Any repair work is not a simple matter, which requires serious financial investments, as well as time. While you can still find time in your busy schedule, money is not so easy for everyone. And the prices for such work are steep.

That is why, in order to save money, you can put some work on your shoulders, especially such as puttingtying window slopes with your own hands. Today, many people are interested in the question of how to properly putty the slopes on the windows so that they come out smooth and beautiful? But, it’s not so important how you putty them, but how the old window block was dismantled.

That is, a positive result largely depends on the condition of the opening. Of course, the whole problem here is who will dismantle the windows. But, as a rule, dismantling is carried out immediately before installation by the same craftsmen, so they must approach the issue with full responsibility. Next, we will talk about the most common problems and also tell you how to get rid of them.

Why putty slopes

To achieve comfort in your home, it is not enough to install metal-plastic windows. An assembly seam is cut between the wall and the structure and blown in with construction foam. It holds the window, closes all the cracks, and prevents drafts from appearing in the house. Over time, it deteriorates under the influence of ultraviolet radiation, moisture, temperature changes, and loses its properties. To prevent this from happening, it is necessary to make slopes.

Previously, they were made from a mixture that was laid out in several layers on a rough coating, putty on top, plastered, and covered with paint. Now there are several options for window slopes - plastic, plasterboard, galvanized structures. Next, we’ll look at how to putty slopes on windows, what building material to choose, and the sequence of work.

Plastic and drywall

These two materials are at the peak of popularity today. Each of them has its own disadvantages and advantages. Therefore, before purchasing one or another sample, you need to figure out which slopes are better, plastic or plasterboard.

What can you say about finishing slopes with plasterboard? There are several technologies used to install them. You can choose the simplest one, and if it is carried out correctly, the quality of the final result will be at its best.

Of the two options offered, this is the cheapest. GCR slopes are easy to install; insulation can be laid under them. The only negative is the so-called semi-finished product. The drywall will have to be modified. That is, it is necessary to putty to bring it to the maximum level of evenness.

Puttying plasterboard slopes is a simple operation. To do this, you must first treat it with a primer, and after drying, apply a thin layer of the mixture. Most often, the desired result is achieved in one pass. Next, the plane is sanded and painted.

Many people try to bring the evenness of the slopes to zero by applying repeated layers several times. This is not recommended. Firstly, sanding with sandpaper will bring this indicator to the maximum. Secondly, this is not the most critical plane. If it were a ceiling, then it would be a different matter. Thirdly, the window opening will still be hidden under curtains and tulle.

This is the most convenient option. A plastic slope is a finished product that is simply installed at its destination, fastened and that’s it. No additional procedures for leveling, painting, etc. Its only drawback is the high price. Although this is compensated by ease of installation, smooth surface with a presentable appearance.

Until recently, manufacturers offered plastic slopes only in white or grayish colors. Today the palette of shades has expanded greatly. There are even products that imitate wood.

Slope putty

Puttying slopes depends not only on the efforts of the worker, but also on the quality of installation of doors, windows, openings and walls. If there is damage, then they require dismantling. To make the walls more even, it is worth using plasterboard blocks, and only then deal with the slopes. The main condition for the success of repair work is the sequence of actions. First you need to prepare the necessary material, carry out installation, apply a base layer and then proceed to the finishing putty.

IMPORTANT! Particular attention should be paid to installing a perforated metal corner or replacing it with a plasterboard template.

Plastering work for window and door slopes Plastering slopes requires preparation. First, let's look at the problematic issues that may arise. It is necessary to install the structure and take into account the area where the electrical wire passes, if any. The room must have a comfortable temperature for repair work, otherwise cracks may appear later or the plaster may come off completely. Let's consider a step-by-step algorithm of actions.

Insulation

A process such as thermal insulation is not superfluous; you need to remember that it is the insulation of slopes that can in the future save your internal slopes from excessive moisture formation and subsequent mold.

In principle, any material will do - both mineral wool and polystyrene foam, but the latter is still more convenient for installation.

The polystyrene foam is attached either with glue or with special self-tapping screws - parachutes, but in the case of mineral wool you will have to organize a mini-frame.

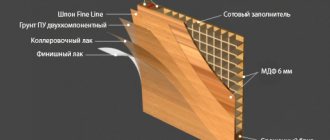

Sandwich paneling

When choosing this option, it must be taken into account that the minimum panel thickness is 20 mm.

Without auxiliary profiles, the slope is sewn up within a few hours. The order of plating is as follows:

- The panels are cut to fit the dimensions of the slope.

- “Liquid nails” are applied to the panel and it is pressed tightly against the surface of the slope.

- The gaps between the frame and the panels are sealed.

- The corners are installed on the outside with glue.

Lining and sandwich panels cannot be repaired. As a rule, they change when damaged. In this case, the choice of shade is of great importance, since it differs in different batches of material.

How to plaster window slopes

Unfortunately, companies involved in the installation of metal-plastic windows, in most cases, are limited to installation only. But what about the cracks and collapsed slopes? If you undertake to replace a window, then please return everything to its previous condition. So the problem arises of restoring all this, where to find specialists.

Improper plastering of slopes after installing plastic windows leads to the formation of condensation on the glass, and subsequently the appearance of fungus and mold. Of course, modern technologies greatly facilitate the work of craftsmen, but they do not eliminate all the problems associated with the installation of metal-plastic windows.

All these plastics, plasterboards, foam plastics, of course, have an aesthetic appearance, but they do not solve the problems of fogging and fungus. So the masters returned to the old grandfather’s methods. Properly done plastering of walls along beacons will not replace any polymer. This is what this article will discuss.

The choice is always yours

It would seem that finishing methods such as puttying and plastering of slopes should be gone a long time ago. But life shows that many people still use this technology. Especially in situations where the old window is not replaced. Simple repairs in the form of putty or minor plastering of window slopes are used quite often today.

As mentioned above, this process is complex and long-term. But for small country houses this is a good option. Especially when the slope plane itself is small in size. It is difficult to install a small strip of drywall in such an opening. And, even more so, pick up and insert a plastic product. Although everything is changing every day. In the near future, simplified technologies for fastening both plastic and gypsum boards may appear.

We would like to invite you to discuss this topic. Maybe someone will share their personal experience, or maybe someone has questions. We are ready to answer everything.

Preparation of materials and tools

To understand how to putty the slopes on windows with your own hands correctly, you must first fulfill some conditions:

- Make the right choice of putty.

- Prepare the surface.

- Equip your workplace with everything you need.

Tool for puttying window slopes

So what kind of putty should I use to putty the slopes on the windows?

- Putty for external window slopes should be selected according to the application and scope of work.

- The outer slope should be puttied only with frost- and water-resistant compounds. Any façade putty is perfect for outdoor work.

- To seal the slopes on the inside of the house, you need to take into account the microclimate of the room. If there is always a high level of humidity in the room, then it is better to putty with a polymer or cement composition. If the finishing will be done in an ordinary living room under normal conditions, it is permissible to use putties on a lime-gypsum basis.

- If the slopes are not level enough, they will need to be leveled first. To do this, it is better to choose a finishing and starting putty, or purchase a universal composition.

Please note that if the installation of slopes is carried out in a new building, they are given shape by plaster, after which puttying helps to even out the errors. In addition to the fact that the surface will have to be puttied, a deep penetration primer is also necessary to increase the adhesion of the mixture for leveling with the base. To do this, it is better to choose a solution with an antifungal effect to avoid the appearance of fungus and mold in the future. Also get silicone-based sealant and perforated corners.

The following tools will help you do the job yourself:

- Spatula with narrow and wide working blade.

- Building level.

- Stationery knife.

- Brushes and rollers for priming and painting.

Puttying slopes for painting (video)

Features of finishing

Puttying slopes for painting

If home owners plan to cover the slopes with ceramics or hide them under wallpaper, finishing is not required. But, if in the future you decide to paint the walls, you will have to carefully plaster and putty them. We talked about how to putty a brick or block slope with starting putty, now we’ll tell you in more detail about the finishing design. The finishing putty can be used even when the starting putty has not dried, but only if gypsum was used as the starting mixture.

To complete the finishing, you will need 2 spatulas with different widths of the working blade. Using a small spatula, apply the mass onto a large one, which is used to directly pull the putty along the slope. Please note that it is recommended to take a wide spatula wider than the slope itself. This will allow you to avoid scarring, resulting in a much faster resurfacing process.

Tools and materials

Before you putty the slopes on the windows with your own hands, it is recommended to prepare materials and tools.

If the surface is uneven, then it must be treated with a starting or universal putty, and then covered with a layer of primer. If the slopes are installed in a new building, then the shape is given with plaster and only then putty is used. In this case, you should choose a primer mixture with antifungal properties.

The following tools will help you putty the slopes on the windows:

- container for preparing the solution;

- construction mixer;

- spatulas of different sizes;

- metal scissors;

- building level;

- reinforcing and troweling mesh;

- paint container;

- rollers and brushes;

- masking tape;

- putty of 2 types (starting and decorative);

- primer;

- corner;

- water-based paint.

Surface preparation

Puttying slopes is quite labor-intensive and slow work. Before you begin the putty process itself, you need to prepare the work surface.

Frame pasting

Cover the frames with masking tape

First, take masking tape and begin to cover the window frames with it. This will help keep frames clean, especially wooden frames, because... Plastic frames can be washed if you try hard enough. This will also protect the windows from damage and dirt.

It would be recommended to additionally cover the window glass with polyethylene, because... When it gets on glass, if it is not washed off immediately, it dries quickly and is difficult to clean.

Installing a perforated corner

The installation of a perforated corner is necessary to protect the surface from possible mechanical damage. Also, with a corner it is more convenient to distribute the material evenly.

It is necessary to measure the distance on the corner corresponding to the dimensions of the slope and cut off a piece with scissors for working with metal. You need to make an even cut to avoid unevenness and inconvenience in the future. Next, the corner is smeared with a small layer of putty and pressed against the corner of the window and installed in place. It is important to install the corner straight, as any distortion of the corner will be noticeable.

To install the corner levelly relative to the plane, use a building level.

The installation of a perforated corner is necessary to protect the surface from possible mechanical damage.

Slope priming

We definitely take deep penetration soil, thanks to which we can achieve the best adhesion of the putty and the slope.

The choice of material should be approached responsibly, because the final result of the work will depend on the quality of the solution.

The primer itself has the properties we need, such as adhesion, moisture repellency, strengthening the surface itself, and has no complaints regarding environmental safety.

It is best to choose a primer that has antifungal properties. It will prevent the formation of fungi and mold on the surface in the future.

Before applying the primer, it is necessary to thoroughly clean the surface to be treated from dust and dirt.

If there are elements of old finishing (paint, wallpaper, plaster that does not hold well), then we get rid of them.

Then, using a brush, carefully apply the solution itself. It is not recommended to use a spray bottle here, because... The working surface is small and there is a chance of splashing everything around.

Preparation of putty

While the primer is drying, it is worth preparing the putty solution itself.

Putty for slopes can be different: ready-to-use and dry mixture that requires preliminary dilution. The finished putty already has the consistency needed for work. It is released in sealed packaging. It does not require any preparation before application. This material perfectly shades all the irregularities and cracks on the surface and creates a thin finishing layer.

Dry mixture, unlike ready-made mixture, is produced in paper bags or plastic bags. Their advantage is a longer shelf life compared to the ready-made mixture. Buy ready-made or dry mixture - you should decide on this yourself.

Slope leveling

Surface preparation before puttying

Now the time has come to tell you how to putty the upper slope of a window, as well as the opening at the door or window block. The most popular material for leveling slopes is plasterboard. To level the slope, it is enough to screw an L-shaped profile onto the window frame and adjust the inner side, which can be hidden under the finishing putty.

The outer part of the drywall sheet is set vertically using a level. But, it’s even easier to glue a perforated corner in advance and use it as a guide along which to adjust the gypsum board. Between the window and the drywall you need to lay mineral wool, which will act as insulation, and outside you can use Knauf Perlfix drywall.

Plaster

Repairing a cracked slope

Before you start plastering the external slopes with your own hands, let's prepare all the tools and materials that may be useful to you:

- Mixture for plaster

- Drill with stirring attachment

- Container for plaster

- Mesh for reinforcement (if you insulated the slope)

- Glue for mesh

- Cover bucket

- Planks to frame

- Plaster corners

- Level

- Rule

- Primer

- Masking tape

- Maklowitz

So, is everything there? Great, let's get started!

To begin with, set up the corners for the plaster.

Important! You need to set it according to the level! And one more thing - if there are 2 windows on this side of the house and you have not yet made the facade, then the corners are installed first on:

Left window left;

On the right - right.

And all the rest will already be exposed in this plane, thus you will ensure that the wall and the exposed slopes are harmonious.

Next, attach the bar to the frame. This plank has two shelves, the outermost one, closest to the slope, will eventually be buried under the mortar, and the one closer to the window will be the starting point for placing the rule, and then you will remove it too.

Attach masking tape to the frame and cover the glass with either plastic wrap or wet newspaper.

Now you can add the solution, immediately leveling it using the rule.

What's the catch - you put on one layer, stop. Then you will be able to work only when it has completely set. So, layer by layer, you plaster the outer slope with your own hands.

Mixing mortar for slopes

The dry primer mixture is combined with water 5-10 minutes before starting work. It helps eliminate defects and unevenness, so the consistency should be quite thick and not spread. The building materials market offers users a wide selection of dry powder compositions and ready-to-use paste-type solutions. The latter will be an excellent option for beginners who have not encountered construction work before.

Puttying windows is a difficult process that requires a responsible approach. Therefore, experts advise choosing dry mixtures and diluting them yourself with water in accordance with the instructions indicated on the manufacturer’s packaging. This approach will help you get the consistency you need. To avoid the formation of voids and lumps, the solution is thoroughly mixed with a construction mixer.

Step by step guide:

- water is poured into the container according to the proportions (on average 2-2.5 liters per 1 kg of dry putty);

- add the powder and mix thoroughly;

- leave for 2-3 minutes for swelling;

- add a little more liquid if necessary.

The resulting solution is immediately used in work. Before purchasing, you need to pay attention to the expiration date of the product. Expired material loses its characteristics and is often no longer suitable for surface treatment.

How to putty the external slopes of windows?

There is a need to repair the external slopes of the windows of the house.

Over the past 25 years, the slopes have cracked in places and cracks have appeared under the window frames. Since my hands grow from the right place and I have a tool, I will try to do this work myself. Masters, please tell me how to putty the external slopes of windows? It is best to putty external slopes with cement putties, that is, it is necessary to abandon gypsum putties.

Gypsum putties are most often used indoors, and not in wet rooms (rooms with high humidity).

As for specifics, there are a lot of cement putties, I can recommend cement putty from Volma,

There are cement putties (as in the photo above), for the base layer, and there are finishing ones, that is, for finishing.

For example, finishing cement putty from Volma.

But before you putty the slope, it must be dust-free and primed.

The primer must dry.

It is better to use a primer with deep penetration, it will tighten and strengthen your old plaster, plus it will improve adhesion (adhesion of the putty to the surface).

Sometimes it makes sense to prime in two layers.

You write about cracks, tap the slopes with your knuckles, if the sound is empty, then most likely your old plaster has moved away from the base, it is better to knock it off completely.

After puttying with cement putties, it makes sense to paint the slope with façade paint.

Facade paint will protect the slope for years.

But do not forget to prime and dry the surface before painting.

If the old plaster is knocked down, it will no longer have to be puttied, but plastered.

You can get by with cement + sand, proportions 1 to 3, and then putty, after drying the plaster.

Or paint over plaster, see for yourself.

The building materials market is replete with various plaster mixtures, but are they all suitable for finishing external slopes? Of course not. The fact is that there are a number of requirements for finishing external slopes. We will talk about them further.

To solve this problem we have the following plaster mixtures:

- on a cement-sand base. Such mixtures are characterized by strength and, what is important for us, moisture resistance. But when drying, such compositions are prone to cracking, and this in our case can lead to drafts and noise penetrating from the outside;

- homogeneous and complex gypsum mixtures. Great option. Such mixtures are easy to use and durable. And yet, there is one big BUT - the influence of excess humidity is detrimental to them;

- polymer mixtures. They have excellent qualities, namely, they are not prone to cracking, are not afraid of moisture, and are durable. Of course, you have to pay for quality; such mixtures are much more expensive than those we reviewed earlier;

You can also make the mixture yourself. To do this we need to mix one part cement and three parts sand. In this case, the brand of cement does not play a big role, but the sand must be fine-grained. Use only clean, sifted sand.

Take a dry container and pour the components into it. Mix them (necessarily dry) using a drill with a stirrer attachment.

Next, when the components have become a homogeneous mass, add water. We do this by eye so that in the end we get a solution that is not too liquid, but not too dry. When you put the resulting mass on the trowel, it should come off it gradually, but under no circumstances should it fall off or run off.

Among the factory mixtures I can note the following:

1 Cement-lime plaster TiM No. 25,

2 Polymer plaster Ceresit CT29 (plaster and repair putty)

Before starting work, be sure to prime the surface.

We install perforated corners and beacons

The perforated corner is installed on the outer corners of the slopes. To do this, cut it to this size, apply putty on both sides of the corner and press the corner to the putty. We use starting putty.

We install the plaster beacon along the window frame. Installed strictly vertically. To do this, you need to cut it to a certain size, apply putty along the box, diluted 50/50 with plaster, and attach a beacon to it. The lighthouse is set according to level. Gypsum is necessary for quick drying of the putty.

We repeat the same operation with all the slopes that need to be made.

Starting putty

Applying the mixture to the slope

And so, the matter came directly to the puttying process. To do this, you need to take a tool of a suitable size and apply the solution to the surface. If it was not possible to plaster the surface efficiently, you will have to putty the slopes in 2 approaches: the first layer is the starting mixture, the top layer is the finishing one. As a rule, slopes need to be sealed with putty to a depth of 5-7mm so that all defects are hidden. It is best to work with a spatula with a wide working blade.

After the mixture is applied, the spatula is pressed tightly to the surface and moved in the direction “you”. If the wall is severely damaged and needs to be leveled with a large amount of mortar, reinforcement will be required to better fix the building mixture.

To work in slope corners, you can choose a special corner spatula, which will simplify the work and improve the final result. If you need to re-treat the slope with starting putty, this can be done no earlier than 24 hours after the first layer has completely dried.

Subtleties of applying putty on slopes

The final solution distribution technology depends on the condition of the wall. The technician must evaluate the presence or absence of serious defects on the surface. If the problem areas are already plastered, then you just need to level the surface with a special finishing putty. This will help get rid of scratches, potholes, roughness and even cracks.

But most often, craftsmen have to deal with situations where slopes need leveling. All initial work must be done with durable putty, which can be safely applied in a fairly thick layer.

Important! Before you start finishing, you need to make sure that the ambient temperature is above +11 C. Otherwise, it will be difficult to achieve the necessary adhesion of the surfaces.

Experts have created instructions for applying putty:

- Using a tape measure, measure the width and height of the opening. It is necessary to cut fragments of the required sizes from the perforated corners.

- To prepare the putty solution, use a drill with a mixer attachment. The amount of the mixture must be selected so that the master has time to use it before it hardens. This parameter is always indicated by manufacturers on the packaging.

- The verticality and horizontality of the corners are carefully checked with a building level. When applying a putty layer, be sure to ensure that it corresponds to the indicators of the device.

- Carefully glue the prepared corner onto the fresh solution, pressing it into the mixture. The final position of this element is also controlled by the level.

- It is necessary to allow the solution to set as much as possible. Otherwise, when applying putty, you may accidentally disturb the position of the corner.

- Use a wide spatula to distribute the prepared solution, pressing it to the surface at an angle of 30. All movements should be directed from bottom to top. Excess is removed with a quick movement from the window to the wall.

- One layer of solution should not be more than 6 mm. If a large number of layers are necessary for high-quality leveling and elimination of surface unevenness, then each of them must be thoroughly dried.

- After the putty has completely dried, it is necessary to use a special sandpaper, which is first fixed on a grater. The surfaces are carefully treated, removing all traces of the spatula and sagging.

- At the final stage, a maximum of 1 mm of the finishing mixture is applied.

Important! Experts recommend using plastic mesh reinforcement to prevent the thick ball of putty from falling off over time.

Solution distribution

Preliminary work

The surface adjacent to the window must be prepared before applying the leveling layer.

It is advisable to install the window sill before leveling the slopes. This will allow you to carry out all the work more efficiently in one go.

- The polyurethane foam protruding beyond the surface of the window structure is carefully cut off with a stationery or construction knife. In this case, it is recommended to go a little deeper behind the window block: in this case, the cut can be filled with sealant. It will close open pores in the foam and prevent unwanted moisture from entering there.

- Use masking tape to protect the elements of the window opening from contamination. If there are surfaces that can be damaged by masking tape, then cover them with plain paper.

- The entire surface is cleaned of old wallpaper, paint and dirt.

- Remove poorly adhering pieces of plaster or brick and prime the surface.

It is desirable that the primer mixture has pronounced antifungal properties.

The right set of tools: how to plaster slopes for plastic windows simply

Photo from the site: DvervDome.ru

After replacing conventional wooden frames with new plastic window systems, many are surprised to discover that the cost of finishing will not be much cheaper than the blocks themselves, which is why many decide to figure out how to plaster slopes on windows with their own hands, without resorting to the expensive services of specialists. However, it is also worth understanding that there is no way to do this without special tools, but if you have experience in plastering, then you will probably find everything you need in the “arsenal” of any home craftsman. Materials for plastering window slopes will not be expensive unless you choose the most expensive mixtures, so it’s definitely worth a try.

- Brush and also primer. Regarding the brand and quality of the primer, you can consult with consultants in the store, who most often have similar information and are willing to give recommendations based on their own knowledge and demand.

- The plaster itself or putty in the form of a dry mixture, or cement and sand.

- Roller for applying the finishing coat.

- A straight wooden strip, as well as a level, ideally a laser or even a water level, but you can also use a regular bubble level.

- Convenient, not very wide spatula. It is best to take a tool 45 centimeters wide.

Photo from the site: dachnaya-zhizn.ru

When choosing tools for work, you should pay attention to the fact that you will not have to process a large surface, because large equipment will simply be inconvenient. It’s simply inconvenient for you to turn around with a long level or a wide spatula, so be sure to take this into account. Among other things, to work with cement mixtures you may need a grater and a trowel, and with gypsum mixtures you may need a trowel and a sponge trowel.

You also need to purchase special gloves, since your hands will be in direct contact with the solution. A work surface, for example, a plastering table, on which you can place a container of putty or stand to reach the top of the window opening, will also not hurt. You can use a regular kitchen table covered with thick oilcloth.

How to prepare the surface before work?

Before plastering and puttingtying the slopes, you need to prepare the surface and the necessary materials. Better not buy ready-made mixtures! Each master is accustomed to working with his own solution consistency, so a purchased product may turn out to be too liquid or vice versa, which will negatively affect the result of the work performed.

Both external and internal slopes require preparation. To do this, you need to remove old finishing materials, as well as surface fragments that do not adhere well. Only after this can the walls be primed. Both plastic and wooden window blocks require such preparation. Then it won’t hurt to cover the glass and window frame with tape and protective film to avoid contamination.

Decor

Painting window slopes after puttying

No matter how carefully you work with putty, you will still have to sand the surface after drying. To treat the surface with paint, it is better to get a wool or mohair roller. Basically, for painting slopes, water-dispersed or water-based paints are selected, which are used to cover the wall in 2-3 layers. This is what allows you to achieve the most suitable shade.

If the interior of your house or apartment allows it, the slopes can not only be painted in one color, but also decorated with stucco molding and other decorative elements. Today, thanks to the Internet, you can watch many video lessons from experienced finishers, as well as get acquainted with design solutions. This is very appropriate if you do the work yourself and are trying to save on the services of professional designers.

OK it's all over Now! I would like to believe that our article has given you confidence in your own abilities and that you will cope with the task not only without difficulty, but also with high quality.

Sanding and painting

After the finishing putty has dried, the surface must be leveled, even if the layer seems perfect.

To treat the working surface with paint, use a wool or terry roller. It is better to choose water-dispersed or water-based paints as a coloring composition. They cover the wall in several layers. Usually 2-3 stains are enough to get a good quality finish. The slopes can be painted in a color suitable for the interior or decorated with stucco molding and decorative elements.

The final leveling is carried out with a trowel and an emery mesh. At the same time, you should protect your face and body from construction dust. You must wear a respirator, goggles, and gloves. Use a grater to go over all crooked places and uneven areas:

- waves;

- mounds;

- lumps of solution;

- stuck particles.

It is important not to go too far and not remove the putty to the base of the drywall. Carefully process the internal corners, since in these places there is a high probability of leaving grooves from the grater on the wall adjacent to the work area.

Advice! The putty area under the wallpaper is primed. Use a special mixture under the soil or dilute the wallpaper glue to a more liquid consistency. This layer will ensure ideal adhesion of the wallpaper to the wall.

Useful tips

Remember that plastering can be carried out in a room where the temperature is at least 6 degrees Celsius. If this rule is not followed, the quality of the slopes will be low.

Carefully read the instructions for preparing the solution that the manufacturer puts on the packaging. The expiration date is also important, since after its expiration the mixture will not have the necessary characteristics. The expiration date that is close to expiration may also not have a very good effect on the final result.

When working with plastic windows, do not forget to make a groove along the entire perimeter between the frame and the slopes, 5 mm deep. After the solution has dried, the recess is filled with silicone sealant. This ensures that in extreme heat, when the volume of plastic increases, the slope will not crack.

Let's move on to practice

Plastering window slopes with your own hands begins from the inside. First they do the lower and sides, then move on to the upper slope.

- Part of the solution must be diluted thinner and distributed over the areas of the window opening. This step will promote good adhesion of the surface to the plaster. The mixture is taken with a spatula and spread along the openings. It is important that it does not spread, but sticks to the surface.

- Let the first layer dry.

- We install the corner profile using a level.

- We continue laying layers on the slopes, not forgetting to monitor the leveling of the surface.

- As the solution dries completely, you need to adjust the corners.

- We grout using a grater.

- Apply a layer of primer.

- We move on to the finishing, which can be decorative plaster or tiles.

Finished slopes are finished with decorative plaster

After installing plastic windows, the following points are added to the standard technology:

- on the plastered slope, using a spatula, make a 5 mm furrow;

- in the made track we lay a layer of silicone, which will not allow cracks to form in those places where the window connects to the slope.

Otherwise, plastering of slopes of plastic windows occurs according to the technology described above. If a gypsum mixture was used in the work, then at the final stage it is necessary to dismantle the elements of the window strips by bending .

Plastering of external slopes is carried out after finishing the internal ones

Next, you can proceed to plastering the external slopes of the windows. If you follow the basic rules and know how to plaster slopes on windows, you can significantly improve the thermal insulation of your house and give it a beautiful appearance.

Step-by-step instruction

So that after plastering the window slopes you do not have to deal with the restoration of the window sill and window, and do not wash the glass from the solution, they need to be covered with cellophane film. Plastering of slopes of plastic windows is carried out both from the inside of the room and from the outside of the window. The surface to be plastered must be free of dust; a deep penetration primer is perfect for this. Also, do not forget to treat the surface with antifungal agents.

Installation of beacons

High-quality plastering of slopes is obtained with the correct installation of beacons. Beacons are installed level and attached to the surface using alabaster. Installing beacons is a guarantee that your plaster will be smooth and attractive. Having installed the beacons around the perimeter of the window, you can begin plastering.

We plaster the slopes along the beacons

Plastering is not particularly difficult; even an amateur can handle it. The main thing here is to maintain proportions in preparing the plaster mixture. If preparing the mixture is a problem for you, buy it ready-made. The most difficult part is plastering the upper slope. You throw the solution up, and it keeps falling and falling. Alabaster will come to your aid here.

By adding a little alabaster to the solution, you speed up its hardening.

Now, having thrown a small layer of solution on top, you do not have to wait a day for the solution to set. And after half an hour you can continue plastering the slopes. Do not prepare a lot of this solution and do not add a lot of alabaster. This solution cools very quickly. If the solution has hardened and you have diluted it with water, then you need to add alabaster again. You need to rub the plaster with a polisher, removing excess mortar to the level of the beacons.

Slope putty

When the plaster has dried, this can be determined by its color, it becomes gray in color, and you can begin to putty. To do this, attach a perforated corner to the corners using diluted putty. They will prevent your corners from chipping and crumbling over time. After that, using a spatula, we putty the surface. It is better to select a spatula according to the width of the slope.

If you still have any scratches or defects after puttying, do not be alarmed. They can always be corrected with sandpaper. Cured putty is easy to process.

Proper plastering of window slopes guarantees the heat resistance of the window block.

Determining the scope of work for finishing slopes

First of all, it is necessary to determine the quality of the old plaster that is applied to the slopes. Of course, the best option is to dismantle it down to the wall material (brick or concrete). But not everyone can master the complex plastering process. Although, having thoroughly understood it, you can try to make it yourself.

Here is the algorithm for how to plaster slopes:

- The old layer is being dismantled. This must be done carefully so as not to damage the surface of the plastic window.

- Priming is being carried out.

- After drying, a thick layer of plaster mixture is applied. With its help, you must immediately achieve the creation of the required shape of the plaster slope. This is the most difficult stage, not every beginner can cope with it. Please note that if the load-bearing facade wall is a concrete slab, then to plaster the window slopes you need to fix the plaster mesh to the plane. If the wall is brick, then you can do without it. The mesh is attached to the plane with dowels or screws.

- After the solution has dried, another layer of primer is applied. It should dry out too.

- Now a thin layer of finishing putty is applied. This is a leveling operation that requires care.

- After the putty has dried, the surface is refined with fine sandpaper, primed and painted.

Many may ask, why do you need to prime each layer to plaster window slopes? The thing is that this liquid performs two functions at once. The first is that a layer with a high adhesion (fastness) index is formed on the surface being treated. That is, the primer helps any material cling to the treated surface. Secondly, penetrating into the upper layers of the material being processed, the primer polymerizes, thereby strengthening these same layers.

Having examined the surface of the slope, it was found that the old plaster was in good condition. For beginners this is the best option. You just have to learn how to putty slopes.

- Detected surface defects (such as cracks, chips or gouges) must be repaired. That is, expand and deepen. Then fill with putty solution.

- Then the slope is primed.

- After drying, a layer of putty is applied, which, after drying, is sanded, primed and painted.

Here are two options for the wet process, where plaster and putty mixtures are used. Let's face it, the process is not the most convenient because it takes a lot of time. We offer two other options that use ready-made products.

How to putty the surface of slopes on plastic windows with your own hands

High-quality putty directly depends on how exactly the old window was dismantled. Experts must take into account the actual state of the opening, which may turn out to be dilapidated or not touched at all. In 90% of all cases, dismantling is carried out before installing a new product. Classic window blocks are not able to significantly improve the aesthetic characteristics of a room if they are framed by uneven slopes with multiple defects. The situation can be radically changed if a layer of solution is applied correctly.

Giving the structure aesthetic appeal

How to do it?

When all the tools and materials are prepared and the working surface is cleared of dirt, proceed directly to finishing the slopes.

Beacon fasteners

Installation of beacons will be needed if the slope plane is uneven and requires plastering. Beacons can be wooden slats, metal profiles or long rules. Beginners are recommended to use ready-made plaster beacons - with their help it is easier to create an even layer of plaster and level slopes.