A door closer is often installed on the door leaf, which simplifies the opening process. This mechanism takes on a significant part of the effort applied by a person; with this principle of operation, there is no need to control the operation of the door leaf. It opens easily and smoothly returns to its original position. However, installing a closer is not a prerequisite for closing the door. It is preferable to install it in places with high traffic, which helps reduce wear on the door mechanism.

Operating principle

If you are interested in how closers work, you should know that the design is based on a spring, but auxiliary elements are also provided. It accumulates mechanical energy by contracting. When a person releases the sash, the spring straightens. In addition, front door closers operate smoothly. This possibility is provided thanks to the hydraulic system.

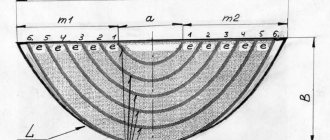

To ensure that the spring straightens smoothly, an oil shock absorber is used. The design includes a system of special valves, thanks to which oil flows from chamber to chamber. In this way, the speed of operation of the installed closer is regulated, and at the same time the speed of movement of the web. Due to a sufficient level of viscosity, the mechanism also ensures silent operation.

Internal structure

Device nodes:

- traction - connects the door and the door closer, with the help of this element the force that a person applies to the door when trying to open it is transmitted;

- rotary axis;

- a cylindrical piston connected to a spring - the unit is driven by a gear, which, in turn, depends on the position of the rotary axis;

- oil valves containing a viscous liquid, which ensures smooth movement of the structure;

- adjusting screw - allows you to set the spring compression power;

- a screw responsible for limiting the opening of the sash.

The operating principle of a door closer is based on the interaction of two main components: a piston with a spring and a valve system. The remaining elements are auxiliary in the circuit and help ensure correct adjustment of the mechanism. Screws are used to control the operation of the closer. Without these elements, the sash will close too slowly or, conversely, quickly, and will also create a noise effect. The design of the door closer, in particular the lever arm and the housing, can be different; on the basis of this, the design is divided into groups.

Rear doorman

For ease of use of the trunk, we came up with a hands-free access system

. We have already discussed the principle of its operation. And here is how the power drive of the luggage compartment lid works.

An electric motor with a gear reducer that turns the lid by its hinges.

An electric motor with a gear reducer that turns the lid by its hinges.

Moreover, such devices are used both on heavy fifth doors of station wagons and on the lids of sedans.

There are also cars with a hydraulically driven trunk lid.

, but

the drive in the form of a sliding rod with a built-in electric drive

.

Hydraulic drive of the trunk lid of the Volkswagen Phaeton sedan: 1 - hydraulic cylinder; 2 - hydraulic unit; 3 - electric motor; 4 — trunk loop.

Hydraulic drive of the trunk lid of the Volkswagen Phaeton sedan: 1 - hydraulic cylinder; 2 - hydraulic unit; 3 - electric motor; 4 — trunk loop.

Types and types of door closers

There are 3 main types of such structures:

- top;

- lower, or floor;

- hidden, or mortise.

In the first case, the mechanism is installed in the upper part of the sash. The second option involves the need to install the product at the bottom of the door leaf, the drive mechanism is mounted on the floor. The hidden, or internal, mechanism remains invisible when looking at the sash. According to their intended purpose, devices are divided into:

- to internal;

- to the street.

The first option is designed for indoor installation, which allows you to extend its service life. Outdoor analogues have a reinforced design, they are better protected from external factors. In addition, there is a closer for sliding doors and mechanisms for swing doors. The first option is equipped with a linear traction, and the canvas will move along the wall. The device for swing doors assumes in the design the presence of a rod capable of changing position. If the canvas is opened, the draft will move in the direction from the load-bearing walls.

Spring

Separately, we should consider the closer mechanism for pendulum structures. In this case, it is not possible to use the classic design for swing doors, since the leaf can move in the opposite direction: forward, backward, repeating the movement of the pendulum. This means you need to use an alternative solution. For this reason, in order to control the movements of the door, a hidden or floor-mounted design is provided.

Hinges with closer

This is a compact design that also works on the basis of hydraulic oil and a cylindrical piston. To regulate the speed of movement of the web, screws are provided, which are located in the inner part of this element of the fittings. Adjustment is carried out using a hex key. This control method is suitable for lightweight options. The weight of the sash should be in the range from 50 to 90 kg, which will allow the installation of 2 such elements. There is a door closer for a metal door and a wooden leaf.

Street

It is often necessary to improve the principle of operation of a canvas located not inside the object, but outside, while the outer element must have a more powerful design. Considering that entrance doors weigh much more than interior doors and are large in size, when choosing, you need to focus on the parameters of the door. If this is not done, the device will not perform its function. Additionally, the operating conditions must be taken into account. So, for example, a door closer must withstand temperatures within the range of -40...+65°C.

Floor-standing

Such designs are similar in principle to the classic design. However, floor-type devices are somewhat different in design: the lever is attached to a spring and a piston, connected to a roller that performs translational movements, and drives the heart-shaped axis. It is advisable to use a mechanism of this type to control the mobility of pendulum doors and leaves, and swing-type door leaves.

Install the closer on a wooden door, products with glass inserts. Despite its small size, it is a universal option that can withstand significant loads. Moreover, floor-standing devices often perform the function of a rotating mechanism. Scope of application: public facilities, shopping centers in which double doors with glass inserts without a frame are installed. It is preferable to mount such mechanisms on the entrance doors.

Hidden door

Devices of this type are presented in two varieties:

- hinge closers;

- with sliding rod.

The first option has already been considered. These are elements that are used as a turning mechanism and are responsible for opening/closing the sash. If we are considering door closers with a sliding rod, then in this case we install the device body on the leaf. A sliding rod will be connected to it on one side, and the other will be attached to a groove that is cut with a milling cutter in the door frame.

When you plan to install hidden door mechanisms with a sliding rod, it is important to make sure that there is a gap between the leaf and the frame of sufficient thickness for the draft to pass through it. There are several nuances of such door closer designs:

- small operational resource;

- the need for accurate calculation of the installation location;

- ability to withstand small closing and opening forces;

- Installation options for hidden door closers are limited;

- narrow scope.

Classification by closing force

Closers are divided into several types, differing in force class, which correlates with the inertia of the door leaf. This parameter is influenced by the following characteristics: the mass of the leaf and the length of the arm, which corresponds to the width of the door. The force class is determined by the EN 1154 standard. Taking these parameters into account, the price category of the mechanisms is formed. Classification based on the width of the web and its weight, respectively:

- EN1: 750 mm, 20 kg;

- EN2: 850 mm, 40 kg;

- EN3: 950 mm, 60 kg;

- EN4: 1100 mm, 80 kg;

- EN5: 1250 mm, 100 kg;

- EN6: 1400 mm, 120 kg;

- EN7: 1600 mm, 160 kg.

The first options are designed for installation on lightweight sashes. For this reason, they are often attached to interior walls. Products of the latest classes are designed for heavy doors.

Famous manufacturers

Among the most popular manufacturers that you should pay attention to when choosing are:

- Dorma;

- Cisa;

- KDS;

- O&O;

- Ryobi;

- Abloy;

- Diplomat;

- Boda.

The most popular accessories of this type are German, Japanese and Italian manufacturers. They offer an extremely wide selection of high quality products. Each product corresponds to the classification, has a reliable design and durability.

How to choose the right one

If you need to purchase a door closer, first of all, it is recommended to determine the force class. To do this, you need to know the width of the sash, as well as its mass. Based on these parameters, a product is selected to adjust the forces. Other characteristics:

- door design - for swing and sliding doors it is advisable to purchase various options for door closers;

- features of the mechanism: what parts it consists of (body, rod, etc.), how it works;

- method of installing door closers: located in the upper, lower part or hidden in the door frame, hinges;

- subtleties of the door design - in particular, they take into account the possibility of installing a hidden closer, for which you need to choose a leaf with sufficient clearance between it and the frame;

- adjusting the screws that determine the opening capabilities of the sash and the intensity of the spring pressure;

- operating conditions, for example, for entrance doors the recommended temperature range is -40...+65°C;

- additional functions - in particular, we are talking about the possibility of fixing the sash in the open position at a given angle and adjusting the mechanism to delay closing;

- product design with adjustable draft - now you can choose a door closer that suits your interior;

- number of opening/closing cycles or working life of the mechanism;

- protection against vandalism - helps prevent damage.

Application area

The door closer is an adjustable, spring-loaded mechanical lever filled with hydraulic fluid that is used to smoothly close the door after it has been opened. It dampens pops and increases safety:

Different types of door closers

Although they all perform a similar function, there are different types of mechanisms that influence choice. The popularity of the model depends on the average price range, as well as on your needs.

There are products that are better suited for wooden doors, automatic or electromagnetic. Proper sizing also affects operational efficiency. If you choose equipment with unsuitable characteristics, it will be difficult to use it.

DIY adjustment

If you are selecting a door closer, take into account the possibility of changing the position of the screws located on the body:

- adjustable opening angle: from 90 to 180°;

- the speed of closing the sash changes;

- Smooth running is ensured when the specified angle is reached.

The screws are turned clockwise or in the opposite direction. If you need to adjust a mechanical door closer, find the fasteners on the body and turn the screw 1/4 turn to determine how the operation of the leaf changes. Based on the changes, adjustments are made in the right direction.

Rating of quality closers for entrance doors for 2022

This rating is based on real customer reviews and contains useful information that will help you navigate among the new products, tell you which company’s equipment is better to purchase and not end up at a loss.

The equipment is used for comfortable use of doors weighing 20-40 kg. The movement of the mechanism is soft, without visible jerks. This manufacturer has been working in the mechanical fittings market for many years and has proven itself only on the good side. There are settings for “latching” and locking speed.

| Options | Characteristics |

| Landing dimensions, mm. | 132*19 |

| An effort | up to 45 kg |

| Equipment weight | 970 |

| Material | Aluminum |

| A country | China |

| Color | Brown |

| Guarantee | 1 year |

The DS-16 has a strong aluminum casing that protects the mechanism from shock. This model has received many positive reviews from customers and is very popular due to its ease of maintenance. The planned weight of the door on which the equipment is installed should not exceed 65-85 kg.

NOTEDO operates reliably in extreme temperatures (-40 to +55°C) and humidity, without unnecessary debugging, thanks to high-quality oil and a waterproof housing.

Adjustable speed significantly improves the quality of the mechanism, ensuring quiet, trouble-free operation for many years.

| Options | Characteristics |

| Weight Limit | 85 kg |

| Color | silver |

| Brand | Rexant |

| Manufacturer country | China |

| Weight | 1.7 kg |

| Dimensions (L x W x H) | 240 mm x 155 mm x 140 mm |

| Weight with packaging | 1.7 kg |

The STAYER company has long earned a reputation as a manufacturer of high-quality construction equipment, and door closers are no exception.

Most users note the smooth operation of the mechanism and its reliability in rooms with high traffic. Time-tested components ensure resistance to adverse climates, and adjustable closing speed gives the product individuality.

| Options | Characteristics |

| Unit | PC. |

| Material | metal |

| Color | silver |

| Term of the work | 400,000 cycles |

| Weight | Up to 80 kg |

| Weight | 550 g |

The line of frost-resistant hydraulic closers from the URBOnization series is relatively new on the market, but has already earned a lot of positive reviews.

| Options | Characteristics |

| Class | EN2-3 |

| Weight, kg | 15-60 |

| Lever length | 205-280 mm |

| Temperature, C | `-40 to 60C |

| Fire protection | + |

| Fixing the position | No |

| Housing material | Silumin |

| Closing speed is controlled by two independent valves | Yes |

| Landing dimensions, mm | 126*19 mm |

| Color spectrum | White, Silver, Grey, Bronze, Brown |

| Certification | Certificate GOST GOST R 56177-2014, GOST 538-214 |

| Guarantee | 1 year |

DORMA ITS 96 is a bright representative of Cam Action technology. It is distinguished by a special installation: it is installed on the canvas, and the guide channel cuts into the box. This type of installation will better preserve the design of the door, and the presence of additional equipment will make it invisible.

The kit includes a rubber opening angle limiter. It is possible to purchase an open position lock and fasteners for mounting on metal.

| Options | Characteristics |

| Type | Mortise |

| Weight | 30 – 100 kg |

| Lever type | Guide channel |

| Blade width | up to 700 mm |

| Product weight | 2 kg |

Easy to maintain and compact domestic mechanism for doors weighing no more than 100 kg. Equipment from the “Master” line has a simple and robust design that does not require special skills for installation. The product is suitable for residential premises and offices.

| Options | Characteristics |

| Material | steel |

| Product weight | 1000 g |

| Equipment | screws, 4 pcs., door closer, counter plate, additional insert, |

| Web weight | Up to 100 kg. |

The equipment body is made of aluminum, which makes it resistant to mechanical damage and increases service life. The closer effectively copes with the assigned tasks, closing is smooth, suitable for any premises, including can be used at low temperatures (-40 to 55°C), which is important in cold winter conditions. The hydraulic fluid used in the product does not freeze.

The equipment can be installed on doors up to 35-65 kg. Adjusting the valve mechanism allows you to reduce the closing speed, which is important for families with children. There will never be drafts or unexpected guests in the room where “REXANT” is used.

Source

Installation methods

Depending on the type of construction, the door closer mount is attached in different ways:

- on the surface of the door frame;

- in the floor;

- in the groove of the box;

- closers for sliding doors are hidden in hinges or are linear-type devices that are attached to the door frame (they work on a different principle than their counterparts for swing doors).

When determining the installation method, you need to take into account the characteristics of the door frame and the thickness of the gap between the frame and the leaf. For example, a closer on a plastic door is mounted on the surface of the door frame and connected to the door leaf with a rod.

Possible installation options on the door leaf

The closer body is positioned in several ways:

- on the canvas, then the rod will be fixed to the door frame or in a groove, which is also cut out in the frame;

- on the door frame, accordingly, the free end of the rod is located on the leaf.

If you plan to secure the end of the rod in the groove of the door frame, in this case there is only one option for locating the closer body - on the door leaf. The mechanism is always installed on a balcony door in the standard way: the closer body is on the sash, the rod is fixed to the surface of the door frame.

DIY installation features

In accordance with the selected opening force of the blade, the distance between the hinges and the mechanism body is determined. A door closer for a lightweight door must be of class EN1-EN4. For installation, a template on a 1:1 scale is used. It needs to be glued to the door leaf with tape. After this, they proceed to drilling holes for fasteners. The lever that performs the traction function should be divided into 2 elements. After this, one part is installed on the door frame, and the second on the door leaf. Then the elements of the lever are connected and it is adjusted in length.

What to do if nothing works out?

There are several reasons why the setup may not produce results:

- An inappropriate mechanism has been selected, the door is too heavy, and heavy objects are frequently hung on the door leaf.

- Incorrect fastening of the iron angle, misalignment of parts.

- Displacement of the holes for the screws on which the device is attached, unscrewing.

If one of the above points applies, then there are only two options - change the door, install a different closer. There is a third option - try to fix it yourself, but lack of experience can lead to worsening.

The lever must be positioned strictly perpendicular to the canvas, otherwise one of the parts must be moved.

Repair

If the mechanism is overloaded, which leads to wear, some parts are replaced. Spare parts for the closer are selected taking into account its type. If there is an oil leak, the condition of the housing is assessed; if the defect is small, the gap is closed with sealant. If there is severe deformation, the part is replaced. When the metal of the rod breaks, a welding machine is used. Corrosion is eliminated by cleaning. The bend of the rod is corrected manually, and the shape of this element is restored. The door closer on a glass door, metal or wooden door is repaired in the same way.

Design of hydraulic finishing mechanisms

The hydraulic frost-resistant closer consists of a spring and a piston. They are located inside a housing filled with synthetic antifreeze oil.

When the entrance door is opened, the spring is compressed, and when closed, it straightens. Oil acts as a shock absorber. Smooth closing of the door occurs due to its smooth flow from one compartment to another.

Rating TOP 5 best door closers: which one to choose, characteristics, prices, reviews

It’s good when the doors open and close smoothly, don’t slam, but neatly fall into place. This is especially important in public buildings and large stores. But in work premises and even apartments and houses, it is now impossible to do without it. This effect can be achieved using door closers. How to choose the right one? The question is not at all easy. We suggest learning about existing types and taking a closer look at the characteristics of the five rating models in our article. We will be glad if this review will help you select the model that best suits you. We wish you pleasant reading.

Closers are divided into types according to the location of installation of the models:

Based on the main operating mechanism, the devices are divided into closers:

Comparison table of characteristics

The summary table contains the main parameters of the considered models.

| Model | Dimensions (cm) | Weight, kg) | Sash width up to (cm) | Price, rub.) |

| Maxbar TS 2000 VBC EN2/4/5 | 22.6x6x4.8 | 2,14 | 125 | from 3860 to 4000 |

| DORMA TS-90 IMPULSE EN3/4 | 5.6x24.6x46 | 1,7 | 110 | from 10310 to 11200 |

| APECS DC-26/100-120-F2-MS | 13x31x8 | 3,25 | 140 | from 3729 to 4100 |

| HAG-603 | 23x30x56 | 1,5 | 60 | from 8890 to 9500 |

| Geze TS 500 NV EN1-4 | 27.8x8.2x4.2 | 4,5 | 110 | from 9527 to 10500 |