Even if low-power heaters are used in the room, properly selected insulation will help maintain a comfortable temperature. When answering the question of what Izolon is, what first comes to mind is its improved capabilities in creating high-quality thermal insulation. Let's figure out what the features of the canvas are, what characteristics it has and how to choose the right option.

A popular variety is foil Izolon Source sevparitet.ru

Material and its varieties

Isolon is a brand of insulation. The name hides foamed polyethylene foam with a closed-type fine-cell structure (the cells are closed, separated from each other). The structure determines the improved physical and mechanical characteristics of the canvas. The industry produces the following types of Izolon insulation:

- Izolon PPE (polyethylene foam). Multifunctional material, heat, sound and vapor barrier. The abbreviation PPN refers to the production method - it is an ethylene polymer with cross-linked molecules (physically cross-linked foam or cross-linked polyethylene). It is found on sale in the form of rolls of different windings or sheets (100x200, 140x200 mm).

- Izolon adhesive (self-adhesive). Foamed polyethylene with an adhesive layer, sold in rolls of different windings, the thickness of the material also varies (2, 4, 10 mm). A physically cross-linked structure of cross-linked molecules improves performance properties.

Above – uncrosslinked PPE, below – crosslinked Source cdn-ru.bitrix24.ru

- Izolon foil. A thin layer of aluminum foil is applied to one side, and the other is sometimes additionally coated with glue. Foil insulation is sold in the form of rolls; the foil can have different thicknesses.

- Colored isolon. The insulation initially had two colors: white and gray, but today multi-colored versions are produced, known as foamiran. The material is produced in the form of rolls and sheets of different thicknesses and qualities, and is used in decoration, design, and handicrafts.

- Izolon block (slab). It is used not only in construction, but also as flooring in sports halls, and also as a target for arrows.

Specifics of Izolon

Izolon is produced by foaming polyethylene with small cells and closed pores.

Izolon based on fine-cell polyethylene foam has high thermal insulation properties and low weight. Some modifications are made with single- or double-sided lamination with aluminum foil. The thickness of the coating is 14 microns and provides waterproofness as well as reflective properties.

The material also has a reinforced frame in the form of a propylene mesh. The basis of Isolon is self-adhesive or glueless. There are combined varieties with foil and adhesive base on sale. To prevent the sheets from sticking together during transportation, a protective film is applied to the adhesive surface.

Advantages and disadvantages

The porous structure with cross-linked molecules provides the following properties of the Izolon material:

- Excellent ability to retain heat and sounds. A polymer with a thickness of 1 cm in terms of thermal insulation properties corresponds to 15 cm of brickwork or 5 cm of solid pine timber; slightly superior to polystyrene foam and mineral wool (they will need 1.5 cm).

Foamiran is a decorative variety of PPE Source shopify.com

- High level of waterproofing. Thanks to the closed pores filled with air, the material practically does not absorb moisture and remains vapor-tight.

- High inertness in contact with oil and petroleum products, with chemical compounds; Izolon is compatible with most building materials.

- Impressive service life: manufacturers talk about 80-90 years without loss of performance properties.

- Health safety. The material does not emit substances that are hazardous to health or cause allergies, does not rot and does not become a haven for microorganisms and fungi.

Builders note the following advantages of Izolon:

- Elastic and lightweight insulation makes installation simple and quick. It is easy to process - just a sharp knife is enough to cut the workpieces to the desired size.

- Reasonable price and no waste make it an economical insulation option.

- The polymer is resistant to atmospheric factors and solar ultraviolet radiation, so it is used for facade (external) insulation.

Isolon blocks serve as a reliable shock absorber Source prom.st

See also: Catalog of companies that specialize in home insulation

The following features of foil insulation can turn into disadvantages:

- Low strength. It is also typical for other insulators of this class: any of them is easy to pierce, so care is required during installation.

- Foil materials require a ventilation gap of 1-2 cm; this helps to avoid the formation of condensation, but at the same time increases the cost of insulation.

- With constant high humidity, the aluminum coating begins to corrode, and over time the thermal insulation ceases to perform its functions.

Sequence of work during insulation

First of all, you need to decide on the thickness of the material, which depends on the availability of free space and climatic conditions. In cold regions, the insulating capabilities of isolon may not be enough, and it is better to use thicker layers of traditional insulation for this.

The leaves must be laid end-to-end, trying to avoid the appearance of gaps. To prevent this when finishing complex surfaces, you should carefully measure all the parameters and cut off the fragments with a high-quality sharp knife. In this case, the joints between the sheets are closed with aluminum tape, which also ensures the reflection of infrared rays.

In this case, empty space should be left between the isolon and further finishing, since otherwise condensation will collect on the material, which has mediocre vapor permeability.

Important! Do not place this foil material in close proximity to electrical wiring, as aluminum conducts electricity.

As for fasteners, many models of such insulation have a self-adhesive base, which allows you to radically simplify the process. If this element is not there, then the ideal solution would be to use acrylic-based adhesives or those marked No. 888.

Scope of application

A universal set of characteristics contributes to the widespread use of Izolon; Application covers the following areas of the economy:

- In construction. With its help, heat and waterproofing of walls, floors, floors and ceilings is arranged. It is needed for waterproofing communication systems, basements and foundations, for insulating balconies and loggias. The fabric copes well with thermal insulation of saunas and baths - objects with regular fluctuations in temperature and humidity.

PPE in floor insulation Source stroyfora.ru

- Automotive industry. Thermal fabric is used for interior trim; it not only reduces heat loss, but also reduces vibrations and protects against noise. It is also used to make various sealants to protect against corrosion.

- Mechanical engineering. Izolon is used to insulate the surfaces of refrigeration equipment, air conditioners, and heat-reflecting screens. It is used to produce seals and vibration isolators.

- Manufacturing of medical products. These include a variety of thermal blankets and orthopedic products (for example, insoles).

- Production of consumer goods (household goods), including for recreation, sports and tourism. Polymer is used to make fillings for life jackets, mats, helmets, shields, gloves and punching bags.

- In the furniture, leather goods and footwear industries.

- As packaging material. Its shock-absorbing properties are important here, protecting the finished product from deformation.

High-quality sound insulation of the car interior Source recn.ru

Step-by-step instructions for insulating floors with isolon

- We will assume that you have already gotten rid of the old rough finish and have approached the stage of preparing the foundation. First of all, it is necessary to repair all cracks and level the surface. In case of large differences in heights, it will be necessary to fill the screed, which will provide a smooth surface suitable for further finishing;

- The floor surface is primed, and after the primer has dried, polyethylene or a waterproofing film is laid on it. In this case, the latter must be placed on the wall to a height of 10-15 centimeters. As an alternative, you can use bitumen mastic, which is laid on a previously cleaned floor in two layers;

- Isolon is installed. As with walls, you should try to fill the entire floor space, avoiding even small gaps. The joints are taped with aluminum-containing masking tape.

Important! If work is carried out with isolon covered with foil on only one side, it is necessary to lay it with this layer inside the room, since the task is to retain heat inside, preventing IR rays from escaping into the walls or ceilings.

At the final stage, the joists are installed and the floor is finished. Sometimes, to achieve maximum insulation, roll insulation is placed in the space between the joists, and a second layer of isolon is mounted on top. Boards or sheet materials are laid on top, finished on top with linoleum, laminate or other methods.

Performance characteristics

The overall dimensions of the insulation are as follows:

- Roll material. Winding (length) – 10-220 m, width 150-200 cm, thickness 2-20 mm.

- Plate material parameters: 1×1 m, 1.4×2 m.

Foil insulation has an additional letter classification:

- "A". This polymer is coated with a metallized layer on one side. The thickness is in the range of 3-10 mm.

- "B". There is a foil layer on both sides. The material is more resistant to mechanical deformation.

- "WITH". Cross-linked polyethylene foam with an adhesive layer on one surface. Thermal insulator with a self-adhesive base is popular in private construction due to its convenient use.

- "ALP" Self-adhesive insulation, on one side of which there is an adhesive layer, on the other - aluminum foil. The metallized layer is additionally protected by a transparent polymer film 1-3 mm thick.

Isolon is used in construction with the following technical characteristics:

- The application range is limited to operating temperatures from -80 to +80 °C. The fabric retains its elasticity at temperatures from -60 to +80 °C.

Installation of a heated floor with a heat-reflecting substrate Source stroyfora.ru

- Average density 25-45 kg/m³.

- Thermal conductivity coefficient: 0.031 – 0.04 W/m·S.

- Infrared radiation reflectance (for products with a foil layer): 95 – 97%.

- Water absorption. Does not exceed 1%, by volume – up to 0.2%.

- Vapor permeability: 0.001 mg/m·h·Pa.

- Noise insulation. The strength of sound absorption depends on the thickness of the material. Depending on the desired suppression of external sound, a material with a thickness of 8 to 50 mm is selected. The level decreases by 60-80%.

- Isolon is considered a moderately flammable insulation and is included in group G2-G4 (flammability class according to GOST 30244). Its properties can be improved if treated with a fire retardant. Foil heat insulator is a moderately flammable material (B2).

- The melting point is 105-130 °C (depending on the manufacturing method).

Thin Izolon does not reduce the free space of the balcony Source cottage-lux.com

Flaws

- Izolon has a relatively high cost, so for large volumes of work this can become a problem;

- Despite its flexibility, the aluminum layer is very fragile and can be damaged by external influences during storage, transportation or installation. If there is damage, a cold bridge is formed, which, with a relatively small thickness of the material, becomes very noticeable;

- Not every finish is suitable for isolon. The material can be covered with a protective film or painted, but cannot be used as a basis for wallpapering and plastering. The classic application scheme involves fastening the material for subsequent finishing with suspended structures, such as drywall or the same lining.

How to choose

When choosing, it is important to pay attention not only to the type of Izolon, but also to its thickness, since this parameter depends on the area of application. The following ratios are recommended:

- If you want to additionally insulate the floor, PPE with a thickness of 2-5 mm is suitable as a substrate. You can use regular or foil polymer.

- Insulation of concrete or wood floors is made from 8-10 mm fabric.

- Rolled Izolon 4-10 mm thick will help to reliably isolate the roof and premises from external noise.

- Izolon in the form of blocks is suitable for internal thermal insulation of rooms and interfloor ceilings. With its help it is convenient to insulate the foundation and roof of any type (flat, pitched).

Heat and sound insulation of a residential building Source vesta-teplij-pol.ru

- Pipes located underground are insulated with 15-45 mm polyethylene foam.

- To install heated floors, you need thin (up to 2-4 mm) material.

- Foil fabric is chosen for insulating pipes and dry screed. If you want to level the floor using a wet cement-sand screed, use a sheet with a double-sided metallized layer.

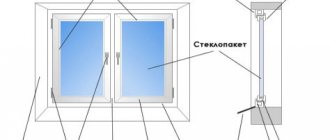

- For small jobs, Izolon, produced in the form of a tape, is suitable. It is used to glue cracks and seal door and window openings.

Facade insulation works Source znatoktepla.ru

Areas of operation

The versatility of the characteristics determines the use of the material in many areas:

- underlay – after insulating the subfloor with Izolon, you can lay carpet or laminate in a wooden house;

- protection of communication systems - climate and refrigeration units, gas and water supply lines, as well as ventilation;

- thermal insulation of any surfaces - subfloor, walls, roof, ceilings or basement;

- insulation of outbuildings (bathhouse, sauna) and utility rooms.

The insulator is also used in commercial construction.

Features of loggia insulation

Insulating a loggia with foil Isolon

To insulate a balcony or loggia you will need rolled Izolon, as well as a drill, a screwdriver, 2x4 cm and 5x4 cm bars, a stationery knife, and a furniture stapler. Using the material it is easy to create a kind of cocoon that retains heat:

- Attach the slats vertically to the walls in 90 cm increments.

- Form layer-by-layer thermal insulation - put foil Isolon 5 mm thick at the bottom, then foam plastic, then again foil Izolon 3 mm thick.

- Secure the insulation with a stapler. One edge is fixed with staples, the rest is stretched to the rail and nailed with staples.

- Seal the joints with metal tape or masking tape.

- Treat wide gaps with polyurethane foam to eliminate “cold bridges.”

The loggia is insulated with Izolon with a foil layer on the inside.

Creation of wall thermal insulation

Izolon under the counter-lattice

Foil insulation is best suited for walls - the shiny surface of Izolon will direct thermal energy back into the room. When sticking to a polyethylene base, good sound, moisture and vapor insulation can be achieved. The work is performed as follows:

- Installation of wooden slats 2x4 cm with a gap of up to 1 m.

- Laying mineral wool into the frame by surprise.

- Attaching foil-isolon to the beams using a stapler - the shiny layer is directed into the room.

- Lay out the rolls so that all the joints match.

- Sealing the cracks with metal tape.

- Padding over the thermal insulation of the counter-lattice.

- Installation of decorative finishing.

The distance from the foil to the finishing material is from 15 mm.

Thermal insulation of floor covering

To properly insulate the floor, you will need to additionally use mineral wool, polystyrene foam and expanded polystyrene. It is allowed to work on standard surfaces or to organize a substrate for heated floors. Experts provide a step-by-step algorithm of actions that must be followed:

- Preparation. The old covering is dismantled and garbage is removed from the room.

- Inspection of the lower structure. The peeled and cracked screed is removed and a new one is installed. All cracks are closed with mounting foam or cement-sand mortar.

- Making a subfloor. Boards are attached to the surface in increments of up to 1 m, and chipboard or plywood is fixed to the joists. 5x4 cm beams are attached on top of the materials.

- Installation of waterproofing. The surface is first coated with a primer and then lined with a waterproof film. Its edges protrude beyond the walls by 10-15 cm and are fixed with a stapler. The film is overlapped by 10-15 cm, all connecting lines are taped with metal tape.

- Laying Isolon. It is allowed to use material 4-10 cm thick. Before installation, the insulation is cut into the required sections. Laying is done on top of the waterproofing coating, the joints are taped with metal tape.

- Lag fastening. The extreme ones are located near the walls, the intermediate ones - in increments of 50-69 cm. They are fixed with self-tapping screws.

- Installation of the second layer of thermal insulation. The auxiliary material is adjusted to the size of the cells and laid out without gaps. The cracks are closed with polyurethane foam. A polyethylene waterproofing film is placed on top of the mineral wool or polystyrene foam, which is secured with staples.

- Laying the final coating.

For finishing flooring, you need a backing made of sheet plywood or boards 3 cm thick.

Briefly about the main thing

Isolon is a universal insulation material that is widely used not only in construction, but also in other areas of the economy. Thanks to its closed porous structure, it has improved performance characteristics: plasticity, minimal water absorption, high levels of noise and heat protection.

The chemically neutral material is produced in the form of canvas (roll), plates and construction tape; There are colored varieties for creative needs. The canvas may have an adhesive and/or foil layer. The choice of the appropriate PPE option depends on the type of work to be done.

Installation features

The insulation reflects heat from the radiator into the room.

Instructions from specialists apply to any surface for insulation. When laying insulation, the following rules should be observed:

- Internal insulation involves fastening Izolon between the finishing and the wall - the thermal efficiency of the structure increases.

- The highest percentage of heat retention is provided by material with double-sided foil.

- Two layers are laid on the concrete. The first is on the covering, the second is on the joists.

- It is better to insulate a loggia or balcony with single-layer foil Isolon according to the “construction pie” principle.

- In the apartment, you can place the material behind the radiators - this eliminates the need to dismantle the walls.

- The foil layer should not come into contact with the wiring.

- To prevent the formation of condensation, an air gap is required between the insulation and the rest of the structure.

The material is laid only joint to joint and must be glued with aluminum adhesive tape.

Thanks to closed cells of rolled insulation, 70% more heat is retained in the room. When performing thermal insulation, additional load on the structure is eliminated - a thin layer of material is highly energy efficient. It can be laid on any surface - walls, ceiling, floor or laid out on the balcony.

Production technology

Due to the fact that foamed PE appeared on the construction market quite a long time ago and is in great demand among users , a large number of manufacturers began to produce PE. In order to standardize the process of producing material, a common production technology was adopted, which all companies and firms must follow.

First of all, it should be noted that the manufacturing technology of foamed polyethylene consists of several stages. Moreover, some of them require the use of gas, while others do without it.

The general production scheme includes the following elements:

- extruder;

- compressor for gas supply;

- cooling line;

- packaging.

It is worth keeping in mind that the type of equipment used largely depends on what kind of product the manufacturer wants to get in the end. For example, bag-making, pipe-stitching and many other devices and mechanisms can be used. Also, many manufacturers use devices such as flying shears, punching presses, molding machines, etc.

For the direct production of the material, specially designed LDPE and HDPE granules are used (various elements based on them can also be used). In some cases, primary raw materials can be combined with so-called regranulates. At the same time, it should be borne in mind that foamed polyethylene can also be produced from recycled materials. At the same time, it must meet certain requirements, namely, its composition must be free of any impurities, and the raw material itself must have an average molecular weight and be uniform in color.

We recommend: Circulation pump for heating: types and characteristics, how to choose the right one, review of popular models and manufacturers, their pros and cons

Summing up

Foil-coated isolon has a number of advantages over conventional isolon, and since the latter is superior to any other thermal insulation material in at least one parameter, it will be difficult to find better thermal insulation. It’s not for nothing that the use of foil-coated isolon is so widespread in many industries. Even the thinnest layer of this material reduces heat loss by approximately 85%.

Choice of insulation

If you decide to insulate your home yourself, you will have to make several decisions:

- Which structures require insulation?

- The better to insulate each of them.

- Can you handle this yourself?

- How much money are you willing to spend on this?

Saving wisely is not a shame. Therefore, we recommend turning your attention to the new generation of insulation - foil Izolon. Due to its high reflectivity and low emissivity, Izolon will allow you to get the maximum effect from the thermal insulation of buildings.

By insulating with Izolon, you save not only money by reducing the thickness of the insulation, but also living space. This is important if you are the “lucky” owner of a small apartment with low ceilings and can only be insulated from the inside. The cost of Izolon, in comparison with traditional insulation, is an ideal combination of price and quality.

For your information! Do not forget that foil Izolon has a very low coefficient of vapor permeability and water absorption. That is why it does not require the use of additional vapor-hydroprotective films to perform thermal insulation functions.

Sources of cold

Even if during construction you spared no expense on thermal insulation of the roof and foundation, there are other areas through which heat can escape:

- First of all, these are entrance doors and windows;

- Balcony, if available.

- Walls - in the event that the builders “scraped” and did not treat the work process with due professionalism.

Minimizing heat loss and maintaining comfort in your home directly depends on high-quality insulation. In addition, good thermal insulation will significantly save your money on heating costs, since the current price of energy is quite high.

Foil material is suitable for baths and saunas, retains heat perfectly and maintains the required temperature

What is penofol?

Penofol is a foamed, foil-coated polyethylene with a closed-cell structure. Today you can buy the following types of this material:

The thickness of the pillow may vary.

Penofol has the following characteristics:

How to make long-burning stoves with your own hands: diagram, necessary materials and tools, useful tips.

About where a long-burning furnace can be useful during mining is written here.

By the way! It will be interesting to know: Balcony insulation: is a vapor barrier needed, how to install it