The main component of any modern (wooden, plastic, aluminum) window is undoubtedly a double-glazed window. In terms of area, a double-glazed window occupies from 70% to 90% of the window area; accordingly, the properties of the double-glazed window will be fundamental in the overall properties of the window. Whether a window is warm, energy-saving, or noise-proof directly depends on the double-glazed window.

A window made even from super warm window profiles will not be warm if the selected double-glazed window has low thermal insulation.

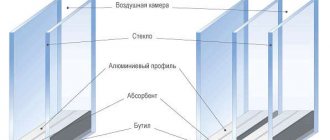

A double-glazed window is a structure consisting of two or several glasses, separated along the perimeter by a spacer frame, hermetically sealed with sealant, forming hermetic chambers that are filled with dried air or inert gas.

What is a double glazed window?

This product is a glass rectangle of specified dimensions depending on the size of the window. For its production, glass measuring 4-8 mm is used, the distance between them is set by a dividing frame 4-36 mm wide. This value is specified by international standards.

In practice, the most common formula is “4-16-4”, which means the presence of a pair of glasses with a thickness of 4 mm and a separating frame 16 mm wide.

A layer of sealant is applied to the 4 end surfaces. The separating frame is made of aluminum alloys or plastic. Glass can be used with various properties: armored, light-protective, heat-resistant, etc. The thickness and characteristics of the glass are specified in the order.

Key indicators considered when purchasing these products:

- Heat transfer resistance – R, m2*оС/W.

- Thermal insulation coefficient – RW, Db.

- Glass unit weight – m, kg/m2.

Standard bags are produced in the following sizes:

- 16 mm thick (“4 – 8 – 4”), R=0.28; RW=21; m=21.7.

- 18 mm (“4 – 10 – 4”), R=0.29; RW=22; m=22.13.

- 20 mm (“4 – 12 – 4”), R=0.30; RW=23; m=22.56.

- 24 mm (“4 – 16 – 4”), R=0.32; RW=24; m=23.45.

- 32 mm (“4 – 24 – 4”), R=0.34 – extended.

The data is given for products that use standard glass of category M1. The chambers are filled with air, the dividing frame is made of aluminum alloy.

The coefficients of light transmission and heat resistance for all single-chamber bags are the same and amount to 0.80 and 0.78.

The weight of the product directly depends on the design of the window. The size of the camera has little effect on this indicator, since it changes due to the width of the dividing frame. Every millimeter increase in the width of the chamber leads to an increase in weight by 0.2 kg.

When the size of the glass thickness changes by 1 mm, its weight increases by 2.5 kg, that is, if the thickness of two glasses in a package changes, the total weight increase will be 5 kg.

Design:

Pricing

We give an example of pricing for double-glazed windows. They may include polished glass: tinted, covered with anti-vandal film - protection class A1 - A3, K4, energy-saving and sun-protective.

Table 1:

| Thickness st./pack, mm | Formula | Price up to 200m2 (rub) | Price over 200 m2 (rub) |

| 14 | 4 – 6 – 4 | 1231 | 1151 |

| 18 | 4 – 10 – 4 | 1241 | 1151 |

| 20 | 4 – 12 – 4 | 1271 | 1201 |

| 24 | 4 – 16 – 4 | 1281 | 1201 |

| 28 | 4 – 20 – 4 | 1351 | 1281 |

| 32 | 4 – 24 – 4 | 1401 | 1221 |

| 24 | 4 – 6 – 4 – 6 – 4 | 1641 | 1501 |

| 28 | 4 – 8 – 4 – 8 – 4 | 1651 | 1501 |

| 32 | 4 – 10 – 4 – 10 – 4 | 1651 | 1501 |

| 36 | 4 – 12 – 4 – 12 – 4 | 1701 | 1561 |

| 44 | 4 – 16 – 4 – 16 – 4 | 1751 | 1601 |

| 52 | 4 – 20 – 4 – 20 – 4 | 1861 | 1701 |

The width of spacer frames made of aluminum alloys is up to 24 mm. TPS frame width up to 19 mm.

Table 2:

| Variable data when ordering | Price formation |

| One glass 5mm | +140 RUR/m2 |

| One glass 6 mm | +190 RUR/m2 |

| One glass 8 mm | +350 RUR/m2 |

| When the glass unit size is less than 0.1 | +60% to the price per m2 |

| Size st./pack 0.1 – 0.5 | +15% to the price per m2 |

| Size st./pack 2.5 – 5.0 | +25% to the price per m2 |

| Size st./pack 5.0 – 6.0 | +50% to the price per m2 |

| Size st./pack over 6.0 | negotiable |

| Style/pack figured – trapezoid, triangle | +20% to the price per m2 |

| Style/pack figured – arch, circle | +40% to the price per m2 |

| Steel/pack of structural glazing | Consider Individually |

| Production of steel/pack according to a template | +50% to the price per m2 |

| Non-standard, technologically complex steel/pack | +75% to the price per m2, considered individually |

As can be seen from the data provided, single-chamber and double-chamber packages are not fundamentally different in price. When choosing, additional factors should be taken into account: weight, installation location, design option.

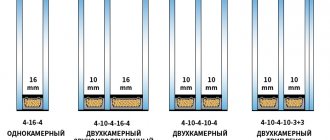

Classification of double-glazed windows by the number of chambers and their designations (abbreviations)

A formulaic entry may begin with an abbreviation indicating the number of cameras.

If SPO appears at the beginning, this means that the double-glazed window has one chamber. Formulas for double-glazed windows begin with the abbreviation SPD. Here SP is an abbreviation for “double-glazed window,” and O and D are, respectively, “single-chamber” or “double-chamber.” A single-chamber glass unit is a glass unit consisting of two glasses arranged in parallel and hermetically connected by one spacer frame. A double-glazed window is a design consisting of three glasses connected by two frames.

For example, this is what the formula for a single-chamber double-glazed window with a width of 24 mm will look like:

4M1-16-4M1 (4 mm – glass thickness, 16 mm – spacer frame width, M1 – glass type).

If, instead of regular float glass, energy-saving glass is used, then the formula will look different:

4M1-16-4i (here the internal glass ensures heat retention inside the room and protects the space from drafts, resistance to heat loss reaches 0.59 m2 C/W, compared to the previous formula - 0.32 m2 C/W).

But the calculation of the formula for a double-glazed window with a width of 32 mm looks different:

4M1-10-4M1-10-4M1 (the formula already takes into account three glasses and two spacer frames, 10 mm wide, thermal insulation is 0.47 m2 C/W).

If we replace regular glass with energy-saving glass, we get the following formula:

4M1-10-4M1-10-4i (the principle is the same, the inner glass is indicated by a different marking inherent in energy-saving glass, the thermal insulation increases to 0.64 m2 C/W).

The total thickness of the structure may be indicated in parentheses after the chamber designation. For example, the formula for a 32-mm double-glazed window is SPD(32) 4M1-10-4M1-10-4M1. Here you can see that the product is made up of three 4 mm glasses and two 10 mm frames, totaling 32 millimeters.

GOST R 54175-2010 “Glued double-glazed windows. Technical Specifications” also describes double-glazed windows with special properties, which are then displayed in the formula.

Their properties can also be included in the abbreviation in the form of letters:

UD - shock resistant; E - energy saving; C - sun protection; Ш - protected from noise; M - frost-resistant.

There are also multifunctional products that combine several properties, for example, energy-saving and noise-proof. These characteristics can be determined by the properties of the glass.

How to check?

This task poses two questions for the future user:

- What to choose?

- How to check compliance and quality?

Choosing the right window begins with understanding the basic requirements that are important to the consumer.

The problem is the huge supply of different types of double-glazed windows:

- reflective;

- energy saving;

- sound-absorbing;

- reinforced (triplex);

- stained glass , etc.;

Without complicating the task, we will choose from three options:

- Single chamber.

- Energy saving.

- Two-chamber.

The choice of single or double package was discussed in the previous section, and there is nothing to add here. In the case of energy-saving, you need to check its formula using the documents, it should look like: “4i – 16 – 4” or “4k – 16 – 4”.

If preference is given to double-glazed windows, you need to take into account the increase in the depth of the product. The camera size will not be 16 mm, but smaller. Considering that the minimum acceptable camera size is 10 mm, the final product size will be 32 mm.

You can check its quality using the following parameters:

- The end should be covered with a thick film of black silicone sealant. The surface of the coating must be flat.

- The glass must be clean , free of streaks, and there must be no debris or dust inside the glass unit.

- The spacer frame must not have cracks , dents or bends. The cut on it should be in one place, which indicates production on high-precision automatic equipment.

- On energy-saving double-glazed windows, the coating should be directed inside the room. If you light a candle, you can see three flames in the reflection. In the middle light there should be a violet-burgundy border.

Disadvantages and advantages of single devices

Speaking about the advantages, you should pay attention to the low weight compared to two-chamber products. Accordingly, the price of single-chamber units is lower.

Among the disadvantages, the main one is that single bags retain heat less well.

In the standard version, a “4-16-4” double-glazed window retains heat 20–28% worse than a two-chamber “4–14–4–12–4” formula. Accordingly, its noise insulation properties are 20% lower.

Based on this, the use of single-chamber bags is advisable in places where thermal and noise protection factors are not critical. For example, glazing of windows facing a glazed balcony or loggia.

The main thing is that when choosing packages, you need to focus not on the price of the window, but on its consumer properties. The price of a two-chamber device differs slightly from the price of a single-chamber device, and the main characteristics are higher.

Single-chamber PVC windows

Most owners of plastic windows equipped with single-chamber double-glazed windows agree that with proper selection and installation, such windows look much more attractive than ordinary wooden frames with classic glazing.

And their technical characteristics are much better. Well, the design of each window, as well as its design, should be chosen based on a number of conditions: design features of buildings, climatic conditions of the region, location of the house and many others.

And in any case, great attention should be paid to the choice of double-glazed windows - it is the main component of the window. Therefore, it would not be amiss to tell you in more detail about single-chamber plastic PVC windows and highlight their main advantages and disadvantages.

To begin with, it is worth noting that the concepts of single-chamber double-glazed windows and single-chamber plastic windows are analogues of the verbal designation of the method of glazing window sashes. But a double-glazed window, from the point of view of a specialist, is a more correct concept.

More on the topic Are wooden windows with double glazed windows any good? Let's look at examples.

Single-chamber double-glazed window

- Consists of two glasses forming a heat-insulating chamber.

- When using KBE58 Etalon/Engine profiles, the thickness of the glass unit is 24 mm (4M1-16-4M1)

- When using KBE70 Expert/Energy profiles, the glass thickness is 32 mm (4M1-24-4M1)

- This double-glazed window has a reduced heat transfer resistance coefficient of 0.34 (as part of a window block 0.4-0.44) m2 oC/W, that is, water vapor can concentrate on the surface of the glass unit already at an outside temperature of 8 oC, and reduces the level of external noise approximately 34 dB.

- Such a double-glazed window can only be used in administrative buildings (SNiP II-3-79) and, based on many years of experience in our work, in those windows that overlook already glazed loggias/balconies.

- According to the Moscow State Construction Norms and Rules (MGSN), the reduced heat transfer resistance coefficient of a window structure should be 0.54 m2 oC/W. Such thermal protection is provided by a window unit with double-glazed windows or single-chamber double-glazed windows with energy-saving glass. For additional thermal insulation and to reduce the likelihood of ice formation in the edge zone of a double-glazed window, it is possible to use a thermal frame.

Is it possible to replace the glass unit with a better one?

The most often asked question is “Can a double-glazed window be replaced with a new one with the same characteristics?” - people who do not know that replacing double-glazed windows can be done with a better one.

In case of breakage, it is recommended to install a double-glazed window with impact-resistant tempered glass, protective film or shockproof triplex to avoid recurrences. Impact-resistant double-glazed windows

To reduce heat loss and get rid of frequent condensation, it is recommended to apply energy-saving spraying to the glass unit. Such glasses have low heat emission (heat transfer) and therefore better protect against overheating and cooling.

Single-chamber energy-saving double-glazed window

Windows with such devices appeared relatively recently. Structurally, they differ little from conventional products.

Its peculiarity is as follows:

- The chamber is filled with an inert gas, the thermal conductivity of which is almost two times lower than the thermal conductivity of air.

- One of the glasses is coated with a special composition that reduces the thermal conductivity of the glass.

Such features significantly reduce heat exchange from the room to the external environment.

The service life of the energy-saving package is 6-10 years, after which it gradually turns into a regular single-chamber package and continues to serve as such.

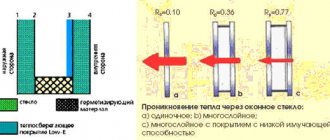

Low-emissivity glass

Low emission - the ability to reflect thermal radiation. The lower the emission coefficient, the better the material reflects energy, which means it is a better heat insulator.

In the domestic GOST 24866-2014, the characteristic “Reduced resistance to heat transfer” is used - the inverse of the emission coefficient. The higher the heat transfer resistance, the better the thermal insulation ability of the glass unit.

There are low-emissivity glasses with hard and soft coatings.

- Low-impact K-glass (hard coated glass) can be used with the coating facing out as it is weather and abrasion resistant. Can be hardened.

- Low-emissivity I-glass (glass with a soft coating) is used only as a coating inside the package - it is not resistant to external influences, but has better thermal insulation properties (almost 1.5 times).

The glass in a double-glazed window is designated: 4k and 4i, respectively, where 4 is the value of the glass thickness in millimeters.

Soft low-emission coating (i-glass) is used more often for the manufacture of heat-saving and energy-saving double-glazed windows.

Low emissivity glass

Low-emission glass with a special heat-reflecting coating works on the principle of a thermos: it insulates from the outside environment, maintaining the temperature inside.

The coating applied to the surface of the glass remains transparent and, unlike films, cannot peel off. The coating itself can be applied:

- on the outer glass (inside the chamber) - for better heat reflection to the street;

- on the inner glass (inside the chamber) - for better heat reflection into the room.

Video: production of low-emissivity glass for double-glazed windows

Double-glazed window

- Consists of three glasses forming heat-insulating chambers.

- When using KBE58 Etalon/Engine profiles, the thickness of the glass unit is 32 mm (4M1-10-4M1-10-4M1)*

- When using KBE70 Expert/Energy profiles, the glass thickness is 40 mm (4M1-16-4M1-12-4M1)*

- When using MONTBLANC QUADRO profiles, the thickness of the glass unit is 42 mm (4M1-16-4M1-14-4M1)*

- When using TROCAL profiles, the thickness of the glass unit is 40 mm (4M1-16-4M1-12-4M1)*

- When using GEALAN S8000 profiles, the thickness of the glass unit is 44 mm (4M1-16-4M1-16-4M1)*

- When using GEALAN S9000 profiles, the thickness of the glass unit is 52 mm (4M1-20-4M1-20-4M1)*

- This type of double-glazed window has a reduced heat transfer resistance coefficient of 0.47-0.52 (as part of a window block 0.55-0.6) m2 oC/W. and reduces the external noise level by approximately 34 dB. In this case (provided that the indoor air humidity is normal - up to 50%), condensation can form only at an outside temperature of 25 degrees Celsius.

- In order to get an even “warmer” double-glazed window, you can replace one or two glasses in a double-chamber double-glazed window with “energy-saving” ones and replace the frame with a composite one.

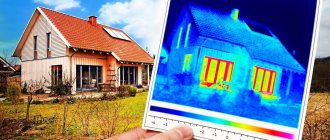

Single chamber or double chamber?

Designs can be single-chamber (two glasses) and double-chamber (three). The width ranges from 24 to 40 millimeters, depending on the number of cameras in it and the width of the glass. Single-chamber structures are not recommended for installation in central Russia, where winter temperatures drop below minus 20 degrees Celsius. In Moscow and the region it is prohibited to install such windows in new buildings, but no one will forbid you to install them in a private house or apartment. But, if ice appears on your window at minus 18 degrees, you should not call the window company and complain about low-quality products. But they can also be placed, for example, on a balcony or loggia, in a summer house or garage. A very detailed article about single-chamber windows and their application.

The generally accepted practice is to install two-chamber structures. Even inexpensive products provide a sufficient level of comfort and warmth in a normally heated room.

Where is it advisable to install single-chamber structures?

There are situations where the installation of such windows is not only acceptable, but even necessary. Let's consider these cases.

Balconies and loggias

If you do not plan to make the balcony a living room, it is enough to choose a single-chamber version. The fact is that in this case the loggia will still remain a cold place. And it makes absolutely no sense to pay extra for a window with two cameras.

Dacha, summer house

If you are looking for suitable glazing for a country house, you should calculate and weigh everything correctly. In the case where the dacha will be used only in the summer, you can limit yourself to one camera. By the way, currently the cost of such a window is not much higher than classic wooden frames. And PVC is in any case much stronger and more durable.

Terrace

As a rule, this part of the house is used only in summer. Is it worth installing structures with two chambers here? Perhaps this is an unnecessary overpayment.

Apartments and houses in the southern regions

The choice of window also depends on the temperature outside the window. If in winter it does not drop below zero, a single-chamber product is sufficient. In other cases, it is advisable to install two-chamber analogues with three glasses.

Thus, a double-glazed window has an important task: to protect the house from drafts, cold and noise. It is important to calculate whether in a particular situation it is worth paying extra for two cameras. Often, one camera is enough. Therefore, the costs will be lower, the house will be brighter, and this model will last much longer.

manufactures, sells and installs single-chamber double-glazed windows. All our products meet the strict requirements of sound and heat insulation, as well as being durable and attractive.

Before ordering such windows, please ask our managers about the feasibility of such a choice. We will advise you on this issue, taking into account the specific operation of the structures and help you make a choice. Call now!

Is wider the better or not?

The same two-chamber product can have a width from 28 to 42 mm. And a reasonable question arises, which one is better, or is this just an advertising gimmick by the manufacturers. In fact, everything is simple - a wider plastic profile has a wider glass unit. Profiles with a width of 60 mm (the so-called economy) have a package size of 28-32 mm, profiles with a width of 70 mm (standard or premium) - from 36 to 42 mm, that is, depending on which profile you choose, you will receive the appropriate package. By and large, this figure affects not so much the heat as the sound insulation of the room, that is, the wider it is, the quieter the room will be. Although company consultants usually focus specifically on the thermal properties of wider products, this is not true.

Distance frames in double glazed windows

The separating glass frames in a double-glazed window perform several functions simultaneously:

- form a heat-insulating air chamber,

- silica gel filled into the frame dries the air inside the chamber,

- decorative - one of several colors can be selected.

Distance frames differ in type and material from which they are made. The most common: plastic, aluminum, combined (TGI).

The material, such as aluminum, used in the production of the frame is a good thermal conductor. Plastic, on the contrary, is a heat insulator. Depending on the glass unit ordered for production, or more precisely the type of frame, a cold bridge and fogging may (or may not) occur. Distance frames for double-glazed windows and their properties

Decoding the glass unit formula

Deciphering the formulas of double-glazed windows requires knowledge of their general design, as well as the designations used by manufacturers. First, let's look at the labeling structure.

It includes two blocks.

- Block of letter designations. It indicates the number of cameras and key features of the double-glazed window. Example - “SPD Ud E”.

- Block format x1–y1–x2–y2–x3. It indicates the thickness of the glass and the width of the spacer frames. Various qualifying notations are added to the numbers. Example - 4ESG–16–4M1–14Ar–4i.

As a result, the formula of this double-glazed window looks like this: SPD Ud E 4ESG–16–4M1–14Ar–4i. As you can see, the result was something incomprehensible to an unprepared customer. Next we will tell you how to read such markings.

Formulas for standard single and double glazing

Standard glass units include double-glazed windows that do not have special additional properties. These are increased impact resistance, frost resistance, sound insulation, energy saving, protection from ultraviolet rays, etc.

The structures look like this.

Image No. 1: single-chamber and double-chamber double-glazed windows as standard

Formula of single-chamber double-glazed windows in the standard version

The formula of a single-chamber double-glazed window contains “SPO” (Single Glass Packet). Let's look at an example.

SPO 4M-10-4M

The marking indicates that the package includes two glasses 4 mm thick. The width of the spacer frame is 10 mm. The letter M denotes the quality of glass obtained by drawing. The range of values is from M1 (highest quality) to M8 (low quality). If the marking simply contains the letter “M”, then this means “M1”, i.e. the highest quality.

The main characteristics of standard single-chamber double-glazed windows with various formulas are presented in the table below. As you can see, with the highest quality glass, the letter “M” is not indicated in the formulas at all.

Image No. 2: main characteristics of standard single-chamber double-glazed windows

Formula of double-chamber double-glazed window in standard version

The formula of a double-chamber double-glazed window contains “SPD” (Double-Chamber Glass Packet). Let's look at an example.

SPD 4M-10-4M-10-4M

In this case, we have a double-chamber double-glazed window made of 4 mm glass of the highest quality. The width of the spacer frames is 10 mm.

The main characteristics of standard single-chamber double-glazed windows with various formulas are presented in the table below.

Image No. 3: main characteristics of standard double-glazed windows

Formulas of special and improved double-glazed windows, markings of their parts

The formulas of special and improved double-glazed windows are distinguished by expanded structural blocks. Various letter designations are added to the first, and clarifying information is added to the numbers of the second.

Formulas for double-glazed windows with special glasses

When using special glasses, the second blocks of formulas are expanded. The following designations are assigned to the numbers indicating the thickness of the sheets.

- F or float. The marking indicates the use of float glass, manufactured by the method of continuous casting of a silicate mixture onto a layer of tin with cooling. Example - SPO 4F-10-4F.

- Fjumbo. These are large architectural float glasses. Maximum size - 6*3.21 m. Example - SPO 4Fjumbo-10-4Fjumbo.

- A. It says that the glass is reinforced. During their production, low-carbon steel wire meshes are installed in silicate mixtures. SPO 4A-10-4A.

Photo No. 1: reinforced glass

Formulas for double-glazed windows with tinted glass

If the glass unit contains tinted glass, the following designations are added to their thickness.

- Ton, T, Tone, ton.mass. These are generalized abbreviations for tinted glass. Example SPO 4T-10-4T.

- Bronze, Green, Gray etc. n. Indicate a specific tint color. Example - SPO 4Green-10-4Green.

Tinted float glass is made by adding metal oxides to liquid raw materials.

Photo No. 2: tinted windows

Triplex formula

The triplex formula looks different. Multilayer glass is produced by gluing several sheets together using special polymer films or compounds. This ensures maximum impact resistance and increases operational safety.

Image No. 4: triplex

Triplex is indicated in markings in two ways.

- 3-3-1 (3(1)3, 3.1.3). Triplex is glued together from two 3 mm glasses. Film thickness - 1 mm.

- MC1. "MS" stands for Laminated Glass. In this case, it is glued together from two 4 mm sheets. Film thickness - 1 mm.

Characteristics of double-glazed windows 4 16 4

- heat transfer resistance – 0.35 (m2 - C)/W;

- sound insulation – 26 dB;

- light transmission – 84%.

Leave a request to agree on a convenient time for you for a measurer to arrive Leave a request to call a measurer

When using sprayed glass, the heat transfer resistance increases to 0.51. The sound insulation parameter also increases to 27, but at the same time light transmission decreases to 70%.

For glazing of country cottages and apartments in big cities, we recommend choosing a double-chamber 24 mm 4 16 4 instead of a single-chamber double-glazed unit. It protects rooms much more effectively from noise from the street and saves up to 40% of heat.

I-glass and multifunctional: which is better, what is the difference?

I - glass

- low-emissivity glass with a high ability to reflect infrared (thermal) radiation.

Multifunctional - glass

- glass that combines two functions. The first is the ability of I-glass to reflect infrared (thermal) radiation. The second is the ability of solar reflective glass to reflect the thermal energy of the sun.

Comparison of I-glass (ClimaGuard N) and Multifunctional glass (ClimaGuard Solar)

| Formula | Light transmittance τv(%) | Solar factor g (%) | UV transmittance τuv(%) | Heat transfer resistance m2 S/W |

| 4M1-16Ar-4M1-14Ar-I4 | 73 | 60 | 30 | 0.95 (calc.) |

| 4CGS-16Ar-4M1-14Ar-4M1 | 62 | 40 | 24 | 1.0 (calc.) |

Conclusion:

multifunctional glass in a double-glazed window makes it not only heat-saving, but also better shades the room and protects it from the heat.

What does a plastic double-glazed window look like?

Actually, a blind PVC double-glazed window, not yet inserted into the profile, is a glass block usually in the shape of a parallelepiped, the width and height of which significantly exceed the thickness.

There are also double-glazed windows of more complex shapes. Visually, the third glass, located in the middle of the glass unit, is practically indistinguishable. Therefore, from a distance, a double-glazed window gives the impression of an all-glass monolith inserted into a window block.

Up close you can see that this design has glass at the front and back, spacers around the entire perimeter inside, and sealant along the entire contour outside (at the ends, top, bottom).

If the glass unit is already installed in the sash, the sealant and the main part of the spacer frame are hidden from view, only the glass and the side of the spacer (dividing frame) facing the inside of the glass unit are visible, which is visually perceived as a metal (less often polymer) strip with small perforations - diffusion holes.

Without a profile, in the edge zone of the glass unit, the sides of the spacer frame are visible, glued to the glass with a thin layer of sealant.

The easiest way to visually distinguish a double-glazed window from a single-chamber one is to turn off the overhead light in the evening and go to the window with a lighter or flashlight.

Double-glazed glass design

Some elements of the glass unit are hidden from view. The composition of a two-chamber double-glazed window includes:

- glass – 3;

- chambers (interglass spaces) with air or gas filling – 2;

- distance (dividing) frames – 2;

- desiccant;

- internal (primary) sealant;

- external (secondary) sealant.

Glass can differ in production and processing technology, PVC profile, composition, coating, color, thickness, and it is on their characteristics that the properties of a double-glazed window largely depend.

It is also important to fill the chamber between the glasses; regular moist air must be pumped out of it; the inside of the glass unit must contain a minimum of moisture, otherwise condensation will negate its heat-protective properties.

The spacer frame is a hollow tube with a cross-section close to rectangular, lightweight but durable. Initially, spacer frames were made of aluminum, less often of steel; later, a technology for producing frames from polymers with lower thermal conductivity than metal was developed.

The frame can consist of four straight segments connected by corners, or bend at the corners. In the second case, the structure has only one joint and the likelihood of depressurization through the joints is significantly reduced.

The spacer is filled with a desiccant (absorbent, desiccant - a substance with a large number of pores), and there are small diffusion holes along the top of the frame. Through them, moisture molecules penetrate from the air in the chamber into the frame and are absorbed by the absorbent. The following are used as a desiccant:

- molecular sieve;

- silica gel;

- a mixture of them.

Primary sealant - butyl mastic or tape, which retains elasticity after hardening, is used to firmly connect glass and frames into a single structure and to protect against water vapor contained outside.

After gluing the glass and frames, a secondary, external sealing is carried out to give the structure additional strength and moisture-vapor resistance. For external sealing, plastic masses based on:

- polysulfide;

- silicone;

- polyurethane.

Double-glazed window: formula, thickness and advantages

Compared to a single-chamber double-glazed window, the formula for a double-chamber double-glazed window is more complicated, it consists of 5 elements, 1, 3 and 5 - glass characteristics (thickness, category), 2 and 4 - chambers (width, filling).

You can calculate the thickness of a two-chamber double-glazed window using this formula by adding all the numbers - the thickness of three glasses and the width of two chambers. A double-chamber double-glazed window can be symmetrical or asymmetrical; different design options for glazing are possible:

- all glass is the same thickness, and the chambers are of equal width;

- the width between the glasses is the same, but the thickness of one of the glasses differs from the thickness of the other two, or all three have different thicknesses;

- different glass thicknesses and different chamber widths.

Thicker glass not only absorbs noise better, but if the thickness of the glass in a double-glazed unit does not match, the resonance that occurs between them is dampened, so that the sound insulation characteristics of the double-glazed window are increased.

The different widths of the chambers also contribute to noise absorption; the best performance will be with an asymmetrical double-glazed window with different thicknesses of all three glasses. The width of the chambers and the thickness of the glass also affect the thermal insulation characteristics, but it is more effective to increase them by replacing standard glass with low-emissivity glass in combination with filling with argon.

The standard thickness of the glass used in double-glazed windows is 4 mm; to improve heat conservation and noise protection, 1-2 glasses are replaced with thicker ones - 5 or 6 mm; glasses of smaller and larger thickness (3 or 7-8 mm) are used much less frequently, on order.

The width of the chambers in double-glazed windows often varies in the range of 6-16 mm. Double-glazed windows with a width (mm) available on the Russian market are:

- 24, with 6 mm chambers between 4 mm glasses;

- 32, along with the formula (4-10-4-10-4), the options (6-8-4-8-6), (4-10-4-8-6) are used;

- 36, 12 mm chambers, 4 glasses;

- 40, 14 mm cameras.

Double-chamber windows of greater width - 42, 44 mm - are still a new product, the standard formula of the latter (4-16-4-16-4), its sound insulation and heat transfer resistance are the maximum among all of the above, but the weight is also the heaviest.

In terms of performance characteristics, taking into account the price, the thickness of the double-glazed window is considered to be 40 mm; another popular solution is a double-glazed window of 32 mm.

Theoretically, the thickness of a double-glazed window can reach 72 mm if the interglazing spaces are widened to 24 mm and thickened glass of 8 mm is used. And the minimum width, based on technical conditions, is 24 mm.