- Veka - eight varieties with different characteristics, reliable, environmentally friendly, functional.

- Rehau - considered the most popular in the world, includes budget, mid-priced and premium models.

- Schuko - with 3-8 cameras, with excellent burglary protection.

- Proplex is Russian-made, produced on German equipment in workshops in the Moscow region. There are 3-6 chambers. They are distinguished by stylish design and durability. Convenient to use.

- KBE - resistant to temperature changes, wear, and mechanical stress. Significantly more expensive than analogues.

How to determine the profile of a plastic window?

When purchasing a PVC window profile, it is important to make sure that you are getting exactly the product you are paying for and not a pig in a poke.

Buyers sometimes have doubts whether the profile they ordered is delivered to their facility, or whether it is the same glass that they chose in the catalog. It happens that the products in the company’s office look different from those that arrive to the customer. Sometimes the reason is just different lighting. However, there are also unscrupulous contractors who pass off ordinary glass as energy-saving glass. For some buyers, new locks do not close due to defects. From this article you will learn how to determine the type of profile and thereby protect yourself from counterfeiting or notice a supplier’s mistake in time.

Checking the fittings

Window fittings ensure a tight fit of the sashes to the frame, locking them, opening them and fixing the sashes in various positions. The operation of the entire window unit depends on its quality.

Cheap fittings are usually made of soft metal, and some of their elements may even be plastic.

Such products require constant adjustment, and after a couple of years, all the fittings will have to be changed.

The manufacturer of the fittings is also added here. If it was produced by an unknown company, then you can’t hope for high quality.

For increased convenience, you can order the installation of additional elements:

- Slot ventilator.

- Window sash tilt limiter.

- Sash opening limiter.

- Microlift.

- Locks on the handle.

Check how the fittings function and evaluate the ease of effort. Make sure the sashes turn where you point them.

Use a ruler

The Internet and the ruler will help you. Most manufacturers mark their profile and indicate its name on their products. Using a ruler, you can measure the dimensions of the profile, for example, the depth of the glazing beads, the thickness of the sashes and frame, the distance of the strip for the fittings from the edge of the frame. Compare the measurement results with typical profile parameters - on the markings or based on the dimensions for profile sections indicated on the Internet.

This method is unlikely to help you recognize a specific model of a popular brand, because external parameters within the same brand, as a rule, are not very different. This may work if you received windows from an unpopular brand. Internally, the profiles are arranged differently - the thickness of the walls and the number of chambers can be different.

Examine the inside of the frame

On the inside of the frame, the manufacturer usually indicates the date of manufacture of the profile and its name. Therefore, when you open a plastic window sash, you can see the corresponding markings on it. It is more difficult to determine the structure and manufacturing company of a double-glazed window - to do this, you will have to remove the glass package from the structure and look at the data on the side sticker, which is often (but not always) indicated there. Take a look at all the grooves of the profile - the model of the profile system may be indicated in the glazing bead groove.

Classification of PVC profiles

If you are thinking about replacing windows or purchasing new window and door structures for a house that is just under construction, then you will probably have to face the problem of choosing and finding answers to the questions:

- What is a fair price for windows that I can pay?

- Which window brand to choose: Kbe, Rehau, Veka, Salamander.

- What characteristics should the profile have and what is better for me - inexpensive 3-chamber profiles, or more expensive 5 or even 7-chamber profiles?

...and this is not a complete list...

Undoubtedly, these are extremely important questions and finding the answer to them will be your priority. But there is also another, often hidden from view, criterion that cannot be neglected - this is the class of the profile, and in fact the quality of the profile from which your plastic window or door will be made.

Compare these specifications with the manufacturer's part numbers

When determining a profile, it is necessary to rely on accompanying documents. They will also help you prove that you are right in case of delivery of products that do not correspond to the receipt. Pay attention to the specifications indicated in the documents - compare them with information on manufacturers' article numbers. However, do not panic if, when ordering a REHAU Delight profile, you see the SIIB marking and numbers. This means the following:

- S – climate type in which the window profile is used;

- II – category of impact strength;

- B – classification of profile walls by thickness;

- 401 is the country code;

- 02 – factory code;

- 04 – extruder designation;

- numbers of the form “17 08 23” – date of manufacture.

Doors are marked with the letters Z and T. Typically, the nuances of the profile that can be used for verification are indicated in the annex to the contract. It is worth paying close attention to this document when purchasing window systems.

Choice

Taking into account external factors such as annual temperature fluctuations, windiness and noise levels in the surroundings of the house, an appropriate design is selected. To decide which profile is best for plastic windows, reviews come to the rescue. When choosing it, you need to pay attention to the thickness of the walls (plastic) and the thickness of the reinforcement. Ideally, these indicators should be: 3-4 mm (class A) for the profile and 1.5 mm for reinforcement. They directly affect the rigidity and strength of the structure, so you should not skimp on these indicators. Class B has a plastic thickness of 2.5-3 mm, class C is not standardized.

Also, the level of strength depends on the installation width of the profile: the larger it is, the stronger the structure. The width on average is 58-70 mm, depending on the number of air chambers, and sometimes can exceed 100 mm.

Metal carcass

To give strength and rigidity, the profile is reinforced with a metal (galvanized steel) frame, which prevents the window from deforming under the influence of changeable weather. It is important that the reinforcement is made with galvanized steel, otherwise the drainage holes for water drainage will rust and the strength of the structure will lose its value.

The shape of the frame is:

- L-shaped (placed so that two in total form a rectangle);

- U-shaped;

- closed (used for large windows).

ATTENTION: How to determine the authenticity of a KBE profile and its country of origin. Updated and supplemented

Those who have been searching for information about plastic windows, types and features of profile systems for several days now have encountered the following situation. It turns out that the same profile (seemingly) can be produced in different countries. This is absolutely normal practice. After all, every large concern or manufacturing company strives to develop its network of factories for a number of objective reasons. In addition, a PVC profile of the same brand produced in different countries may have a number of distinctive characteristics predetermined by territorial features and climatic conditions in a given region. It is also important that the presence of manufacturing plants for PVC profiles KBE in neighboring countries of Belarus is an opportunity to purchase PVC profiles with significant savings on transport services and customs clearance. As a result, the cost of the finished window for the end consumer will be lower than, for example, it will be made from a profile imported from Germany.

Russian and European PVC quality classes

In Europe, the standard used for classification is EN 12608 SR - Unplasticized polyvinyl chloride (PVC-U) for the manufacture of windows and doors.

In Russia, profile classification is carried out according to GOST 30673-99 PVC profiles for window and door units.

Technical conditions. GOST 30673-99 PVC profiles for window and door blocks. Specifications Download Microsoft Word Document 330.0 KB

Note that the requirements of these two standards differ. This is due to the fact that traditionally different measurement systems are used in different countries, and the specifics of construction also vary. However, the general features of these standards are the same. They necessarily determine the thermal insulation properties, durability and some technical parameters that allow profiles to be correlated with a certain class.

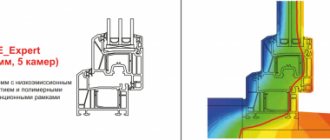

Design features of PVC windows

The inner side of the PVC profile is divided by partitions that form chambers. Any profile system has at least three air chambers, the largest ones have eight. Their number affects the heat and sound protection of the opening. Warmer and quieter windows with a large number of cameras. Window systems with three to five are more popular than others. Consumers are attracted by their ratio of weight and sound and thermal insulation. To increase strength, the profile is reinforced with metal reinforcement made of galvanized steel. It comes in form:

- L-shaped

: two profile walls are reinforced. - U-shaped

: 3 walls are reinforced. - closed

: all parts are reinforced.

Popular manufacturers

Many manufacturers offer their profile systems to consumers. The most common window brands are:

- Veka

- eight varieties with different characteristics, reliable, environmentally friendly, functional. - Rehau

- considered the most popular in the world, includes budget, mid-priced and premium models. - Schuko

- with 3-8 cameras, with excellent burglary protection. - Proplex

is Russian-made, produced on German equipment in workshops in the Moscow region. There are 3-6 chambers. They are distinguished by stylish design and durability. Convenient to use. - KBE

- resistant to temperature changes, wear, and mechanical stress. Significantly more expensive than analogues.

How to determine which windows are installed?

REHAU, KBE, VEKA. There are many manufacturers of window components. To find out which company produced your profile system, carefully inspect the elements of the window unit and read the inscriptions on the products. How to determine the brand of a plastic window profile? Examine the outside of the sash. According to GOST 30673-99, its profile must be marked with the name in increments of up to 30 cm. The most popular brands in our country are: VEKA, KBE, Rehau, PROPLEX, Mont Blanc, Brusbox, Schueco, Plafen, LG.

In the southern Russian regions, it is quite enough to use a three-chamber profile with a depth of up to 6 cm; in the central regions, a five-chamber profile with a depth of at least 7 cm is preferable. The thermal conductivity coefficient of a reinforced 5-chamber profile is above 0.8 m²°C/W. In the north of the country, this solution is the required minimum.

Tips from REHAU

Determining the quality of installation

In addition to the properties of the profile, glass unit, and fittings used in production, the issue of high-quality installation . Most of the problems that end users encounter are due to errors made during installation. To avoid unpleasant consequences, you should find out in advance what parameters to check the correctness of the installation.

Fastening strength

It is important to correctly carry out the initial measurements of the blocks and draw up an accurate sketch of the design of the window opening. The measurement process should not be underestimated. To find out the correct width and height of the future structure, it is necessary not only to measure accurately, but also to take into account many nuances that craftsmen are well aware of.

First of all, incorrect measurements will lead to the product not fitting into the opening. This entails significant additional costs for the manufacture of new structures. Before installation, you should measure the window delivered by the manufacturer to see if it corresponds to the actual dimensions of the opening. By identifying the error at this stage, you can eliminate the risk of the opening remaining open after the discrepancy is discovered.

The strength of the structure must be able to withstand heavy loads. In some cases, the weight of the entire block can be up to hundreds of kilograms. You need to be especially careful when using fasteners - a double-hung window must have at least 14 fasteners (anchor plates). If the number of fasteners is less, this will cause the entire structure to sag in the near future, the sashes will warp, and cracks will appear at the installation seams.

The process of checking the quality of installation includes monitoring the tightness of the shutters. There is no need to wait for frost to set in or strong winds to appear. By placing a regular sheet of newspaper between the frame and the window, the sash is closed using fittings. Next, you need to try to pull out a thin sheet of newspaper. If a person experiences difficulty when stretching, then the density is sufficient.

Repeating a similar procedure along the entire perimeter will allow you to comprehensively check the structure. If in some places the sheet is easily pulled out, but in others it is clamped tightly, you need to check the seal. If the seal is in order, adjust the window fittings.

The installation should also be checked vertically. The window itself should not move when opened. Detection of such a defect requires urgent reinstallation of the product. The plugs at the ends on the side of the thresholds and window sill are also checked. In some cases, the manufacturer forgets them or their dimensions are shorter than required.

Quality factor of assembly seam

Building regulations require maintaining a certain distance between the structure frame and the wall surface. It can vary within 1.5-5.0 cm. Such a measure is necessary in order to qualitatively perform an assembly seam consisting of polyurethane foam, sealant, and tape. The mounting seam serves as a kind of layer between the wall and the frame. Installing the window tightly against the wall can cause the window to freeze in winter.

The assembly seam is based on foam that hardens after application. You can use ordinary mounting foams used in everyday life, as well as brands created specifically for installing plastic structures. You can choose between winter and summer options, depending on the time of year for installation. When using, you should take into account the rules for working with polyurethane foam.

When filling installation seams, the formation of voids should be avoided; hardened foam should not be cut off from the street side , as this entails damage to the protective crust and opening of hygroscopic pores, which contributes to the accumulation of moisture, which on frosty days causes the destruction of the foam.

One protective crust will not be enough. Additional foam protection is required even if the crust is kept intact. You can observe signs of aging in window structures some time after installation; the resulting microcracks cause unwanted air exchange, leading to heat loss from the room. High humidity causes the formation of fungus and mold on various parts of the structure (frame, slopes). Thus, the polyurethane foam itself should receive additional protection in the form of sealants and sealing tapes.

Blitz survey: Which brand of plastic windows is the best? From our reviews of window manufacturers you can find out the advantages and disadvantages of each brand of plastic windows: KBE, Deceuninck, Proplex, Brusbox, Schuco, Grain.

The ability of plastic parts to expand when exposed to intense heat when the window is in the sun is known. Despite the fact that these changes are almost invisible to the eye, they will negatively affect the condition of the assembly seam. The installation of special support blocks made of wood and plastic will allow you to avoid deformation and strengthen the frame structure. The material for the pads is impregnated with an antiseptic that protects it from destruction. If the pads are not installed, the seam seal will be compromised.

Residues of polyurethane foam must be removed

It is necessary to ensure that there are no pieces of foam left on the structure being installed. The presence of foam means that the protective film was removed from the product ahead of time, before the foam hardened. To remove foam, use fine sandpaper, then polish with white paste. If rough plastic was used in manufacturing, this method of removing foam should be abandoned. Sanding will damage the surface and change its structure, which will be noticeable.

Certification

How to find out the brand of a plastic window for sure? Complete information about the product is provided by the PVC profile certificate. Not every subsidiary of a popular manufacturer has the right to issue a RAL certificate for its products. The VEKA and REHAU concerns issue such a document to all enterprises, which include Russian ones. The RAL certificate serves as a guarantee that the frames are produced strictly according to technology and the source material is of high quality.

When choosing reliable windows, pay attention not only to the thickness and number of chambers in the profile system. Products produced at the plant are required to be certified. They must have a RAL certificate or ISO9001:2000. The first quality passport indicates the type of product and place of production, the second indicates compliance with technical regulations during the manufacturing process. The certified product can be safely used in glazing residential buildings.

Types of certification with increased requirements

Profiles produced by factories of foreign brands in Russia must also usually comply with European quality standards: German, pan-European, French. Let's take a closer look at the features of their requirements.

RAL certification

RAL certificate – German quality standard. In Europe, window manufacturers prefer to work with RAL-certified window profiles. It's not that easy to get. It is conducted by an independent commercial organization. Twice a year, every manufacturing company is subject to a new and unexpected audit. Inspectors appear without warning and select samples for testing “to their taste.” The main criterion for the quality of a metal-plastic profile according to RAL is the wall thickness, which should be exclusively 3 mm. For unscrupulous manufacturers, there is no guarantee that the certificate will not be revoked after the next inspection. The “stamp paper” received two years ago may be just paper this year.

As of the end of 2022, there is no information about RAL certificates on the Russian REHAU website. On a similar Ukrainian site there is. Strange? The solution is that the profile is supplied to Ukraine by two German factories and one Polish one (which have passed RAL certification). It is not the company as a whole that is certified, but its individual plant with production lines. There may well be situations where foreign factories of a certain profile brand have a number of “strict” certificates, but Russian factories do not.

Certificate DIN EN 12608

DIN EN 12608 is another pan-European standard developed and approved by the European Committee for Standardization, or “Euronorm”. According to it, window profiles are divided into three classes: A, B and C. The difference between the classes lies in the thickness of the profile walls. The highest class A provides the thickest profile walls of 2.8-3 mm. A class B profile must have walls at least 2.5 mm wide. For class C (lowest quality) the parameter is at least 2 mm. PVC blanks complying with DIN EN 12608 are designed for the production of durable windows.

ISO 9001:2008 Certificate

ISO 9001:2008 is a standard that regulates the principles of operation of the quality management system at an enterprise. It determines how control of raw materials and finished products should be organized, what documentation should be drawn up and what tests should be carried out. If an enterprise has a certificate of compliance with this standard, then it produces high-quality products.

When communicating with window companies, be sure to clarify what certification requirements the profiles they use meet. Information about a profile's compliance with certain certificates must be displayed in markings on the profile.

How to determine the profile of a plastic window?

The content of the article:

The basis of any window unit is a profile. Its characteristics determine the durability and reliability of the glazing. The number of chambers and the thickness of the PVC window, thermal insulation and its other parameters affect the comfort in a glazed room. Knowing the type and manufacturer of the profile installed in the window openings, you can understand what level of thermal insulation you should expect, how the profile system is designed, and how vulnerable it is.

What profile material should I choose?

Without any doubt, in our time, polyvinyl chloride is the most popular in the manufacture of metal-plastic window systems. This material was first used to create products of this type back in the seventies of the last century. Since that time, it has significantly displaced its analogues, primarily wood, from the market.

Unlike more fragile and expensive wood, polyvinyl chloride has impeccable performance qualities. It looks great, is lightweight, and is incredibly flexible and easy to work with. With its help, you can create windows of any type and shape, including rectangular, arched and others. In addition, PVC is an incredibly durable material. Unlike wood, it does not require additional processing and protection, and products made with it will serve you for at least 20 years.

In addition, today you can find structures made of aluminum. This type of metal is very versatile and is just as well suited for window systems as PVC.

Design features of PVC windows

The inner side of the PVC profile is divided by partitions that form chambers. Any profile system has at least three air chambers, the largest ones have eight. Their number affects the heat and sound protection of the opening. Warmer and quieter windows with a large number of cameras. Window systems with three to five are more popular than others. Consumers are attracted by their ratio of weight and sound and thermal insulation. To increase strength, the profile is reinforced with metal reinforcement made of galvanized steel. It comes in form:

- L-shaped : two profile walls are reinforced.

- U-shaped : 3 walls are reinforced.

- closed : all parts are reinforced.

Popular manufacturers

Many manufacturers offer their profile systems to consumers. The most common window brands are:

- Veka - eight varieties with different characteristics, reliable, environmentally friendly, functional.

- Rehau - considered the most popular in the world, includes budget, mid-priced and premium models.

- Schuko - with 3-8 cameras, with excellent burglary protection.

- Proplex is Russian-made, produced on German equipment in workshops in the Moscow region. There are 3-6 chambers. They are distinguished by stylish design and durability. Convenient to use.

- KBE - resistant to temperature changes, wear, and mechanical stress. Significantly more expensive than analogues.

How to determine which windows are installed?

REHAU, KBE, VEKA. There are many manufacturers of window components. To find out which company produced your profile system, carefully inspect the elements of the window unit and read the inscriptions on the products. How to determine the brand of a plastic window profile? Examine the outside of the sash. According to GOST 30673-99, its profile must be marked with the name in increments of up to 30 cm. The most popular brands in our country are: VEKA, KBE, Rehau, PROPLEX, Mont Blanc, Brusbox, Schueco, Plafen, LG.

In the southern Russian regions, it is quite enough to use a three-chamber profile with a depth of up to 6 cm; in the central regions, a five-chamber profile with a depth of at least 7 cm is preferable. The thermal conductivity coefficient of a reinforced 5-chamber profile is above 0.8 m²°C/W. In the north of the country, this solution is the required minimum.

How to determine the brand of a plastic window profile other than by looking at the side of the sash? This can be determined by inspecting the frame when the sash is open. The brand is applied to the frame after 1-1.5 m as a seal or embossed so that the inscription is almost invisible. She is transparent.

How to determine the brand of window fittings? Its manufacturers apply logos to each fitting part. For Russian windows, the optimal fittings are MACO, Kale, SIEGENIA AUBI, ROTO, WINKHAUS.

Existing profile classification

Technical requirements for the manufacture of plastic window profiles and classification parameters are given in GOST 30673-99 and European EN 12608 SR. According to these regulatory documents, the classification of profile products is determined by several different indicators. Let's try to use them to determine which profile to choose for PVC windows.

Wall thickness

The cross-section of a plastic window profile is a hollow structure built in the form of a system of external and internal partitions. External surfaces include all surfaces that are visible after the final installation of the window.

This means that the walls resting on the wall and located under the glass unit are internal. The strength, durability and cost of the profile depend on the thickness, size, number and location of the walls.

Depending on the wall thickness, accepted standards define 3 classes of window profiles:

- “A” with a thickness of external walls of more than 3.0 mm (according to the European standard at least 2.8 mm) and internal walls of more than 2.5 mm. Structures with such parameters have the highest strength and excellent thermal insulation properties.

- “B” with outer walls 2.5-3.0 mm and inner walls 2.0-2.5 mm. This profile is less resistant to mechanical deformation by an average of 15% and has a thermal conductivity coefficient that is 10-15% higher.

- “C” are materials for which certain requirements are not imposed. These economy class profiles are usually used to make plastic windows for industrial and unheated facilities.

Please note that the classification of the profile by wall thickness is made according to the lowest indicator. If the outer thickness is 3.2 mm and the internal partitions are 2.1 mm, then this section is classified as class “B”, despite the thick outer walls. You can find out the exact dimensions and make a choice of profile for plastic windows only by taking measurements using measuring tools.

Depending on climate zones

Manufacturers of plastic profiled products produce products with different technical characteristics for countries with hot, temperate and cold climates. Therefore, depending on the average outside temperature in January, window profiles are distinguished:

- light – for regions where the average January temperature does not fall below -5°C;

- normal version – for areas with outside temperatures from -5°C to -20°C;

- frost-resistant - for harsh northern conditions, where below -20°C.

Russian manufacturers produce only the last two types of profiles. The lightweight version can only be purchased on order from foreign companies and Russian companies from Krasnodar.

In addition, the State Standard defines 5 classes of plastic window profiles according to the coefficient of heat transfer resistance. Digital readings range from 0.4 m°C/W to 0.4 m°C/W, with a step between classes of 0.1 m°C/W.

By mechanical strength

Based on their ability to resist mechanical loads, PVC profiles are divided into classes I and II. Class 1 materials must withstand without damage the impact of a special test impactor when dropped with a mass of 1 kg when dropped from a height of 1 meter. For class II, it is tested at a fall height of 1.5 meters. The temperature of the plastic during testing should not exceed -10°C.

Mechanical tests make it possible to determine how well the internal partitions are located, and which profile to choose for plastic windows, depending on the resistance to mechanical shocks at subzero temperatures.

Certification

How to find out the brand of a plastic window for sure? Complete information about the product is provided by the PVC profile certificate. Not every subsidiary of a popular manufacturer has the right to issue a RAL certificate for its products. The VEKA and REHAU concerns issue such a document to all enterprises, which include Russian ones. The RAL certificate serves as a guarantee that the frames are produced strictly according to technology and the source material is of high quality.

When choosing reliable windows, pay attention not only to the thickness and number of chambers in the profile system. Products produced at the plant are required to be certified. They must have a RAL certificate or ISO9001:2000. The first quality passport indicates the type of product and place of production, the second indicates compliance with technical regulations during the manufacturing process. The certified product can be safely used in glazing residential buildings.

.

Don't waste your time

We will call you back in 15 minutes and tell you useful information that is of interest to you:

other articles

How to successfully glaze a dacha

19.11.2020

Every owner of a country house sooner or later faces the question of high-quality glazing - either at the construction stage, or when the first problems appear with already installed windows (blowing, freezing, heat loss, unaesthetic appearance). Ordering windows with installation is not difficult, but choosing really high-quality glazing is not easy, especially if you are encountering this for the first time.

MORE DETAILS

Why do plastic windows sweat from the inside in an apartment?

24.12.2019

Even high-quality plastic windows can “cry”. Condensation forms on them - droplets of water when the air temperature indoors and outdoors differs significantly. As a rule, such phenomena are not observed in the warm season. It is worth considering that temperature changes are not the only reason why plastic windows sweat. What is the main cause of condensation, why is it dangerous, and why is it worth fighting the causes of its occurrence? Let's take a closer look.

MORE DETAILS

Should I replace windows in a new building? We check the quality of standard windows

23.01.2021

With the company “Windows Harmony” you can be sure that your windows will be manufactured and installed in full compliance with GOST. That is why we without a doubt provide a 10 year guarantee on our windows.

MORE DETAILS

ATTENTION: How to determine the authenticity of a KBE profile and its country of origin. Updated and supplemented

Those who have been searching for information about plastic windows, types and features of profile systems for several days now have encountered the following situation. It turns out that the same profile (seemingly) can be produced in different countries. This is absolutely normal practice. After all, every large concern or manufacturing company strives to develop its network of factories for a number of objective reasons. In addition, a PVC profile of the same brand produced in different countries may have a number of distinctive characteristics predetermined by territorial features and climatic conditions in a given region. It is also important that the presence of manufacturing plants for PVC profiles KBE in neighboring countries of Belarus is an opportunity to purchase PVC profiles with significant savings on transport services and customs clearance. As a result, the cost of the finished window for the end consumer will be lower than, for example, it will be made from a profile imported from Germany.

Briefly about the design of plastic windows

To understand how places are distributed in the ranking of the best profiles for plastic windows, it is worth understanding the general structure of translucent structures. Physical parameters and PVC finishing are not the main criterion for choosing glazing.

Structurally, a PVC window consists of manual binding, double-glazed windows and fittings. The frame is a profile system consisting of plastic (external) and reinforcing (internal) elements. In fact, it is the load-bearing part of the entire product, the nature and characteristics of which determine the scope and durability of the entire window. Therefore, it is important to choose the right profile.

Double-glazed windows can be represented by sheets of different thicknesses and in different quantities. For example, 3-4 mm glass is relevant for a summer veranda or living space in a warm climate zone. In the conditions of the harsh north, the choice should be made in favor of 5-6 mm and double, triple glazed windows with thermal tape inside a solid structure.

Three-chamber double-glazed window Source i-okna.ru

The fittings include all other components. These are mechanisms, seals, handles with loops. This also includes additional locking systems and stoppers, ventilation inserts, etc. That is, this group of window components can be classified as additional, and not basic, against the background of profiles and double-glazed windows.

A few words about double-glazed windows

Products are made from at least two glasses of varying thickness. The canvases are tied together into a single structure using a thin frame binding and sealing materials. As a result, there is air or gas between the glasses, which provide additional resistance to the penetration of heat outside and cold into the room.

The void between the translucent panels is conventionally called a chamber. The more there are, the better the thermal insulation and acoustic properties of the double-glazed window. At the same time, the weight of the structure increases, which is important to consider when choosing glazing along with a PVC window profile.