In order for modern windows to have excellent characteristics, the production of double-glazed windows must be carried out in strict accordance with technological standards. The main requirement for these products is absolute tightness. However, in addition to this, there are a number of equally important criteria - stability of shape, sound and heat insulation declared by the manufacturer, as well as the absence of condensation on the inside of the glass. This result can only be achieved if all standards are met during the production process.

Terminology nuances

The technology for manufacturing double-glazed windows for windows made of plastic, eurobeam and aluminum is the same.

As a result, there is no separate production of wooden double-glazed windows and their other types. Moreover, this term itself contains a semantic error that can be misleading. After all, there are no wooden parts in any double-glazed windows, and in this case we are talking about the manufacture of double-glazed windows for wooden windows. To produce these elements of window structures, the following are used:

- various types of glass;

- metal or plastic spacers;

- sealants;

- inert gas;

- moisture absorber;

- decorative elements - fusing, polymers, beveli and broaches;

- energy-saving and soundproofing coatings.

For the manufacture of heated double-glazed windows, additional materials and special technologies are used. Read more about this unique product on OknaTrade.

No. 4. Glass spacing and soundproofing

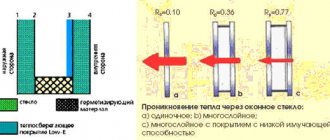

Modern double-glazed windows can effectively solve not only the issues of thermal insulation, but also the absorption of street noise. City dwellers should appreciate this property.

Sound insulation characteristics depend on the following parameters:

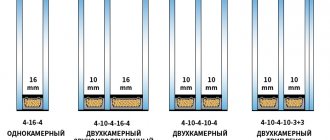

- width of the glass unit and number of cameras;

- distance between glasses;

- glass thickness and combination of glass of different thicknesses;

- type of glass.

The wider the double-glazed window, the better its sound insulation, and a double-chamber double-glazed window 42 mm wide will be much “quieter” than a double-chamber double-glazed window 28 mm wide. When the chamber increases by 3 mm, sound insulation increases by an average of 10%, and a double-chamber double-glazed window is already 40-45% more effective in terms of sound insulation than a single-chamber one. At the same time, the thermal insulation characteristics increase as the chamber increases to 16 mm, stabilize in the range of 16-24 mm, and then deteriorate due to convective heat transfer.

The distance between the glasses should not be more than 20 mm, but, as a rule, it is 6-16 mm, and the more glass is used, the smaller the distance between them, since the total width of the glass unit should not exceed 60 mm. And then manufacturers resort to a trick and make chambers of different thicknesses , achieving destruction of the symmetry of the system, leading to resonance.

The use of glass of different thicknesses also has an excellent effect in terms of sound insulation . When a sound wave collides with barriers of equal properties (glasses of the same thickness), it easily passes through them. If the barriers have different parameters, then it will be more difficult for the sound wave, and it will lose a huge part of the energy. Glass of different thicknesses does not resonate and allows you to make the apartment quieter by about 30%. In a double-glazed window, only one glass should be 6 mm thick, the rest should be ordinary, 4 mm thick, so that the structure is not overweight.

If, in addition to everything, you use triplex glass in a double-glazed window, which dampens noise well, then you can achieve the best results.

Stages of manufacturing double-glazed windows

Thanks to the automation of some stages of this process, it was possible to achieve higher quality and reduce the production time of double-glazed windows. The entire production procedure consists of 7 stages:

- cutting glass;

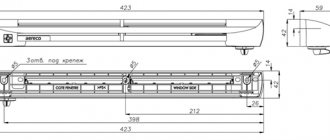

- cutting spacers – spacer frames;

- glass washing;

- applying sealant;

- polishing glass edges;

- primary assembly;

- final sealing.

After completing all of the above processes, the double-glazed windows are ready for integration into window frames.

Required number of cameras

May vary. Plastic frames range from two to seven chambers. In this case, it is better to choose designs with a large number of cameras. They have a number of advantages:

- Structural rigidity. The more cameras, the more internal partitions, the more powerful the profile. As a result, all parts of the window as a whole (fittings, seal) work longer and more comfortably.

The pictures show profile systems with different numbers of chambers

- Good thermal protection. The more air “compartments” (chambers) in the frame, the harder it is for cold air to penetrate the room.

Based on this parameter, profiles are divided into classes:

Information on the resistance of window profiles to heat transfer is indicated on page 4 in GOST 30673-99 “Polyvinyl chloride profiles for window and door blocks”

The division of structures by cash desks occurs as follows:

- The first is six-, seven-chamber profiles or five-chamber profiles without reinforcement with thermoplastic inserts.

- The second and third ones are five-chamber.

- The third and fourth are three-chamber.

- The fifth is two-chamber.

But it is not always necessary to overpay and install the most durable structure. It is important to understand where you plan to place the window. For a warm apartment in the Far North, a six- or seven-chamber option is suitable, and for a summer veranda in Sochi, a two-chamber version will be sufficient.

For example, for warm rooms in our Sverdlovsk region it is necessary to install at least three-chamber frames, since the standardized heat transfer resistance is 0.61 m 2 per °C/W.

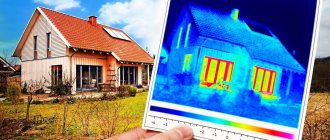

Please note: on average, the profile (frame) occupies 30–40% of the total window area. So when it comes to warmth, don't forget to think about double glazing!

Glass cutting

One of the main and most important procedures is glass cutting.

Moreover, in this process, not only accuracy is important, but also preserving the structure of the material being cut, as well as ensuring smooth fracture edges. The fact is that during the cutting process, microcracks form on the glass, which have the ability to “self-heal” quite quickly. As a result of this feature, if you hesitate, you can cause a defect, so with high-quality cutting, the break should be made immediately after the cut. Today this process is fully automated, so manufacturers of double-glazed windows have managed to improve quality. Cutting is carried out on special format-cutting machines with CNC and special air cushions for glass sheets. In addition, to prevent chipping, the cutting line is immediately and automatically treated with a low-viscosity lubricating fluid. Thanks to this, the process of “self-healing” of glass significantly slows down, and it is possible to achieve perfectly even breaks without chips.

Interior windows in the interior of the house

Interior windows in the wall visually expand the space and change the decor in the rooms for the better, which is why they are often used by interior designers.

However, these elements must be installed with caution and not blindly follow fashion. Interior windows that are poorly designed can ruin the interior. To prevent this from happening, it is recommended to follow a few simple rules:

- For high-tech style, designs made of aluminum profiles are best suited.

- When decorating classic interiors, it is recommended to use wooden frames.

- You always need to take into account the ratio of wall area and openings.

- When decorating rooms in country style, it is advisable to equip the windows with shutters. Shutters are perfect for this purpose.

- For large glazing areas, regardless of the type of profile system, dividing elements for internal light openings should be used - strips and other types of decorative layouts.

To help you choose the optimal model, there are programs that help you choose the design of an interior window, the photo of which can be combined with the future decor of the room. In this case, it is better to immediately seek help from interior designers who work with such software. If it is not possible to make an opening in the load-bearing wall, you can install an interior decorative window. This design can be fixed to the walls at any convenient time and does not require major construction work.

Preparing spacers

Simultaneously with the glass cutting process, spacer frames are prepared, the types of which can be found in the review on OknaTrade. Since spacer frames are made by pre-cutting profiles and then assembling them into a solid frame or by bending, the preparatory procedure may differ depending on the choice of spacer profile. During assembly, a molecular sieve - special absorbing granules - is poured into the internal cavities of the spacers. There are a number of requirements for this material:

- the ability to absorb exclusively moisture and inertness to other substances contained in the air;

- a suitable diameter of granules that will not allow them to spill out of the holes in the spacer frame.

The production of double-glazed windows at this stage is carried out taking into account that the glass does not fog up from the inside during the operation of the windows. During this process, it is important to correctly determine the “dew point”, so that the correct amount of moisture absorber will be selected.

When ordering double-glazed windows, it is recommended to give preference to models made from spacer frames with a thermal break. The use of such spacers allows you to eliminate “cold bridges” in this area of the window structure.

When to install interior windows

The most optimal time for installation is during construction. However, this method is available only to owners of private cottages who planned in advance the installation of interior windows. Residents of apartment buildings are deprived of this opportunity, so they deal with such issues after moving in. To ensure that the installation of an interior window does not cause trouble, you need to immediately find out in which walls you plan to prepare openings. Load-bearing structures cannot be touched without permission for redevelopment, so installing windows between some rooms may involve bureaucratic red tape.

Since such work is mainly carried out during major renovations, it is recommended to take care in advance of conducting an examination and obtaining permission for redevelopment. If you postpone this event until the last minute, the repair may be delayed.

Primary assembly

At this stage, the glass is connected to the spacer frames, to which sealant has previously been applied. It is very important that the binder composition after assembly is exclusively black. After all, the presence of white spots on the sealant means that it was touched by hands or the glass was not washed properly. This negatively affects the quality of the connecting seam. To avoid such situations, workers wear gloves and keep the glass clean. After assembly, the structures are placed under a special press, where under pressure the butyl coating penetrates the structure of the silicate mass and ensures a reliable connection.

Double-glazed windows with white spots in places where glass and spacer frames are glued together are not suitable for installation and operation. The use of such products can lead to a rapid reduction in the energy efficiency of windows and the level of sound absorption.

What parameters are important for a plastic frame (profile)?

- Structural rigidity. It should not bend due to changes in pressure and temperature. A good frame will support the weight of other elements - the sashes will not sag.

- White. Affects aesthetics. A window that has yellowed over time looks simply terrible.

- Elasticity and frost resistance. Plastic should not become brittle from the cold.

- Thermal protection. The window frame must withstand our harsh winters and prevent the room from cooling down.

Compliance with all these characteristics is achieved by creating special plastic for window structures.

Reinforcement

The rigidity of even the most powerful and wide frame is not enough to bear the entire load. Therefore, the frame of each plastic window is equipped with a reinforcing steel profile.

The exception is profiles with thermoplastic inserts, for example, Aluplast Energeto 4000, but that's a completely different story.

When temperature changes, profiles can deform by 2–6 mm.

Colored frames are more deformed than classic ones. This is due to the presence of pigments in their composition.

If you add wind load to this, the figures will increase by 10%. Reinforcement (duplicating the PVC profile with metal from the inside) does not allow the plastic to bend in different directions.

Metal elements clearly follow the shape of plastic ones

Reinforcement can be open (as in the figure above), where only part of the profile is duplicated, and closed - with complete reinforcement of the walls.

This way, without seams or openings

Full reinforcement is ideal for high-rise buildings and regions with harsh climates.

Correct thickness

If you have thought of everything, this is where they can guide you. Just for the word “reinforcement” people are asking to pay more. However, the metal will only be truly effective if it meets the parameters.

According to GOST, the optimal reinforcement thickness should be at least 1.2 mm.

Do sellers suggest installing an open structure made of metal 0.5 or 0.7 mm thick in a frame, citing mild climatic conditions? You are being deceived. Such a thin layer will not provide additional protection. You pay for “gold plating” that no one will ever see.

Accessories

Handles, hinges on which the doors are hung, locks for closing, and internal mechanisms that set them in motion are classified as fittings. These are the parts with which the doors open, close, and turn.

Locking mechanism

The main lock is installed on the handle side of the sash, the “scissors” are located along the upper edge, and the middle lock is located at the bottom. The two upper elements are connected by an angular transmission via a tire. The middle one is equipped with its own angular gear.

By turning the handle, the steel rail is set in motion, and the sash is drawn to the frame. When you turn the handle 90 degrees, it opens. When turning the knob up, ventilation is set, and at 45 degrees - micro-ventilation.

“Scissors” are involved in changing regimes. There is a “microlift” lever to prevent errors.

Ventilation devices

The fittings kit provides ventilation of the room, having different configurations and functionality. Ventilation can be divided into the following types, according to which the corresponding parts are used.

- Microslit. It is provided by an element that slightly opens the sash by 2 mm by turning the handle. In winter, this method is used more often, as it can limit the intensity of air intake.

- Seasonal is implemented by a two-position switch that regulates the width to which the sash opens in the “recline” position. In summer the solution is maximum, and in winter it is half as much. The mechanism can be adjusted once per season.

- Step ventilation is carried out using a small part equipped with toothed hooks. Or a plastic comb on the outside. You can select the width to which the sash opens in 5 positions.

Window trims

The strip is a component that ensures that the sash structure adheres to the frame. It is also responsible for the safety of the window opening as a whole and ensures the tightness of the seams. Durability and strength depend on the number of slats, so preference should be given to windows with more than two slats.

There are two types of planks:

- Responders, whose main task is to ensure a tight fit and secure the premises from burglary.

- Swivel and tilt, which allow partial opening without harm to the structure as a whole.

The planks are installed at the factory; it is not recommended to change the damaged profile yourself; this requires professional equipment and materials.