PVC material was first discovered by a German chemist Regnald at the end of 1835. Since 1912, the search for possibilities for its production on an industrial scale began, and in 1931 the BASF concern received the first tons of this material. PVC (polyvinyl chloride, or thermoplastic polymer) is made from bleached plastic. This is a fairly hard material. The polymer is created chemically from tiny particles of petroleum products. Thanks to them, the durability of the product is maintained. All polymers are adapted to different climatic conditions (exposure to sunlight, moisture).

Petroleum products contain various modifier additives that are used for the manufacture of PVC profiles. Thermoplastic polymer withstands high temperature differences: from -50° to +60° C. Chemical formula: [-CH2-CHCl-]n. The service life of polymer profiles is approximately 20 years. PVC production experts note that the inherent hardness of the polymer helps preserve the properties of the material for 5-15 years. Rubber gaskets in this material are used for seals.

What are PVC windows and profiles and what are they made of?

Metal-plastic structures have long been part of our lives.

Forgotten are wooden surfaces that allow drafts and suffer from moisture. Gone are the drying frames covered with cracks. Old methods of protecting a home from cold and noise have been replaced by new ones: now most consumers prefer windows made of PVC. What it is? You will find the decoding in this article. Many of us have thought about renovation at least once in our lives. And what is there that no major home renovation can do without? Structures that protect the room from wind and moisture must be strong and reliable. Modern manufacturers offer an excellent replacement for wood - polyvinyl chloride, which has high thermal insulation and helps maintain a stable temperature in the apartment for a long time. But what does the wording “PVC windows” mean? Why are doctors and environmentalists around the world calling for a ban on the manufacture of products from this material? Owners of such structures have been convinced more than once of the durability of the profile made using original technology. The largest manufacturers confirm the safety of their products with numerous certificates. There are special international quality standards that all plastic windows must meet. However, this fact does not negate the fierce controversy surrounding the irreplaceable invention.

Why do opponents of durable profiles still exist today? Let's try to understand this issue by debunking the myth about the dangers of polyvinyl chloride structures, which are ideal not only for apartments, but also for various country buildings.

PVC-U sewer pipes

Here we will answer the question of how PVC sewer pipes differ from uPVC sewer pipes. First of all, let us point out the incorrectness of the question. For the production of sewer pipes, only PVC-U is used. Other types of polyvinyl chloride have clearly redundant characteristics for this. If you can afford not to count money, then the sewer can be assembled from pressure pipes in accordance with GOST R 52134-2003. Moreover, a significant part of the range of pipes made of uPVC and PVC according to different GOST standards coincides in standard sizes.

What is the environmental friendliness of PVC profiles?

Today, many experts talk about the environmental friendliness of PVC profiles. Thermoplastic profiles are made of heavy metals and aluminum is used to paint them white. The windows turn out snow-white, as they are made on the basis of potassium salt, soda, chalk and other mineral resources. PVC, created on the basis of the latest technologies, does not emit any toxic substances.

Thanks to special additives, this material is fireproof. The flame spread index for PVC windows is zero. This means that the plastic will not support the combustion process. Moreover, if a fire starts in the apartment, such a window should “strangle” it: vacuum double-glazed windows of new windows are good heat insulators, the glass will not burst from the heat, there will be no influx of oxygen, which means the fire will not intensify.

PVC window profiles are supplied to us from Austria, Switzerland, England, France, Turkey and other countries, but Germany undoubtedly holds the lead. The Germans own up to 90% of the Russian plastic window market (manufacturers: Actual, Aluplast, ARtek, Brugmann, Gealan, KBE, Knipping, Plustek, Rehau, Roplasto, Schuco, Thyssen, Trocal, Veka and others). Fittings and other components also come from Europe and also mainly from Germany (Aubi, Rota, Siegenia, Winkhaus). The companies are listed simply in alphabetical order, since it is difficult to objectively say whose products are better. One of the reasons for this is that sometimes quite prestigious European manufacturers supply us with simplified, cheaper options.

Not so long ago, our own licensed production appeared in Russia. Prices for domestic goods are one and a half to two times lower. You can save money by purchasing PVC in the cold season; some companies offer discounts of up to 20% for an easily tolerated inconvenience: 20-30 minutes with exposed frames. And yet, cheaper does not mean better. The fact is that the technologies on the lines installed by us are not always followed. “Licensed plastic” may indeed turn out to be not environmentally friendly enough, not white enough and completely unstable to our frosts, sudden temperature changes and acid rain. Although, of course, this is not a rule.

Nevertheless, taught by bitter experience and frightened by rumors, many of our fellow citizens consider it a safer option to order windows from dealers of reliable European companies. How to distinguish their products? It’s very simple - along the entire perimeter of the frame (from the side of the window opening) on each linear meter of the inner side of the sash there is a logo, without which, for example, German manufacturers do not have the right to supply products. These branded windows are not cheap, but they are worth it.

Strengthening films

To protect your home from intruders entering your home through a window, triplex security glass has long been produced. It is made according to the automotive principle: two or more glasses are sandwiched with a special durable film. The more layers, the higher the reliability. Triplex may crack, but will still stand. There are also double-glazed windows with strengthening film. It is much thinner than triplex, but is not inferior in strength. Depending on the thickness, it can withstand up to several hits with a sledgehammer. The thicker the film, the stronger it is.

Basic properties and structure of PVC profiles.

Window profiles have a complex design. They contain several air chambers. Iron reinforcement is installed on the middle chamber, which ensures the rigidity of the frame. Ventilation holes are drilled at the top of the window to remove the resulting condensation. The glass is based on the "mirror reflection effect". The sun's ray hits the mirror surface of the glass and is refracted, penetrating into the room. This results in good energy savings. The window frame consists of four ribs, which are made of metal-plastic covering.

Application area

PVC is a universal material used in many industries:

- More than 50% of the polyvinyl chloride produced in the world is used in the construction industry. This is facilitated by light weight, durability, high mechanical strength and thermal insulation properties, corrosion resistance, wear resistance and chemical resistance of the material. It is widely used for the production of load-bearing window contours, doors, linoleums, finishing materials, and various film products. Many modern engineering communications are made from PVC pipes.

- The use of the polymer in the medical field is facilitated by its inertness, chemical stability, high biocompatibility, compliance with toxicological standards, the possibility of sterilization and other properties. All kinds of plastic containers, disposable instruments, parts of medical devices, medical masks for surgery, and blister packaging for medicines are widely used here.

- The vehicles are equipped with PVC instrument panels, interior trim, seals, airbags, armrests and other elements. On average, 16 kg of plastic products are used in one car.

- Among polyvinyl chloride packaging, rigid film takes the lead (51%), followed by bottle products (35%), film (11%), and caps (3%).

- Among children's products there are many plastic toys - dolls, ducklings for the bath, inflatable beach items, balls.

In addition, hard types of plastic are used in the production of furniture and sports equipment, while softer types are used in the production of bags, shoes, clothing and other household goods.

See also on the topic “Polyvinyl chloride (PVC) – what is this material, properties, products”:

Advantages of uPVC pipes

The growing popularity of uPVC and PVC pipes is due to such advantages of their use as:

- reliability;

- durability;

- ease of installation;

- a sharp reduction in operating costs for pipeline maintenance;

- pipes are completely harmless to humans and the environment.

Nowadays, polymer pipes are widely used in the modernization of utility networks and in new construction. They replace pipes made of steel, cast iron and other materials.

How to decipher the PVC window markings?

Some time ago you decided to replace wooden frames with PVC windows. Then you found a company willing to manufacture the structures, deliver them to your home and install the windows. Already at the stage of taking measurements and signing documents, you may come across abbreviations that are incomprehensible to the average person, which are usually used to designate window and door structures. In order not to encounter unpleasant surprises, each customer should delve into the nuances of their labeling.

- Numerator and denominator

- How to decipher the numerator?

- How to decipher the denominator or description?

- How to check if a product matches your order?

- How to prevent errors when ordering PVC windows?

Numerator and denominator

The “classic” marking of a PVC window is similar to a mathematical fraction with a long numerator and denominator. The upper part of the fraction - the numerator - contains information about the type of product, design features and standard sizes. The denominator indicates performance characteristics, which we will discuss below.

Some manufacturers indicate performance classes not in the labeling, but as a separate description - in the product passport, design documentation or in the supply contract. This is not a violation, since GOST 23166-99, in accordance with which windows and balcony door blocks are marked, allows the use of descriptions instead of indicating classes in the denominator.

If you are now leafing through documents for the design and installation of windows, but do not find designations or descriptions of classes in the papers, this means that the product you ordered has minimum values of operational parameters.

How to decipher the numerator?

- The first letter in the numerator is the type of product. Regular PVC windows are marked with the letter “O”, balcony door blocks – with the letter “B”.

The second position is the designation of the material: P corresponds to PVC, A to aluminum, D to wood.

The numerator also indicates the dimensions in decimeters; for example, 30 - 15 (length and width, respectively).

- The last letters are a design option where the letters F (window windows), Fr (transoms), PO (turn-and-tilt), as well as the letters P and L (right and left versions in the opening direction) are found.

Door opening mechanisms

Manufacturers now offer two types of window units: American (sliding) and European (tilt-and-turn).

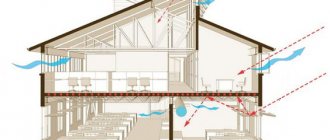

Sliding window units are most successful when glazing loggias and balconies. They will not take up a single extra centimeter of space, as is the case with conventional frames that open inwards. Tilt-and-turn blocks allow the doors to open in two planes: on vertical hinges, like conventional windows, and on horizontal hinges, like transoms. The last option is the most convenient for ventilation: it does not blow.

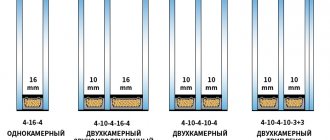

Double-glazed windows

The design is a combination of three 4 mm glasses and two air chambers between them, 10 mm each. The total thickness of the glass unit is 32 mm. This type is most often chosen when renovating residential buildings, since it combines efficiency and decent heat and sound insulation properties. A double-glazed window allows you to combine various glass characteristics: color, impact resistance, thickness, and the presence of decorative elements. The set of characteristics is selected taking into account the wishes of the customer and depends on many factors: location of the house or apartment, floor, distance from the road, presence of heating, south or north side of the house.

The formulas of double-glazed windows are very different. For example, it could be like this - 4-10-4-10-4. The first in the formula is always the glass facing the street; do not forget about this when choosing difficult double-glazed windows.

The main characteristics of standard single-chamber double-glazed windows with various formulas are presented in the table below.

Tinted windows

Today we offer a large selection of tinted glass (up to 20 shades). They dim the bright sunlight.

There are also mirrored translucent glasses that reflect the sun's rays and create summer coolness in the house. Even if you use an air conditioner, such glass will provide significant savings in the energy consumed by it.

It is preferable to tint “in bulk” (that is, the glass is cast at the factory already colored in its entire thickness. Other methods of tinting - spraying and film coating - are less reliable. Spraying after a few years may become unsightly spots or fade. In addition, the production time for ordered double-glazed windows with toning it increases by a week.

Advantages of PVC in other areas of production:

For small structures, a non-insulated metal air duct may be suitable, and for large facilities, polymetallic elements are used, which maintain the output characteristics of the air flow longer.

Disadvantages of PVC:

- minor restrictions on heat (thanks to thermal insulation, repairs and lining of equipment are carried out, PVC pipes have certain boundaries with the air temperature, about +60° C);

- quite expensive material (the price increases with the size of the pipe diameter);

- heavy material (relatively thick steel part covered with metal sheets);

- the difficulty of replacing metal products (these products are not produced in the same sizes and shapes by other companies, so you will have to order from suppliers);

- difficulty of disposal (when the material is burned, toxic organochlorine substances appear, which are popularly called toxins).

Energy saving glass

Some companies have recently been making the outer side of double-glazed windows from the so-called K-glass from the English company Pilkington. This is low-e energy-saving glass with metal spraying. It prevents the radiation of heat from the room to the outside and allows you to get by with thinner single-chamber double-glazed windows even in cold climates.

At the same time, the heat transfer resistance coefficient of such an energy-saving double-glazed window without filling with inert gas is 0.56 units (temperature of the double-glazed window from the room side is +14.5°C), and with inert gas - 0.67 units (internal temperature +16°C). K-glass and gas filling solve the problem of “crying” windows, and not only that. Another interesting property of energy-saving glass is the ability to reflect infrared sunlight, keeping the room cool in the summer heat.

Based on materials from vira.ru

Subscribe to our Telegram channelExclusive posts every week

Basic properties and structure of PVC profiles.

Window profiles have a complex design. They contain several air chambers. Iron reinforcement is installed on the middle chamber, which ensures the rigidity of the frame. Ventilation holes are drilled at the top of the window to remove the resulting condensation. The glass is based on the "mirror reflection effect". The sun's ray hits the mirror surface of the glass and is refracted, penetrating into the room. This results in good energy savings. The window frame consists of four ribs, which are made of metal-plastic covering.

In the production of PVC, a flexible and soft structure is distinguished. The flexibility material is called phthalate.

PVC is used to insulate electrical wiring; insulation is obtained using plasticizers. Electrical wires burn quickly, the insulating material is soaked in chlorine solution. Polyvinyl chloride is widespread in the USA and Europe, as almost 80% of water supply pipes are made from it.

- ↑ Chernyak L. M.

From the history of glass - ↑

Ivan Zabelin “Home life of Russian tsars in the 16th and 17th centuries.” Publishing house Transitbook. Moscow. 2005 ISBN 5-9578-2773-8

Wikimedia Foundation. 2010.

- Windows GROWTH

- Windows of satire ROSTA