What are roof windows

François Mansart was the first architect to convert an attic space into living space. This happened in 1630. Therefore, the attic began to be called “attic”, and the windows “dormer”.

Their main difference from façade ones is that the former are mounted in an inclined plane, the latter in a vertical plane. Hence the increased requirements; they will have to withstand strong gusts of wind, rain, snow, and hail. They must be installed carefully so as not to be bent and they do not leak. But if you look at the photo, it immediately becomes clear that even self-made ones make the house stand out from other buildings.

Features of installation in the roof

When installing window structures in a roofing pie, it is necessary to take into account a number of features :

Installation gaps must be at least 15 - 20 mm to allow unimpeded installation of sealing tapes and foam.- Before installation, it is recommended to check that the dimensions between the rafters and the dimensions of the window unit match.

- Unlike installing standard windows, when installing a translucent roof element, it is not recommended to dismantle the sashes and double-glazed windows.

- Considering that the maximum amount of excess heat accumulates in the under-roof space, when installing a movable sash, it is necessary to carefully adjust the fittings to ensure normal ventilation and prevent the accumulation of condensation.

- When sealing installation joints, it is necessary to use only vapor-permeable materials.

- Before fixing the window block to the anchor plates, it is necessary to temporarily wedge it, and then check the alignment with the inclined rafter leg. In case of misalignment, the structure of the seam may be damaged and stress concentration may occur.

Before finishing the slopes after installing the window, you need to make sure that the joint is tight, since even with the slightest defect in the sealing layer, a leak may form.

Standard sizes of roof windows

dormer windows photo

Installation should be carried out on roofs with a slope of 150 to 900. Manufacturers offer from 6 to 14 standard sizes. The rest of the differences concern:

- material of manufacture;

- option for opening the doors;

- complete set of fittings;

- type of glass unit.

Custom orders are limited to the minimum and maximum design sizes available from the manufacturer.

The rating of manufacturers in our market consists of 3 companies:

- Velux (Denmark). In the industry since 1941.

- Fakro (Poland). The company has been operating since 1986 and has been able to develop from an ordinary carpentry workshop into a leading manufacturer.

- ROTO (Germany). The company has satisfied the needs of 500 million people and has been in the industry for over 80 years.

The standard minimum size is 55X78 cm, maximum 114X140 cm. Each manufacturer has its own line:

| width, cm | height, cm | approximate effective lighting area, m2 | Velux | FAKRO | ROTO |

| 114 | 140 | 1,16 | + | + | + |

| 134 | 98 | 0,92 | + | ||

| 114 | 118 | 0,95 | + | + | + |

| 94 | 140 | 0,92 | + | + | + |

| 94 | 118 | 0,75 | + | + | |

| 78 | 160 | 0,85 | + | + | |

| 78 | 140 | 0,73 | + | + | |

| 78 | 118 | 0,59 | + | + | |

| 78 | 98 | 0,47 | + | + | |

| 74 | 160 | 0,83 | + | ||

| 74 | 140 | 0,70 | + | ||

| 74 | 118 | 0,50 | + | ||

| 74 | 98 | 0,40 | + | ||

| 66 | 118 | 0,47 | + | + | |

| 66 | 98 | 0,38 | + | ||

| 65 | 140 | 0,39 | + | ||

| 65 | 118 | 0,38 | + | ||

| 55 | 98 | 0,29 | + | ||

| 55 | 78 | 0,22 | + | + | |

| 54 | 98 | 0,21 | + | ||

| 54 | 78 | 0,20 | + |

Kinds

Based on the type of material used, the following are distinguished:

- Wooden , with doors and a frame made of laminated veneer lumber.

- With polyurethane coating . This is a wooden structure, with a coating that protects the color and protects against yellowing.

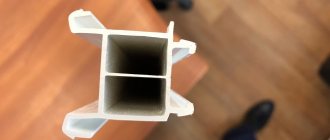

- With PVC profile . Recommended for installation in bathrooms and kitchens.

- Armored.

The latter type is mounted only on roofs made of concrete monolithic structures, as they have significant weight. Wooden frames are an expensive pleasure.

Wooden roof windows

Depending on the opening method, there are:

- with a central axis of rotation of the sash;

- with a raised steering axis;

- with a side pivot axis or roof hatches;

- with a lower rotating axis, that is, the frame opens forward;

- combined, opening outwards up to 450 and rotating.

The latest development is designs that can be opened by remote control or “smart windows”. This is a good solution for rooms where the glazing is very large. There are models that close and open depending on rain or smoke. They can be set to open at a certain period of time.

Smart windows

Classification by design features:

- Standard. They are made in the form of a square or rectangle. They have the simplest design: a sash and a frame, and can be blind.

- Extensions. They can have a rectangular or semicircular shape. More often used as an additional decorative top element.

- Balcony models. They allow a person to go outside, that is, they form a kind of balcony. The second option is that in the closed position it follows the shape of the roof, and after opening, the sash rises up and out.

- Light tunnel. A structure that does not have direct contact with the room and is intended to illuminate a space where artificial lighting is not possible.

- Additional window element. It must be mounted in the same plane as the roof window. These models are installed in cases where the existing glazing is not enough to illuminate the room, and 2 standard structures cannot be installed due to the small height of the roof.

- Arc, that is, the structure has curved shapes, depending on the radius of the roof.

- Cornice. Designed for roofs with a high wall underneath the wall.

- Anti-aircraft or intended for flat roofs.

Combined structures are placed in a separate category. Up to 6 double-glazed windows of different sizes and shapes can be installed on one slope. Manufacturers also offer models for ridges and sloping roofs. It is possible to combine translucent façade structures with existing ones.

Which manufacturers supply roof window systems?

Among the available diversity on the construction market, leading positions are occupied by models from reputable manufacturers.

Wooden windows from the Danish company Velux

Glued laminated timber made from northern pine wood, processed using a special technology, followed by impregnation with an antiseptic agent and a multi-layer varnish coating, ensures the high environmental friendliness of Velux roof windows. These products will last for many years, not succumbing to negative climatic and other stresses.

The design of the double-glazed window with rounded glass corners around the perimeter of the frame prevents the accumulation of condensation, and impeccable heat conservation is ensured thanks to a chamber layer of inert gas.

The listed factors give roof windows good thermal insulation properties. During experimental tests, Velux windows were exposed to low temperatures (down to -55 degrees), with which they coped well.

Velux manufactures high quality wooden roof windows

A special ventilation valve of the window frame allows you to ventilate the room when the window is closed, regardless of weather conditions. You can open the sash using the handle included in the kit, as well as by activating the slot ventilation mechanism. The uniqueness of the ventilation devices of all Velux window models lies in the presence of a special filter that reliably protects the room from dust particles and annoying insects, and in case of contamination can be easily washed.

This manufacturer pays great attention to ventilation systems, so all of its products are equipped with modern devices to perform this function. Velux roof windows differ from similar products in their powerful insulation due to a two- or three-level seal (the thickness is determined by the specific features of the model range), as well as the possibility of additional arrangement of a layer of insulation.

The manufacturer, in addition to high-quality technical indicators, endows the products with a unique design. Modern products can be freely combined with attic spaces of any interior. For example, there are windows that are streamlined, with smooth corners and an ergonomic appearance.

Video: installing a Velux window unit on the sheathing

Window blocks from the German company Fakro

The production of roof windows from the manufacturer Fakro is carried out in standard sizes, so when choosing a product you should take into account the architecture of the existing structure. To ensure sufficient visibility, higher windows are installed on flat roofs than in the case of a lower roof slope. The width of the window block is determined based on the distance between the rafters of the structure.

Fakro - German quality at an affordable price

You can choose Farko windows of any price category, but then the main material of the product also varies - the windows can be wooden, aluminum or plastic. The most budget option is a window with a PVC profile. Despite the minimal acquisition cost, such double-glazed windows will last about 40–50 years without losing their performance qualities, without being subject to corrosive changes or rotting. The next price category is aluminum construction, which, thanks to modern technologies, has undergone significant changes. Currently, the impeccable thermal insulation of the blocks allows them to be used in residential construction.

Plastic moisture-resistant windows Roto

Long production time and high quality products are the main criteria for the success of the German company Roto, which supplies durable plastic windows for the attic. In addition to the main tasks (maximum transmission of sunlight and visibility of the external environment), the profiles are perfect for any interior design. The unique fittings of the models allow you to adjust the sashes inside the frame even after the installation of all window components is completed. Thus, the rubber seals will be fully pressed, which is the key to reliable sealing of the window.

When it comes to choosing window units for installation in wet rooms, Roto products stand out from the competition, since plastic profiles are able to fully function even with constant exposure to moisture. It is a pleasure to take care of windows by periodically damp cleaning with a regular rag. Frames retain their original color after many years of work, so there is no need for constant tinting and treatment with special compounds.

Roto roof windows have a special closing mechanism

The absence of the need for constant maintenance makes plastic windows very convenient for installation in offices, clinics, hospitals and other institutions with a limited staff involved in cleaning. There is a great demand for double-glazed windows with three or four chambers, which allow achieving high-quality heat retention.

Roto windows guarantee safety of use in everyday life: since they are mounted at a certain distance from the floor, you can look out of them without any special manipulations, for example, diving under the transom. An additional precaution is the high location of the axis of rotation of the window mechanism, which protects household members from the danger of hitting the profile. It is very convenient that furniture and other interior elements can be placed next to the window block, thereby increasing the usable space.

The advantage of windows from a German manufacturer is a reliable security system, which is important when installing units in offices and rooms for various purposes. Protection is created due to a locking mechanism based on a four-point touch device, equipped with an additional anti-burglary glass unit. The manufacturer was able to prevent the formation of cold bridges thanks to a special aluminum structure and sealed rubber gaskets - this way warm air is retained in the interior space.

If necessary, replacing the glass unit of Roto roof windows is quite simple due to rubber linings, the main function of which is to prevent the formation of condensation, which is a problem for many analogues of this product.

Video: installation of Roto roof windows

How to choose a roof window

Before purchasing you need to decide:

- with dimensions;

- quantity;

- opening method;

- material of manufacture.

Depending on the purpose of the room, it is recommended to give preference to wooden structures for bedrooms, children's rooms and living rooms. Wood is an environmentally friendly material; winter-harvested pine performed best in this class. It is labeled as class 1A.

Most often, installation is carried out between the rafters. The distance between them should be 4-6 cm greater than the width of the frame itself. It is very simple to calculate, with a distance between the rafters of 84 cm, you will need a double-glazed window 78 cm wide, that is, there is a margin of 3 cm on each side.

The height (length) is selected depending on the roof slope. If the slope varies from 150 to 300, then the height should be 160 cm. It will provide a good overview, and there will be excellent lighting inside.

When calculating the quantity, use the ratio 1:10. This means that for 10 sq.m. you will need 1 sq.m. glazing. If you want to make the room as illuminated as possible, it is recommended to use a ratio of 1:6. It should also be taken into account that glazing on different sides will give much more light than one large one on one wall.

When choosing an opening method, you must be guided by the convenience and configuration of the roof. The most popular model is mid-rotation. The structure can be in an inclined position or rotated around its axis by 1800.

There are many options for opening, the main thing is to choose only those functions that are really needed in a particular situation, so as not to overpay for features that will not be required during operation. Particular attention should be paid to service windows if you have to go onto the roof in the future, for example, to remove snow or carry out repair work. They can act as an emergency exit. But, if you want to get maximum comfort, buy “smart” ones.

At the next stage, you need to choose between wooden and plastic structures. The thermal conductivity of both is the same, so this property is not decisive when choosing.

The resistance to environmental influences of plastic is an order of magnitude higher than that of wood. However, wooden structures covered with PVC also tolerate precipitation well.

In terms of strength, wooden structures are not inferior to PVC models, reinforced with aluminum load-bearing profiles.

Wooden models will be more expensive, but plastic ones are easier to install, make repairs and do not require additional maintenance. They do not fade, manufacturers offer a wide range of colors. However, wooden structures look natural and beautiful, and are environmentally friendly.

A few more tips:

- in rooms where you plan to dry clothes, do laundry, or have a bathroom or toilet room, it is better to choose a moisture-resistant design;

- Regardless of the chosen design, the outer glass must be tempered;

- ideal window ventilation should look like a labyrinth, with an adjustment function, this will keep the room warm and ensure the passage of a sufficient amount of air;

- it is necessary to check all wooden parts of the windows; they must be varnished to protect the wood from moisture and extend their service life;

- You cannot buy wooden models with knots and defects; all parts must have the same color and structure.

Particular attention must be paid to slopes. The lower ones are made perpendicular to the floor, and the upper ones - parallel. This will make it possible to avoid condensation on the glass during operation.

Under no circumstances should you be embarrassed to ask about the price. The cost depends not only on the type and size of the structure, but also on the popularity of the brand and accessories. Be sure to make sure that the manufacturer provides a warranty; it should not be less than 5 years.

Dormer windows in the interior are an opportunity to realize the most daring ideas in interior design. Once again you can be convinced of this if you look at photos of attics with and without windows.

Types of attic window blocks

For the manufacture of attic windows, in the same way as in the production of traditional models, various materials are used, so you have the opportunity to choose wooden, metal and plastic products to suit your taste. Each of them has its own positive and negative characteristics.

Characteristics of aluminum roof windows

The assembly of structures is carried out on the basis of aluminum profiles, which provide the products with long-term operation, ease of repair, as well as resistance to corrosive changes and deformations.

Such a window will last for more than half a century without requiring special care, while perfectly protecting it from negative atmospheric influences. The peculiarity of the material is that only from it can the largest window frames be made.

Aluminum roof windows can be warm or cold

Aluminum roof windows are:

- Cold - used for glazing balcony blocks and non-residential premises.

- Warm - suitable for installation in attics of houses and dachas.

The profiles of warm structures consist of three parts with a thermally insulating polyamide insert between the profiles. The main function of such a thermal bridge or thermal break is to prevent warm air from escaping outside and cold air from entering inside. Filling extruded polystyrene or polyurethane foam between thermostats helps to achieve high quality; The space from the glass unit to the frame or sash is foamed with a sealant.

An aluminum window system is assembled from several parts, which includes:

- profile frame;

- set of doors;

- impost;

- shtulpa;

- glazing bead

The method of opening such a window can be chosen by the master and is implemented without additional spare parts.

The roof window can open in different ways

You can get an answer to the question of why the demand for aluminum windows is much higher based on their technical characteristics:

- no problems arise during operation;

- unpretentious in care;

- manufactured at the customer's request in any size and with a suitable opening mechanism;

- Available in a wide range of colors according to the RAL scale;

- are not affected by different temperatures, cope with their tasks for many years;

- have protection against acid precipitation and UV rays.

The versatility of wooden roof windows

When building a roof, the frame is laid from wooden beams, and the sheathing is made from boards, so it is advisable to make roof windows from a similar material. Due to the similar reaction of wooden products when exposed to climatic conditions or loads, the expansion of the material structure occurs evenly across all roofing structures, including windows.

With a high density of laminated wood, there is sufficient flexibility of the products in the event of any movement, which significantly reduces the number of necessary fasteners. The advantage of wood is the ability to manufacture any decorative elements - arched transoms, window-balconies.

Wooden blocks can have different shapes

Indoors, roof windows are protected from moisture, and on the outside they are covered with special linings, which allows them to extend their service life. For prevention, it will be enough to paint the frames with water-based varnish every 2-3 years.

Impeccable moisture resistance of plastic products

In damp rooms, for example, in the bathroom or kitchen, the best option would be to install plastic windows. Such products, unlike ordinary wooden frames, do not require special care (just wipe with a damp cloth) and do not corrode as a result of exposure to water, dirt, or wind.

Currently, moisture-resistant roof windows are very popular due to their resistance to aggressive environments; without them it is impossible to imagine the functioning of swimming pools, saunas, greenhouses, and conservatories. The only factor that should be taken into account when choosing a plastic frame is the angle of inclination of the roof slope - within 15–90 degrees.

A plastic window can also be used in the bathroom

Any window, regardless of the material used and design features, provides the ability to ventilate the room. Thus, all models of roof windows are equipped with special valves that will help you take care of ventilation in a timely manner.

Dormer windows pros and cons

windows on the roof of the attic photo

The main advantage is the ability to create interesting lighting in the attic. Other advantages include:

- the number of double-glazed windows and their shape can only be limited by the buyer’s imagination;

- there is much more light from attic glass structures than from façade ones;

- modern materials make it possible to produce roof windows that can withstand any load;

- a huge range: anti-vandal designs, with a mirror effect and even absorbing light.

But attic structures are not the only advantages. The main disadvantage is that they get dirty very quickly. This must be taken into account when choosing an opening method to make it convenient to wash the glass. The second disadvantage is the high price for the structures themselves and their installation. But if you have certain skills, you can install and do them yourself.

Types and their characteristics

Before placing windows in the attic, it is recommended to select the type of opening. In most cases, attic spaces have an unusual shape. That is why the installation of natural light sources requires increased attention to detail.

Interior design gives you the opportunity to experiment, but to achieve a positive result, you should take into account that manufacturers produce the following types of blocks for attics:

- birdhouse;

- façade;

- cornice

There is also a classic option that allows you to install a window in the attic roof for the implementation of design and interior projects that do not involve the use of unusual solutions or bold ideas.

"Birdhouse"

It is mounted in vertically located walls.

The design assumes that the following functions will be implemented with its help:

- usable area increases;

- the space next to the window opening is not affected by anything;

- natural light penetrates.

It is recommended to additionally use insulation during installation. This type can be used to organize a source of natural ventilation.

Facade or cornice

When choosing between façade or cornice options, you need to consider what goals you want to achieve.

If windows are installed on facade connections, the room can be used as an individual development facility. Such openings combine the properties of ordinary full-fledged windows and openings for ventilation in the attic floors. Facade structures are a successful element of the design of the exterior of the house; they provide an influx of natural light and clean air.

Cornices - additionally promote better water drainage, prevent clogging of the facade, and maintain its visual appeal.

Cornice dormer windows

Facade roof windows

Pediment dormer windows

Finishing the attic window from the inside

Dormer windows require a high degree of watertightness around the entire perimeter of the roof. For this purpose, special salaries are established. They protect against freezing and liquid accumulation.

The next important point is the insulation of the glazing installation area and slopes. For these purposes, soft thermal insulation materials are used, for example, mineral wool. You cannot foam with polyurethane foam, as it will begin to crumble over time.

finishing of the attic window photo

The lower slope must be made perpendicular, and the upper slope parallel to the floor. Otherwise, condensation will collect, and fungus and mold may appear around. To finish slopes you can use:

- drywall;

- lining;

- plastic panels;

- plaster, although it does not retain heat well;

- OSB boards.

In rooms where high humidity is expected, it is better to use materials that are resistant to moisture, for example, moisture-resistant plasterboard. The slabs are fastened to a special frame using self-tapping screws. It would not be superfluous to lay a hydro- and/or vapor barrier layer.

Cold attic

Perhaps the main advantage of a well- ventilated attic above the attic is the ability to create a buffer zone between the premises of the building and the external environment.

Such a zone provides protection from sharp fluctuations in temperature and humidity characteristic of the climate of many regions of Russia. This makes it easier to maintain conditions for comfortable living in the house. In addition, when installing a cold attic, the service life of the roof is significantly extended. In particular, due to the fact that achieving high-quality ventilation of the under-roof space in the case of an attic is much easier than in the case of an attic.

Any pitched roof needs ventilation in order to remove water vapor that inevitably gets there beyond its limits. It is contained in warm air, which is directed as a result of convection from the premises of the building upward and through the gaps in the vapor barrier (and they, alas, are not uncommon) penetrates under the roof. It can get there in other ways, for example, through diffusion through poor-quality vapor barrier or through walls (made of slotted brick, foam concrete, etc.). If the steam is not removed, then in the off-season, when the temperature drops, it condenses on the cold surfaces of the roof, which results in a number of problems. In the presence of an attic, this leads to the formation of frost on the waterproofing, to moistening and subsequent rotting of the wooden elements of the roof, to leaks on the walls of the building, etc. And in the case of an attic, among other things, it causes ice to freeze on the fibrous insulation and its further wetting, which causes sharp deterioration its heat-shielding properties (the house begins to freeze) and its service life is reduced. In this regard, the attic has an advantage

: high-quality ventilation of the under-roof space is facilitated by the large volume of the attic space and the absence of barriers to air movement.

There are other advantages to the attic compared to the attic.

Its design is simpler (in particular, it is easier to install insulation and a vapor barrier), and in addition, all its elements are accessible for inspection (for example, it will not be difficult to detect a leak in the roof) and, if necessary, they are more convenient to repair. Finally, in some cases the attic turns out to be the only solution. Thus, it is impossible to create an attic on the roof, where the rafter structure is a truss (a system of rods connected to each other at nodes).

Let us add that there are many ways to arrange an attic: you can make here a summer playroom or a guest bedroom, a technical room for supply and exhaust ventilation system equipment, a warehouse for building materials, tools, things, food supplies, etc.

In order to preserve the attic structure for a long time, it is necessary to provide for its ventilation. In winter, the air temperature in the attic should be close to the outside temperature

When installing a cold attic, you need to remember a number of important points. First of all, it is necessary to perform high-quality vapor barrier and insulation of the ceiling of the last floor. Often the ceiling is a structure made of logs. Plates of fibrous insulation are laid between them, covering them from below with a vapor barrier film to protect them from water vapor. Note:

some amount of steam will still get into the thermal insulation, and in order to ensure its unhindered exit from there, it is recommended to leave the insulation open from the attic side, and to use, for example, wooden walkways for walking around the room.

The problem area is the hatch to the attic.

It must be reliably heat and vapor insulated around the perimeter, and also have a good seal between the lid and the frame, otherwise it can become an area of abundant steam penetration into the roof structure.

Some experts

also advise creating an insulated and vapor-insulated vestibule at the point of access to the attic

in order to completely cut off steam from this room. A waterproofing film is laid over the rafters to protect roof elements from leaks through the roof.

Be sure to provide an attic ventilation system

- with such a condition that it ensures that in winter the air temperature here is close to the street temperature. Air flow is carried out, as a rule, either through gaps in the overhang of the eaves (moreover, air must flow into the space both above and below the waterproofing), or through lattice dormers located in the wall of the building at the attic level. The exhaust is organized using holes in the ridge or special pitched ventilation elements (plastic pipes, ventilation tiles, etc.) installed close to the ridge. Moreover, in the area of the ridge, a gap is made in the waterproofing film so that air from the attic can flow freely to the ridge.

An alternative solution is deflectors or ventilation turbines

, capable of creating forced draft. Their lower part must pass through the waterproofing in order to draw air specifically from the attic. On roofs with a low slope in winter, the ventilation gaps provided in the ridge can be filled with snow, so it is recommended to install ventilation elements here in the form of pipes, the height of which is greater than the height of the snow cover, as a hood.

Some experts consider the construction of mansard roofs unnecessary in our climate. This is explained by the following factors. Sudden changes in temperature and humidity necessitate a cold attic - a buffer zone between the street and the upper floor, which would compensate for climatic loads, thereby maintaining comfortable living conditions for people in the house, as well as increasing the service life of the roof structures and finishing materials of the attic. In addition, in the case of an attic, it is much easier to achieve high-quality ventilation of the under-roof space due to its large volume. In the case of an insulated roof, this is much more difficult to do: the ventilation gap itself is small (usually the channel is 50 mm wide), moreover, if one slope is heated by the sun and the other in the shade, then the pressure difference necessary for air movement will only be in the zone one slope, which means the ventilation of the roof will be uneven. Finally, for an attic roof it is easier to create a reliable foundation, since there is space for installing supporting elements (trusses, etc.), while an attic roof most often has to rest only on the mauerlat and ridge.

Decoration of dormer windows

The easiest way to decorate is with the help of a lower and upper cornice. For decoration, it is better to choose the lightest tulle or curtain that will not sag. If they are located almost at the intersection of the fold of the roof, and the curtains are too low, then it is better to fix the cornice higher, even on the ceiling. Decorating with cafe cornices will look impressive, as they do not distract attention from the beauty of the entire structure and curtains, for example, pleated curtains.

design of dormer windows photo

If there is a very large bevel or windows with a large slope, then roller blinds or Roman blinds are suitable. They are convenient because they are easy to open and close, even if the glass unit is tilted, and they do not require careful maintenance. Austrian roller blinds will look beautiful.

If you like an ascetic interior, then you can completely abandon any textiles. On the attic floor, such a solution will look as natural as possible.

Oblique-shaped structures in the attic can be decorated with bending models of cornices made of polymer materials or corner ones with rotating elements.

dormer windows photo design

What features does the attic design have?

Located under the roof itself, the attic design has features that directly affect the windows, which have a slope that determines the shape of the room itself. The roof, in turn, can be pitched with one wall at an angle and gable with two such walls.

In this case, the windows are located at an angle directly on the slope itself (with a pitched roof) or in the straight part of the room (front), although in most cases they have an irregular shape, which cannot but affect the design of the windows. The main thing here is to take into account the irregular shape of the attic, for which classic shapes with straight lines are not acceptable. Typically, roof windows are decorated with cornices and a number of additional elements, which we will discuss in more detail below.

Condensation on roof windows

The appearance of condensation on roof windows in winter is a natural phenomenon. This is due to the large temperature difference between inside and outside. But condensation can also appear for other reasons:

- improper installation of slopes;

- violation or absence of hydro- and thermal insulation of the layer;

- poor insulation or incorrectly selected material for this;

- violation of installation technology.

Poor installation leads to the appearance of cold bridges, after which condensation appears in winter.

The last factor that provokes the appearance of condensation is the defective glass unit itself, which is also characterized by the appearance of liquid between the glasses. The design is subject to free replacement under the manufacturer's warranty.

There are completely harmless reasons that are very easy to eliminate. Condensation may appear if the room is not ventilated. If drops of moisture appear while taking a shower, then this is a natural process. This also applies to rooms where food is prepared. The main thing is that after cooking or taking a shower, condensation does not appear again.

Condensation on roof windows

If condensation appears during and immediately after construction and repair work, this is normal. When building materials dry, a lot of moisture is released. The same situation arises if there are a lot of living plants in a room under the roof. Some of them are prone to releasing excess moisture.

Sealing of joints and junctions

Many years of experience of builders and scientific research show that through loose joints and abutments of the vapor barrier, much more water vapor penetrates into the roof structure than as a result of its diffusion through the vapor barrier layer.

Therefore, it is necessary to properly seal the joints of rolls of vapor barrier film and its junctions with walls, chimneys or ventilation pipes, antennas, and skylights, which is often not done. Moreover, it is important to choose the right material for sealing. To glue the film to a smooth surface (planed wood, metal, plastic), you can use any specialized products - single- and double-sided tapes, adhesives, pastes. If the base is rough (unplaned wood, brick, concrete, plaster), single-sided tapes are unacceptable; double-sided tapes are suitable, but require additional compaction with pressure strips, and the best option is adhesives and pastes. In the case of complex junctions, the highest quality seal is provided by a viscose-based paste: it is applied in two layers, between which a reinforcing mesh made of non-woven polyester is embedded. Let's turn to waterproofing.

When laying diffusion film, it is also necessary to seal the joints and junctions for better protection against leaks and to prevent heat from being blown out of the insulation by air entering the ventilation gap on the eaves overhang. It is not recommended to use vapor-proof films on an attic roof, especially of complex shape: they require two ventilation gaps - above and below the film, and ensuring air flow under the film in the case of a roof that has, for example, a valley is extremely problematic.

To avoid the insulation getting wet due to condensation of water vapor, it is unacceptable to construct a staircase leading from the pool on the lower floor of the house to the attic

As we can see, the normal functioning and durability of the attic roof directly depend on the correct execution of all complex components. Moreover, most of them subsequently turn out to be hidden, and therefore customers have to either rely on the qualifications of roofers, or constantly monitor the construction with the involvement of experts, which significantly increases the cost of constructing an attic. Let us add that experts strongly recommend not to forget about installing a supply and exhaust ventilation system in the attic room, as well as throughout the building as a whole, in order to achieve a good microclimate in the room and protect the roof structure from the pressure of excess water vapor on it.

What to do if it's blowing from the attic window

Blowing is often associated with:

- cheap accessories;

- poor fit of all parts, that is, poor quality manufacturing of the structure;

- poor quality installation.

Problems arise due to insufficient pressure on the sash. If a draft is felt throughout the entire perimeter, then this is the reason. To correct the situation, it must be switched to winter mode.

If you start blowing from under the seal, most likely it has dried out or lost its elasticity. The problem is solved by replacing the seal.

If it blows from the side of the hinges, they need to be tightened. It is necessary to check the structure for the presence of through and oblique holes. They could be made for installing roller shutters or curtains. To prevent blowing from the holes, it is necessary to seal them with sealant.

Is it possible to make it yourself?

You can make a roof window for installation in a pitched roof pie :

- Preliminary development of design solutions.

- Purchase or rent the required set of tools.

- Purchase of the required amount of materials - translucent structures, profile elements or hardwood bars.

- Selection of high-quality fittings with an increased level of reliability.

- Purchase of wear-resistant polymer seals.

- Availability of skills in handling power tools, compliance with safety regulations.

- Thorough execution of a pre-designed technological map.

Before starting work on the manufacture of such translucent structures, it is also recommended to familiarize yourself with master classes from professionals and take into account all the existing nuances in order to avoid gross mistakes.

When is this appropriate?

The manufacture of window structures for subsequent installation in a pitched roof pie is advisable in the following situations :

Carrying out cosmetic repairs that eliminate significant capital investments.- Availability of your own workshop with the necessary equipment at your summer cottage.

- The difficulty of selecting and installing a roof window with modular dimensions due to the functional and planning limitations of the attic floor or roof structure.

- Replacement of a window unit, if it is possible to use some parts from the old structure, after its dismantling.

At the same time, in the following cases, doing such work does not make sense :

- Construction of a new property using new materials, with a complex order of several window structures for the entire house.

- The need to hand over the construction to the state commission, which requires certificates for each product specified in the project.

- The home craftsman does not have a lot of free time, since independent production of a full cycle window, including all preparatory work, takes several working days.

Before making a final decision, it is recommended to evaluate the labor costs and time required to make a structure with your own hands, and then compare the prices for finished structures and the cost of materials.

How to make a roof window with your own hands

The simplest design consists of:

- base plate;

- frames with glass;

- coaming or continuous fencing for the opening.

The support plate is made of sheet steel, its thickness should be from 1 mm to 1.5 mm. It is secured to the supporting structure with nails. It is better to use pine or PVC as a frame. It is better to take tempered glass, in extreme cases, only the top glass, since attic structures are subject to a large load from snow and rain.

Coamings are made from boards with a thickness of 40 mm to 50 mm. To achieve maximum joining in the corners, use waterproof glue. The support plate is attached to the coaming with screws.

The frame must have overlaps on the coaming; if this is not done, rainwater will penetrate into the room. It is necessary to attach sealing tape around the perimeter of the frame and coaming. Glass installation is carried out using putty, with additional fixation with glazing beads.

Before installation work, all wood parts must be impregnated with scrap wood or hot drying oil. Only after the drying oil has completely dried can oil paint be applied.

It’s unlikely that you can make the fittings (self-locking hinges and handles) yourself, so it’s easier to purchase them. The fastening mechanism that is installed on industrial windows can be replaced with a toothed rack.

If you have carpentry skills, you won’t have any problems creating a roof window with your own hands. You can always watch a video that describes the whole process in detail, download photos with drawings. You can also buy a new one, but if you install it yourself, the manufacturer’s warranty will not be provided.

How to correctly calculate the number of windows for an attic?

“In order to have enough light in the attic, you need to follow the main lighting rule when using skylights: according to SNiP 2.08.01-89, for every 10 m² of room there should be 1 m² of glazing (for vertical windows this figure is 1:8). You need to understand that these standards regulate the minimum acceptable level of lighting, so for a children's room, studio or winter garden it is better to provide more windows. For residential premises, it is better to use medium-sized windows: for example, 78*118 cm or 78*140 cm (small windows 60 cm wide are intended for bathrooms and storage rooms).

Since roof windows are made in standard sizes, the area of the light opening can be easily determined from the manufacturer’s table. For example, a 78*118 cm window has a glass area of about 0.6 m² and can illuminate a room of 6 m².” (OK.)

How to insulate roof windows

Before installation, the external flashing is installed from the outside. Thermal insulation material is laid out over the entire area of the slopes inside, without gaps.

The following are used as thermal insulation materials:

- glass wool, which is very soft and elastic, inexpensive and lightweight;

- basalt wool, which is universal, but quite hard;

- expanded polystyrene: durable and inexpensive material, with low thermal conductivity.

After laying the insulation, the installation work is completed by laying the waterproofing.

You cannot use metal elements to install insulation; they will conduct cold air.

Tools and consumables

To make your own window unit, you will need the following set of tools and consumables:

- For taking measurements and marking parts:

- Roulette.

- Building level.

- Carpenter's corner.

- Steel ruler with blade length 1 m.

- Pencil with soft lead.

- For cutting elements:

- Miter box and hacksaw with fine teeth.

- Cross-cutting machine with a lowering working body and a rotating bed.

- Grinder with abrasive disc.

- A file with a coarse abrasive to refine the cutting plane.

- Drill with disc attachment for grinding surfaces.

- Milling cutter for preparing the end when mating wooden profiles using the “groove-tenon” method.

- For assembling a window block:

- Clamps for fixing mating elements in an orthogonal position.

- A screwdriver with a set of bits for mechanical fixing to self-tapping screws.

- A screwdriver with a slotted and Phillips tip for tightening fasteners, as well as for adjusting fittings.

- Rubber hammers for driving in glazing beads that secure double-glazed windows.

- Consumables:

- Two-component adhesive composition based on epoxy resin with a hardener.

- Corners and screws for fastening wood profiles.

- Polymer seals for sealing the joints of moving sashes of a window block.

- Butyl sealant for reliable fastening of double-glazed windows.

- Paint and varnish compositions for surface treatment of wooden profiles.

- Rags and alcohol liquid for degreasing the surface to be treated.

To achieve the expected result, it is recommended to choose tools from trusted brands.

Frame development

Having decided why there is a dormer window on the roof, and having figured out the project, you will need to create a drawing of the window structure, determine the size of the openings, and the location of each product. It is necessary to take into account which side the windows will be turned on, how many of them there will be, and what the under-roof space will be used for.

The width of the auditory opening is calculated taking into account the width of the attic floor: it should be more than half of this parameter.

Choosing an interior style

The only limitation when choosing an interior style for an attic is the specifics of its design. Small cottages look best with laconic and minimalist interiors that create a sense of space. And it is most convenient to work with directions that allow you to leave open beams, communications and complex shapes.

Modern style attic

Modern style balances between solid classics and elegant high-tech. This is what you need to design an elegant and at the same time functional attic. Natural materials are combined with artificial ones, and laconic colors are combined with complex and varied textures.

Classic style attic

The classic style is suitable only for large and spacious attics, so in a small room it is better to combine it with modern elements. Use wood, tiles, stone finishes and textured expensive textiles. This is the best way to recreate the atmosphere of a luxurious country mansion.

Attic in Provence style

When decorating an attic, Provence is not only aesthetically pleasing, but also practical, because it solves several problems at once. Light pastel colors give a feeling of light, air and space even in a small attic room. Natural wood preserves the homely atmosphere, and the beams from the rafter system effectively complement the style of the French province.

Attic in Scandinavian style

Attics are often characteristic of Scandinavian-style houses, so this interior will fit here like home. Keep all shapes and outlines, use natural materials, a light background and a few color accents. Stick to minimalistic furniture and create an atmosphere with cute handmade accessories.

Loft-style attic

Creating loft attics is very convenient, because all communications, beams and complex shapes become an interesting advantage, and not a problem. You don't have to mask the roof structure or completely sheathe the ceiling. The walls also do not have to be leveled and hidden behind plasterboard structures or panels.

80 design ideas for a small children's room (photo)

Design features

An attic can be built in almost any private house, be it a large cottage or a small country house. The shape of the structure can be different - triangular, broken, symmetrical or asymmetrical. The attic part can be located either over the entire area of the house or part of it.

The dimensions of the attic are limited by the perimeter of the house. When drawing up drawings of an attic roof, it is necessary to take into account the load-bearing capacity of the walls and foundation.

The structure may protrude slightly beyond the external walls. In this situation, it is necessary to move the ceilings to an appropriate distance. The latter will serve as support for the attic roof. You can make a large extension, but you will have to build supports.

The minimum height of the attic roof is 2.5 m. If the structure is lower, it will not be possible to create a comfortable living space.

Increased demands are placed on windows. They must have a high-strength frame and double-glazed windows made of tempered glass. This entails additional costs.

You can insulate the entire attic, or only that part of it that is used for residential purposes and is heated. The rafter system of the attic roof must have a high load-bearing capacity. Therefore, you need to use strong rafters, the cross-section of which is determined based on the angle of inclination of the slopes.

But, the minimum cross-section is 50x150 mm for a step of 1 m. If the angle of inclination is 45°, you can use a step of 1.4 m. In this case, climatic conditions must be taken into account. If heavy rainfall is typical in winter, the rafter pitch should not exceed 0.8 m.