The demand for plastic windows today does not surprise anyone; any construction of both residential and industrial facilities uses metal-plastic structures. In addition, an increasing number of people want to replace their old windows with new, more beautiful and reliable ones. Therefore, organizing a business in this industry will be very successful. The main component of this business is an automated line for the production of plastic windows, because in-house production will allow you to gain advantages over intermediary companies that sell products of leading brands, but waste time waiting for their turn in production.

Start of activity

A room for assembling plastic window parts

To start production, it is necessary to establish an enterprise, obtain tax and state registration, conduct tests and obtain quality certificates. Tests for compliance with GOST standards, SNiP requirements, as well as for obtaining foreign quality standards - DIN and RAL. Having as many certificates as possible, you can profitably establish yourself in the market of metal-plastic products. Before starting production and sales, a sanitary and epidemiological conclusion must be obtained; without it, sales will be impossible.

Preparation of production areas

Plastic windows and double-glazed windows

To organize a small business with an average productivity of up to twenty structures per shift, you will need a room with an area of at least 200 m2, and take into account the ceiling height - above three meters. A line for the production of PVC windows will be located here. Next to the production workshop there should be premises for storing finished products and raw materials. An administrative building will also be needed to house management personnel. For uninterrupted operation of the line, electricity is required; the voltage in the sockets must be at least 380 V. The workshop must be equipped with an air conditioning system, maintaining the temperature within 18-20 oC. If the temperature regime is violated, the technological process may fail, which will negatively affect the quality of the finished product. Provide in the room not only general, but also local lighting in some areas of the automatic PVC window production line. If it is not possible to purchase production space, you can use rent. Approximate rental costs per month will be 50 thousand rubles, utility bills - 25 thousand rubles.

Service staff

One person is enough to assemble a window.

Six people will be required to work on the production line, plus one more storekeeper to receive finished products and issue raw materials. Production cannot be done without an engineer who can quickly troubleshoot equipment problems, as well as a chief technologist who will monitor the manufacturing process and the quality of finished products. Labor costs can amount to 100 thousand rubles.

Components and consumables

The PVC profile forms the basis of the frame for plastic windows.

For the production of metal-plastic structures, the following main components will be needed:

- PVC profile;

- rolled metal;

- glass;

- butyl;

- shell.

The table shows the consumption rates of component materials for the production of 1 m2 of windows and their cost:

| Name of material | Cost rate | Cost of consumption, rubles |

| PVC profile | 0.5 m/m2 | 500 |

| glass | 2 m2 | 600 |

| butyl | 0.1 kg | 5 |

| shell | 4 m | 400 |

| rolled metal | 1 m2 | 585 |

| other components | — | 2200 |

The total cost of producing 1 m2 of window construction will cost 4,290 rubles.

Table for combining glass CLLFZ-1712

| Model | CLLFZ-1712 |

| Air pressure, MPa | 0,4-0,6 |

| Maximum piston stroke, mm | 500 |

| Maximum lift angle | 80° |

| Working frame size, mm | 2010X1400 |

| Dimensions, mm | 2210x1500x810 |

| Power consumption, kW | 1.5 |

| Weight, kg | 100 |

The table is mainly used for combining glass with a spacer applied and just glass. Particularly convenient for the production of single-chamber and double-chamber double-glazed windows. The welded parts of the table are durable and resistant to corrosion. The table consists of a stand, a working frame and a rotating mechanism. The table is designed simply and conveniently.

Components of automatic window production line

Since the production of metal-plastic windows is considered a profitable business and the demand for automated lines is growing, the number of companies offering their equipment is also increasing.

PVC profile cutting saw

The most common installations are from brands such as Yilmaz, Kaban, Nissan, Nikman, Caliber, Oskar, Startech. Equipment from different manufacturers may vary significantly, but there is always the opportunity to purchase additional equipment. According to the technological process, the following basic equipment is required for the manufacture of window structures:

- profile cutting saw;

- welding machine;

- milling machine;

- angle cleaning machine;

- cutting saw;

- glazing stand.

This set of line elements for the production of double-glazed windows is designed for a maximum load of 15 - 20 windows per shift. Additionally you can purchase:

- extruder;

- washing machine;

- demineralizer

Mechanisms and components of lines from different manufacturers differ in power, dimensions, and output.

The table saw cuts the profile according to the specified parameters. It can cut at different angles - 15o, 45o, 90o. Equipped with mechanical clamps and rubber supports to reduce vibration. Characteristics:

- operates from a 220V power supply;

- weight - 30 kg;

- dimensions 56*45*45 cm;

- the cost of the saw is 372 thousand rubles (Yilmaz).

The welding machine is designed to connect the components of a PVC structure at various angles. Automatic heating temperature control, an emergency stop button, and the presence of rubber body supports ensure its safe operation. Why does Mikhail Kokorich need publicity? Specifications:

Angle cleaning machine for PVC profile

- power – 1.5 kW;

- compressed air supply – 35 l/min;

- welded angles - all in the range from 0° to 180°;

- profile width – maximum up to 130 mm;

- machine dimensions – 65*65*52 cm;

- weight – 120 kg;

- cost – 411 thousand rubles (“HEGSAN”).

The milling machine is designed to create holes and grooves of various sizes in aluminum profiles. The holes further serve as places for fastening fittings and connecting various components provided for by the technological process. Characteristics:

- power – 1200 W;

- power supply – 220V;

- cutter rotation speed – up to 23000 rpm;

- dimensions – 55*46*55 cm;

- weight – 27 kg;

- cost – 106 thousand rubles (Yilmaz model).

The angle cleaning machine is designed for cutting off irregularities and excess formed after welding work. Characteristics:

- weight – 26 kg;

- control type – manual;

- dimensions – 68*57*54 mm;

- cost – 225 thousand rubles (Yilmaz).

A notching saw is necessary for drainage holes. This is a desktop unit, powered by 220V power. Characteristics:

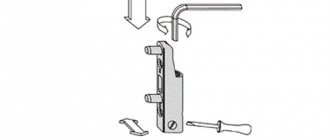

Glazing stand for assembling plastic windows

- control type – manual;

- power – 800 W;

- weight 26 kg;

- rotation speed – 3000 rpm;

- dimensions – 56*45*45 mm;

- cost – 86 thousand rubles.

The glazing stand is designed to collect finished parts of the window structure. It allows you to accurately simulate the installation of a window and facilitates the glazing process and the adjustment of fittings. The cost of the stand is 160 thousand rubles.

The kit can be supplemented with saws for cutting glazing beads, a compressor, and equipment for cutting reinforcement. The price of a window production line can be 1,365,000 rubles. The costs of transportation and installation should also be added here if the manufacturer did not take them into account in the price of the automated line - 50 thousand rubles.

Stand for applying sealing tape to glass CLLJT-1815

| Model | CLLJT-1815 |

| Nutrition | 380V 50Hz |

| Air pressure, MPa | 0,4 |

| Air consumption, l/min | 20 |

| Vertical stroke of the suction cup, mm | 50 |

| Weight, kg | 200 |

| Dimensions, mm | 1350x2010x750 |

The stand is used when assembling double-glazed windows. Glass is placed on it and spacer tape is applied. An air cushion is used to move the glass. The spacer is applied to fixed glass using an automatic vacuum suction cup. The stand is equipped with an energy-saving, quiet fan that provides high air pressure. The glass heating system uses hot air, which meets environmental requirements. The operator can control the temperature of the glass during processing. The suction cup device allows you to easily move the glass across the surface. The rotating system facilitates the entire processing process, including the installation of the spacer tape.

Technological process

Cutting PVC profiles

The production process of metal-plastic windows begins with cutting the profile in accordance with the required dimensions; they are calculated individually for each type of structure. Different types of buildings have individual window opening sizes, so profiles will be made in accordance with the parameters specified in the order. Having purchased a PVC window production line and started the production process, you should understand that this will be work for the customer, and not the production of template windows.

The next stage of production will be milling the frame for drainage channels, which will compensate for wind pressure and remove excess moisture.

After processing the metal profile, it is fixed in the plastic profile using self-tapping screws. An automatic screwdriver or a manual screwdriver is used here.

Then comes the process of milling the frame for installation of fittings; it is performed on a copy-milling machine.

When the metal-plastic elements are prepared, it is necessary to connect them into a solid frame, this happens using a welding machine. At this stage, it is better to use an automatic welding unit, since it is important to comply with the temperature conditions and heating time of the seam.

Milling a plastic frame

And before starting welding, you should remove dust and shavings from the surface of the frame, since contamination can reduce the quality of welding and affect the finished result.

The price of a line for the production of plastic windows includes a cleaning unit; it is used after the welding process to remove plastic deposits at the joints of the profile.

It is necessary to insert a sealing rubber into the finished frame, which is attached with glue. This process is completely manual.

The assembly of the metal-plastic structure takes place on a glazing stand. Here a double-glazed window, the necessary fittings, seam inserts, and gaskets are inserted into the profile. At this point, the technological process is completed; all that remains is to check the finished product for the functioning of all systems - this is a task for the chief technologist. The windows are ready for sale and subsequent installation.

Glass washing and drying machine CLLQ-1600/CLLQ-1800

| Model | CLLQ-1600 | CLLQ-1800 |

| Glass width maximum (minimum), mm | ≤1600/450 | ≤1800/450 |

| Glass thickness, mm | ≤15 | ≤15 |

| Brushes/wringing shafts pcs. | 4 / 4 | 4 / 4 |

| Diameter, mm | 126 | 126 |

| Suction roller, pcs. | 3 | 3 |

| Suction roller diameter, mm | 80 | 80 |

| Engine power, kW | 0,75 | 0,75 |

| Heater power, kW | 4,5 | 4,5 |

| Pump power, kW | 0,36 | 0,36 |

| Brush rotation, rpm | 850-900 | 850-900 |

| Brush ratio | 0,77 | 0,77 |

| Water heater power, kW | 6 | 6 |

| Fan power, kW | 0,75 | 0,75 |

| Total power, kW | 12 | 12 |

| Glass transfer speed, m/min | 3,5 | 3,5 |

| Power supply | 380V, 50Hz (3-phase) | 380V, 50Hz (3-phase) |

| Weight | ≈ 0.8 tons | ≈ 0.85 tons |

| Ground resistance | 4Ω | 4Ω |

| Dimensions, mm | 2040*2100*1100 | 2300*2200*1100 |

The glass washing machine is used for efficient horizontal washing and drying of glass and is used at the preparatory stage of insulating glass production to ensure the cleanliness of the glass surface. The frame for fastening the glass is located horizontally. Sequential feeding, washing, drying and removal of glass is performed automatically. The processing speed is smooth. The equipment is reliable and easy to set up.

Water supply is implemented in a closed cycle. Water is supplied from a tank built into the unit. The first supply circuit is brushes, the second is washing the glass after the brushes. After the washing process, water collides with the surface of the glass by two pairs of squeezing rollers made of dense porous material. This device allows you to use harder water without compromising the quality of glass cleaning. No detergents are used. The water must be changed every two days or when the slightest stains form on the glass. Once a month you need to wash the squeezing rollers.

- The machine is equipped with a high-quality smoothness control device; the processing speed is adjusted by the operator, which ensures high quality washing.

- When washing glass, water from two tanks is used. This ensures a high degree of glass cleaning.

- The machine uses a two-stage water circulation system that separates clean and cloudy water, which saves water consumption.

- All parts of the glass cleaning and installation system (including the warm air supply pipe, temperature sensors, pipes, tanks, etc.) are made of high-quality stainless steel. The anti-corrosion coating prevents clogging of the water circulation system and the formation of rust.

- Four brushes, which are pressed tightly against the glass surface during processing, provide high quality cleaning.

- The machine is equipped with three absorbent rollers made of high-quality polymer, which ensures their excellent absorbency and long service life.

- The machine is equipped with a roller made of special rubber, which has high wear resistance, long service life and good processing quality.

- The tanks are designed in such a way that they are easy to fill with water.

Production of PVC window sills

PVC window sill

It is advisable to produce window sills along with windows, since the cost of a line for the production of PVC window sills is low. The line is an extruder complex, which includes molds, a slitting mechanism, and a laminating unit. The line may include a more complex design for the production of PVC itself, but for a small enterprise with a maximum load of up to 20 windows per shift, it is not needed. The finished material can be purchased from large industrial enterprises and cut independently according to the required dimensions. The cost of such a line will be 150 thousand rubles.

Profitability of production of metal-plastic windows

Plastic windows are installed in all new buildings or renovation houses.

The costs of organizing a business can be divided into capital and current.

Capital costs include the price of a line for the production of double-glazed windows - 1,365,000 rubles.

The amount of these costs will be partially included in the cost of the finished product. And it will fully pay for itself over time. Current costs include the cost of materials - 4290 rubles per 1 m2, in terms of 20 finished units per shift, with an average size of 1.68 m2 and the number of shifts per month - 22, you can get a total consumption of materials per month - 3,160,000 rubles.

- The price of one product is 9,500 rubles.

If all the windows produced are successfully sold, you can get 4,180 thousand rubles in profit. Subtract the cost of materials, the cost of maintaining the premises and the wages of workers, resulting in 670 thousand rubles of net profit. The profitability percentage is 19% - a fairly high figure, it indicates a quick payback on invested capital costs, this will happen in a year and nine months, under favorable conditions and constant prices for components.

Hot pressing machine for double-glazed windows CLLR-1600/CLLR-1800

| Model | CLLR-1600 | CLLR-1800 |

| Glass width maximum (minimum), mm | ≤1600/400 | ≤1800/400 |

| Glazing thickness, mm | ≥14 ≤50 | ≥14 ≤50 |

| Infrared lamp, pcs. | 18 | 18 |

| Press rollers | 4 pairs with diameter 90 | 4 pairs with diameter 90 |

| Drive motor power, KW | 0,37 | 0,37 |

| Heating compartment power, KW | 18 | 22 |

| Total power, KW | 18,37 | 22,37 |

| Control temperature range, °C | 0-300 | 0-300 |

| Drive motor speed | 3.3-16 revolutions/min. 1.10~1.40m/min | 3.3-16 revolutions/min. 1.10~1.40m/min |

| Variable Rate Ratio | 1:05:00 | 1:05:00 |

| Power supply | 380V 50HZ three-phase 4-wire system | 380V 50HZ three-phase 4-wire system |

| Weight | ≈0.76T | ≈0.8T |

| Ground resistance | 4Ω | 4Ω |

| Dimensions(L * W * H) | 2070*2110*1170 | 2300*2200*1200 |

The machine is designed for pressing double-glazed windows with spacer-sealing tape. A flexible spacer is placed between the two glasses, the glasses are heated and pressed, resulting in a dry vacuum space between the glasses, while the thickness and size of the processed material meets all glass unit standards.

- The machine is equipped with infrared lamps. Due to them, the glass unit is heated.

- The lamps are highly efficient and have a long service life.

- The mechanism for smoothly adjusting the rolling speed of the glass unit guarantees the required quality.

- Measuring systems allow you to select the pressing force required for processing a glass unit.

- The thermostat is made of high-temperature-resistant material to prevent unnecessary heat consumption.

- Four pairs of rubber rollers of varying hardness ensure uniform distribution of pressure on the glass and uniform thickness of the finished glass unit.

- The high quality of all the most important parts ensures the stability and reliability of the machine.

- Temperature control device with digital display simplifies the operator's work.

- The machine shelf is made of high quality carbon steel, which prevents corrosion and rusting of the surface.