The most common modern window designs include products based on PVC (polyvinyl chloride). They owe their popularity to their excellent performance characteristics, and, above all, to the ability to create the most effective natural lighting, because the glass unit area reaches 90% of the size of the entire structure. Therefore, it is so important to choose the right glass unit, taking into account all its properties.

There are several types of plastic window structures, divided by external features and quality indicators. Of particular interest are structures with double-glazed windows made using triplex technology. Possession of information about the features, properties, and purpose of this technology will allow you to make the optimal choice in favor of a particular product.

The essence of triplex technology

Glass elements of the “Triplex” type:

Glass

Film

Glass

Triplex is a special combination of several equal glasses (at least two). A film (polyvinyl butyral) or a substance of complex composition is used as a layer of glass.

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

Depending on the material and characteristic properties, triplex is distinguished: film and cast.

When processed according to the triplex principle, glass is given a number of additional properties, but the main one is impact resistance. It should be understood that such glass can withstand short-term mechanical stress only to a certain limit.

If the load is too much for the glass, it breaks, but the fragments do not fly apart, but are held on to the applied adhesive film. It is these properties that provide high protection against injury to others when glass breaks, which, by the way, is classified as safe.

Where to buy windows and doors with triplex glass in Moscow?

The plasokna company has its own, fully automatic production of modern window and door structures. We use only certified components from leading world brands for our products. By contacting us, you buy high-quality windows and doors directly from the manufacturer without intermediaries, markups, or overpayments and are guaranteed to receive several advantages at once:

When choosing a company, it is important to make sure that there are certificates confirming the quality of the products, the professionalism of the installation specialists, and that the company has a good reputation.

Manufacturing of triplex glass

Popular color options for durable glass:

Pink triplex

Blue triplex

Dark triplex

Gray triplex

Purple triplex

Plastic windows equipped with double-glazed windows with triplex film are manufactured in two different options:

- With film applied to glass using an autoclave.

- Non-autoclave method.

When using an autoclave, there are some disadvantages:

- the number of application layers and the thickness of the finished material are limited, and the use of color films is not provided;

- high rates of defects due to difficulties in controlling heating and the effect of temperatures on glass.

These properties significantly limit the possibility of producing large volumes of glass, and the cost of products made from it is much higher.

The production of safety glass using triplex technology without the use of an autoclave makes it possible to expand volumes to production scales. Instead of an autoclave, a special vacuum chamber is used to process glass.

In both cases, subsequent glass processing occurs at high pressure and temperature, under pressure. There are no upper thickness restrictions for polymer triplex. Film triplex consists of at least two layers of glass connected by a film, the thickness of which varies, the minimum total thickness is 5 mm, the maximum varies among different manufacturers. Triplex film is used in double-glazed windows; it is also used for glazing buildings and shop windows.

Blitz survey: Do you have plastic windows installed in your home? From our previous article you can find out which PVC windows are best installed in your home and why.

Film triplex is inferior in strength characteristics to jellied glass, but significantly superior to ordinary glass. To violate its integrity, one has to make very significant efforts; in situations where ordinary glass shatters into fragments or a hole forms in it, the triplex becomes covered with a network of cracks, but the connecting element - the film - continues to hold all the parts together, no fragments are formed.

If it is possible to make a hole in the triplex, then its dimensions do not exceed the size of the object that impacted the glass, and one such hole is not enough to penetrate inside. Tempered glass under a similar impact shatters into injury-proof fragments with blunt edges.

Results

Now you can correctly decipher the glass unit formula given at the beginning of the article.

So, the SPD marking Ud E 4ESG–16–4M1–14Ar–4i means that:

- in front of you is an impact-resistant energy-saving double-glazed window;

- thickness of all glasses - 4 mm;

- the first is hardened using thermal hardening technology;

- the second is normal;

- the energy-saving properties of the third glass are due to a soft silver oxide coating;

- the first chamber is filled with air;

- its width is 16 mm;

- the second chamber is filled with argon;

- its width is 14 mm.

As you can see, if you know the notation, then there are no difficulties in deciphering the formulas. We also recommend that you familiarize yourself with GOST standards for double-glazed windows.

Description of technology

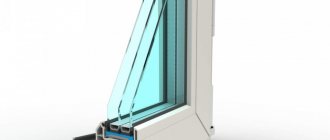

Triplex double-glazed window in section:

Metal-plastic thermal frame

Triplex with noise-proof film

Energy saving glass

Argon chamber

A triplex glass unit is created as follows:

- 2-layer glass with a gasket is placed in the chamber.

- By creating additional pressure, the glass receives the required characteristics, and the film is given any shade as needed.

Modern technologies allow the inclusion of various types of materials into the structure of triplex glass (for example, a regular layer of glass is combined with tempered or curved glass).

Double-glazed window formula: let's start decoding.

What is the most important thing in PVC windows? Of course, energy saving. And it is the double-glazed window that provides it, and not the profile at all.

Do you want to be sure that you bought energy-saving PVC windows?

Look carefully at the glass unit formula, which a specialist from a company installing plastic windows must provide you with when calculating the structure.

A 2-chamber double-glazed window with 2 energy-saving layers and internal filling with argon gas in this calculation will be “prescribed” as follows: 4i-14Ar-4-14Ar-4i or 4i-12Ar-4-16Ar-4i.

How to decipher this set of numbers and letters?

4 - glass thickness. The unit of measurement is millimeters. Important! In a 2-chamber double-glazed window there are 3 glasses installed, in a single-chamber one - 2. Another “chamber” is by analogy.

i is an indicator of the presence of an energy-saving layer. Remember! For climate zone I, 2 energy layers are applied: one on the outer glass, the second on the inner glass.

12, 14, 16 — distance between glasses. The unit of measurement is millimeters. It just seems to you that this is a minor figure. In fact, when filled with inert gas, the greater the distance, the better the thermal insulation. The accepted standard is 10-20 mm. An upward change does not increase the thermal efficiency of a double-glazed window. But reducing the distance will reduce this figure to a minimum.

Ar - a mark indicating that the space between the glasses is filled with argon. It is this gas, in combination with energy-saving layers, that ensures the high energy efficiency of PVC windows.

Other indicators in the glass unit formula

T - warm frame. Such frames reduce the risk of condensation around the perimeter of the glass unit. Most often they are installed on small “warm” double-glazed windows.

Advantages of triplex systems

Triplex technology gives PVC windows many useful properties:

pros

Strength - resistance to increased and impact loads, pressure

Safety – damage to furniture and injuries from splinters are excluded

Heat resistance - withstands sudden temperature changes

Increased sound insulation - with triplex, noise protection is 4 dB higher

Increased thermal protection - increases thermal insulation and helps save energy resources

Translucent - with a thickness of up to 40 mm, it transmits sunlight well

Double-glazed window formula: how to understand the “hieroglyphs”?

Modern PVC windows have simple designs.

On the one side. On the other hand, they are very complex. It’s impossible to figure out the issue of choosing a double-glazed window “at once”. And it’s not necessary - it’s better to take the time to read useful material that will help you understand everything thoroughly. And no need to wince! The knowledge shared by experts will help you avoid the most offensive mistake - paying dearly for something that is cheap.

Glazing classes

Safety glass is divided into several classes depending on the impact that glazing based on it can withstand.

| Class A | Impact-resistant glazing is used to protect against vandalism; when struck by a thrown object, a hole does not form in the glass. Suitable for objects where there are no significant values. |

| Class B | Break-resistant (burglary-resistant) glazing. It can serve as protection against unauthorized entry; it can withstand blows with a hammer, ax and similar objects for up to half an hour, aimed at punching a hole through which a person can penetrate. The number of impacts that glass can withstand without breaking depends on the thickness of the film. |

| Class B | Bullet-resistant glazing is intended for objects that may be subject to armed attack. Depending on the thickness of the protective film, it can withstand a shot from a weapon from a PM or revolver to an AK and SVD rifle. Glazing of this class also provides penetration protection that is more reliable and durable than class B triplex and can withstand more than 70 strong impacts. |

| Class D | Explosion resistant glazing. It is used for objects where an explosion may occur, including glazing of indoor structures. Depending on the thickness of the film, it can withstand an explosion from 100 to 400 g of TNT. |

Bullet-resistant and explosion-resistant glass are armored.

Marking of spacers

The spacer frame is a curved metal contour filled from the inside with a moisture-absorbing composition. This element of the glass unit forms its dimensions and the thickness of the chamber. Most often, spacer frames, which are essentially the frame of a double-glazed window, are a bent aluminum profile. Since the production process does not use fundamentally different blanks of this type, only the width of the frame is marked, which is also the thickness of the inner chamber. However, information about these elements of a double-glazed window is not always included in the labeling. If thermal inserts are integrated into the aluminum profile of the spacer frame, making it significantly warmer, they are designated with special codes - TD or TP.

Triplex double glazed windows

In double-glazed windows intended for residential buildings, triplex glass of class A is used, they can withstand being hit by a ball, and when hit by a stone or stick, they can develop a network of cracks, but at the same time, until replacement, they continue to provide thermal insulation, protection from wind and dust.

Triplex glass units vary in size, number of chambers, glass thickness, shape, decorative features and a number of other characteristics. The shape of double-glazed windows can be:

- rectangular;

- polygonal;

- round;

- arched.

Related articles:

◾Round plastic windows

◾Why do double-glazed windows sweat?

◾Panoramic windows

Advantages and disadvantages

The advantages of double-glazed windows made from triplex include:

- Protection from injury thanks to shatterproofness.

- High-quality insulation of the room from street noise.

- Protecting the premises from unwanted entry.

- High level of transparency.

- Strength and resistance to microdamage.

- Protection from excess solar UV rays.

- The appearance and high transparency are maintained throughout the entire period of use.

The only significant drawback is the rather large weight of such double-glazed windows. This is due to multi-layering.

Decorative triplex

Thanks to the expansion of technological capabilities in the production of these products, today decorative triplex is not just two glasses with a colored polymer film between them. Textured fabric, foil, film with photo printing, polymer sheets with LEDs and even compositions from plants can be used as decorating elements.

Thanks to this, it is possible to produce double-glazed windows and showcases to suit every taste and for the implementation of non-standard design projects.

Related articles:

◾Plastic sliding windows to the balcony

◾Reliable windows

◾What is between the glass windows?

Triplex – definition, history and application

Triplex is a composition of two or more glasses and polyvinyl butyral (PVB) film (film triplex) or polymer resin (cast triplex).

Photo: classic composition of triplex glass Triplex can be seen everywhere today - windshields of cars, trains, airplanes, windows of space stations, glass stairs, floors, furniture, shop windows of shopping centers. Armored glass of banks, fire-, bullet-, explosion-resistant glass is also triplex.

The case of the invention of triplex is simple, like all ingenious things. A glass flask with chemical residues fell from the shelf. But, to the surprise, the chemist Eduard Benedictus, who worked in the laboratory, did not crash. The glass was cracked, but did not lose its shape. Benedictus, impressed by reports of car accidents in which drivers and passengers were severely injured by shards of glass, began experimenting.

Photo: triplex in a car windshield protects the driver from injury. The result was a “glass multilayer sandwich” of two glasses and a layer of cellulose nitrate between them. In 1909, the inventor patented his invention for the safety of motorists called “Triplex”. The invention immediately found application in military technology, aircraft manufacturing and other areas. In 1919, Henry Ford used triplex in the production of cars, becoming an example for other automakers - fifteen years later, all windshields of new cars were made of triplex.

Where are triplex double-glazed windows used?

Impact-resistant double-glazed windows are more expensive than standard models, so customers take a rational approach to the issue of ensuring safety.

Most often, triplex glass is used in the arrangement of:

- windows into rooms where children are located - this applies to both private residential real estate and educational institutions;

- glazed entrance groups for any objects;

- various partitions in offices, shopping malls and so on;

- transparent protective structures for museum and exhibition exhibits;

- apartment windows facing playgrounds;

- showcases

Related articles:

◾Glass unit design

◾Energy-saving windows

◾German windows

Content

- Double-glazed window formula

- Decoding the glass unit formula

- Formulas for standard single and double glazing

- Formula of single-chamber double-glazed windows in the standard version

- Formula of double-chamber double-glazed window in standard version

- Formulas of special and improved double-glazed windows, markings of their parts

- Formulas for double-glazed windows with special glasses

- Formulas for double-glazed windows with tinted glass

- Triplex formula

- Impact-resistant glass formula

- Formula for soundproofing glass

- Formula for solar control glass

- Frosted glass formulas

- Patterned glass formulas

- Spacer markings

- Camera markings

- Results

- GOST standards for double-glazed windows

The formula of a glass unit is its marking. We will talk about it in this article. After reading it, you will learn:

- how to decipher the glass unit formula;

- how different types of glass are labeled;

- what designations are found in the formulas of impact-resistant, sun-protective, energy-saving, soundproofing packages and triplex;

- what technologies are used in their production;

- production of double-glazed windows of what type to order in this or that case.