To ensure that your home always has an optimal climate in winter and summer, you need to install high-quality double-glazed windows on your windows. This will save electricity consumption on:

- conditioning;

- heating.

It is important to consider all the criteria for choosing double-glazed windows that are suitable for you. Why do you need to know their heat transfer coefficient when choosing double-glazed windows?

If we consider the concept of heat transfer, then it is the transfer of heat from one medium to another. Moreover, the temperature in the one that gives off heat is higher than in the second one. The whole process is carried out through the structure between them.

The heat transfer coefficient of a double-glazed window is expressed by the amount of heat (W) passing through m2 with a temperature difference in two environments of 1 degree: Ro (m2. ̊C/W) - this value is valid on the territory of the Russian Federation. It serves to correctly assess the heat-protective properties of building structures.

General definition of the term

The concept of heat transfer resistance (HTR) is formulated in GOST R 54851-2011. Windows, along with walls, doors, roofing, etc., are structural elements that enclose the internal space to create a comfortable human living environment. STP fencing is the R coefficient, the value of which demonstrates the thermal insulation properties of the structure. The greater the absolute value of R, the less heat loss from the room there will be.

The unit of measurement R in the SI system is [m2* 0С/W]. The value of R is equal to the temperature difference on the outer (Tn) and inner (Tvn) surfaces of the fence for a heat flow Q of 1 W power passing through 1 m2 of thermal protection.

The formula for calculating R is as follows:

R = (Tvn - Tn) / Q

The higher the R value, the less heat loss will be. This formula resembles the expression for Ohm's law, so R is sometimes called thermal resistance, by analogy with the electrical term.

Soundproofing

According to the sound insulation indicator, windows are divided into classes with a reduction in airborne noise from urban traffic flow:

Specification table

| Class | windows with air noise reduction over |

| A | 36 dBA |

| B | 34-36 dBA |

| IN | 31-33 dBA |

| G | 28-30 dBA |

| D | 25-27 dBA |

Specification table Window class with airborne noise reduction over A 36 dBA B 34-36 dBA C 31-33 dBA D 28-30 dBA D 25-27 dBA | |

If a reduction in the airborne noise level of urban traffic flow is achieved in the ventilation mode, the letter “P” is added to the designation of the sound insulation class. For example, the designation of the sound insulation class of a product “DP” means that a reduction in the airborne noise level of urban traffic from 25 to 27 dBA for this product is achieved in the ventilation mode.

Window heat transfer resistance

A modern window (based on plastic, aluminum and even wooden profiles) is a high-tech constructor consisting of elements with different thermal properties.

The total resistance of a window unit is obtained by summing the thermal resistances of its homogeneous components:

- translucent filling (silicate, stained glass, acrylic glass, translucent films, etc.);

- framing elements - profiles made of various materials (wood, aluminum, steel, PVC plastic);

- metal and plastic fasteners.

Main types of double-glazed windows

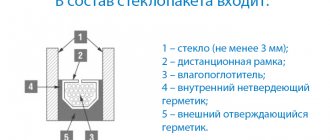

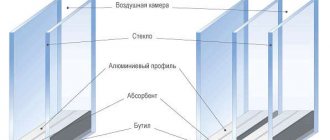

The double-glazed window (IG), being the main part of the window, structurally consists of several glasses connected by metal (intermediate) frames. The space between the glasses is called the chamber.

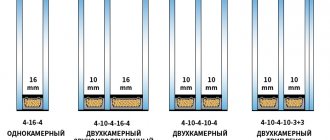

There are three main types of glass packages most often used:

- single-chamber - two glasses (internal and external);

- two-chamber - three glasses (internal, external and intermediate);

- three-chamber - four glasses (internal, external and 2 intermediate).

The thickness of the glass used varies from 4 to 6 mm. For glazing objects with increased strength requirements (high wind loads), glass with a thickness of 8-10 mm can be used. The gap between the glasses can vary - from 8 to 36 mm. The thickness range of double-glazed windows is from 14 to 60 mm.

The FSW of the glass itself is relatively small due to its high thermal conductivity. To reduce heat loss, the space between the glass is filled with air or an inert gas (argon Ar, krypton Kr, nitrogen N2). Gas-filled chambers make the main contribution to increasing the STP of a double-glazed window Rsp. It is also possible to significantly increase the value of Rsp by creating a vacuum in the chamber, but this leads to a sharp increase in the cost of the final product.

According to wind load resistance

Based on wind load resistance, products are divided into classes:

| Class | C resistance to wind load, Pa |

| A | More than 1000 |

| B | 800-999 |

| IN | 60-0799 |

| G | 400-599 |

| D | 200-399 |

| Note: products with wind load resistance below 200 Pa are not assigned a class | |

The specified pressure drops are used when assessing the performance characteristics of products.

Deflections of product parts are determined at pressure drops that are twice the upper limits for the classes specified in the classification.

Reduced heat transfer resistance of windows

To calculate the characteristics of objects being designed and under construction, a value called the reduced heat transfer resistance of window blocks Rpr is used. This is an average value that takes into account the STP of the glass package, window profile and fastening elements. The greater Rpr, the less heat flows through the window “to the side.”

Manufacturers offering their products for glazing work are required to provide thermal insulation parameters in accordance with GOST 30674-99, which applies to window blocks made of PVC profiles. This document specifies the required levels of Rpr for various designs of double-glazed windows based on three-chamber profiles.

Typical values of Rpr are presented in the following table:

| GLASS UNITS | Rpr range |

| For 1-chamber | 0,35 — 0,63 |

| For 2 chamber | 0,49 — 0,56 |

| For 2-chamber with reflective coating | 0,57 — 0,72 |

The values of Rpr are regulated for window openings in which the translucent part is 70% of the total area. In cases where profiles of a different design are used (for example, a different number of chambers), Rpr is determined experimentally using special equipment.

Resistance to climate influences

Depending on resistance to climatic influences, products are divided into types of execution:

Specification table

| Class | Condition |

| normal execution | for areas with an average monthly air temperature in January of minus 20°C and above (control load when testing products or components and parts - no higher than minus 45°C) in accordance with current building codes |

| frost-resistant version (M) | for areas with an average monthly air temperature in January below minus 20°C (control load when testing products or components and parts - no higher than minus 55°C) in accordance with current building codes. |

Specification table Class Condition for normal performance for areas with an average monthly air temperature in January of minus 20°C and above (control load when testing products or components and parts - not higher than minus 45°C) in accordance with the current building codes for frost-resistant design (M ) for areas with an average monthly air temperature in January below minus 20°C (control load when testing products or components and parts - no higher than minus 55°C) in accordance with current building codes. | |

Main dimensions (classification of windows by modular sizes)

The modular overall dimensions of products are based on a building module equal to 100 (mm) and denoted by the letter M.

Recommended (main) modular dimensions of products: width - 6M;

7M; 9M; THEM; 12M; 13M; 15M; 18M; 21M; 24M; 27M; height - 6M; 9M; 12M; 13M; 15M; 18M; 21M; 22M; 24M; 28M. Table of modular product sizes

| 570 | 720 | 870 | 1170 | 1320 | 1470 | 1770 | 2070 | 2370 | 2670 | |

| 580 | 6-6 | 6-7 | 6-9 | 6-12 | 6-13 | 6-15 | — | — | — | — |

| 860 | 9-6 | 9-7 | 9-9 | 9-12 | 9-13 | 9-15 | — | — | — | — |

| 1160 | 12-6 | 12-7 | 12-9 | 12-12 | 12-13 | 12-15 | 12-18 | 12-21 | 12-24 | 12-27 |

| 1320 | 13-6 | 13-7 | 13-9 | 13-12 | 13-13 | 13-15 | 13-18 | 13-21 | 13-24 | 13-27 |

| 1460 | 15-6 | 15-7 | 15-9 | 15-12 | 15-13 | 15-15 | 15-18 | 15-21 | 15-24 | 15-27 |

| 1760 | — | 18-7 | 18-9 | 18-12 | 18-13 | 18-15 | 18-18 | 18-21 | 18-24 | 18-27 |

| 2060 | — | 21-7 | 21-9 | 21-12 | 21-13 | 21-15 | 21-18 | 21-21 | 21-24 | 21-27 |

| 2175 | — | 22-7 | 22-9 | 22-12 | 22-13 | 22-15 | 22-18 | — | — | — |

| 2375 | — | 24-7 | 24-9 | 24-12 | 24-13 | 24-15 | 24-18 | — | — | — |

| 2755 | — | — | 28-9 | 28-12 | 28-13 | 28-15 | 28-18 | — | — | — |

Heat transfer resistance coefficient of double-glazed windows

In the accompanying documentation for the finished product, Rcп is often called the heat transfer resistance coefficient (HTTC), which is equal to the amount of heat passing through one square meter of glass unit area with a temperature difference of one degree (Celsius or Kelvin). The physical meaning and dimension of these quantities (HTP and KSTP) absolutely identical. GOST 24866-99, which has the status of an interstate standard, does not use the word “coefficient” for this parameter.

Table 4 of this document presents the basic requirements for Rcп:

| Double-glazed window | Number of cameras | Rc p , not less, m2* 0С/W |

| General construction purposes | 1-chamber 2-chamber | 0,32 0,44 |

| Impact resistant | 1-chamber 2-chamber | 0,32 0,44 |

| Sun protection | 1-chamber 2-chamber | 0,32 0,44 |

| Energy saving | 1-chamber 2-chamber | 0,58 0,72 |

| Frost-resistant | 1-chamber 2-chamber | 0,58 0,72 |

| Noiseproof | 1-chamber 2-chamber | 0,32 0,44 |

Air and water permeability

Based on air and water permeability, windows are divided into classes:

Specification table

| Class | Volumetric air permeability at DP = 100 Pa, m3/(h?m2) for constructing standard class boundaries | Water resistance limit, Pa, not less |

| A | 3 | 600 |

| B | 9 | 500 |

| IN | 17 | 400 |

| G | 27 | 300 |

| D | 50 | 150 |

Specification table Class Volumetric air permeability at DP = 100 Pa, m3/(h?m2) for constructing standard class boundaries Water tightness limit, Pa, not less than A 3,600 B 9,500 B 17,400 D 27,300 D 50,150 | ||

Additional ways to reduce heat loss

An impressive reduction in heat loss can be achieved using special coatings. An ultra-thin layer of metal oxides is applied to the inner surface of the glass, which guarantees its safety during operation. This additional film completely transmits visible light, but at the same time acts as a kind of “mirror” that reflects electromagnetic radiation in the infrared (IR) range. As is known from physics, heated bodies emit a significant part of their internal energy in this region of the spectrum.

There are two types of glass with additional coating:

- k-glass - obtained by applying metal oxides. A coating with a thickness of 0.4-0.5 microns has virtually no effect on the light transmission of the window;

- i-glass is a more complex technology, which means the glass is more expensive. The film is obtained by double deposition in a vacuum of several alternating layers: layers of pure metal are deposited between the oxide layers (usually silver 10-15 nanometers thick is used).

The use of such coatings can reduce heating costs by 15-20%.

Which aluminum windows are warmer?

Aluminum is considered the coolest material for windows. Its thermal conductivity is a thousand times greater than that of wood or plastic. But modern aluminum windows are easy to make warm. To do this, a thermal break (or thermal bridge) must be installed inside the profile.

Photo: The thermal bridge can have different widths and additional insulation, © alutex The central part of the aluminum profile (thermal bridge) is made of polyamide. Thermal bridges vary in width - the wider it is, the warmer the profile. Each aluminum profile manufacturer offers thermal bridges in several sizes. In some systems, polyurethane foam inserts are installed in the internal chambers and thermal bridge for additional insulation. As a result, premium aluminum profiles provide better thermal insulation than wood or plastic.

Double-glazed windows

The double-glazed window plays a key role in the heat conservation of the window, as it occupies 75-90% of the area.

| A double-glazed window is a sealed combination of several glasses separated by spacer frames. |

Thermal insulation of double-glazed windows depends on the type of glass, the material of the frames and the filling of the space between the glasses. If you change the components, you can significantly increase the thermal insulation of the double-glazed window and the window as a whole.

Photo: a double-glazed window may have one, two or even three air chambers, © oknamedia

Double-glazed windows in the window are:

- Single-chamber double-glazed windows (2 glasses) are more suitable for non-residential premises and summer cottages.

- Double-glazed windows (3 glasses) are a standard position for apartments and residential buildings.

- Three-chamber double-glazed windows (4 glasses) are still not widespread on the window market. Their installation leads to a significant weighting of the structure and an increase in cost. 3-chamber double-glazed windows are installed in “passive” houses, where energy use for heating is minimized.

Its heat saving performance largely depends on what kind of glass is used in a double-glazed window.

Sputtered glass or heat-saving glass has made an evolutionary leap in energy saving. Regular glass is at least 65% cooler than heat-saving glass (I-glass or multifunctional glass).

The heat-saving category includes glass with low-emissivity and multifunctional coating.

Low-emissivity (I-glass) reflects thermal radiation back into the room. It is installed first on the side of the room with the coating inward (if there is only one in a double-glazed unit) or first on the side of the room and street with the coating inward (if there are 2 of them).

The use of 2 energy-saving glasses and argon in a 2-chamber double-glazed window makes it almost 2.7 times warmer than usual.

Read more about the properties of I-glass here

Let's consider what heat transfer resistance indicators do double-glazed windows have (using the example of the most popular 2-chamber ones) with different glasses and filling the inter-glass space.

Dependence of the heat transfer resistance coefficient of a double-glazed window on the glass used and filling

| Formula of 2-chamber double-glazed windows (3 glasses) | R glass unit, m2•°C/V t |

| 2-chamber with conventional glasses Formula (4 x 12 x 4 x 12 x 4) | 0,53 |

| 2-chamber with I-glass Formula (4 x 12 x 4 x 12 x 4I) | 0.81 (+65% to regular 2-chamber) |

| 2-chamber with 2 I-stacks Formula (4I x 12 x 4 x 12 x 4I) | 1.04 (+96% to normal 2-chamber) |

| 2-chamber with multi and I-glass and argon Formula (4MF x 12Ar x 4 x 12Ar x 4I) | 1.45 (+173% to the usual 2-chamber) |

| 4 – ordinary glass 4mm 4I – low-emissivity glass 4mm 4MF – multifunctional glass 4mm 12 – width of the spacer frame, distance between glasses 12Ar – filling the air chamber with argon R – calculated value of the heat transfer resistance coefficient for the central part of the glass unit | |

Multifunctional glass is used in windows that face the sunny side. It retains heat in winter and protects against heating the room in summer, thereby reducing air conditioning costs. It is installed first on the street side. Can be combined in one double-glazed window with I-glass.

Read more about the properties of multifunctional glass here

| Important! The thickness of the glass does not in any way affect the thermal insulation capacity of the glass unit. |

How to calculate the thermal conductivity of a double-glazed window

Thermal conductivity is a physical quantity that characterizes the ability of a substance or body to conduct heat. The greater its value, the faster the transfer of heat from a body with a higher temperature to a lower one. That is, the thermal conductivity coefficient K is the reciprocal of R0 - FSW adopted for use in Russia.

The lower K, the better the thermal insulation properties of the structure. The K coefficient is used in standards and norms developed by DIN (German Institute for Standardization), which has the status of the leading standardization body in Europe.

For approximate calculations, you can use the formula:

K = 1 / R0

Dimension K in the SI system is [W/m2*/0С]. Some manufacturers present an online calculator on their websites, with which a potential buyer can calculate the characteristics of a future window opening with individual (“customized”) parameters.

Which windows are the warmest - plastic, wooden or aluminum?

Photo: dependence of heat loss and heat transfer resistance coefficient (Rpr) on the material and composition of the window, © oknamedia

Conclusion: a 2-chamber double-glazed window with 2 I-glasses (or 1 I-glass and multifunctional, plus argon filling) gives the highest heat saving performance. Profiles of 80 mm in plastic, 78 mm in wood and 72 mm (or 112 mm) with thermal bridge and insulation in aluminum are necessary for the warmest windows.

Don't forget to include in the package of a warm double-glazed window:

- Warm spacer. Regular aluminum frames conduct heat well. Along the perimeter of the glass unit, an “edge effect” occurs - a zone with a lower temperature than in the center of the glass. This is where condensation falls first and ice can form. Plastic frames solve the problem and reduce the “edge effect”. They are recommended for use in warm double-glazed windows.

- Inert gas. Dry air is a sufficient heat insulator in itself. If the air inside the glass unit is replaced with an inert gas (argon, krypton), then the thermal insulation of the glass unit will increase by about 10%.

Accessories

If your warm windows have a wide and warm profile and energy-saving double-glazed windows installed, but the fittings are of poor quality, then all attempts to retain heat will be in vain.

The fittings in the window are responsible for the tight pressing of the sash to the frame and for the absence of blowing.

Photo: strike plate + locking pin = clamping point, © Roto To ensure the required clamping, it is important to follow the manufacturers' recommendations - the distance between the pressing points of the sash to the frame should be within 500-700 mm.

A distance greater than 700 mm, as well as the absence of pressure points on the horizontal parts of a sash longer than 700 mm, will lead to blowing.

Blowing occurs from under the top hinge - it pinches the seal. As a result of which blowing is formed, it is better to choose hidden loops.

Photo: hidden hinges eliminate blowing in the upper part of the window, © oknamediaFittings for a warm window:

- European manufacturer.

- The distance between the pressure points is no more than 700mm.

- Hidden loops.

Sealant

The seal is the “last barrier” to completely sealing your windows. If the seal is of poor quality, then there will be air from the windows and it will be uncomfortable.

The seal closes the gap between the sash and the frame. The main condition for its high-quality work is maintaining elasticity and the ability to restore its shape after long compression. Not all seals are able to do this over a long period of window service. Poor quality sealant dries out quickly and becomes deformed.

Silicone and EPDM seals remain elastic the longest. They should be given preference when choosing windows.

Photo: if the seal begins to delaminate, it’s time to change it, © oknamedia Installation

The joints of building elements are always the most problematic from the point of view of heat conservation. They most often begin to blow. Therefore, it is important to install a warm window correctly.

The thermal insulation layer of the installation seam is responsible for retaining heat at the junction of the window and the wall. Most often it is made of polyurethane foam, but it can be filled with thermo-Flax and other materials. Problems with blowing and freezing of the assembly seam may arise if:

- The foam is applied with gaps.

- Air bubbles in poor quality foam are too large. When cutting off the excess, a through hole may form. A hole even 1 mm in size will lead to blowing.

- The foam has become wet from precipitation or vaporous moisture from the room. Wet foam is unable to retain heat.

- The foam collapsed from exposure to ultraviolet radiation.

Photo: the foam must be protected from getting wet from the outside and indoors, © robitex The installation seam according to GOST for a warm window must consist of three layers. The foam must be protected from moisture and ultraviolet radiation on all sides. The good news is that windows can be installed in winter. This is a good time, since all the shortcomings are immediately visible.

Robitex is an expert in the production of installation tapes on the Russian window market. The company has been producing materials for window installation in accordance with GOST for more than 25 years.

Robiband tapes from the Robitex company retain their properties in the temperature range from -40° to + 80°C, and installation with them can be carried out even in -20°C frost.

Installation of plastic slopes can be done immediately, while the foam is still wet, which is impossible to do with other materials for sealing the seam. Installation materials from Robitex have been tested at the Institute of Window Technology in Rosenheim (IFT Rosenheim Germany).

The installation seam for a warm window is made of high-quality materials:

- High quality foam with small bubble diameter.

- On the inside there is a vapor barrier layer, for example, the universal tape Robiband VM. This tape fits both under the plaster slope and under the slope panel, and is securely glued to the opening and window.

- On the outside - a vapor-permeable self-expanding sealing tape, for example, Robiband PSUL. For damaged and uneven slopes, it is better to use Robiband KMP tape with a plastic strip. It serves as a “beacon” for further plastering.

Reminder for choosing the warmest window

| Window component | What to choose |

| PVC plastic window profile | Width/number of cameras: ✔ Apartments, cottages, loggias with regular windows – from 70mm/5 cameras ✔ Apartments with panoramic windows from 75mm/from 5 cameras ✔ Country houses – 80 mm from 6 cameras |

| Wooden profile of a wooden window | Pine, at least 78mm wide |

| Aluminum aluminum window profile | Warm, width from 72mm, thermal bridge at least 34mm with insulation inside |

| Accessories | High-quality fittings Hidden hinges |

| Sealant | EPDM or silicone |

| Double-glazed window | 2-chamber with chambers filled with argon Choice of glass: For apartments with windows of standard sizes ✔1 I-glass or multifunctional glass For apartments with panoramic windows and country houses ✔2 I-glass or 1 I-glass + 1 multifunctional glass, Distance frame – warm, plastic |

| Installation according to GOST | 3-layer seam according to GOST External mounting tapesRobiband ✔ Window opening with a quarter – Robiband PSUL, Robiband KMP ✔ Window opening without a quarter – Robiband NL diffusion tape ✔ Destroyed and uneven window openings – Robiband KMP ✔ Low tide – Robiband NL diffusion tape Sound insulation of ebb - Robiband PBT (adheses to ebb) or PSUL |

Robiband tapes from the manufacturer |