Light in the ancient world

People used to think that the world was filled with mysteries. Even the human body carried a lot of unknowns. For example, the ancient Greeks did not understand how the eye sees, why color exists, why night comes. But at the same time, their world was simpler: light falling on an obstacle created a shadow. This is all that even the most educated scientist needed to know. Nobody thought about light transmittance and heating. And today they study this in school.

Light meets obstacle

When a stream of light hits an object, it can behave in four different ways:

- to be absorbed;

- dissipate;

- reflect;

- go further.

Accordingly, any substance has absorption, reflection, transmission and scattering coefficients.

Absorbed light changes the properties of the material itself in different ways: it heats it, changes its electronic structure. Scattered and reflected light are similar, but still different. When reflected, light changes its direction of propagation, and when scattered, its wavelength also changes.

A transparent object that allows light to pass through and its properties

Reflection and transmittance coefficients depend on two factors - the characteristics of light and the properties of the object itself. What matters is:

- Aggregate state of a substance. Ice refracts differently than steam.

- Structure of the crystal lattice. This paragraph applies to solids. For example, the transmittance of coal in the visible part of the spectrum tends to zero, but a diamond is a different matter. It is the planes of its reflection and refraction that create a magical play of light and shadow, for which people are willing to pay exorbitant amounts of money. But both of these substances are carbons. And the diamond will burn in a fire no worse than coal.

- Temperature of the substance. Oddly enough, at high temperatures some bodies themselves become a source of light, so they interact with electromagnetic radiation somewhat differently.

- The angle of incidence of a beam of light on an object.

In addition, we must remember that the light that comes out of the object can be polarized.

Operator Transfer Ratio

Main article: History of automation.

The rapid spread of telegraphy, and later telephony, from the mid-nineteenth century stimulated much research into the behavior of electrical circuits. For several years, starting in 1888, British engineer Oliver Heaviside published his articles on the operator's account. In principle, it can be said that between 1892 and 1898 Oliver Heaviside invented operator calculus, studied the transient behavior of a system, and introduced the later concept of transmittance. Although his methods produced convincing results regarding the short-term response of electrical systems, he was harshly criticized by his contemporaries for his lack of rigor and was ultimately cursed by the modern scientific community.

The development of operator calculus as methods for solving certain types of differential equations on algebraic grounds dates back to the early 19th century. This approach was popularized by Oliver Heaviside (1892, 1899), who used operator calculus in electrical problems, reducing differential equations to algebraic equations. It was not until the 1920s and 1930s that Heaviside's idea (a concept corresponding to the later transmittance) was associated with the Fourier and Laplace transforms (Bromwich, Carson, van der Pol, Deutsch), leading to wider uses of operator calculus. in many problems of physics and technology, as well as in problems of automatic control of mechanical systems. Finding these connections also ultimately proved Heaviside's methods to be correct.

Certain restrictions on the applicability of integral transformations, and above all the development of functional analysis, prompted mathematicians to look for new concepts of operator calculus. A complete return to the original point of view of the operator can be observed, for example, in Jan Mikusinski. He gives a rigorous justification for the Heaviside operator calculus without reference to the Laplace transform. Further work on new general foundations of operator calculus also relates in some way to Heaviside's concept.

Classical operator calculus as a mathematical tool is widely used in the theory of linear dynamical systems. This is one of the areas of modern mathematics that owes much of its importance to technical applications. The use of operator methods greatly simplifies calculations and leads to solutions in a very convenient form for further analysis and synthesis of the system. Due to its simplicity and efficiency, as well as many advantages over other methods, operator calculus has become one of the main methods for studying dynamic systems, despite the many restrictions imposed on the input and output quantities of the system.

Wavelength and transmission spectrum

As we mentioned above, transmittance depends on the wavelength of the incident light. A substance that is opaque to yellow and green rays appears transparent to the infrared spectrum. The Earth is also transparent to small particles called neutrinos. That is why, despite the fact that the Sun generates them in very large quantities, it is so difficult for scientists to detect them. The probability of a neutrino colliding with matter is vanishingly small.

But most often we are talking about the visible part of the spectrum of electromagnetic radiation. If there are several segments of the scale in a book or problem, then the optical transmittance will relate to that portion of the scale that is accessible to the human eye.

Reflection, transmission and absorption coefficients, optical density.

The color of different objects illuminated by the same light source (for example, the sun) can be very diverse, despite the fact that all these objects are illuminated by light of the same composition. The main role in such effects is played by the phenomena of reflection and transmission of light. As has already been clarified, the light flux incident on a body is partially reflected (scattered), partially transmitted and partially absorbed by the body. The proportion of the luminous flux participating in each of these processes is determined using the corresponding coefficients: reflection r, transmission t and absorption a (see § 76).

Each of the indicated coefficients (a, r, t) can depend on the wavelength (color), due to which various effects arise when illuminating bodies. It is not difficult to see that any body in which, for example, the transmittance coefficient for red light is large and the reflection coefficient is small, and for green light, on the contrary, will appear red in transmitted light and green in reflected light. Such properties are possessed, for example, by chlorophyll, a green substance contained in plant leaves and responsible for their green color. A solution (extract) of chlorophyll in alcohol appears red in transmission and green in reflection.

Bodies in which absorption is high for all rays, and reflection and transmission are very small, will be black opaque bodies (for example, soot). For a very white opaque body (magnesium oxide), the coefficient r is close to unity for all wavelengths, and the coefficients a and t are very small. Completely transparent glass has low reflection coefficients r and absorption coefficient a and transmittance coefficient t close to unity for all wavelengths; on the contrary, for colored glass for some wavelengths the coefficients t and r are practically zero and, accordingly, the value of the coefficient a is close to unity. The difference in the values of the coefficients a, t and r and their dependence on color (wavelength) cause extreme diversity in the colors and shades of different bodies.

Optical density is a measure of the attenuation of light by transparent objects (such as crystals, glass, photographic film) or the reflection of light by opaque objects (such as photography, metals, etc.).

It is calculated as the decimal logarithm of the ratio of the radiation flux incident on an object to the radiation flux passing through it (reflected from it), i.e. it is the logarithm of the reciprocal of the transmittance (reflection) coefficient.

D = log Ф in / Ф out

For example, D=4 means that the light was weakened by 104=10,000 times, i.e. for a person it is a completely black object, and D=0 means that the light passed (reflected) completely.

In terms of optical density, the exposure requirements for negatives are specified.

A device for measuring optical density is called a densitometer. In x-ray non-destructive testing methods, the optical density of an x-ray image is a parameter for assessing the suitability of the image for further interpretation. Acceptable values of optical density in x-ray non-destructive testing methods are regulated in accordance with the requirements of GOST.

Reflectance coefficient is a dimensionless physical quantity that characterizes the ability of a body to reflect radiation incident on it. Greek or Latin is used as a letter designation [1].

Quantitatively, the reflection coefficient is equal to the ratio of the radiation flux reflected by the body to the flux incident on the body [1]:

The sum of the reflection coefficient and the absorption, transmission and scattering coefficients is equal to unity. This statement follows from the law of conservation of energy.

In cases where the spectrum of incident radiation is so narrow that it can be considered monochromatic, we speak of monochromatic

reflection coefficient.

If the spectrum of radiation incident on a body is wide, then the corresponding reflection coefficient is sometimes called integral

.

In general, the value of the reflectance of a body depends both on the properties of the body itself and on the angle of incidence, spectral composition and polarization of the radiation. Due to the dependence of the reflectance of the surface of a body on the wavelength of light incident on it, the body is visually perceived as colored in one color or another.

Transmittance is a dimensionless physical quantity equal to the ratio of the radiation flux passed through the medium to the radiation flux incident on its surface:

In general, the value of the transmittance [1] of a body depends both on the properties of the body itself and on the angle of incidence, spectral composition and polarization of the radiation.

Transmittance is related to optical density as follows:

The sum of the transmittance and reflection, absorption and scattering coefficients is equal to unity. This statement follows from the law of conservation of energy.

Absorption coefficient is the percentage of absorption by an object of another object interacting with it. The interacting object can be electromagnetic radiation, sound wave energy, ionizing or penetrating radiation, or a substance (for example, hydrogen gas).

— flux ratio ,

absorbed by a given body, to the flux of radiation falling on this body.

If the incident flow has a wide spectrum, the indicated ratio characterizes the so-called. integral P. k.; if the frequency range of the incident light is narrow, then they speak of monochromatic absorptivity - the absorption capacity

of the body.

In accordance with the law of conservation of energy for monochromatic The sum of the radiation coefficient, reflection coefficient

and

transmission coefficient

is equal to unity.

In contrast to the absorption indicator,

which characterizes the properties of a substance, the absorption coefficient depends on the thickness of the layer through which light passes, i.e. on the size of the body, on the temperature, on the state of the reflective surface. Spectroscopy is sometimes referred to as “P.” To." understand the absorption rate.

Optical density is a measure of the attenuation of light by transparent objects (such as crystals, glass, photographic film) or the reflection of light by opaque objects (such as photography, metals, etc.).

It is calculated as the decimal logarithm of the ratio of the radiation flux incident on an object to the radiation flux passing through it (reflected from it), that is, it is the logarithm of the reciprocal of the transmittance (reflection) coefficient [1]:

For example, D=4 means that the light was weakened by 104=10,000 times, that is, for a person it is a completely black object, and D=0 means that the light passed (reflected) completely.

In terms of optical density, the exposure requirements for negatives are specified.

A device for measuring optical density is called a densitometer. In x-ray non-destructive testing methods, the optical density of an x-ray image is a parameter for assessing the suitability of the image for further interpretation. Acceptable values of optical density in x-ray non-destructive testing methods are regulated in accordance with the requirements of GOST.

Optical density

D, a measure of the opacity of a layer of substance to light rays. Equal to the tenth logarithm of the ratio of the radiation flux (See Radiation flux) F0 incident on the layer to the flux F weakened as a result of absorption and scattering passing through this layer: D = log (F0/F), otherwise, O.p. is the logarithm the reciprocal of the Transmittance coefficient of the layer of matter: D = log (1/τ). (In the definition of the sometimes used natural op., the decimal logarithm lg is replaced by the natural ln.) The concept of op. was introduced by R. Bunsen; it is used to characterize the attenuation of optical radiation (See Optical radiation) (light) in layers and films of various substances (dyes, solutions, colored and milky glasses, and many others), in light filters and other optical products. O.P. is used especially widely for the quantitative assessment of developed photographic layers in both black-and-white and color photography, where the methods of its measurement form the content of a separate discipline—densitometry. There are several types of optical radiation depending on the nature of the incident radiation and the method of measuring the transmitted radiation fluxes ( Fig. ).

The operating frequency depends on the set of frequencies ν (wavelengths λ) characterizing the original flow; its value for the limiting case of one single ν is called monochromatic OP. The regular ( Fig. a) monochromatic OP of a layer of a non-scattering medium (without taking into account corrections for reflection from the front and rear boundaries of the layer) is equal to 0.4343 kνl, where kν is the natural Absorption index of the medium, l is the thickness of the layer (kνl = κcl is the index in the Bouguer-Lambert-Beer law equation; if scattering in the medium cannot be neglected, kν is replaced by the natural Attenuation index). For a mixture of non-reacting substances or a set of media located one after the other, the opacities of this type are additive, that is, equal to the sum of the same opacities of individual substances or individual media, respectively. The same is true for regular nonmonochromatic radiation (radiation of a complex spectral composition) in the case of media with nonselective (independent of ν) absorption. Regular non-monochromatic The O.P. of a set of media with selective absorption is less than the sum of the O.P. of these media. (For instruments for measuring O.P., see the articles Densitometer, Microphotometer, Spectrozonal aerial photography, Spectrosensitometer, Spectrophotometer, Photometer.)

Coefficient formula

Now the reader is already sufficiently prepared to see and understand the formula that determines the transmission of a substance. It looks like this: T=F/F0.

So, transmittance T is the ratio of the radiation flux of a certain wavelength that passed through the body (F) to the initial radiation flux (F0).

The quantity T has no dimension, since it is designated as the division of identical concepts into each other. However, this coefficient is not without physical meaning. It shows how much electromagnetic radiation a given substance transmits.

Mathematical definitions[edit]

Hemispherical transmittance[edit]

Hemispherical transmittance

surface, denoted by

T

, is defined as [3]

T = Φ e t Φ e i , {\displaystyle T={\frac {\Phi _{\mathrm {e} }^{\mathrm {t} }}{\ Phi_{\mathrm{e}}^{\mathrm{i}}}}, }

where

- Φ et is the radiant flux transmitted

by this surface; - Φ ei is the radiant flux received by this surface.

Spectral hemispherical transmittance[edit]

Spectral hemispherical transmittance by frequency

and

the spectral hemispherical transmittance along the surface wavelength

, denoted

T

ν and

T

λ respectively, are defined as [3]

T ν = Φ e , ν t Φ e , ν i , {\displaystyle T_{\nu }={\ frac {\Phi_{\mathrm {e},\nu}^{\mathrm {t} }}{\Phi _{\mathrm {e},\nu}^{\mathrm {i} }},} T λ = Φ e , λ t Φ e , λ i , {\displaystyle T_{\lambda }={\frac {\Phi _{\mathrm {e},\lambda } ^{\mathrm {t} } } {\Phi_{\mathrm {e},\lambda}^{\mathrm {i} }},}

where

- Φ e, ν t is the spectral flux of radiation at frequency transmitted

by this surface; - Φ e, ν i is the spectral flux of radiation at the frequency received by this surface;

- Φ e, λ t is the spectral flux of radiation at the wavelength transmitted

by this surface; - Φ e, λ i is the spectral flux of radiation at the wavelength received by this surface.

Directional transmission[edit]

Directional transmission

surface, denoted

T

Ω, is defined as [3]

T Ω = L e , Ω t L e , Ω i , {\displaystyle T_{\Omega }={\frac {L_{\mathrm {e},\ Omega}^{\mathrm {t}}}{L_{\mathrm {e},\Omega}^{\mathrm {i}}}},}

where

- L

e, Ω t is the brightness

transmitted

by this surface; - L

e, Ω i is the radiance received by this surface.

Spectrally directional transmission[edit]

Spectral-directed frequency transmission

and

the spectral directional transmittance along the surface wavelength

, denoted

T

ν, Ω and

T

λ, Ω respectively, is defined as [3]

T ν , Ω = L e , Ω , ν t L e , Ω , ν i , {\displaystyle T_{\nu,\Omega}={\frac {L_{\mathrm {e},\Omega,\nu}^{\mathrm {t} }}{L_{\mathrm {e},\Omega ,\nu} ^{\mathrm {i} }}},} T λ , Ω = L e , Ω , λ t L e , Ω , λ i , {\displaystyle T_{\lambda ,\Omega }={ \frac {L_{\mathrm {e} ,\Omega ,\lambda }^{\mathrm {t} }}{L_{\mathrm {e} ,\Omega ,\lambda }^{\mathrm {i} }} },}

Where

- L

e, Ω, ν t is the spectral brightness at the frequency

transmitted

by this surface; - L

e, Ω, ν i is the spectral brightness perceived by this surface; - L

e, Ω, λ t is the spectral brightness at the wavelength

transmitted

by this surface; - L

e, Ω, λ i is the spectral brightness at the wavelength received by this surface.

"Radiation Flow"

This is not just a phrase, but a specific term. Radiation flux is the power that electromagnetic radiation carries through a unit surface. In more detail, this value is calculated as the energy that radiation moves through a unit area in a unit time. Area most often refers to square meters, and time refers to seconds. But depending on the specific task, these conditions can be changed. For example, for a red giant, which is a thousand times larger than our Sun, you can safely use square kilometers. And for a tiny firefly - square millimeters.

Of course, in order to be able to compare, unified measurement systems were introduced. But any value can be reduced to them, unless, of course, you mess with the number of zeros.

Also related to these concepts is the value of the directional transmittance. It determines how much and what kind of light passes through the glass. This concept cannot be found in physics textbooks. It is hidden in the technical specifications and rules of window manufacturers.

Transmittance

The transmittance coefficient m characterizes the ratio of the radiation flux transmitted by the body to the radiation flux incident on [p.232]

For calculations related to the transition from transmittance to optical density, it is recommended to use the table. 15.1. At the intersection of the row and column, the corresponding optical density values are given. Using this table you can find the optical density corresponding to any transmittance value from 0 to 99%. Intermediate values of optical density are found by linear interpolation. When determining the optical density corresponding to transmittances less than 10%, it is recommended to first increase this transmittance by 10 times, then find the optical density corresponding to the obtained transmittance, and add one to this optical density value. [p.137]

KFO - photoelectric single-beam colorimeter - is designed for measuring the transmittance of transparent media in the visible region of the spectrum. The optical design of the device and its appearance are shown in Fig. 15.4, 15.5, characteristics of light filters - in Fig. 15.6. [p.137]

Infrared spectrophotometric method for measuring humidity. Based on the relationship between the water content in the emulsion and its spectral properties [144]. Typical spectrograms of transmittance coefficients for water and oil are shown in Fig. 9.4 (curves 3 and 4). The measurement method is as follows. The oil sample to be measured is poured into a transparent cuvette and a light beam produced by a narrow-band optical filter is passed through it. The spectral characteristics of two such filters are shown in Fig. 9.4 (curves I and 2). The intensity of the light signal passing through the cuvette is measured by a photocell. If we denote by /o and 1 the intensity of the light flux before and after passing through the oil, and by and k2 - the absorption coefficients of water and oil in the measured spectral range, taking into account the thickness of the oil layer in the cuvette, then we can write the following equality [p.169]

Comparison of the curves of changes in the color index (transmittance coefficient K on the KFK) and the relative content of various types of contaminants depending on the cleaning time shows their opposite change, that is, with a decrease in the amount of impurities, the color index increases and vice versa (Fig. 2). [p.115]

What is called transmittance T and optical density /) Within what limits do these quantities vary [p.135]

The SF-46 spectrophotometer, like the SF-26, is designed to measure the transmittance of liquid and solid transparent substances in the spectral region from 190 to 1100 nm, but is equipped with a microprocessor system (MPS) Electronics MS-2703, which significantly expands the capabilities of the spectrophotometer. Thus, in addition to the values of light transmittance and optical density, the device can directly display the concentration of a substance both in a one-time mode and in a cyclic mode with a period of 5 s. It is also possible to determine the rate of change in optical density [p.146]

From the analysis of the given kinetic curves it is also clear that at the initial moment of the sorption purification process, with a sharp increase in the purity of paraffin (in terms of transmittance), practically no aromatic compounds are removed. This allows us to conclude that the aromatic compounds contained in solid paraffins do not affect their color and are represented by hydrocarbons identified by the GCS method as light aromatic [3], that is, compounds with one aromatic ring and a long paraffin chain. The relatively low content of compounds including aromatic fragments (according to IR spectroscopy) confirms the previously stated assumption [3] about the non-aromatic nature of heterocompounds present in solid paraffins. [p.115]

Transmittance is the ratio of the radiant energy transmitted through the body to the incident energy [p.11]

E) must be established empirically. This can most simply be done using a step attenuator, which is a quartz or glass plate coated with a set of translucent metal strips with different transmittance coefficients T/. [p.76]

O to 1. This value is often expressed as a percentage. If the T value is related to a layer thickness of 1 cm, then it is called the transmittance coefficient. Absorption of radiation is characterized by optical density [p.179]

Relative aperture of the monochromator 111 Range of transmittance scale indicators, %. from O to 110 [p.130]

To measure the transmittance of liquids, there is a set of paired cuvettes with layer thicknesses of 5, 10, 20 and 50 mm. [p.215]

If it is necessary to measure the transmittance coefficient more than 90% with great accuracy, then handle 2 is set to position 3 and the reading taken on the transmittance scale is multiplied by 0.1 and 90 is added to it. [p.82]

The SF-26 spectrophotometer (Fig. 32) is equipped with a number of devices to improve the accuracy of the measurement: the handle 12 turns on the compensation resistors when stretching the 10 /o range to the full scale, which has ten positions, ensuring operation in transmittance ranges from 110 to 100, 100 - 90, from 10 to 0 handle 13 count for selecting a measurement scale with four positions. Position X1 of the handle, the countdown is used for measurements in the range from 100 to 0, position X0, b> - to stretch the 10% range to the full scale of the measuring device when the compensator is turned on; position gauge - to set a 100% countdown when working with highly absorbing materials samples, when the light fluxes passing through the sample being measured and falling on the photodetector are small. In this case, the measurement is carried out with wider slits to increase the light flux, position X0.01 is used when measuring samples with a transmittance of less than 10% for stretching [p.82]

The SF-26 spectrophotometer is designed to measure the transmittance or absorption coefficient of liquid and solid substances in the spectral region from 186 to 1100 nm. [p.130]

If the T value is related to a layer thickness of 1 cm, then it is called the transmittance coefficient. Thus, O = -log T, [p.374]

The main error of transmittance measurements in the spectral region from 190 to 1100 nm, % abs., no more. . I [p.130]

Transmittance, optical density, concentration (in single measurement mode), change in optical density over time [p.136]

Spectrophotometers. The dual-beam spectrophotometer SF-26 is designed for measuring transmittance and optical density of liquid and solid substances in the spectral range from 186 to 1100 nm. The optical design and appearance of the spectrophotometer are shown in Fig. 15.12 and 15.13. To ensure operation of the device in such a wide spectral range, two radiation sources are used: a DDS-30 deuterium lamp for operation in the spectral region of 186-350 nm and an OP-33-0.3 incandescent lamp for operation in the 340-1100 nm region. Two photocells also serve as radiation receivers. Antimony-cesium with a quartz glass window is used for measurements in the spectral region from 186 to 650 nm, oxygen-cesium for measurements in the range from 600 to 1100 nm. The wavelength of the incident radiation is determined by rotating the quartz prism. The analyzed sample can be either in solid form (then it is placed in a special holder) or in the form of a solution [p.143]

Further work depends on whether you want to measure transmittance or optical density. [p.140]

Law of energy conservation

This law is the reason why the existence of a perpetual motion machine and the philosopher's stone is impossible. But there are water and wind mills. The law states that energy does not come from anywhere and does not dissolve without a trace. Light falling on an obstacle is no exception. It does not follow from the physical meaning of transmittance that since some of the light did not pass through the material, it evaporated. In fact, the incident beam is equal to the sum of absorbed, scattered, reflected and transmitted light. Thus, the sum of these coefficients for a given substance must be equal to one.

In general, the law of conservation of energy can be applied to all areas of physics. In school problems, it often happens that the rope does not stretch, the pin does not heat up, and there is no friction in the system. But in reality this is impossible. In addition, it is always worth remembering that people do not know everything. For example, during beta decay some energy was lost. Scientists did not understand where it went. Niels Bohr himself suggested that at this level the conservation law may not be observed.

But then a very small and cunning elementary particle was discovered - the lepton neutrino. And everything fell into place. So if the reader, when solving a problem, is not clear where the energy goes, then we must remember: sometimes the answer is simply unknown.

Application of the laws of transmission and refraction of light

We said a little higher that all these coefficients depend on what substance gets in the way of the electromagnetic radiation beam. But this fact can also be used in the opposite direction. Taking a transmission spectrum is one of the simplest and most effective ways to find out the properties of a substance. Why is this method so good?

It is less accurate than other optical methods. Much more can be learned by making a substance emit light. But this is the main advantage of the optical transmission method - no one needs to be forced to do anything. The substance does not need to be heated, burned or irradiated with a laser. Complex systems of optical lenses and prisms are not required, since the light beam passes directly through the sample being studied.

In addition, this method is non-invasive and non-destructive. The sample remains in its original form and condition. This is important when the substance is scarce or when it is unique. We are sure that Tutankhamun’s ring should not be burned in order to find out more precisely the composition of the enamel on it.

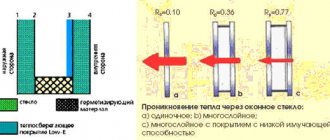

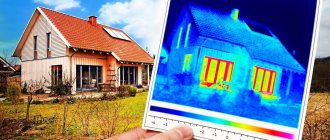

Glass and double glazing

Glass and double glazing

1. Characteristics of glass

Heat transfer coefficient (U-value) or heat transfer coefficient. Used to quantify heat transfer through glass (or wall). The coefficient determines the amount of heat in W passing through 1 m2 of glass per hour when the temperature difference on the sides of the glass is 1°C. This is the amount of heat loss. The lower the U-value, the greater the level of insulation and the less heat loss.

Light transmission, luminous transmission (LT) - the ratio of the luminous flux passing through the glass to the incident luminous flux, expressed in illuminance units.

Light reflection (LR) is the ratio of the luminous flux reflected from the glass to the incident luminous flux.

Transmission of ultraviolet radiation (UV) is the ratio of the magnitude of the flux of UV radiation passing through the glass to the magnitude of the flux of UV radiation incident on the glass (in the spectral range of 280-380 nm).

Direct solar energy transmission (DET) is the amount of luminous energy transmitted directly through the glass, expressed as a % of the total luminous energy incident on the glass surface (in the spectral range 300-2150 nm).

Energy reflection (ER) is the amount of luminous energy reflected by glass, expressed as a percentage of the total luminous energy incident on the glass surface.

Energy absorption (EA) - the amount of luminous flux energy absorbed by the mass of glass, expressed as a % of the total amount of luminous flux energy incident on the glass surface.

Solar factor (SF) or total energy transmission, or solar heat gain coefficient, or total transmitted energy is the ratio of the total amount of energy of the luminous flux passing through the glass to the absolute amount of energy of the luminous flux incident on the surface of the glass. The total amount of energy refers to the combination of direct transmission energy (DET) and the amount of energy emitted by the glass into the room during the process of energy absorption (EA).

Shading Coefficient (SC) - Calculated by dividing SF by 0.87 (solar factor for 3mm clear glass).

Emissivity is a measure of the ability of any surface to absorb or lose heat. Emissivity is assessed on a scale from “0” to “1” (from 0 to 100%). A high value on the scale indicates that the surface is a good heat emitter (loses heat quickly). A low value on the scale indicates that the surface is a poor heat emitter (loses heat slowly).

Emissivity of the surface of ordinary glass = 0.9.

Emissivity of the glass surface with a “hard” coating (K-glass) = 0.17.

Emissivity of a glass surface with a “soft” coating (i-glass) = 0.06.

These coefficients show that ordinary glass has a high emissivity of 0.9 and is therefore a poor thermal insulator (loses heat quickly). Low-emissivity glass with a soft coating has a very low emissivity of 0.06. Therefore, it loses heat slowly and is a good thermal insulator.

2. Main characteristics of double-glazed windows

Light transmittance

— determines the proportion of light penetrating through the glass unit. This figure decreases if the thickness of the glass unit increases.

Total solar energy transmittance

— determines the proportion of infrared radiation from the sun penetrating through the glass unit. This figure decreases if you increase the thickness of the glass unit or use an energy-saving glass unit.

Noise-proof and anti-resonance double-glazed windows

Noise-proof double-glazed windows are those that provide sound insulation of at least 34 dB (regardless of the number of chambers). This effect is achieved by using thicker glass (for example, 6mm instead of 4mm), which dampens most of the noise. An additional measure in noise reduction is cameras of different thicknesses in multi-chamber packages.

Anti-resonance double-glazed window is a double-glazed window, the design of which not only provides increased sound insulation, but also prevents the amplification (due to resonance) of external noise.

The solution to this problem is to manufacture a double-glazed window with glass of different thicknesses at different distances between them. In the resulting design, both glass and chambers have different widths. Combinations of glass and chambers of different thicknesses reduce the effect of resonance or prevent its occurrence.

Since increasing the level of sound insulation requires an integrated approach, inert gases, such as Argon, are widely used to improve the acoustic properties of all double-glazed windows, including anti-resonance ones.

Safety double glazed windows

Safe double-glazed windows are those that do not cause injuries or cuts when broken. This can be achieved in several ways:

the use of special films or glass glued together (triplex);

glass tempering.

When using films or glass glued together (triplex), when broken, the fragments do not fly apart, but remain on the film.

When tempered glass breaks, it shatters into small fragments that do not have cutting edges.

3. Types of glass

1 Low-E glass

I-glass (ClimaGuard N) is a high-quality glass with a low-emissivity coating applied to one surface of the glass under vacuum conditions using cathode sputtering in a magnetic field of metal-containing compounds with specified selective properties. A layer of silver is applied to the float glass, and titanium oxide is applied as a secondary coating. These layers applied to glass are called “soft coatings”.

Arrangement of layers of “soft coverings”

A significant disadvantage of glass is the low mechanical and chemical resistance of the coating. This is explained by the fact that in order to realize the phenomenon of interference (in order to obtain a transparent coating), coatings (in this case, silver and titanium oxide) are applied at a strictly defined thickness, as a result of which they have a loose structure and are “transparent” to atmospheric moisture and air, which oxidize silver. Hence the special requirements for i-glass. Storage in sealed packaging and limited period of installation work in an open environment. At the same time, in an inert gas environment, the coating material on i-glass is protected from the oxidative effects of atmospheric oxygen and is operational until the glass unit depressurizes.

Applications of Low-E Glass:

Glazing of stained glass windows, windows, entrance doors, glass roofs, winter gardens.

• I-glass is used only as part of a double-glazed window.

• It is installed in a double-glazed window only by spraying inside.

• Installed on the room side.

• Middle glass cannot be used in a double-glazed window, as this can lead to overheating of the air chambers and destruction of the double-glazed window!

• No films, including Accentrium, can be glued to the coated side.

How windows with low-emissivity coating work:

In winter, the glass coating simultaneously prevents ultraviolet radiation from penetrating into the room, as well as infrared rays from heating devices from escaping outside. Thus, the heat is kept inside and the cold outside.

In summer, the sun's rays enter the room, but the glass coating prevents heat penetration. As a result, the house is illuminated but not heated.

How can you tell if there is a coating on the glass?

To check the presence of low-emission spraying, it is enough to do a fire test from a candle (lighter, match). Regular glass will reflect flames of the same color and size, while energy-saving glass will reflect a slightly different shade of fire (usually pinkish or crimson)

2 Energy saving glass

Energy-saving glass Guardian ClimaGuard Premium2 This glass is a further development of the already familiar low-emission glass Guardian ClimaGuard. A key improvement is that the new product is made on the basis of Guardian ExtraClear semi-coated glass (see above), which has a better color rendering coefficient. This guarantees, along with energy-saving functions, more natural colors in the rooms, more comfort and light in the interiors. It is worth noting that in the case of a single-chamber double-glazed window using new glass, the light transmission coefficient is 82%, in the case of a two-chamber double-glazed window - 74%. The improvement in this parameter compared to the previous generation ClimaGuard is approximately 5%.

Thickness of glass used: 4 mm.

3 SunGuard HD solar control glass

Super durable coating

The uniqueness of the SunGuard HD Colors technology lies in the highest mechanical and physical-chemical resistance of the spraying to any negative factors, due to which glass with such a coating can be used in monoglazing, installing the coating towards the room.

Versatility and high optical properties

SunGuard HD Colors glass looks great from the outside and allows you to see the outside world from the inside without distortion, in the most natural colors. It can be hardened, bent and laminated.

Latest Magnetron Coating Technology

SunGuard HD Colors glass is manufactured using advanced magnetron sputtering technology, which provides superior optical and solar control performance.

Ideal for all areas of the window market

The combination of the highest optical properties in its class and the unique resistance of the coating to any negative influences makes SunGuard HD Colors glass the optimal solution for architects, facade designers, processors and distributors.

4 color options available (thickness 4, 5, 6, 8 or 10 mm):

SunGuard HD Silver Gray 32

SunGuard HD Neutral 67

SunGuard HD light Blue 52

SunGuard HD Silver 70

Advantages of glass

• Excellent aesthetic and performance qualities compared to conventional pyrolytic glass.

• High color rendering coefficient compared to tinted glass.

• Easier recycling process compared to standard magnetron-coated glass.

• Increased mechanical and physico-chemical resistance.

• Does not require removal of coating in the edge zone**.

• Glass can be tempered, bent and laminated*.

• Already the basic version of the glass is suitable for both wet use and tempering.

• Unlimited shelf life.

• Possibility of screen printing using approved ceramic inks*.

Areas of application

• External glass in double facades.

• Balconies and balustrades.

• Ventilated facades.

• Glass canopies, doors, partitions, slats.

• Glazing of opaque areas.

4 Reflective glass

Reflective glass is a solar reflective glass that is produced by applying a layer of metal oxide to one of the surfaces of float glass during its production process (at a glass temperature of 650 ° C). It is made on the basis of transparent or tinted glass. The coating is “hard” (pyrolytic), resistant to mechanical and atmospheric influences, thanks to which the product can be used even in single glazing. The solar control properties of reflective glass are based on the simultaneous reflection of part of the energy of the solar flow by spraying and the absorption of part of the energy by the thickness of the glass. Reflective glass has a mirror-type coating, but with less saturation, which limits the transmission of solar heat into the room with the maximum amount of natural light. In this case, during the daytime, a “mirror” effect will be observed from the outside and a “tinted” effect when viewed from inside the room. Due to the high reflective properties of this glass, the interior of the room is not visible from the outside, but only if the illumination outside is stronger than indoors (during the daytime). Turning on indoor lights at night will cancel this effect.

Types of reflective glass

Application of reflective glass: Glazing of stained glass windows, doors, partitions, glass roofs, winter gardens

.

• When glazing large areas with glass from different batches, differences in the color of the glass may occur.

• If reflective glass is installed using street glass sprayed inside the glass unit, a tinted mirror is visible from the street side.

• If the installation of reflective glass is carried out with glass from the room sprayed inside the glass unit, then from the street side there is simply a mirror.

• Installation of reflective glass when glazing with one glass (not as part of a double-glazed window) is carried out only by spraying inside the room.

• In a single-chamber double-glazed window, installation of reflective glass in the presence of low-emissivity glass (I-glass) is IMPOSSIBLE due to the possible formation of thermal shock, which will lead to destruction of the double-glazed window.

• In a two-chamber double-glazed window, installation of reflective glass with the middle glass is possible provided that low-emissivity glass is not available (Expired), otherwise the double-glazed window may be destroyed due to the formation of thermal shock.

5 Patterned glass

Patterned glass is a special type of decorative glass with a repeating pattern in relief on one or both surfaces, and can be either clear or colored. Colored glass is obtained from glass colored “in bulk” or by applying metal oxide coatings to one of the surfaces. The depth of the relief lines is from 0.5 to 1.5 mm. Patterned glass should transmit and diffuse light. The light transmittance of the colorless version when illuminated with diffused light, if the patterns are applied only on one side, is at least 0.75, if the patterns are on both sides, 0.7.

Applications of Patterned Glass:

• glazing of window and door openings;

• installation of partitions in residential, public and industrial buildings;

• external and internal stained glass windows, screens, partitions.

• It is not recommended to use patterned glass in rooms with a lot of dust, soot, etc. (very difficult to clean).

• Gloria, Strip and Chinchilla glasses have a clearly oriented pattern. By default, glass is installed in a product with a vertical pattern.

• Glass Iron, Damas, Matelux - always placed with the matte (embossed) side INSIDE the camera

• Patterned glass is installed in a double-glazed window with the corrugated side facing the outside of the double-glazed window. Can be used for both outdoor and indoor glass. You cannot use middle glass in a 2-chamber s/p, because in this case it will not be airtight.

• DO NOT apply any films to patterned glass!

6 Shock-resistant glass

Impact-resistant glass is a protective glass that can withstand repeated impacts from a freely falling body with standardized values. The protective film is always applied to the street glass from the inside of the glass unit. In the program, the protection class must be selected specifically for the outer glass. Glass protection classes according to GOST R 51136-98

Note. A2 (412 µm) = 300 µm + 112 µm (two films glued one on top of the other) A3 (600 µm) = 300 µm + 300 µm (similar)

Impact-resistant glazing of class A1, A2 is installed:

• at facilities that do not have significant material assets and are under centralized or internal physical security (grocery stores, restaurants, bars, institutions, offices, industrial premises).

Impact-resistant glazing of class A2, A3 (and also P4A) is installed:

• at objects that have material assets of high consumer value, historical and cultural values and are under centralized or internal physical protection;

• in the operating rooms of banks, premises of administrative and government bodies (if the installation of bullet-resistant glazing is not required), trading floors of jewelry, weapons stores, pharmacies (provided that there are no precious metals, weapons, or drugs in them during off-hours);

• in museums, art galleries (in the form of screens, showcases to protect individual exhibits in exhibition halls).

Thickness of glass used: 4, 5, 6 mm.

7 Protective glass

Safety glass is designed to protect human life and health, ensure the safety and reliability of storing and transporting material assets. Glass is used in vehicles, administrative, public and residential buildings, where there is a need to protect human life and material assets. Break-resistant glass is a protective glass that can withstand a certain number of blows from the butt and the blade of an ax, applied with standardized indicators. Classification of break-resistant glass

• at facilities that do not have significant material assets, in the absence of centralized or permanent physical security; Safety glazing of class B1, B2 (R6B and R7B) is installed:

• in warehouses, regardless of the type of security; repositories and depositories of museums under centralized or internal physical security.

Safety glazing of class B2, BZ (R7V and R8V) is installed:

• at objects with material assets of high consumer value, in the absence of centralized or internal physical security;

• in the trading floors of jewelry, weapons stores, pharmacies (if they contain precious metals, weapons, drugs during off-hours), premises for storing precious metals, weapons, drugs, cash registers (regardless of the type of security);

• in the internal premises of banks (if installation of bulletproof glazing is not required);

• in storage facilities and depositories of museums that do not have centralized or internal physical security.

8 Wired glass

Wired glass is a material that is widely used and used in places where increased safety is required. It has the property of forming an effective barrier against smoke and hot gases and, upon impact, does not fall into pieces due to the holding reinforcing mesh inside the glass. One of the disadvantages of such glass is the visible reinforcement, which reduces transparency and increases the level of distortion.

Wired glass.

Product Features. The main characteristics of this type of sheet products are determined by a non-standard glass casting technique (filling the reinforcement on both sides). The mesh is placed throughout the sheet space parallel to the two sides of the glass. The distance between the surface and metal material is about 1.5 mm. It is worth noting that the reinforcement procedure does not provide an opportunity to increase the strength of glass, but it gives the final product quite good characteristics, namely, in the event of mechanical stress, the fragile material will not shatter into small pieces. In addition, if the room catches fire, the glass surface may be damaged, but thanks to the presence of reinforcement, the structure itself will remain intact and will eliminate the increase in draft and prevent the growth of the flame. If high-quality glass was used in the production of reinforced products, then it will peel off directly along the cut lines without any difficulties. Glass with metal mesh is distinguished by its good impact resistance and fire resistance. It is these factors that have made this type of product popular in the modern world. Reinforced glass. Areas of use of products. This product is widely used when it is necessary to glaze such objects as:

· interior, as well as entrance doors and windows;

· window openings of fire-hazardous buildings;

· general purpose objects where increased strength plays an important role;

· rooms where it is necessary to prevent injuries from possible glass fragments;

· lanterns. These products are widely used for glazing window openings in various industrial premises and workshops. Reinforced glass products are also used to create dormer windows. They are indispensable when arranging external coverings of facades, elevator shafts and even basements. Quite often in the modern world, reinforced glass is also used for glazing balcony railings, since it not only has a certain strength and safety, but also an attractive appearance. Features of manufacturing reinforced glass. Reinforced glass material is produced using a welded mesh made from durable steel wire. To improve the quality characteristics of such products, the surface of the wire is coated with a special aluminum layer, due to which the finished sheets acquire improved properties. The steel mesh can have cells whose cross-section reaches 12.5 mm or 25 mm. The metal element is placed in accordance with established standards, which indicate that the metal support must be located over the entire area of the glass sheet.

9 Tempered glass

Tempered glass is any glass that has been subjected to a special heat treatment called tempering. Tempering is a process of thermal strengthening of glass based on the specifics of its physical properties. Glass does not have a specific solidification point at which it changes from a liquid to a solid state. If glass is heated so that its volume has the same temperature (slightly above 570 ° C), and then quickly cooled, its surface will harden, but the inner layer will still remain plastic. As the glass cools further, the inside will also harden. Thus, as a result of heat treatment, the outer layers of glass come into a state of strong compression, and the inner layers into a state of tension. The stress system formed in the glass ensures its high mechanical and thermal strength - compared to ordinary glass, it increases by 3-6 times. When broken, glass breaks into small fragments that do not have sharp edges. Tempered glass can be installed as both internal and external glass in a double-glazed window. Thickness of glass used: 4, 5, 6, 8, 10 and 12 mm.

10 Laminated triplex glass

Laminated glass is a composition of several sheets of glass and an adhesive layer. Film lamination is based on the principle of an airtight connection between glass and polyvinyl butyral film (film thickness 0.38 mm or 0.76 mm). The film is placed between sheets of glass. The lamination process itself occurs under the influence of temperature in an autoclave. Laminating glass does not increase its mechanical strength, but still gives the glass safe properties. When glass breaks, its fragments are securely held on an elastic film. Possibilities when laminating glass:

• Production of glass of any shape (arched, polygonal, curved).

• Production of protective glasses (bulletproof, noise-proof, impact-resistant, etc.).

• The use of colored films or resins makes it possible to produce colored triplex.

• Production of triplex using glass with any coating. Application of laminated glass: Stained glass windows, partitions, furniture, interior items, windows, doors, winter gardens, glass roofs, canopies, floors, steps. Note!

• Film triplex can be up to 3200x3200 mm in size.

• Aspect ratio no more than 1/10 Laminated glass can be installed as both internal and external glass in a double glazing unit. Thickness of glass used: 3.1.3, 4.1.4 mm.

11 Semi-coated glass

Guardian ExtraClear™ glass

Its main features are the highest optical properties, a high degree of color neutrality in transmitting and reflecting light, as well as increased transparency. Guardian Extra Clear glass uses the world's best selected raw materials, such as low-iron quartz sand. Guardian ExtraClear™ glass contains up to 5 times less iron than standard float glass. Guardian ExtraClear offers increased light transmittance and a more natural and neutral color in a variety of lighting conditions and applications. Standard glass, if you look at its cross-section, has a pronounced greenish color. When looking at a cross-section of Guardian ExtraClear™ glass, this tint is completely absent. Thanks to this property of glass, objects behind it are visible in their most natural, natural and absolutely undistorted colors. Glass can be subjected to heat treatment (hardening) and coloring; it can be used to make triplex and polyplex; the technology for its processing and processing is similar to standard float glass.

Thickness of glass used: 4.6 mm.

12 Multifunctional glass

Multifunctional glass is glass with a soft coating that combines sun protection and low-emissivity properties. The improved selectivity of the coating guarantees maximum energy savings and very high visible light transmission. Multifunctional glass can selectively transmit or selectively block solar rays according to their wavelength. Most of the thermal radiation is reflected, while natural daylight is allowed in. Due to its low emissivity, the coating provides optimal thermal insulation with the highest possible heat transfer resistance. The use of ClimaGuard® HP multifunctional glass reduces the cost of air conditioning and heating of a building without loss in illumination and color rendering. Improved thermal insulation increases glass surface temperature, which reduces cold air circulation and the likelihood of condensation on the interior glass in cold climates, and reduces condensation on the exterior façade glass in hot, humid climates.

Types of multifunctional glass

• M/F glass is used only as part of a double-glazed window and only as glass from the street side. Application of multifunctional glass: Glazing of stained-glass windows, windows, entrance doors, glass roofs, winter gardens.

• It is installed in a double-glazed window only by spraying inside.

• Middle glass cannot be used in a double-glazed window, as this can lead to overheating of the air chambers and destruction of the double-glazed window!

• DO NOT apply any films to the coated side.

• CANNOT be used for single pane glazing.

Multifunctional glass is glass with multilayer coating, which is applied to the surface of the glass using an environmentally friendly deep-vacuum magnetron process, where one of the functional layers is a highly selective layer - silver

Multifunctional glass structure:

1. Upper and lower layers: oxides, nitrides. They affect specularity, light transmission and coating color.

2. Functional layer: silver, chrome. Reflection of short-wave and long-wave thermal radiation.

3. Protective layers: protection of functional layers from mechanical and chemical damage, reflection and absorption of short-wave thermal radiation.

How it works ?

In summer

Multifunctional glass reflects infrared solar radiation outward, preventing the room from overheating even on the hottest days. Up to 58% of thermal energy does not penetrate into the room, and you save on air conditioning. It is important to note that the level of transparency of such glass is almost the same as regular glass.

in winter

With the onset of cold weather, glass works on an energy-saving principle, retaining heat in the room. The silver coating reflects long-wave thermal radiation from heating devices into the room, preventing heat dissipation outside. Heat loss is reduced to 22%, and heat savings reach 78% - you save on heating. The ability to transmit maximum daylight is also most relevant in winter.

Advantages of multifunctional glass

— Protecting the premises from overheating in summer

- Preservation of heat indoors in winter

— Maintaining maximum levels of natural light

— Strength and resistance to mechanical damage

— A slight mirror effect reduces the level of visibility of the room from the outside

— Reducing the cost of paying for energy consumed by heating and air conditioning equipment

— Possibility of lamination, cutting, tempering, heat treatment of glass

Glass is recommended for use in rooms where energy saving, sun protection and natural lighting of the premises are especially important.

Argon filling

Argon is an inert gas, i.e. it does not enter into chemical reactions with anything, so it is absolutely harmless to humans. Argon does not burn, does not explode, and is not radioactive. Compared to conventional dried air, this inert gas increases the functionality of double-glazed windows: - its thermal conductivity is almost 2 times lower, this property allows improving the thermal insulation characteristics by 10-15%

Insulating glass unit

Plastic windows have undergone changes more than once throughout their existence. Initially, they concerned quantitative additions - double-glazed windows became multi-chamber, their manufacturing technologies were improved, new materials appeared, energy-saving, noise-absorbing and other layers and films were added. The only stumbling block and a kind of core of cold remained the metal reinforcement used to strengthen the structures. It was this that limited the energy-saving capabilities of PVC windows. Another problem was the limitation in size - large sashes tended to warp under their own weight. The solution to these problems was the new revolutionary technology of glued double-glazed windows. It was based on the technology of installing automobile windshields. The glass in glued double-glazed units is industrially glued to the sash and becomes the support for the entire window structure. The basic principle of glued double-glazed windows is that the glass holds the sash, not the sash glass. In standard windows, the glass unit is wedged and fixed with inserts in the sash frame. For this reason, all forces affecting the window are distributed in a small number of places in a concentrated form on the sash profile. This leads to profile deformations and sagging of the sash over a long period of time. Gluing a double-glazed window allows you to reduce peak loads, since the impact is evenly distributed along the entire perimeter of the gluing. Window designs using double-glazed glass technology allow you to use the inherent static capabilities of glass to expand the possibilities of design and architectural solutions. When is it necessary to install double glazed windows? Why glue double-glazed windows if windows have been successfully installed in the classical way for many years? Windows of standard sizes and shapes can continue to be installed using the wedging method, but in the case of bulky structures, arched swing-and-turn sashes, hinged doors, etc., it is impossible to do without gluing in double-glazed windows. Gluing process . Gluing a double-glazed window involves applying a special two-component adhesive, using a hand gun, around the perimeter of the sash, on the outside of the glass in the overlap (next to the seal)

ATTENTION !!! To glue a double-glazed window, two colors of silicone glue are used:

BLACK, used on product with black seal; GRAY, used on product with gray seal

Advantages of glued double-glazed windows:

1. Increased sealing, heat and sound insulation of the window.

Achieved by tightly gluing the glass unit to the plastic profile

2. Increased structural rigidity.

Statically, it is rigidity that has the maximum impact on the service life of the product. When installing a double-glazed window the old way, by wedging, the entire load falls on the places where the double-glazed window comes into contact with these wedge-shaped supports. Thus, in cases where the glass unit has a large area and, accordingly, a large weight, the loads in these places increase several times, which often led to deformation of the profile or glass unit itself. The use of glued double-glazed windows reduces loads by 70%, because it is fixed around the perimeter. Thus, the load is distributed evenly and the glass unit is less susceptible to destruction during transportation, installation and operation.

3. Protection against sagging of the sashes.

Sagging sash is one of the most common problems with windows; the larger and heavier the structure, the greater the likelihood of sagging. Sashes with non-glued double-glazed windows have size restrictions. Over time, a sash that is too large loses its correct geometric shape and begins to leak. The glued double-glazed window keeps the profile from breaking its shape and prevents deformation of the sash and allows you to increase the size of the sash many times, without any violation of the window geometry.

4. Maintaining the original shape

For non-standard window structures (triangular, round, trapezoidal, etc.), gluing in double-glazed windows is a guarantee of stable shape and durability.

5. Increasing the permissible dimensions of a double-glazed window. In modern architecture, large-format translucent structures and mullion-free structures are in demand; gluing of double-glazed windows is the key to solving current architectural problems. This method of fixing a double-glazed window allows you to increase the dimensions by at least 25% in width and height.

6. Increased burglary resistance of the window around the perimeter of the glued glass unit. The most common ways for intruders to enter a room through a window opening are: breaking glass, squeezing out a double-glazed window and removing pins from the strikers. The most impregnable and safe window will be one where three conditions are met: impact-resistant glass, burglary-resistant fittings, and a double-glazed window that cannot be squeezed out. The glued glass unit cannot be squeezed out of the sash.

7. Increased service life.

The window will last longer without losing its original characteristics.

ATTENTION !!! 1. When gluing a double-glazed window into the blind parts of the product, the product must be installed on anchor plates.

2. Gluing in a double-glazed window does not affect the warranty of the product.