Thermal conductivity of a plastic window, thermal conductivity of a double-glazed window compared to wall materials

The better the house is insulated, the less it needs to be heated in cold weather.

What is more profitable: thoroughly insulating the house or not spending money on it? You will save money, but then for many years in the winter you will be, as they say, warming the atmosphere, that is, throwing money down the drain, in the literal sense of the word.

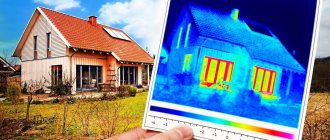

So, first of all, you need to figure out how much heat your house loses (this also applies to a newly designed home). If you look at a residential building through a night vision device, you can see, as they say, with your own eyes, how it loses heat - not very much through the walls, even less through the roof; strong heat emissions come through the windows; Heat also goes into the ground, although our device will not show this.

Heat escapes through (blue areas are “cold” and red areas are “hot”):

- Walls ~ 30%;

- roofing ~ 14%;

- gender ~ 12%;

- windows ~ 44%.

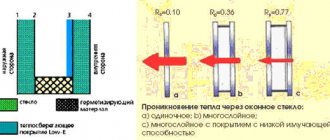

Important! Only 30% of all losses through windows are due to convection (heat transfer by air currents within the glass unit) and heat transfer (heat transfer through the solid material of the window), and 70% of all losses through windows are due to long-wave infrared thermal radiation through glass , which can and should be prevented, and you can learn how to do this from this article.

Calculation of thermal conductivity coefficient

K or thermal conductivity coefficient is expressed by the amount of heat in W passing through 1 m2 of the building envelope with a temperature difference in both environments of 1 degree on the Kelvin scale.

And it is measured in W/m2. The thermal conductivity of a glass unit shows how effective insulating properties it has. A small k value means little heat transfer and therefore little heat loss through the structure. At the same time, the thermal insulation properties of such a double-glazed window are quite high.

However, a simplified conversion of k to Ro (k=1/Ro) cannot be considered correct. This is due to the difference in measurement methods used in the Russian Federation and other countries. The manufacturer provides consumers with a thermal conductivity indicator only if the product has passed mandatory certification.

Metals have the highest thermal conductivity, and air the lowest. It follows from this that a product with many air chambers has low thermal conductivity. Therefore, it is optimal for users using building structures.

Comparative table of double-glazed windows efficiency

| Glass unit formula (“k” - K-glass, “a” - argon) | Thickness, mm | How much “warmer”, % | How much “quieter”, % | How much more expensive, % | Resistance heat transfer, m2*C/W | Soundproofing, dBA |

| 4 — 6 — 4 | 14 | -15% | -16% | 0,308 | 30 | |

| 4 — 8 — 4 | 16 | -9% | -13% | 0,33 | 30 | |

| 4 — 10 — 4 | 18 | -4% | -10% | 0,347 | 30 | |

| 4 — 12 — 4 | 20 | -1% | -6% | 0,358 | 30 | |

| 4 — 16 — 4 | 24 | 0,361 | 30 | |||

| 4 — 14 — 4 | 22 | 0% | -3% | 0,362 | 30 | |

| 4 - 6 - 4k | 14 | 7% | 46% | 0,386 | 30 | |

| 4k - 6 - 4k | 14 | 11% | 107% | 0,4 | 30 | |

| 4 - 8 - 4k | 16 | 24% | 49% | 0,446 | 30 | |

| 4 — 6 — 4 — 6 — 4 | 24 | 25% | 32% | 39% | 0,452 | 34 |

| 4k - 8 - 4k | 16 | 30% | 111% | 0,469 | 30 | |

| 4 - 6a - 4k | 14 | 31% | 66% | 0,472 | 30 | |

| 4 — 8 — 4 — 8 — 4 | 28 | 37% | 41% | 46% | 0,495 | 35 |

| 4 - 10 - 4k | 18 | 38% | 52% | 0,498 | 30 | |

| 4k - 6a - 4k | 14 | 39% | 127% | 0,5 | 30 | |

| 4 — 9 — 4 — 9 — 4 | 30 | 42% | 41% | 49% | 0,512 | 35 |

| 4 - 16 - 4k | 24 | 45% | 62% | 0,524 | 30 | |

| 4 - 12 - 4k | 20 | 46% | 55% | 0,526 | 30 | |

| 4 - 6 - 4 - 6 - 4k | 24 | 46% | 32% | 101% | 0,526 | 34 |

| 4 — 10 — 4 — 10 — 4 | 32 | 47% | 52% | 52% | 0,529 | 36 |

| 4 - 14 - 4k | 22 | 47% | 59% | 0,529 | 30 | |

| 4k - 10 - 4k | 18 | 47% | 114% | 0,532 | 30 | |

| 4 - 8a - 4k | 16 | 51% | 69% | 0,546 | 30 | |

| 4 — 12 — 4 — 12 — 4 | 36 | 54% | 62% | 59% | 0,555 | 37 |

| 4k - 16 - 4k | 24 | 55% | 124% | 0,559 | 30 | |

| 4 — 14 — 4 — 14 — 4 | 40 | 55% | 74% | 65% | 0,561 | 38 |

| 4k - 12 - 4k | 20 | 57% | 117% | 0,565 | 30 | |

| 4k - 14 - 4k | 22 | 57% | 120% | 0,565 | 30 | |

| 4k - 8a - 4k | 16 | 64% | 131% | 0,592 | 30 | |

| 4 - 10a - 4k | 18 | 67% | 72% | 0,602 | 30 | |

| 4 - 8 - 4 - 8 - 4k | 28 | 68% | 41% | 108% | 0,606 | 35 |

| 4 - 6 - 4k - 6 - 4k | 24 | 68% | 32% | 163% | 0,606 | 34 |

| 4 - 16a - 4k | 24 | 69% | 82% | 0,61 | 30 | |

| 4 - 14a - 4k | 22 | 71% | 79% | 0,617 | 30 | |

| 4 - 12a - 4k | 20 | 72% | 75% | 0,621 | 30 | |

| 4 - 9 - 4 - 9 - 4k | 30 | 78% | 41% | 111% | 0,641 | 35 |

| 4 - 6a - 4 - 6a - 4k | 24 | 78% | 32% | 121% | 0,641 | 34 |

| 4k - 10a - 4k | 18 | 85% | 134% | 0,667 | 30 | |

| 4k - 16a - 4k | 24 | 85% | 143% | 0,667 | 30 | |

| 4 - 10 - 4 - 10 - 4k | 32 | 87% | 52% | 114% | 0,676 | 36 |

| 4k - 14a - 4k | 22 | 88% | 140% | 0,68 | 30 | |

| 4k - 12a - 4k | 20 | 90% | 137% | 0,685 | 30 | |

| 4 - 12 - 4 - 12 - 4k | 36 | 101% | 62% | 120% | 0,725 | 37 |

| 4 - 8 - 4k - 8 - 4k | 28 | 101% | 41% | 169% | 0,725 | 35 |

| 4 - 8a - 4 - 8a - 4k | 28 | 104% | 41% | 127% | 0,735 | 35 |

| 4 - 9a - 4 - 9a - 4k | 30 | 115% | 41% | 131% | 0,775 | 35 |

| 4 - 6a - 4k - 6a - 4k | 24 | 115% | 32% | 203% | 0,775 | 34 |

| 4 - 10a - 4 - 10a - 4k | 32 | 125% | 52% | 134% | 0,813 | 36 |

| 4 - 10 - 4k - 10 - 4k | 32 | 131% | 52% | 176% | 0,833 | 36 |

| 4 - 12a - 4 - 12a - 4k | 36 | 137% | 62% | 140% | 0,855 | 37 |

| 4 - 12 - 4k - 12 - 4k | 36 | 154% | 62% | 182% | 0,917 | 37 |

| 4 - 8a - 4k - 8a - 4k | 28 | 157% | 41% | 209% | 0,926 | 35 |

| 4 - 10a - 4k - 10a - 4k | 32 | 192% | 52% | 216% | 1,053 | 36 |

| 4 - 12a - 4k - 12a - 4k | 36 | 218% | 62% | 222% | 1,149 | 37 |

Explanations and symbols: In the column “glass unit formula” the thickness in millimeters of its “components” is indicated, where 4 mm glass is separated from each other by air layers (chambers) filled with ordinary air or argon (where the letter “a” is indicated).

K-glass is energy-saving low-emissivity glass, which differs from ordinary glass by a special transparent coating made of metal oxides InSnO2. This coating reflects long-wave thermal radiation back into the room. While the emissivity value of plain glass is 0.84, K-glass is usually around 0.2. This means that K-glass returns approximately 70% of the thermal radiation that hits it into the room. At the same time, K-glass can protect the room from heating in hot sunny weather, also reflecting most of the heat waves.

There is even more efficient low-emissivity i-glass (they are not in the table). It is approximately one and a half times more efficient than K-glass and has an emissivity value of up to 0.04.

How is the indicator measured (resistance to heat transfer coefficient R0)

Heat loss is sometimes quantified in terms of the thermal resistance of the glass unit or the heat transfer resistance coefficient R0. This value is the inverse of the heat transfer coefficient U. R = 1/U (when converting European U coefficients to Russian R0, one should not forget that the external temperatures used for calculations are very different).

In turn, the heat transfer coefficient U characterizes the ability of a structure to transfer heat. The physical meaning is clear from its dimension. U = 1 W/m2C – heat flux of 1 Watt passing through a square. meter glazing with a temperature difference (outside and inside) of 1 degree Celsius (In European countries, the thermal conductivity of glazing is calculated according to EN 673). The smaller the resulting number, the better the thermal insulation function of the translucent structure.

Reliable manufacturing companies of translucent structures make the coefficient of resistance to heat transfer of a double-glazed window depend not only on the quality of the structure itself, but also on the use of special technological operations during the manufacturing process, for example, applying a special magnetron, sun-protective and energy-saving coating on the surface of the glass, special sealing technologies, filling the space between the glass with inert gases, etc.

As a result, this indicator characterizes not only the specific thermal protection function, but also the quality of the entire production process and the quality of the finished product. It is recommended to keep this value under control and measure it regularly - both at various stages of production and, with special care, on finished product samples.

Selection of windows, depending on the region of residence

How to choose a window depending on the region of your residence?

What parameters should influence your choice, what is the difference between cities located in the same country, but in completely different regions and climatic zones?

Let's take it in order.

A window is a structure consisting mainly of a window frame (the frame and sash can be made of PVC, wood or “warm” aluminum) and a double-glazed window. Each of these materials has its own energy efficiency (thermal insulation) indicators, which must be taken into account when choosing a window design specifically for your region.

The main task of modern windows is to protect the room from cold and extraneous sounds from the street without sacrificing translucency. Protection from the cold is achieved through window insulation that is necessary and sufficient for a given region.

Thermal insulation is one of the main functions of a window, which ensures comfortable indoor conditions.

In Russia, to assess the thermal protection characteristics of structures, the heat transfer resistance Ro (m²•°C/W) is accepted, a value inverse to the thermal conductivity coefficient k, which is adopted in DIN standards.

Thermal conductivity coefficient k characterizes the amount of heat in watts (W) that passes through 1 m² of a structure with a temperature difference on both sides of one degree on the Kelvin scale (K), the unit of measurement is W/m² K. The lower the value of k, the less heat transfer through the structure , i.e. its insulating properties are higher.

And vice versa (for Russia), the greater the heat transfer resistance Ro (m²•°C/W), the better the thermal insulation properties of the window. It is necessary to understand this and use it when choosing a window.

What factors influence the value of the window's heat transfer resistance Ro (m²•°C/W)?

•window dimensions (the larger the window dimensions, the greater the heat loss and the worse the thermal insulation);

•cross section of the frame and sash (the thicker the section of the sash/frame, the greater their heat transfer resistance and the entire window as a whole);

•window block material (different materials have different Ro (m²•°C/W); wood, PVC, “cold” aluminum, “warm” aluminum with a thermal bridge);

•type of double-glazed window (including the width of the remote frame of the double-glazed window, the presence of selective glass and special gas in the double-glazed window, the number of chambers);

•the number and location of seals in the frame/sash system (the better and tighter the seals fit, the less possible blowing).

The temperature of the surface of the enclosing structure facing the interior of the room also depends on the value of the Ro indicators. When there is a large temperature difference, heat is radiated towards the cold surface.

Poor thermal insulation properties of windows inevitably lead to the appearance of cold radiation in the window area and the possibility of condensation on the windows themselves or in the area where they adjoin other structures. Moreover, this can happen not only as a result of low heat transfer resistance of the window structure, but also due to poor sealing of the joints of the frame and sash.

From this we can conclude: the heat transfer resistance Ro m²•°C/W of a window primarily influences its choice. The heat transfer resistance Ro for a window is calculated based on the climatic parameters of the region of residence, and can vary greatly:

| City name | Duration of the heating period in degree days | Minimum required reduced heat transfer resistance of a window frame, m2 •ºС/W |

| Krasnodar | 2 682 | 0,35 |

| Lipetsk | 4 727 | 0,50 |

| Moscow | 4 943 | 0,56 |

| Khabarovsk | 6 182 | 0,61 |

| Murmansk | 5 985 | 0,60 |

| Surgut | 6 321 | 0,62 |

| Novosibirsk | 6 606 | 0,63 |

| Blagoveshchensk | 6 671 | 0,65 |

| Yakutsk | 10 394 | 0,78 |

When manufacturing products, window companies first of all take into account the region in which their products will be used. When experts calculate the level of climate severity in a region, they use a special formula to find the numerical value of the duration of the heating period in degree days. The higher the numerical value of this parameter, the longer the cold.

Window profiles (PVC, wood, “warm” aluminum) must have reduced heat transfer resistance values that correspond to the climate.

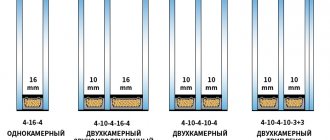

The window frame, of course, is important for the manufacture of a high-quality window, but do not forget about the double-glazed window. It occupies about 80% of the entire window area. Depending on how many glasses are used in a double-glazed window, a distinction is made between single-chamber (two glasses and one air chamber between them) and two-chamber (three glasses and two air chambers).

Ordinary glass serves as a weak barrier to the loss of energy received from heating devices (over 40% of heat passes through ordinary glass), and it weakly prevents excess solar energy from entering the bedroom (ordinary glass allows over 80% of solar heat to pass through).

Therefore, a single-chamber double-glazed window made of two ordinary glasses is not the best choice for Russia, since at an outside temperature of –26ºС and an air temperature in the room of +20ºС, the glass surface temperature on the room side will not be higher than +5ºС.

It will seem like it is blowing from the window. In fact, this is a convection (heat exchange) draft, which will result in the appearance of moisture (condensation) on the surface of the window (as was written about earlier).

To reduce the cost of heating and air conditioning, so-called “selective” glasses were developed: I, K and other types of glass. Their manufacturing technology involves industrially applying special optical (transparent) coatings to the surface of ordinary glass, which do not allow cold and heat to pass through, and also, by reflecting infrared (heat) rays, maintain the internal temperature of the room at a comfortable level. The difference between them lies in the chemical composition of the coatings and their effectiveness.

I-glass is more efficient. Silver oxide is applied to its surface as a coating. Thanks to this, the material has a very good value of reduced heat transfer resistance (2.5 times greater than that of ordinary glass) and reflects almost 80% of long-wave (infrared) radiation.

Installing I-glass as internal glass in a double-glazed window will significantly increase its overall energy efficiency:

| Type of window frame (types of frames are given conditionally) | Reduced window heat transfer resistance, m²•°C/W | |||

| With single-chamber double-glazed windows, 24 mm, both glasses are ordinary | With double-glazed windows, 24–32 mm, all glasses are ordinary | With single-chamber double-glazed windows, 24 mm, I-glass and regular | With double-glazed windows, 24-32 mm, K-glass and ordinary | |

| "Standard" | 0,39 | 0,51–0,53 | 0,61 | 0?79–0,81 |

| "Average" | 0,4 | 0,52–0,54 | 0,63 | 0,81–0,83 |

| "Wide" | 0,41 | 0,53–0,55 | 0,65 | 0,83–0,87 |

The table shows that a single-chamber double-glazed window with 1st glass is almost equal in energy saving to a 2-chamber double-glazed window with ordinary glass. At the same time, the weight of the glass unit remains the same. This reduces the load on the fittings. This means it increases its service life. But it is necessary to take into account that a double-glazed unit with I glass is more expensive than a regular one.

Before purchasing and installing a translucent structure (window), first decide on the type of window profile (PVC, wood, “warm”, “cold” aluminum).

Check with the manufacturer whether this profile is suitable for your region based on heat transfer resistance Ro (m²•°C/W). The choice of double-glazed windows is the second important point; check with the manufacturer which double-glazed windows can be installed on the profile system you have chosen.

And don’t forget to evaluate the ratio of price, quality and overall thermal insulation of the window you choose.

Heat transfer rate of the profile system

GOST 30673-99 specifies the requirements for the energy efficiency of PVC structures:

- 3-chamber PVC profiles - 0.6-0.69 (m2•°C)/W.

- 4-chamber PVC profiles - 0.7-0.79 (m2•°C)/W.

- 5-chamber PVC profiles more than 0.80 (m2•°C)/W.

Since the frames with sashes take up approximately 30% of the entire opening area, the window’s heat transfer coefficient depends by about a third on the properties of the plastic profile. The characteristics of PVC structures are influenced by how many chambers the profile has, how thick the external and internal walls are, whether reinforcement is present and at what depth the windows are installed.

Useful information and recommendations

It is important to note that construction experts distinguish several types of resistance, namely:

- given;

- thermal;

- normative.

” alt=””> They all differ in measurement characteristics, as well as in the way they provide heat transfer. Let's look at each of them in detail. First of all, it should be said that today on the territory of our state there are normative and technical documentation that establishes requirements for the thermal protection of structures (Code of Rules 50.13330.2012).

Basic values of required resistance for structures

Similar articles

about the author

Reduced heat transfer resistance of windows

To calculate the characteristics of objects being designed and under construction, a value called the reduced heat transfer resistance of window blocks Rpr is used. This is an average value that takes into account the STP of the glass package, window profile and fastening elements. The greater Rpr, the less heat flows through the window “to the side.”

Manufacturers offering their products for glazing work are required to provide thermal insulation parameters in accordance with GOST 30674-99, which applies to window blocks made of PVC profiles. This document specifies the required levels of Rpr for various designs of double-glazed windows based on three-chamber profiles.

Typical values of Rpr are presented in the following table:

| GLASS UNITS | Rpr range |

| For 1-chamber | 0,35 — 0,63 |

| For 2 chamber | 0,49 — 0,56 |

| For 2-chamber with reflective coating | 0,57 — 0,72 |

The values of Rpr are regulated for window openings in which the translucent part is 70% of the total area. In cases where profiles of a different design are used (for example, a different number of chambers), Rpr is determined experimentally using special equipment.

Glass Density

It should be noted that the density of glass depends on temperature. When glass is heated, its density decreases due to an increase in volume due to thermal expansion. During the heating process, the density of glass decreases by an average of 7.5 kg/m 3 for every 50 degrees of temperature.

Heat treatment also affects the density of glass. During the process of tempering and annealing glass, its internal structure changes. During hardening, the state of the high-temperature structure of the melt is fixed, which has a larger volume than the structure of glass subjected to prolonged annealing. As a result of heat treatment, the density of tempered glass becomes 4-5% lower compared to annealed glass.

The density of glass or glass products can be determined experimentally with high accuracy using the pycnometer method or using hydrostatic balances. The hydrostatic weighing method is based on Archimedes' law and comes down to determining the volume of liquid displaced by glass.

Glass density in kg/m3

| Type of glass | Glass density, kg/m 3 | Type of glass | Glass density, kg/m 3 |

| Aluminosilicate (20% Al2O3) | 2530 | Sodium-calcium silicate | 2400-2550 |

| Borosilicate heat resistant | 2200-2400 | Ordinary | 2400-2800 |

| Vikor | 2180 | Pyrex | 2230-2250 |

| High lead | 5400-6200 | Lead silicate (21% PbO) | 2860 |

| Quartz | 2200 | Flintglass | 3900-5900 |

| Window glass | 2470 | Crystal | 2600-4000 |

The following table shows the density of optical colorless glass of common brands according to GOST 3514 at room temperature.

Density of optical glass of common brands

| Glass brand | Density, kg/m 3 | Glass brand | Density, kg/m 3 |

| LK3 | 2460 | K14 | 2530 |

| LK4 | 2330 | K19 | 2620 |

| LK6 | 2300 | BC4 | 2760 |

| LK7 | 2300 | BC6 | 2860 |

| FC14 | 3390 | BK8 | 2850 |

| K8 | 2520 | BK10 | 3120 |

| BK13 | 3040 | TK2 | 3200 |

| TK4 | 3580 | TK8 | 3610 |

| TK12 | 3060 | TK13 | 3440 |

| TK14 | 3510 | TK16 | 3560 |

| TK17 | 3660 | TK20 | 3580 |

| TK21 | 3980 | TK23 | 3240 |

| STK3 | 3910 | STK7 | 4220 |

| STK9 | 4110 | BF11 | 3660 |

| STK12 | 3460 | BF12 | 3670 |

| STK19 | 4090 | BF13 | 3820 |

| KF4 | 2570 | BF16 | 4020 |

| KF6 | 2520 | BF21 | 3560 |

| KF7 | 2510 | BF24 | 3670 |

| BF1 | 2670 | BF25 | 3470 |

| BF6 | 3160 | BF28 | 3960 |

| BF7 | 3230 | TBP4 | 4460 |

| BF8 | 3280 | LF5 | 3230 |

| LF9 | 2610 | LF10 | 2730 |

| F1 | 3570 | F4 | 3670 |

| F6 | 3480 | F9 | 2930 |

| F13 | 3630 | TF1 | 3860 |

| TF2 | 4090 | TF3 | 4460 |

| TF4 | 4650 | TF5 | 4770 |

| TF7 | 4520 | TF8 | 4230 |

| TF10 | 5190 | OF1 | 2560 |

Technical characteristics of double-glazed windows

The number of chambers of a product affects the thermal resistance of a double-glazed window, even if the glass has the same thickness. The more chambers are provided in the design, the more heat-saving it will be.

The latest modern designs are distinguished by higher thermal characteristics of double-glazed windows. To achieve the maximum value of heat transfer resistance, modern manufacturing companies in the window industry have filled the product chambers using special filling with inert gases and applied a low-emissivity coating to the surface of the glass.

Reliable manufacturing companies of translucent structures make the coefficient of resistance to heat transfer of a double-glazed window depend not only on the quality of the structure itself, but also on the use of special technological operations during the manufacturing process, for example, applying a special magnetron, sun-protective and energy-saving coating on the surface of the glass, special sealing technologies, filling the space between the glass with inert gases, etc.

Heat transfer in such a modern design between the glasses occurs due to radiation. The efficiency of heat transfer resistance increases by 2 times if we compare this design with a conventional one. A coating with heat-reflecting properties can significantly reduce the heat transfer of rays that occurs between the glasses. Argon used to fill the chambers makes it possible to reduce thermal conductivity with convection in the layer between the glasses.

As a result, the gas filling together with the low-emission coating increases the heat transfer resistance of double-glazed windows by 80%, when compared with conventional double-glazed windows, which are not energy-saving.

Trends emerging in the window industry

The double-glazed window, which occupies at least 70% of the window structure, has been improved to minimize heat loss through it. Thanks to the introduction of new developments into production, selective glasses with a special coating appeared on the market:

- K-glass, characterized by a hard coating;

- i-glass characterized by a soft coating.

Today, more and more consumers prefer double-glazed windows with i-glasses, the thermal insulation characteristics of which are 1.5 times higher than those of K-glasses. If we look at statistics, sales of double-glazed windows with heat-saving coatings have increased to 70% of all sales in the USA, to 95% in Western Europe, and to 45% in Russia. And the values of the coefficient of resistance to heat transfer of double-glazed windows vary from 0.60 to 1.15 m2 *0C\W.

Advantages of s/p with energy-saving I-glass

Firstly, I-glass reflects long-wave thermal rays towards their emitter (that is, in winter towards the apartment where heating devices are working, and in summer towards the street where there are sun-heated stones, asphalt, etc.), which is significant reduces heating costs in winter (up to 60%) and air conditioning costs in summer (up to 30%). In other words, the coating leaves heat where there is more of it (thermos effect). The thermal insulation capacity of s/p with I-glass is significantly higher compared to conventional two-chamber s/p.

Secondly, s/p with I-glass has a significant gain in terms of indoor comfort. For example, at an outside temperature of -26 °C and a room temperature of +25 °C, for a regular single-chamber bathroom the glass temperature on the inner surface of the room will be +5 °C, for a regular 2-chamber bathroom +11 °C , and for a single-chamber s/p with I-glass +14° C. And if you install a 2-chamber s/p with a maximum thickness of 42 mm (possible when using a PVC profile with an installation depth of 70 mm) with I-glass, then the temperature at the window will be more than +17 °C! This means that the room heating mode can be changed, because... the heating system does not need to compensate for the significant “cold” zone near the window.

The area near a window made of conventional glazing leads to the so-called “draft” effect associated with noticeable convection of cold air near the window (the same “draft” can easily be felt by the hand in which you are holding a popsicle - even being in an apartment where there is no wind, the hand feels “ cold breeze"). Consequently, the use of s/p with I-glass increases the usable living area of the room due to the comfortable window space (in a small apartment you can move a table or bed closer to the window), and also prevents moisture from settling on the glass, thereby eliminating the appearance of condensation.

Thirdly, the weight of such a single-chamber s/p is 10 kg per 1 sq.m. s/p is lower compared to 2-chamber, which allows you to design large areas of window and door sashes, significantly reduces the load on the sash fittings of your window and increases its service life.

Fourthly, this I-glass prevents wallpaper, upholstery and interior items from fading due to the lack of solar overheating in the summer without the use of curtains or tinted glass. At the same time, the transparency of I-glass is comparable to the transparency of ordinary glass. A similar set of properties is not available to any other type of glazing today.

To make sure that you are the happy owner of windows with such glass, you can hold the flame of a lighter to the window at dusk and see among the reflections one reflection with a tint of a different color, as in the picture.

To summarize all of the above, let’s say that by installing plastic windows and doors produced by our company Eurostyle with energy-saving double-glazed windows in your home, you save money and create comfortable indoor conditions, which means a good mood and health for you and your loved ones!

conclusions

To summarize, when determining which windows to choose - wooden or plastic, you need to weigh the pros and cons of each material.

Wooden windows pros and cons

The advantages of wooden windows include:

- beauty that makes them an aesthetic addition to any interior;

- low thermal conductivity, allowing them to better retain heat in the house;

- environmental friendliness of the manufacturing material;

- long service life;

- the ability of wood to breathe, there are no problems with ventilation.

The disadvantages of wooden windows are as follows:

- relatively high cost (especially wood-aluminum);

- the frame coating does not last forever and requires regular updating;

- with poor-quality impregnation with fire retardants, there is a high probability of fire;

- take a long time to produce (about a month);

How to calculate the thermal conductivity of a double-glazed window

Thermal conductivity is a physical quantity that characterizes the ability of a substance or body to conduct heat. The greater its value, the faster the transfer of heat from a body with a higher temperature to a lower one. That is, the thermal conductivity coefficient K is the reciprocal of R0 - FSW adopted for use in Russia.

The lower K, the better the thermal insulation properties of the structure. The K coefficient is used in standards and norms developed by DIN (German Institute for Standardization), which has the status of the leading standardization body in Europe.

For approximate calculations, you can use the formula:

K = 1 / R0

Dimension K in the SI system is [W/m2*/0С]. Some manufacturers present an online calculator on their websites, with the help of which a potential buyer can calculate the characteristics of a future window opening with individual (“customized”) parameters.

Advantages of energy-saving I-glass

Glazing with the new product offers the following benefits:

- The ability of I-glass to reflect long heat waves towards the emitter minimizes the cost of heating in winter (up to 2/3) and air conditioning in summer (up to 1/3). The thermal insulation of I-glass is much higher than that of a conventional double-glazed window.

- The presence of I-glass, due to its reflective properties, solves several problems at once: fading of wallpaper, upholstery and other interior items; does not require the use of curtains, blinds and other items that darken the room. The transparency of such glass is no less than that of ordinary glass.

- I-glass provides the most comfortable microclimate throughout the entire room, including the window area. It is here that drafts often form next to a regular double-glazed window (due to the temperature difference in the room, on the surface of the glass and outside the window). On the surface of I-glass, at a temperature outside the window of +24°C and +20°C inside, a comfortable +17°C is formed, while on a single-chamber double-glazed window – +5°C, on a double-chamber glass unit – +13°C. A small difference in temperature between the I-glass and the air in the room prevents fogging and does not create drafts, allowing you to effectively use the space near the window.

Specific heat capacity of glass

The table shows the specific heat capacity of glass of various types and densities depending on temperature. The thermal capacity of glass is given in the temperature range from 173 to 1473 K (-100...1200 °C). The dimension of heat capacity in the table is kJ/(kg deg).

The specific heat capacity of the following glasses is given: quartz glass, crown glass, sodium glass, window glass, pyrex glass, thermometric glass, flint glass, glass made from natural silicates: anorite, albite, wollastonite, diopside, microcline.

The specific heat capacity of glass of the main types is in the range of 490…1125 J/(kg deg). For example, the specific heat capacity of silicate glasses ranges from 300 to 1050 J/(kg deg) and depends on the composition of the glass . Low heat capacity is characteristic of glasses with a high content of heavy elements - such as barium or lead - this applies primarily to heavy crowns and flints. Glasses with high heat capacity at ordinary temperatures include: Pyrex, soda glass, and thermometric glass.

It should be noted that the specific heat capacity of glass depends on temperature - when the glass is heated, its value increases. For example, the specific heat capacity of quartz glass at a temperature of 1200°C is 25-30% higher than this value at 20°C.

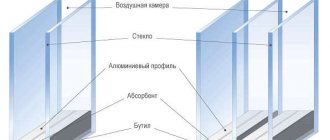

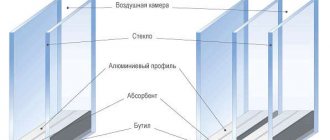

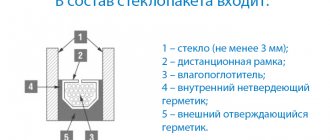

Double-glazed window design

Typically, a double-glazed window consists of two or three sheets of glass that are the same width and height. In this case, the thickness of the glass can be either the same or different. These glasses are installed at a given distance from each other and glued together along their edges. That's why they are called glued

double-glazed windows [1]. A sealed cavity is formed between the glasses - the double-glazed window chamber (Figure 1).

Figure 1 – Double-glazed window design

This chamber contains dry air or, sometimes, the noble gases argon or krypton. In this case, no vacuum is created in this cavity, as is sometimes mistakenly believed.

(About really vacuum

double-glazed windows, see here.)

[link to article 18-03-03 about vacuum double-glazed windows]

The spacer frame, which separates the glass sheets from each other, has a certain influence on the thermal insulation properties of the double-glazed window and, especially, on the dew point at the edges of the double-glazed window. Spacers are often called spacers from the corresponding English term “spacer”. Below, for brevity, we will call them that.

Calculation of the total thermal conductivity of a window

To determine the heat transfer resistance index, you do not need to have special knowledge. It will be enough to use thermal information about profile systems along with double-glazed windows. You need to focus on several coefficients at once. Taking into account the thermal conductivity of the sashes with frames and double-glazed windows, it will be possible to obtain accurate data. During calculations, the following indicators must be taken into account:

- R sp – glass unit coefficient.

- R p – window frame coefficient.

- β – the ratio of the area of the translucent part of the product to the total window area.

These indicators are needed to calculate the thermal conductivity of the structure using the formula:

R= R sp×R p/((1- β)×Rsp + β×R p).

Each profile and glass unit has its own coefficients, so it is not possible to determine the average value. Otherwise, all windows would retain heat exactly the same. To calculate the binding area, the length of the component elements of the sashes with frames is multiplied by the width of the profiles, after which the values are summed. The glazing area is equal to the area of the light openings.

Carrying out calculations: on your own or contact a specialist?

It must be said that determining the heat transfer resistance of windows yourself, without experience and skills in this matter, is not so easy. The best and most optimal option is to seek help from a specialist who probably knows exactly how to carry out calculations so that as a result there are no errors and the errors are minimal. If you don’t have any friends in the construction industry, and your financial situation does not allow you to pay for the services of professionals, then you can use a special calculator that will help you determine in real time how well the product characteristics correspond to the given resistance. In addition, the calculation methodology in this case is very simple and understandable. You can figure it out yourself, so you can determine the area of homogeneous zones for each specific element quite quickly. Almost all thermal properties are presented in thematic tables and excerpts from regulatory and technical documentation. They are freely available on the Internet on various forums and construction portals.

Layout of thermocouples and heat meters on a sample window block (according to GOST).

What is the thermal conductivity of a window and what does it depend on?

To simplify it as much as possible, the thermal conductivity of PVC windows is the ability of a profile structure with closed sashes to retain a certain amount of energy indoors. However, such a definition is not enough to understand the essence of the process. After all, through the same double-glazed windows, heat leakage occurs in different ways:

- 30% of energy losses occur due to convection inside double-glazed windows and air chambers and heat transfer through solid components of window or door units;

- 70% of the heat goes outside the room along with infrared waves.

This simple analysis allows you to understand how you can significantly reduce energy leakage. Since infrared waves pass through glass, it is these areas of window and door units that require double attention. After all, double-glazed windows occupy the largest area in window openings and the maximum amount of heat escapes through them. Statistics show that the energy efficiency of profile structures can be significantly increased if it is possible to block infrared waves. At the same time, PVC systems cannot be ignored, since the coefficient of resistance to heat transfer of double-glazed windows to a certain extent depends on their characteristics. For example, the cross-sectional shape of the profiles affects the planting depth and the maximum thickness of the double-glazed windows. The total energy efficiency of windows depends on the dimensions mentioned. In addition, good profiles slow down the process of heat exchange around the perimeter of light openings and the spread of cold from cooled walls. These processes are interconnected and cause a decrease in temperature in the interior. The last factor that influences the level of thermal conductivity of windows is tightness. However, this parameter is quite difficult to calculate mathematically. Therefore, it is enough for the window customer to know that to ensure tightness, high-quality fittings and profile reinforcement are required. You also need to pay attention to the quality of the installation. If the installation is not carried out according to the rules, the structure may depressurize around the perimeter of the frames. Read more about installation requirements on OknaTrade.

How to calculate the total thermal conductivity of a window

Determining the exact heat transfer resistance of windows is quite simple. To do this, you will need to use thermal information about profiles and double-glazed windows. Moreover, you cannot focus on only one of the coefficients. To obtain reliable data, it is necessary to take into account the thermal conductivity of sashes, frames and double-glazed windows. When making calculations you will need to use:

- R sp – glass unit coefficient.

- R p – window frame coefficient.

- β is the ratio of the area of the translucent part of the structure to the total area of the window.

The thermal conductivity of the window, taking into account these data, is calculated by the formula:

R= R sp×R p/((1- β)×Rsp + β×R p)

The coefficients differ for different profiles and double-glazed windows. There is no average. Indeed, in this case, all windows would have the same ability to retain heat. The exact values of the coefficients are given in this article in the sections on PVC systems and double-glazed windows. To calculate the binding area, you need to multiply the length of the constituent elements of the sashes and frames by the width of the profiles, and then sum the resulting values. The glazing area is equal to the area of the light openings.

Why is it important to correctly determine the heat transfer of a window structure?

As already mentioned, the main function of any double-glazed window is to retain heat in the premises of the house. There is a certain belief that plastic products are many times warmer than wooden structures. But this opinion is subjective, because the frame material, as already mentioned, does not play the most important role. The formula that describes this parameter is extremely simple and has been known to us since the 8th grade physics program. It describes the strength of the energy flow that leaves the room through a barrier of 1 square meter of area with a temperature difference of 1 degree. It is worth noting that the lower the U index, the better the reduced resistance. Any experienced specialist in the construction industry can understand the calculations without any problems, but an ordinary person may find the formula quite complex and intricate. But our compatriots are accustomed to living by the principle “the higher the indicator, the better,” or they simply trust that each supplier indicates the class of the product and its characteristics. But they are not always true, so it’s worth double-checking this information to be sure. That is why recently a quantity called “heat transfer resistance” has been introduced into circulation. To denote it in a formula, use the symbol R.

Minimum heat transfer coefficient of PVC windows

The formula is as follows: R = 1/U.

Main types of double-glazed windows

The double-glazed window (IG), being the main part of the window, structurally consists of several glasses connected by metal (intermediate) frames. The space between the glasses is called the chamber.

There are three main types of glass packages most often used:

- single-chamber - two glasses (internal and external);

- two-chamber - three glasses (internal, external and intermediate);

- three-chamber - four glasses (internal, external and 2 intermediate).

The thickness of the glass used varies from 4 to 6 mm. For glazing objects with increased strength requirements (high wind loads), glass with a thickness of 8-10 mm can be used. The gap between the glasses can vary - from 8 to 36 mm. The thickness range of double-glazed windows is from 14 to 60 mm.

The FSW of the glass itself is relatively small due to its high thermal conductivity. To reduce heat loss, the space between the glass is filled with air or an inert gas (argon Ar, krypton Kr, nitrogen N2). Gas-filled chambers make the main contribution to increasing the STP of a double-glazed window Rsp. It is also possible to significantly increase the value of Rsp by creating a vacuum in the chamber, but this leads to a sharp increase in the cost of the final product.

Thermal conductivity of glass at different temperatures

The table shows the values of the thermal conductivity coefficient of glasses of various densities depending on temperature.

The thermal conductivity of glass is given at negative and positive temperatures - in the range from 4 to 1140 K (-269...867 ° C). The thermal conductivity of various types of glass at room temperature ranges from 0.7 to 1.6 W/(m deg). For example, the thermal conductivity of quartz glass at room temperature is 1.36 W/(m deg) ; the thermal conductivity of crystal is in the range of 0.88-0.91 W/(m deg); The thermal conductivity of porcelain is 1.68 W/(m deg).

At low negative temperatures, glass has a thermal conductivity of 0.13-0.4 W/(m deg). As the temperature of glass increases, its thermal conductivity increases. At high temperatures, the thermal conductivity of glass increases to a value of 2-2.25 W/(m deg).

Note: The thermal conductivity dimension in the table is W/(m deg), all samples are annealed, the thermal conductivity of the glass corresponds to the temperatures indicated in the table, data interpolation is possible.

Required heat transfer resistance of windows

The basic physical unit characterizing the thermal conductivity of a window is the reduced heat transfer resistance Ropr (m2*°C)/W.

For an ordinary person, the Ropr (m2°C)/W value does not mean anything, and when choosing windows you can often hear the following advice:

Pay attention to the thermal insulation indicator of the selected window - heat transfer resistance. The larger the size, the better. I recommend a minimum R of no lower than 0.55 (m2°C/W) – as for central Russia.

That is, the more is better approach is used.

Without knowing the required Ropr value for your region, you are completely “blind” when choosing a window.

we considered the physical properties of heat transfer resistance Ropr (m2°C)/W.

According to SP 50.13330.2012 CODE OF RULES THERMAL PROTECTION OF BUILDINGS

5.1 The thermal protective shell of the building must meet the following requirements:

- a) the reduced heat transfer resistance of individual enclosing structures must be no less than the standardized values (element-by-element requirements);

- b) the specific heat-protective characteristic of the building should not exceed the standardized value (complex requirement);

- c) the temperature on the internal surfaces of enclosing structures must not be lower than the minimum permissible values (sanitary and hygienic requirement).

The requirements for thermal protection of the building will be met if requirements a), b) and c) are simultaneously met.

Heat capacity, composition and other physical properties of porcelain

The table shows the composition, thermal and physical properties of porcelain at room temperature. Porcelain properties are indicated for the following types: installation, low-voltage, high-voltage and chemical-resistant porcelain.

The following properties of porcelain are presented:

Particularly noteworthy is the property of porcelain, such as heat capacity. The specific heat capacity of porcelain ranges from 750 to 925 J/(kg deg) . Installation porcelain has the highest heat capacity, and chemically resistant porcelain has the lowest.

Additional ways to reduce heat loss

An impressive reduction in heat loss can be achieved using special coatings. An ultra-thin layer of metal oxides is applied to the inner surface of the glass, which guarantees its safety during operation. This additional film completely transmits visible light, but at the same time acts as a kind of “mirror” that reflects electromagnetic radiation in the infrared (IR) range. As is known from physics, heated bodies emit a significant part of their internal energy in this region of the spectrum.

There are two types of glass with additional coating:

- k-glass - obtained by applying metal oxides. A coating with a thickness of 0.4-0.5 microns has virtually no effect on the light transmission of the window;

- i-glass is a more complex technology, which means the glass is more expensive. The film is obtained by double deposition in a vacuum of several alternating layers: layers of pure metal are deposited between the oxide layers (usually silver 10-15 nanometers thick is used).

The use of such coatings can reduce heating costs by 15-20%.

The role of a PVC profile window in the thermal protection of a room

Today, most of the enterprises involved in the production of plastic windows and doors use a 3-chamber profile (from various manufacturers) and a double-glazed window (hereinafter referred to as s/p) (4M—10—4M—10-4M). According to GOST 30674-99 “Window blocks made of polyvinyl chloride profiles”, the heat transfer resistance of a window structure made of a 3-chamber profile with a two-chamber s/p 4M-10-4M-10-4M (the most common and frequently used s/p) is 0. 51 (m2•°C)/W.

Single-chamber double-glazed windows

| Formula | Thickness, mm | Heat transfer resistance, m2 °C/W | Sound insulation coefficient, dB |

| 4-8-4 | 16 | 0,28 | |

| 4-8Ar-4 | 16 | 0,3 | |

| 4-8-4K | 16 | 0,47 | |

| 4-8Ar-4K | 16 | 0,53 | |

| 4-10-4 | 18 | 0,30-0,32; 0,32; 0,32; 0,29 | 23-25 |

| 4-10Ar-4 | 18 | 0,31 | |

| 4-10-4K | 18 | 0,49 | |

| 4-10Ar-4K | 18 | 0,55 | |

| 4-12-4 | 20 | 0,32-0,34; 0,32-0,34; 0,3; 0,33; 0,32-0,34 | |

| 4-12Ar-4 | 20 | 0,32 | |

| 4-12-4K | 20 | 0,51 | |

| 4-12Ar-4K | 20 | 0,57 | |

| 4-16-4 | 24 | 0,34-0,37; 0,34-0,37; 0,32; 0,35; 0,34-0,37 | 25-27; 25-27; 26; 25-27 |

| 4-16-4I | 24 | 0,59; 0,59; 0,58; 0,58; 0,58 | 26-28; 27; 26-28 |

| 4-16Ar-4I | 24 | 0,66 | |

| 4-16-4K | 24 | 0,53; 0,50-0,52; 0,53; 0,51 | 26-28; 27 |

| 4-16Ar-4 | 24 | 0,34 | |

| 4-16Ar-4K | 24 | 0,59; 0,53 | 34 |

| 4-24-4 | 32 | 0,37-0,39; 0,34 | 29 |

| 4-24-4K | 32 | 0,55 | |

| 4-24-4I | 32 | 0,61 |

What do these heat losses depend on?

They are larger, the greater the temperature difference between the house and the street. They are smaller, the higher the heat-insulating properties of the wall (or, as they say, the enclosing surface). The wall resists heat loss, so its heat-protective properties are assessed by a value called heat transfer resistance.

Heat transfer resistance shows how much heat will pass through a square meter of wall at a certain temperature difference (or vice versa: what temperature difference will occur when a given amount of heat passes through a square meter of wall).

The formula is as simple as Ohm's law:

- R=d/q

Where:

- q is the amount of heat lost per square meter of the enclosing surface (walls, roof, etc.). It is measured in watts per square meter (W/m2);

- d is the difference between the temperature outside and in the room (°C) and, finally;

- R is the heat transfer resistance (dimension (m2•°C)/W).

As an example: how much will comfort in winter cost the owner of a glazed and perfectly insulated loggia? We will not take into account heating losses of fresh air from the vents and heat losses through the walls, floor and ceiling. Only through today's best glazing with R=0.8 with an area of 10 sq.m at a temperature difference from -20 to +20 will 0.5 kW per hour be lost, i.e. a warm floor will generate approximately 360 kW in a frosty month!

Just as electrical resistance R characterizes the ability of a conductor to prevent the passage of electric current, so thermal resistance R shows how much the surface enclosing a living space prevents heat from leaking out.

This analogy is not accidental - we are dealing with the law of similarity: the passage of current under the influence of a potential difference and heat flow through a substance under the influence of a temperature difference are described by the same mathematical equations.

If we are talking about a multilayer wall, then the resistances of the individual layers are simply added (just like series resistances in an electrical circuit). For example, the resistance of a wall made of wood lined with brick is the sum of three resistances: the brick and wooden walls and the air gap between them:

- R(total) = R(wood) + R(air) + R(brick).

When designing and constructing residential buildings starting from 2003, it is necessary to comply with the requirements of SNiP 23-02-2003 “Thermal protection of buildings”, otherwise the constructed building will not be allowed to be occupied and used. Since the requirements for the resistance of walls to heat transfer according to this document are very high, recently a significant amount of building materials with a low thermal conductivity coefficient have been developed.

These are all kinds of insulation materials, gas silicate and foam concrete blocks, porous and superporous ceramics, large-sized multi-hollow blocks. For our Ural-Siberian region, the heat transfer resistance for the external walls of residential buildings should be from 3.5 (m2•°C)/W (k = 0.29 W/(m2•°C)). Until 1995, the required heat transfer resistance of windows and balcony doors in residential buildings was 0.45 (m2•°C)/W (k = 2.22 W/(m2•°C)). According to modern standards, the required heat transfer resistance of windows is 0.6 (m2•°C)/W (k = 1.67 W/(m2•°C)).

The thermal conductivity coefficient of solid ceramic brick is on average 0.6 W/(m2•°C), and that of silicate brick is 0.8 W/(m2•°C). If we calculate the required thickness of a wall made only from this brick, then for ceramic brick it will be from 2.1 meters, and for silicate brick - from 2.8 meters. This is no longer a cottage, but a medieval fortress! And, for example, for gas silicate blocks with a thermal conductivity coefficient of 0.14 W/(m2•°C), the wall thickness will be only 50 centimeters. However, the strength of gas silicate blocks is such that they cannot be used as a load-bearing material.

Crafty window advertisers are trying to deceive the buyer: “It will never be cold in the new kitchen-living room: a window made of “such and such” profiles with a 5-chamber structure and a system depth of 70 mm is equivalent in thermal characteristics to a 90 cm thick brick wall!” Alas, the best modern window is about three times “cooler” than the wall, otherwise glass walls would cease to be exotic and wasteful in our homes.

Thermal insulation properties of materials

In advertising materials, often, as an argument for the quality of a window, window profile or double-glazed window, the thickness of a brick wall is given, which is equivalent in terms of heat transfer to the advertised product, with figures of the order of 500 - 900 mm. brickwork. They suggest comparing these values with the thickness of the wall in your apartment. This argument has a very convincing effect on the customer.

Let's look at how true this is.

A little theory.

The thermal insulation properties of the enclosing structure (walls, windows, doors, etc.) are characterized by heat transfer resistance Ropr, which shows the ability of a material with an area of one square meter to prevent heat loss. The higher Ropr, the better the design has thermal insulation.

At the same time, heat transfer resistance Ropr depends on the material from which the structure is made and the thickness of the structure.

The thermal conductivity coefficient of the material, λ , shows the required wall thickness H (in meters) to achieve heat transfer resistance Rdef = 1.

These three quantities are related to each other, just like Ohm’s law.

Rdef = H / λ

Accordingly, H = Rdef * λ

That is, the wall thickness is equal to the required heat transfer resistance Rdef multiplied by the thermal conductivity coefficient of the material λ .

As an example, let's look at the window profiles of the Rehay used in the Russian markets, so:

- REHAU BLITZ profile has Rdef = 0.63 , which is equivalent to a brick wall with a thickness of 510 mm ;

- REHAU EURO-Design profile has Rdef = 0.64 , which is equivalent to a brick wall with a thickness of 518 mm ;

- REHAU SIB-Design profile has Rdef = 0.71 , which is equivalent to a brick wall with a thickness of 575 mm ;

- REHAU DELIGHT-Design profile has Rdef = 0.80 , which is equivalent to a brick wall with a thickness of 648 mm ;

- REHAU BRILLANT-Design profile has Rdef = 0.79 , which is equivalent to a brick wall with a thickness of 640 mm ;

- REHAU INTELIO profile has Rdef = 0.95 , which is equivalent to a brick wall with a thickness of 770 mm ;

- REHAU GENEO profile has Rdef = 1.05 , which is equivalent to a brick wall with a thickness of 851 mm ;

As one classic character said: “All this is true, but there is one nuance.”

So what is it?

The thing is that the equivalent is brickwork made of silicate brick, which has low thermal insulation properties, which is used mainly as a facing and load-bearing material. Inside the sand-lime brick masonry there is always a thermal insulation layer that gives the required thermal qualities to the wall.

For brick λ = 0.81

If we take as an equivalent a wall made of PS-4 foam plastic, for which λ = 0.04, then we get completely different values:

- REHAU BLITZ profile has Rdef = 0.63 , which is equivalent to a 25 mm ;

- REHAU EURO-Design profile has Rdef = 0.64 , which is equivalent to a 26 mm ;

- REHAU SIB-Design profile has Rdef = 0.71 , which is equivalent to a 28 mm ;

- REHAU DELIGHT-Design profile has Rdef = 0.80 32 mm thick foam wall ;

- REHAU BRILLANT-Design profile has Rdef = 0.79 , which is equivalent to a 32 mm ;

- REHAU INTELIO profile has Rdef = 0.95 , which is equivalent to a foam wall with a thickness of 38 mm ;

- REHAU GENEO profile has Rdef = 1.05 , which is equivalent to a foam wall with a thickness of 42 mm ;

Since the thermal conductivity of foam plastic is twenty times lower than that of sand-lime brick, the thickness of the equivalent wall will be twenty times less.

For reference, the thermal conductivity coefficients are given below? some materials.

Knowing the formula Rdef = H / λ

you can always determine the required value from the other two.