Glazing in an apartment can be made of various materials. The most common are metal, plastic and wood. Metal is used exclusively in combination with plastic to provide the necessary structural rigidity. However, more and more property owners are ordering wooden glazing instead of plastic, despite the fact that wooden windows are more expensive than plastic ones. The motivation is simple and clear - an extremely environmentally friendly solution. Quite often, special attention is paid to glazing in a children's room.

Country windows made of wood are an excellent option for glazing a cottage. The SK-Bober company offers wooden houses and bathhouses of excellent quality at reasonable prices.

Below we will outline in more detail what kind of wood is used to produce window profiles, and why its technical characteristics can not only compete with plastic, but also surpass it in the long term of use.

Which wood is best for making windows: pros and cons of popular varieties

The main material for the manufacture of wooden windows is three-layer laminated timber, with a thickness of 78 mm. The widespread stereotype that the best windows are solid wood does not stand up to criticism in practice.

Firstly , during the sawing process, internal stress is removed from the wood, which prevents warping and deformation of frames (the main disadvantage of solid wood windows).

Secondly , during the manufacture of timber, wood is rejected - resin pockets, knots and cracks are removed from the boards, due to which the tree is subject to rapid destruction.

Thirdly , when lamellas are spliced first along the length and then across the width, a beam with fibers of different directions is obtained, due to which the resistance to deformation due to humidity and temperature changes increases by 75%, rigidity - by 35% (compared to array).

Larch

It is also a coniferous tree, so everything said above about resin passages fully applies to it. In addition, larch looks much more presentable than pine, especially late larch, with a rich dark brown color.

In nature, wood lives for almost 600 years; after processing, the wood can withstand more than a century without problems. According to physical and technical indicators, larch is 30% stronger than pine, and the same amount is higher in terms of resistance to warping.

Benefits of larch

- High strength.

- Resistance to warping. Larch is the only coniferous tree that is not only not susceptible to rotting, but, on the contrary, reduces the degree of decay.

- Long period of operation.

- The resin in the wood fills the indoor air with a real forest aroma.

- Wood is difficult to process precisely because of the multiple resin passages.

- Poor resistance to mechanical damage.

- If the wood is not dried properly, internal cracks will form, causing the quality of the product to be poor.

Disadvantages of larch

- Wood is difficult to process precisely because of the multiple resin passages.

- Poor resistance to mechanical damage.

- If the wood is not dried properly, internal cracks will form, causing the quality of the product to be poor.

Types of wood

There are countless types of wood that are suitable for making windows. But the most popular are larch, pine and oak. Why? First of all, because these are the most common trees in our country, so there is plenty of material for construction and its cost is quite adequate.

You can, of course, order wooden windows from other wood, for example, merbau (also in demand) or from Siberian cedar, but the price will be very high, and the difference in quality characteristics is insignificant.

| Breed name | Susceptibility to torsion and warping | Environmental resistance class DIN EN 352 |

| Larch | Above average | 3-4 |

| Spruce | good | 4 |

| Pine | Above average | 3-4 |

| Afzelia | Very good | 1 |

| Merbau | Very good | 1 |

| White oak | Above average | 2 |

| Red oak | Average | 5 (only for wood-aluminum) |

As you can see, the wood from which almost 100% of wooden windows in Russia are made belongs to the middle class. Now you might think that it would be better to install windows from merbau, for example. Let's answer that pine windows will last at least a century, merbau windows - about 120 years. Is the difference too noticeable? In addition, if necessary, repairing windows made of pine is much easier and cheaper than those made of expensive wood. But, it's up to you. In the meantime, we will look in more detail at all the pros and cons of “our” wood: pine, larch and oak.

Pine

Coniferous wood, has resin passages. They are what give the fresh forest aroma, and it doesn’t matter whether the wood is treated with protective compounds or not. The substances that are released have a healing effect. In a house where pine dominates, it is always easy to breathe, so people with respiratory diseases are highly recommended to replace all plastic structures with natural ones. And it wouldn’t hurt to do this for disease prevention either.

Depending on the degree of resin, pine is divided into two categories: “tar” and “dutitsa”. “Smolka” has water-repellent properties, so windows made from this type of pine are installed in regions with high humidity. The only caveat: processing “tar”, unlike “dutitsa”, is very difficult, so the price of products may be higher.

Pros of wood

- Pine is a very flexible material, easy to cut and process. It is easy to make windows of any configuration from pine, even carved ones.

- Wood has good breathability.

- Easily repaired.

- With proper care, pine windows will last at least 70 years.

- Good price.

- Pine is a fragile material. Strong impacts or improper closing of the doors will leave dents and scratches.

- If not handled correctly, it will “shrink” on hot days and swell in inclement weather.

- It doesn’t look very solid compared to, for example, oak. But, by and large, the main thing is not the spectacular appearance, but the quality characteristics.

Cons of wood

- Pine is a fragile material. Strong impacts or improper closing of the doors will leave dents and scratches.

- If not handled correctly, it will “shrink” on hot days and swell in inclement weather.

- It doesn’t look very solid compared to, for example, oak. But, by and large, the main thing is not the spectacular appearance, but the quality characteristics.

What are windows made of?

Array

Solid wood windows have long lost their former popularity. Here are the three main reasons for not using solid wood in the manufacture of wooden windows:

- Unaesthetic. Structures quickly lose their attractive appearance under the influence of ultraviolet radiation and weather conditions, regardless of the quality of protective treatment with paints and varnishes. After two or three years, cracks and mold appear on the frame, or worse, woodworm infestation occurs.

- Geometric instability. Wood tends to change shape when humidity levels and temperatures decrease or increase. Frames swollen with moisture become a favorable environment for the development of bacteria that destroy wood.

- Low strength and noise insulation. Naturally, structures that change shape or are infested with mold/bugs cannot provide sufficient levels of heat and sound insulation. Their service life is reduced several times.

Types of ventilation

The natural ability of wooden windows to maintain a normal indoor microclimate is not sufficient to supply the required volume of fresh air, so the design of window units provides for the possibility of ventilation.

There are three main ways to regulate room ventilation:

- Microslit. In this case, to allow fresh air to enter from the street, the sash is tilted a small distance from the frame, while sufficient protection against noise from the street and heat leakage is maintained.

- Comb. An easier way to circulate air. It allows you to open the sash a short distance, usually having three levels of gap adjustment.

- Window. A familiar element from old window frames can also be used in modern woodwork. The location at the top of the window allows cold air from the street to be directed to the ceiling, which gives a more uniform mixing of cold and warm flows inside the room. The disadvantage is a decrease in window transparency.

Oak windows

Resistance to decay, pronounced texture, a wide choice of natural shades and strength contributed to the popularization of oak. Despite the appearance on the market of new exotic wood species with excellent aesthetic and performance characteristics, oak is still considered an elite material. Like larch, the structure of oak contains natural antiseptics that significantly slow down the destructive development of microorganisms and inhibit the processes of decay. At the moment, oak windows, by analogy with other models from other species, are made mainly from laminated veneer lumber, due to which:

- retain their shape better;

- do not crack;

- do not dry out or become loose due to changes in temperature and humidity.

Since the technology for manufacturing oak windows, based on the use of Euro timber, has eliminated the natural shortcomings of this species, the products remain with only two conventional flaws - relatively high cost and heavy weight. However, this fact does not stop connoisseurs of this breed who decided to order such models. In addition, the appearance on the market of a series of oak windows made of jointed lamellas has made products of this class more accessible to a wide consumer audience.

The most popular “trio”

Pine is an inexpensive material with a golden color. It has a beautiful structure in which amber veins are visible. Natural softness makes pine both easy to process and prone to deformation.

Larch is a dense wood with a high content of gum and resins. Be resistant to rot, fungi, blue staining and insect pests. Its high strength only increases over the years, which is explained by the polymerization process of the resin. Larch has special requirements for sawing and drying.

Oak is an elite class of wood, distinguished by its strength characteristics and aesthetic qualities. This lumber requires a special approach to drying and sawing. Products made from it are characterized by significant weight, which can cause problems with fittings.

Ash

Ash windows are perhaps the most popular option after the three most popular types of wood. In terms of density and elasticity, they are comparable to oak products. This material is characterized by high hardness and excellent bending and tensile strength parameters. Ash has an interesting color and structure that can be emphasized through glazing. Usually has a grayish or yellow tint.

White ash is rare. Light colors visually increase the space. This is a durable and wear-resistant material. Therefore, white ash receives positive customer reviews.

Ash structures are more expensive than pine products, but cheaper than oak windows.

Unfortunately, ash is afraid of water. Therefore, windows made of this type of wood are protected from the outside with an aluminum frame, which protects the frames from destruction when they are exposed to snow, rain and ultraviolet rays.

Comparison table of characteristics

| Density Kg/m3 | Viscosity J/m2 | Compression along the fibers, MPa | Statistical bending | End hardness (Brinell) | |

| Pine | 500 | 41202 | 49 | 86 | 2,49 |

| Oak | 690 | 76518 | 58 | 108 | 3,8 |

| Larch | 660 | 51993 | 65 | 112 | 2,6 |

Which wood is suitable for making windows?

The first and most important thing you need to know if you are planning to order wooden windows for your home is that they are made exclusively from completely dry material. Otherwise, when the wood dries, cracks will be guaranteed. Moreover, windows can “screw”, which causes damage to the integrity of the glass. Therefore, the choice of wooden windows should be approached with all responsibility.

Wooden windows are made from two types of materials - laminated veneer lumber or solid timber.

- * Solid timber. This material is excellent value for money if dried and prepared correctly. For the manufacture of windows, timber without knots and cracks is selected. The timber must be checked for residual moisture, as the board may “lead”. But if you are planning to order wooden windows from a manufacturer who provides a guarantee for their product, rather than making them yourself, such screw-ups are practically excluded.

- * Glued laminated timber. It is considered an ideal solution for making windows. It does not deform and has moisture-resistant properties. This material does not deform. This is facilitated by the fact that the wood is maximally dried and multi-layered. The optimal size of laminated veneer lumber for making windows is 5x5cm.

You can find options when windows are made of plywood. But this material is not suitable for solving the problem fully. Plywood is short-lived and absorbs moisture. It can be considered for indoor windows, for example, leading to a covered veranda or a temporary solution when building a house.

Design and colors

The traditional shape of larch windows is square or rectangular. Round or arched ones are also produced, but they are only made to order. Accordingly, the cost of curved products is significantly higher than the price of standard forms. But if the design of the room involves original elements, then larch may well correspond to the planned solutions.

Manufacturers of larch windows offer a wide range of colors - from natural to bright shades. The beautiful texture of the wood allows you to use even a transparent coating; such windows will look decent in any interior. It should be borne in mind that over time, larch will gradually darken and acquire a deeper color. To ensure that the windows fit harmoniously into the interior of the house, they can be painted in any color you like.

Installation of wooden windows

Below we will look at the 3 most popular wood species that are used to make windows.

- Pine

A nice and most budget option among wooden windows. Perfect for those who value the sound-insulating and heat-saving properties of the structure.

© Unsplash

Also, pine windows are much lighter than most of their analogues, so they do not put additional stress on the house. However, keep in mind that they can only be installed in buildings located in places with a relatively dry climate .

© Unsplash

Compared to pine, larch costs about 25% more. However, this material justifies its price in several ways. Firstly, larch windows tolerate high humidity . This will be very useful if the housing is located near a pond or swamp.

© Unsplash

Secondly, larch windows feel great even in severe frosts. So in this case there is still something to overpay for.

© Unsplash

Oak is considered one of the best options for many parameters. True, it is important not to forget about compliance with the rules for operating oak windows and timely prevention. In this case, they will definitely last much longer than windows made from any other type of wood.

© Depositphotos

Do you think wooden windows are really better than plastic ones? Feel free to share your experience in the comments. Good luck!

Wooden double-glazed windows are made from marred wood, so they do not absorb moisture, the wood is prepared using a special technology, these are not the wooden window frames that were 20-30 years ago, so they do not crack, every knot is drilled out.

Since ancient times, all carpentry has been made from “smolyak”. And this is forever.

PVC windows are the death of future generations. Phthalates from them are both mutations and the same SMA. In addition, double-glazed windows also create a radon problem, especially on the lower floors of our houses, and this is additional radiation! As for simple wooden windows, this is what you need. I have had them since 1970 to this day and have no problems. One is to paint it in a timely manner. And most importantly, do not forget that according to technology, PVC windows cannot be installed on the sunlit side of the house, they cannot heat up above 60 degrees (now in the summer this is quite possible!) and after 9 years (.) they are subject to disposal (which we practically have today no)./easy to find all technologies. / And they tell you lies about 50-60 years of operation. Don't be offended - but just “die with these windows!” When you understand everything or suffer (and they also have asthma due to changes in the microclimate and the development of a mass of mold fungi!), you will look for an opportunity to compensate for the loss of health. But it will be too late.

Features of choice

Before contacting a company producing wooden structures, you must make a list of requirements for the product. Some of them depend on the region of residence. For example, energy efficiency and sun protection. Sound insulation is determined by the noise level on the street. Functionality depends on the presence of small children and animals in the house.

Performance characteristics are influenced by a combination of factors, and if one is overlooked, the product will not meet the requirements. It is necessary to take a comprehensive approach to the issue of choice.

You should know that the production time for a wooden window ranges from 30 days to one and a half months. This is due to the complexity of the work.

Wooden windows can decorate any interior and will serve their owners for a very long time. Provided that they are made by experienced manufacturers and from the best materials.

Eurowindows made of laminated veneer lumber - advantages

When choosing which windows are best to install in an apartment or country house, many hesitate between EuroWindows and “joinery”. It would seem that both here and there are wood, and “carpentry” costs less. As one famous advertisement said: “If there is no difference, why pay more?” But there is a difference! EuroWindows made of laminated veneer lumber have a number of advantages:

● Glued laminated timber has increased rigidity. The versatile orientation of the fibers in the layers of the timber makes it resistant to loads and prevents cracking and distortion of frames.

● Additional drying of the lamellas ensures that the timber will keep its shape and will not crack. The slats fit tightly to each other and there are no gaps between them.

● The design of double-glazed windows allows you not to worry about annual insulation of windows for winter. The production technology provides several sealing contours that guarantee good thermal insulation.

● Finally, windows made of laminated veneer lumber look beautiful and presentable even without additional finishing.

Alder

Alder windows for steam rooms attract many consumers. It is also used for cladding the internal surfaces of a given room. A bathhouse, the walls and ceiling of which are decorated with such material, is a popular solution.

Alder exudes a special aroma reminiscent of cognac. Over time, this smell becomes more rich and noble. When found in a humid environment, such wood has a beneficial effect on the immune processes in our body. Alder sauna windows are the optimal solution. This material does not release resin and does not warp during drying. The determining factors when installing such structures in a bathhouse are resistance to destructive factors: temperature changes and moisture.

The strength of an alder window is comparable to its oak counterpart. The softness of this material allows you to make carved decorative elements. Surprisingly, even in the absence of coatings and special impregnations, windows for baths or saunas made of alder are not afraid of mold and mildew.

DIY wooden windows

The process of manufacturing a wooden euro-window will require certain financial investments - the cost of wood, components, equipment. It is also easier to order double-glazed windows from professionals, although some craftsmen manage to assemble this unit themselves. But even taking into account the impressive cost of the finished product, which is an elite and therefore quite expensive product, the savings will be significant. If we are talking about building a new house or completely glazing an old one, the difference can be tens of thousands.

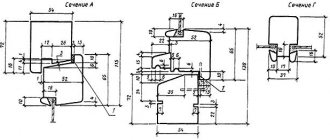

Double-glazed window parameters

Two glasses in a frame or sash form one internal air chamber, respectively, three glasses - this is a two-chamber double-glazed window, four glasses - a three-chamber one. The soundproofing and thermal insulation properties of the entire window unit depend on the number of chambers in the package.

How many cameras you need in a double-glazed window depends primarily on the climatic conditions of your place of residence. So, for the southern regions, single-chamber products are usually sufficient, for the middle zone, two-chamber packages are more often chosen, and for the regions of the Far North, it is recommended to install the warmest three-chamber blocks.

If the building is located next to a busy highway, it is better to take care of additional sound insulation and add one more camera to the recommended number of cameras.

The width of the open glass also affects the ability of the finished product to isolate the room from street noise and low temperatures. Large glasses have lower performance.

The degree of thermal insulation of the package is also affected by the thickness of the glass. In standard versions, glass with a thickness of 4 mm is installed, but for more severe conditions thicker 6 mm glass can be used.

Accessories

No matter how high-quality the glass unit and wooden frame are, if poor fittings are used, the structure will not be durable. Since the weight of a double-glazed window is quite high, and some types of wood are especially heavy, the choice of fittings requires special attention.

A window handle can be made of metal, plastic or wood, and its functions are often not limited to just opening, closing and tilting the window. The handle can be supplemented with a lock that prevents the window from opening, but allows it to be tilted - a necessity when there are small children at home who can open the window, the consequences of which can be catastrophic. Removable handles accomplish the same task. Anti-burglary handles equipped with a special locking mechanism protect against entry by outsiders.

As for the hinges, they can be standard overhead ones: they are clearly visible, but with the right design they become a window decoration. Screw-in hinges are attached to the sash and frame using several pins, providing a secure fit. Mortise hinges are invisible, they allow you to open the window wide and are used more and more often today.

Locks can be used if necessary. They will protect against unauthorized entry or become an additional security feature that does not allow children to freely open the window.

The fittings do not include a mosquito net, window sill and ebb, but these are also important design elements. A mosquito net will protect you from insect attacks in the summer, and in the fall and winter it will become a reliable barrier to poplar fluff, leaves, branches and other debris. Many users do not install flashing, considering it not so necessary, but with it you can maintain the waterproofing of the window for as long as possible.