The reinforcing profile is a hidden but very important element of your window. I would even say “carrying”. With poor-quality reinforcement (or without it at all), the window will not hold its shape, will not be able to resist the wind and will not last long.

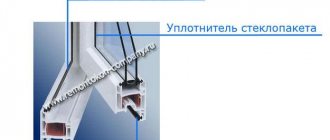

I have already said that the window profile is the basis of the window. However, in order to hold the glass unit, the plastic profile also needs support.

A PVC profile has many advantages: its color and shape can be changed, it is easy to care for, and it is durable. But it has one drawback - the plastic itself does not have much elasticity and strength.

In order to give the profile the necessary rigidity, it is reinforced. In this article I will talk about what reinforcement is and how it affects the profile.

Why is reinforcement needed?

Reinforced windows resist wind loads well and do not deform during thermal expansion. Reinforcement prevents the formation of cracks due to constant wind loads, through which air can pass through noisily. Regular temperature changes also significantly affect the condition of frame structures. Without reinforcement, the profile would expand in summer and prevent the window from closing and opening, and in winter it would narrow, which would lead to blowing. Testing of plastic windows is carried out with reinforcement inserts already inserted.

Reinforcement requirements according to GOST

According to GOST 30674-99, all window units, without exception, must be made using reinforcing metal liners. The window profile must meet GOST standards in order to be approved for installation.

The thickness of the reinforcement of a plastic window according to GOST cannot fall below 1.2 mm. Some manufacturers prefer to deviate from this standard and specify an element thickness of 0.7 mm, which significantly affects the technological characteristics and wear resistance of the structure.

The shape and thickness of the reinforcement walls imposes restrictions on the size of the sash. The proportions between the window dimensions and the characteristics of the steel insert are prescribed in the technical documentation, on the basis of which the products are subsequently manufactured.

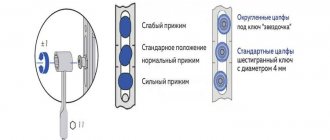

Reinforcement should be installed simply by hand without the help of special devices. If the material fits tightly into the inner chamber, this may result in stretching/rupture of the PVC window walls, especially under the influence of temperatures.

For white plastic profiles that do not belong to imposts and do not have a length exceeding 70 cm, GOST makes a relaxation - it is not necessary to install reinforcement in such areas. The situation changes when it comes to colored, frost-resistant or special plastic profiles; in this case, technical documentation may stipulate mandatory reinforcement of all sections, regardless of their size.

Additional GOST requirements:

- the thickness of the reinforcing insert should not be less than 1.2 mm for regular profiles and 1.5 mm for frost-resistant ones;

- the distance from the edge of the profile to the insert should not be less than 10-30 cm;

- if the weight of double-glazed windows is more than 60 kg, it is necessary to use liners trimmed at an angle of 45 degrees;

- reinforcement is carried out using steel liners, which must be protected with a zinc coating with a thickness of at least 9 microns;

- Within one plastic profile, the reinforcing insert must be solid; joining or tearing is not allowed.

- The inserts are attached with two screws.

What is REHAU window reinforcement and what is it for?

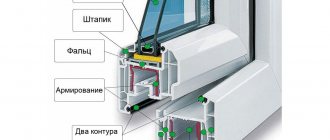

Reinforcement, reinforcing profile, amplifiers is a galvanized steel profile that is installed in the inner chamber of PVC window and door profiles. It is the reinforcement that gives the necessary rigidity and strength to the window, the ability to withstand heavy daily loads from its own weight, strong winds and temperature changes. Window reinforcement can be compared to the skeletal system, which is a reliable support for the entire body. Pumped up muscles without bones will not support the body, and you won’t get far on a broken leg.

Photo: reinforcement gives the necessary rigidity and strength to the window. A window without reinforcement will not be able to support the weight of the sash. It cannot be firmly fixed in the opening. The fastening screws will tear the sash out of the profile under the influence of its weight the first time it is opened.

A window made of the best PVC profile, but with thin reinforcement or without it at all, is a sick window that will not “live” for a long time.

Alternatives to rolled metal

Reinforcement in plastic profiles has a number of disadvantages, the main one being high heat loss. Metal removes heat from the room to the street, which reduces the thermal insulation of windows. Technologists are working to correct this shortcoming and supply plastic windows with thermal inserts with better properties, for example, from glass-composite materials that give off heat less readily.

REHAU plans to abandon metal in its PVC windows in the future. It will be replaced with reinforcements made of fiber material RAU-FIPRO, which have shown themselves well in laboratories, and have already been introduced to the market - the manufacturer has released an experimental Rehau GENEO window system with them. Such a system allows you to save up to 76% of energy, which affects both heating costs and the overall environmental impact on the planet. In the near future, metal inserts may completely disappear from plastic profiles.

Problems due to poor quality reinforcement in windows

The reinforcing profile is an important, but completely invisible component of the window. When the window is installed, it cannot be seen or touched. This moment of invisibility is exploited by unscrupulous manufacturers. And instead of the reinforcement recommended by the system manufacturer, analogues with thin walls and/or inappropriate geometry are used. Because of this, irreparable problems arise during operation.

Signs and consequences of poor-quality reinforcement:

- Deformation (bending) of the profile due to strong temperature changes. At an outside temperature of -20°C, the length of the outer surface of the PVC window profile decreases by more than 2 mm per meter, and the profile bends inward. If the reinforcement power is insufficient to compensate for the bending of the plastic profile, it will be possible to open the sash, but it will be problematic to close it. There is a high risk of damage to the fittings and the profile itself.

- Severance of imposts (vertical and horizontal lintels in a window) occurs if they are fixed only to a PVC profile or the fasteners pass through one wall of thin reinforcement. Loaded by the weight of a double-glazed window or under the influence of temperature, the impost is deformed and gaps form between it and the frame.

- Sagging, jamming, separation of the sash. A sash fixed only to a plastic profile or a thin reinforcing profile will simply tear out the hinges under its weight and may fall.

- Cracks in double-glazed windows. Deformation of the profile, which cannot withstand the weight of the glass unit or wind load, creates a lot of stress in the glass unit and leads to the occurrence of cracks.

- Door deformation. This often happens with entrance doors where the lock is inserted. To install the lock, holes are cut in the reinforcing profile, which significantly reduces its strength characteristics. Sometimes the manufacturer simply installs the reinforcement in two parts - above and below the lock, so as not to have to mill the installation holes, which absolutely cannot be done. A door leaf in which the reinforcement is cut into pieces will certainly become deformed and it will be impossible to correct this.

Photo: lack of high-quality reinforcement leads to sagging door and window sashes, cracks at joints, and damage to glass units

How is a reinforced profile made?

Reinforcement of plastic windows is made using a rolling mill, electromechanical shears, a receiving device and other special equipment. The thickness of rolled steel, which according to GOST must be used in a high-quality profile, is 1.2 mm. The thickness of the galvanizing layer according to GOST must be at least 8 microns. GOST also regulates the type of steel that can be used in the structure - ST2 or ST3.

The size of the metal profile must correspond to the size of the central chamber of the plastic profile. It should go in there easily, without the use of additional force. Otherwise, the windows will lose their performance properties specified in GOST and technical documentation for the manufacture of the product.

The reinforced structure is usually universal and is created according to the dimensions and thickness specified in GOST, however, some brands of plastic windows require their own dimensions and shape. The shape is created by cold bending on profile bending equipment.

REHAU window reinforcement - how to choose the right one

Large windows, panoramic glazing, colored windows, the use of heavy burglary-resistant and sound-proof double-glazed windows, the location of windows on high floors - this is an incomplete list of windows that require increased attention to the choice of reinforcement in a PVC window. For windows in the listed objects, a static calculation must be carried out to correctly select the reinforcing profile and additional reinforcing profiles.

| Buy Rehau windows* |

When purchasing windows, be sure to consider the reinforcement and fix its thickness in the contract. In order not to make a mistake with your choice, it is better to entrust the manufacture of windows to a certified profile processor who uses original components for REHAU windows. A manufacturer receives a REHAU certificate only after a thorough audit by the system provider, if it guarantees the use of all recommended materials, including reinforcement.

| The WINDOWS MEDIA portal recommends: 5 reasons to choose windows from the REHAU profile Why you should choose the original REHAU window seal |

Options for reinforcing profiles from leading manufacturers

- The German brand KBE has developed 4 types of profiles - 58, 70, 76, 88mm. They may differ in the thickness of the rolled metal and the shape of the profile. Both O-shaped and U-shaped profiles are most often used in one design.

- Schuco produces plastic doors in addition to windows. The design also includes an O-shaped and U-shaped profile, the thickness of the rolled metal is 1.5 mm.

- VEKA produces 7 lines of windows + doors for 2022, all differing in chamber size, width, and design. The metal amplifier is designed in the form of a closed circuit.

- Rehau uses profiles with a thickness of 1.2 to 2 mm in its products and is now working hard on alternative reinforcement systems, which were described above.

- Plafen uses a standard reinforcement insert, but the sizes vary from line to line (there are currently five). The wall thickness here corresponds to GOST - 1.5 mm.

- Weltplast chooses a closed loop for its plastic windows. The thickness is in the range of 1.2-1.5 mm, meets GOST standards and provides a standard level of insulation typical for middle-class plastic windows.

- Thussen does not favor U-shape or O-shape and uses both reinforcement options. The wall thickness varies from ruler to ruler, and can be either 1.5mm or 2mm. The greater the thickness, the better - the windows are more durable and warmer.

- Salamander uses standard GOST criteria in production, selecting profile walls of 1.5 and 2 mm.

- Deceuninck uses several sizes of reinforcement, while the wall thickness of the rolled steel is the same for each size - a solid 1.5 mm.

Manufacturers of plastic structures choose profiles depending on the price segment they are targeting, manufacturer prices, delivery complexity, and distributor offers. As a rule, each manufacturer has 3-4 options to choose from that it can offer the client.

Business plan for the production of PVC windows

Features of choosing a room

The area of the premises directly depends on the volume of production. The company plans to produce standard double-leaf windows measuring 1400*1200. To open a workshop for the production of PVC windows, which will produce 20 designs per shift, a room of 200 square meters is sufficient. m. It is worth remembering that the ceiling height should be more than 3 meters.

There should be a warehouse for finished products nearby.

Machines for the production of metal-plastic structures will not be able to work without electricity. The supply voltage should be 380V/50Hz. The optimal room temperature is 18° C, otherwise the production technology may be disrupted.

a good ventilation system must be created in the room . Particular attention should be paid to creating a lighting system. General lighting is provided throughout the workshop area, and local “light” is provided for individual areas.

Recruitment

To organize a small enterprise for the production of PVC windows, you need to hire about 10 people and install a special program.

Such a program will calculate the cost of metal-plastic structures with the smallest errors and provide all the information necessary for production.

Control

The production manager should control the production process, and the chief technologist will be able to check whether the finished product meets generally accepted standards and customer requirements? He must also distribute tasks among workers and control the technological process .

The enterprise must also have an engineer who will monitor the operation of the equipment and, if necessary, eliminate breakdowns. The workforce must include at least 7 people, one of whom must be a storekeeper who receives or dispatches goods. The optimal layout of the technological line and the composition of production sites are shown below.

Capital expenditures

To open a plant for the production of PVC windows with a capacity of 20 finished products per shift, it is necessary to purchase the following equipment:

- Double-head saw with front blade connection – 372,000 rubles;

- Automatic corner cleaning machine (Yilmaz CA) -225,000 rubles;

- Face milling machine (Yilmaz km-212) – 30,000 rubles;

- Double-head welding machine – 411,600 rubles;

- Equipment for cutting reinforcement – 9,000 rubles;

- Copy milling machine (Yilmaz FR-225) – 106,400 rubles;

- Remezza compressor – 26,000 rubles;

- Machine for creating drainage holes - 86,000 rubles;

- Automatic saw for cutting plastic beads – 99,600 rubles;

The total cost of a complete set of equipment is 1,365,000 rubles.

Costs for delivery and installation of equipment – 50,000 rubles;

Other expenses (for obtaining a license, certificates) – 50,000 rubles.

Total capital costs: 1,465,000 rubles.

Calculation of the cost of materials for the production of PVC windows

The cost of materials required for the manufacture of double-glazed windows

Consumption rate, cost per unit of materials, financial costs (rub.) per 1 sq. Product meter:

- Glass (C-300 rub./sq. m): cost rate – 2 sq. m. m; cost of consumption - 600 rubles;

- Shell (C-100 rub./m): cost rate – 4 m; cost of consumption - 400 rubles;

- Butyl (C-35 rub./kg): cost rate – 0.1 kg/sq. m; cost of consumption - 3.5 rubles;

- Other consumables per 1 sq. meter of products – 200 rubles.

Total costs for production of 1 sq. meter of double-glazed window - 1203.5 rubles.

Cost of materials needed to create a metal-plastic structure:

- PVC profile (C-1000 rub./m): cost rate – 0.5 m/sq. m; cost of consumption - 500 rubles;

- Rolled metal (C-582.5 rub./m): cost rate – 1 m/sq. m; cost of consumption - 582.5 rubles;

- Components and other consumables – 2000 rubles.

Total: RUB 3,082.5/sq. m.

The total cost of materials for the production of 1 sq. meter of products - 4,286 rubles.

Material costs per month: 22 shifts * 20 finished products * 1.68 sq. m* 4,286 rubles = 3,168,000 rubles.

Monthly income for the month (taking into account the price of the finished product - 9,500 rubles): 22 shifts * 20 units of finished products * 9,500 rubles = 4,180,000 rubles

Fixed monthly costs

- Rent of production premises and warehouse – 50,000 rubles;

- Utility bills – 25,000 rubles;

- Salary of workers (10 people) – 100,000 rubles;

- The cost of materials and components for production is 3,168,000 rubles.

Total costs per month: 3,343,000 rubles.

Income tax (20%) – 167,400 rubles.

Total expenses: 3,510,400 rubles.