on them and the distances between the glass sheets.

- Two-chamber. The design includes three glasses and two cameras. The technical properties of such a package are significantly higher than those of a single-chamber one. The distance between the glasses and the thickness of the sheets may vary. This helps to enhance some of the characteristics, for example, sound insulation or reduce heat loss.

- Three-chamber. It has three cameras respectively.

The manufacturer can offer its buyer more multi-chamber designs. But, as a rule, they do not make sense due to the fact that the number of cameras will only increase the cost of the finished product.

Analyzing well-known manufacturers, we can say that inert gas, dry air or sulfur hexafluoride are pumped between the glasses.

There are several types of double-glazed windows based on their properties. They can be inserted into a regular PVC frame or Euro-windows made of wood.

Impact resistant designs

Triplex glass is used in this double-glazed window. Due to the fact that they contain several glasses, which are covered and interlaced with a film, their strength is much greater. In addition, when hit by a heavy object, the glass does not shatter into fragments, but remains concentrated in one place.

Energy-saving double-glazed window

To increase the energy efficiency of a window, the chambers inside the glass unit are filled with inert gases - argon or krypton. But for the desired effect, you can still give one of the glasses special properties.

Energy-saving glass can be covered with one of two types of film:

- i-glass. It has a foam coating that effectively reflects heat waves from the surface. In order to determine the amount of losses, they use such a concept as the issuer. The lower it is, the more heat remains in the room. If for ordinary glass the figure is 0.83, then for energy-saving glass the value is reduced to 0.004. This indicates the efficiency of heat wave conservation is up to 90%;

- k-glass. Its spraying has a solid character. It additionally protects against ultraviolet exposure.

The system works correctly not only in winter, but also in summer. In hot weather the room does not overheat, and in winter it does not cool down.

Sun protection

There are two options for manufacturing such a double-glazed window. In one case, reflective glass is used. Its technical characteristics make it possible to reflect ultraviolet radiation from the surface according to the principle of a mirror.

The second uses tempered glass. During production, it undergoes a special heat treatment. This significantly increases its strength properties.

Frost-resistant

They are usually produced for those places where the air temperature in winter can drop below -35. They are provided with such coatings and glass treatment that fogging does not occur when the thermometer readings are above -55 degrees.

Noiseproof

Increased noise insulation is ensured due to the fact that the size of the chambers differs from each other. For example, out of three cameras, two are identical, and the third is slightly narrower. This ensures that less noise comes in from the street. An additional amplifier for sound insulation can be triplex glass and those in which the insulation is made using resin.

Choosing a business direction

Most window manufacturing companies are small businesses, limiting themselves to the assembly and installation of finished products. And although logic dictates that having your own glass line will significantly reduce the cost of windows, manufacturers, in most cases, still prefer to buy ready-made double-glazed windows. Why? It all depends on production volumes.

Options for organizing the production of double-glazed windows:

- Manual assembly (up to 50 double-glazed windows/day)

- Automated or semi-automated production line (100-1500 double-glazed windows/day).

The cost of hand-made and purchased double-glazed windows is almost the same, because manual technology requires the use of expensive raw materials. And when an automated line operates, “manual” materials are replaced with professional, cheaper analogues for mass production - for example, liquid butyl is used instead of butyl cord.

Therefore, manual assembly of double-glazed windows most often becomes a “backup” option to prevent the failure of large orders due to the high (usually seasonal) workload of the supplier and frequent violations of delivery deadlines. Or when orders are not regular and large in volume, and the supplier of double-glazed windows is located geographically far away.

An automated line (fully or partially), as practical experience confirms, will be appropriate for established sales of products of at least 1000 m2/month.

GOST standards for the production of double-glazed windows

All double-glazed windows must be certified and comply with certain regulatory documents. In this case, it is:

- GOST R 54175-2010 (replaces GOST 24866-99) - Glued glass units for construction purposes. Technical specifications;

- GOST R 54174-2010 - Glued double-glazed windows. Rules and methods for ensuring product quality;

- GOST R 54173-2010 - Glued double-glazed windows. Methods for determining the physical characteristics of sealing layers;

- GOST R 54172-2010 - Glued double-glazed windows. Durability assessment method.

Primary certification of any product takes about three months. Most of the time is spent checking for durability.

To control the quality of the glass itself, the following are used:

- GOST 111-2001 Sheet glass. Technical conditions.

- GOST R 54171-2010 Multilayer glass. Technical conditions.

- GOST R 54169-2010 Sheet glass, dyed in the mass. General technical conditions.

- GOST R 54170-2010 Colorless sheet glass. Technical conditions.

- GOST R 54162-2010 Tempered glass. Technical conditions.

Compliance with these requirements will help to obtain high-quality products that will pass certification and help the manufacturer gain the trust of customers.

Equipment for the production of double-glazed windows

With the right selection of personnel and equipment, the process of manufacturing double-glazed windows is simple. It consists of several stages:

- cutting glass according to specified parameters;

- washing of workpieces;

- production of spacer frames;

- applying sealant to the latter;

- assembling a double-glazed window - connecting glass and frames into a single structure;

- insulation using sealant or silicone.

To complete all these steps, the company will need a table. It should work in semi-automatic mode. The canvas is placed on it, where it will be cut in accordance with the dimensions required for the future workpiece. Cutting can be done manually using a cutter, but the accuracy of automatic settings is much higher. In large production, the speed of work completion will depend on automation.

The next station is a sink, which is necessarily equipped with a filter for cleaning the liquid. This eliminates the appearance of unevenness on the surface of the glass caused by the presence of sand or other abrasive particles in the water. All cut pieces must not only be washed, but also dried. This will increase the quality of adhesion of the sealant. Drying is done with warm air or a soft cloth. It all depends on the size of production. Today you can purchase an entire production line that will perform both operations at once.

There are separate lines that are responsible for assembling double-glazed windows. Directly for assembly, a table is useful, which rotates and is equipped with a pneumatic press. Finally, an extruder will be required for final sealing.

Before assembly, the spacer frame must be cleaned in the same way as the glass. This allows for increased adhesion of the sealant. It should be free of dirt, corrosive substances and moisture. The frame is cut on the basis that its perimeter is smaller than that of the glass. The corners are fastened and filled with adsorbent. When using a flexible spacer, no preliminary cutting into pieces is required. Trimming is done after complete fastening. This reduces the number of places for gluing.

To attach to the glass, the frame is coated with sealant. Butyl tape requires manual attachment and the molten material is applied by an extruder. This method increases the strength of the future structure, since the butyl is first heated to a temperature of 120-160 degrees. These are the best conditions for gluing.

The formation of a double-glazed window occurs as follows. The frame, placed between the glasses, is sent into the press. For small production, the press can be manual, then the degree of compression is controlled by a valve. In large production, a pneumatic press is used. For multi-chamber packages, the operation is repeated the required number of times.

Gas filling is performed through a hole in the side of the frame. Here you need to monitor the pressure. The essence of the process is to displace the air mass and fill the vacated space with gas. The outside of the glass unit is treated with silicone or polyurethane sealant.

The finished products are placed on trays and secured. According to GOST, the product must be marked.

What it is?

A double-glazed window for PVC windows is a translucent structure assembled from 2 or more glasses , which are fixed at a certain distance from each other, forming an inter-glass space - a chamber, for example, when using 2 glasses - single-chamber, 3 glasses - two-chamber.

The glass unit is fastened along the contour with spacer frames and sealants. Its main task is to create an energy-efficient window design to increase the thermal resistance of the window and provide the required level of natural light in the room.

The choice of glass depends on the requirements for the object of use. So, to create an energy-efficient design, you will need to use glass modifications i, K and Low. For noise protection, you will need to install thicker glass up to 6 mm.