Wooden windows are making a comeback in residential buildings. PVC, for all its advantages, does not “breathe”. And you can put exactly the same double-glazed window into a wooden frame, and equip the window with an opening mechanism in two planes. In addition, a PVC window, which can last as long as wood, turns out to be much more expensive. But in older houses, window openings often turn out to be warped, and the work of installing custom windows is expensive because of this. However, if you have basic carpentry skills, installing wooden windows yourself is quite a feasible task for you. Next we will describe how to do this in buildings of various types.

Opening: cleaning, measurements, preparation

What's up there?

First of all, if the house is made of stone, we knock down the slopes and plaster along the top of the window opening. Purpose: to find out whether there is a lintel in the opening, or whether a section of the load-bearing wall lies simply on the window casing; This is a common construction hack.

If the house is made of stone and there is no lintel, alas, you cannot continue to work, but you need to consult with the builders about correcting the defect. Living in such a house is simply dangerous, especially if it has two or more floors. But do not be alarmed if in a very old house there is a castle made of bricks or stone instead of a lintel: this is in the order of things, it is quite reliable, and work can continue. Also, in block houses, as a rule, there are no lintels: reinforced concrete slab monoliths are already made using reinforced concrete concrete with window openings.

As for wooden houses, they are either assembled on a frame or made from a log house. In them, window openings either do not carry loads at all, or are lightly loaded, and you don’t have to think much about the lintel.

Mortgages

Now you need to knock down the slopes around the entire perimeter of the window, inside and outside, and remove the window sill. If a quarter is provided in the opening - the flow of masonry from the outside onto the opening, this is very good. But now we need to check the presence and condition of the mortgages: wooden beams embedded into the masonry wall specifically for window installation.

If the mortgages are in place, we check their condition: we stick an ordinary shoe awl into the tree a third of the length of the rod and pull it back. If it doesn’t go in a third of the way when pressed by hand, or it’s impossible to pull it back out without swinging or grabbing the rod with pliers, that’s good, the mortgages are strong. If not, they will have to be replaced.

What if there are no mortgages at all? It’s also okay; it’s possible to insert wooden windows into openings in a stone wall without them.

Measurements

The window opening, cleaned before laying (or before casing in a wooden house), must be carefully measured. If you plan to replace several windows, clean and measure all openings. The goal is to determine the configuration of the opening, and from it - the dimensions of the new window.

Even a house built by the most conscientious builders shrinks over time, and it is never absolutely uniform. The new window should be slightly smaller than the rectangle inscribed in the opening. The gaps that must be maintained are indicated in the figure: 15-25 mm on the sides and top and 40-60 mm at the bottom.

Measurements must be made based on true horizontal and vertical lines. Without any extra hassle, it is done with a laser tape measure. If it is not there, on the wall above the opening we draw a horizontal line along the level, and on the side along the same level or plumb line - a vertical line.

To guarantee, you can cut off the second horizontal line at the bottom, the second vertical line on the other side, and measure the diagonals of the resulting rectangle. If they are equal, everything is in order, the measurements will be accurate. You can now order windows using them.

Modern flooring materials

One of the best floor coverings is parquet boards or regular planed edged boards. Both of these materials are completely natural and have a high level of environmental safety, so they can be used in the nursery, bedroom and other rooms of your home. But having given preference to such a floor covering, you must carefully select the varnish or paint for its treatment. Choose an expensive, high-quality and safe varnish; before purchasing, carefully study the information on the label.

- Ceramic tiles are another safe material made without the use of harmful chemicals. If you are planning an environmentally friendly apartment renovation, this material is perfect for the kitchen, bathroom, hallway; it has enviable durability and practicality.

- The environmental friendliness of a laminate depends on its level of quality. Most of the expensive modern varieties are manufactured in accordance with safety regulations and standards and are suitable for use in any area of your home.

- Linoleum is one of the most unsafe materials, as it is made from petroleum products and contains a lot of chemical additives. The most dangerous types of material are such as relin and linoleum made on the basis of polyvinyl chloride compounds.

- Carpet does not have a high level of environmental hazard, but in some cases it can become a source of allergic reactions. If you want to lay carpet made of natural pile, you should carefully care for it, otherwise it will become a haven for billions of micro-mites.

How to fix windows?

Before ordering or making windows yourself (see below), you need to decide how the windows will be attached and how they will open. In a wooden house there is no choice regarding the method of fastening: through the frame to the casing.

If in a stone house there are mortgages in the window openings, and the opening itself is not very good, then it is better to fasten it here in the same way. The selection criterion will be the difference in the length of the diagonals of the clean opening: if it is no more than 10 mm per 1 m of diagonal length, we fasten it through. If it turns out more, you need to attach it to the wall with anchors.

For example: the opening size is 90x120 cm. The estimated diagonal length is 150 cm (according to the rule for a rectangle). The actual lengths of the diagonals are 1507 and 1494 mm. The spread is 14 mm, and at 1.5 m 15 mm is acceptable. Can be fastened through.

In an apartment in an old, damp block reinforced concrete building (in Khrushchev) there is also no choice: only anchors to the wall. In block houses, they do not make mortgages for windows. But in a block house with a technical floor or attic, you can also fasten it through.

Danger of PVC windows during combustion or fire

Fire is perhaps one of the most dangerous natural disasters. There may be many reasons for it, but the result is always the same: the raging elements burn out everything in its path. In aggressive environments, in particular during combustion, new substances are formed that can harm human health.

Ignition temperature of various materials

| Material | Ignition temperature, 0C | |

| 1 | Wood (pine) | 255 |

| 2 | Wood (oak) | 238 |

| 3 | PVC | 391 |

| 4 | Expanded polystyrene | 346 |

Plastic brought to combustion temperature, like any other material, poses a danger, primarily due to the gases formed during the combustion process

To avoid poisoning from combustion gases, it is important to leave the fire site as quickly as possible, before doing so, breathe through a wet cloth, protecting your respiratory system.

How do plastic windows behave in a fire?

The behavior of windows in a fire deserves special attention. The tightness of plastic windows prevents the penetration of combustion-supporting oxygen from the street, and their ability to self-extinguish are important arguments in favor of choosing this particular glazing in places with a high risk of ignition.

“We wrote about the requirements for fire resistance of structures in the material Fireproof Plastic Windows.

Only aluminum structures can boast the highest degree of fire resistance. "

Aluminum windows and doors produced by Business-M

How will the window open?

If the window opening allows through fastening, the window opening mechanism can be anything, even when hung on anchors. If you decide to anchor it due to a skewed opening, then it is better to limit yourself to opening in one plane: swing doors, one swing door, a folding or tilting door, or a horizontally rotating door.

The fact is that a wooden frame can warp due to uneven load. Very slanted window openings indicate that the building is shrinking unevenly. Fastenings through the frame are rigid connections between the window and the wall, and the opening mechanism in two planes can jam due to a much smaller distortion of the frame than a simple one.

Casing

A special design, which is a wooden box without a bottom crossbar, the purpose of which is to securely fasten the window and maintain the shape of the window frame, regardless of the degree of shrinkage of the house, is called a casing or frame.

There are several types of this design:

- One piece. It is made from specially processed solid material.

- Glue. The individual components are made from type-setting boards, connected by means of microgrooves and glue. All burrs and small knots are removed.

- Mixed. Part of the casing is made solid, and the other is made using glue. Upon completion of installation, the pigtail is varnished. This type is suitable for using large window sills.

The window frame is made according to the size of each window. Moreover, if internal cladding is planned, then sampling can be done for it. When facing on both sides, sampling is not performed.

Assembly of the casing can begin after preparing the window opening.

Its production is carried out as follows:

- Grooves are machined in the base, which is adjacent to the window opening. A beam of the same size is inserted into them, acting as the side of the casing.

- First, place the beam at the bottom of the opening , which will prevent the side elements from moving.

- A sealant made of flax tow is placed under the timber .

- Sealing material is placed in the recesses and side boards are installed.

- The final stage is attaching the top board of the structure.

- A space is left on top of the jamb for the wood to dry out and filled with sealant. This way, during the process of shrinking the logs, the load on the window opening will not be affected.

How long (“thickness”) does the frame need?

The length (“thickness”) of the frame must be such that the so-called dew point is between the glass panes. Simply put, fogging up the interior glass is unacceptable. Approximately, the length of the frame in centimeters can be equated to the annual average subzero temperature in degrees of the coldest month (January - February) in your area, but in any case no less than 12 cm and no more than 22 cm.

If the length of the frame is more than 22 cm, you need to provide additional thermal insulation in the opening during installation, or triple glazing, as is done in the Far North. There is no point in installing a thin double-glazed window into a long frame: then it is better to install traditional glass with glazing beads and putty. But you can install two thin double-glazed windows: you get four-fold glazing, and you don’t have to think about the dew point at all. True, it will cost a lot of money.

It is also necessary to coordinate the length of the frame with the thickness of the wall: the internal slope must be at least 17 cm; external - at least 10 cm. If the masonry of the opening is with a quarter, and this does not allow making the internal slope of the required width, then the frame can be made shorter: the quarter itself already provides additional insulation.

Eco-friendly wall decoration

Wallpaper is the most popular material for wall decoration, and if you want to take care of the environmental aspects of your home, then preference should be given to paper wallpaper. These truly environmentally friendly materials are affordable and suitable for all living areas of your home, with the exception of the kitchen and bathroom, where there is high humidity and temperature changes.

Textile and plant wallpapers made from natural plant materials and not treated with chemicals also have a high level of eco-safety. These types of wallpaper have good wear resistance, do not fade in the sun and do not contain any harmful substances. The choice of wallpaper glue is no less important and preference should be given to an adhesive composition based on starch and other natural additives.

Installation of wooden windows in stone and concrete

Do-it-yourself installation of wooden windows in the openings of stone and block houses of various types begins with the installation of a window sill. It is better to make a cement pad under it and level its surface to a horizontal plane. An attached (hanging) window sill, installed after installing the window, does not make the work any easier, but it holds much less firmly, especially if the walls are thin. Window sill thickness 30-50 mm; if the window sill board is thicker, the lower gap in the opening must be increased in advance by reducing the height of the window.

The window sill is nailed with three or four nails to the bottom mortgage or with 6 mm mounting nails (dowel nails) to the stone. In the latter case, before installation, it is necessary to drill mounting holes in the window sill with a diameter of 3/4 of the nail diameter, mark the locations for holes in the wall for mounting nail sleeves along them, drill holes and drive the sleeves into them. Three holes in a row with a distance of 150-200 mm from the edges of the opening are enough. The outer edge of the window sill board should be flush with the outer edge of the frame. The distance of the row of fastening holes from the outer edge of the board is one and a half of its thickness.

Note: if fastening with anchors is intended (see below), then the window sill is not installed in advance - it will interfere. I'll have to suffer later.

Then, if the masonry has a quarter, roofing felt or polyurethane foam insulation is applied to the inside of the quarter. The insulation can be laid on construction silicone: there will be no load on it, and then it will be pressed against the window frame, so there is no point in fiddling with fasteners.

Next, you need to prepare the window: remove the sashes with glass, hinges and mechanisms, leaving only the frame. This is where the general work for different openings ends.

Option 1: a good opening in a good wall

If the opening is “completely rectangular” and the house is dry block or sand-lime brick, then it is advisable to install the window in the simplest and cheapest way: on blocks. Mounting pads are simply pieces of boards or slats as thick as the gap between the frame and the wall and 120-150 mm wide. One wide edge of each block is slightly bent to a wedge, not to the point.

The location of the blocks for various types of windows is shown in the figure. First, the support blocks are installed; then - spacers. The horizontality of the frame crossbars is continuously controlled by a level, and the verticality of the sidewalls by a plumb line. The pads should not fit very tightly; It is necessary that any block can be pulled out with your fingers. If necessary, the pads can be trimmed or a layer of wood can be removed with coarse sandpaper.

After leveling the frame, the pads are removed one at a time, starting with the spacers; Construction silicone is applied to the places under them, both on the frame and on the wall, and the block is put back. Drips and deposits of silicone from the outside are immediately removed with a rag moistened with table vinegar.

After the silicone has hardened, the gap is filled with construction foam. How to blow out the gap between the frame and the wall is described below. At the end, the foam swells are cut off with a mounting knife, slopes are made, sashes with glass are installed - that’s it, the window is ready.

Note: if you are sure that you will never have a hurricane, you can do without silicone and blow out foam right away. But the foam is not designed to bear the load, and watching the wind squeeze out the window just when there is no way to repair it is a relative pleasure.

Option 2: a good opening in an unimportant wall

If the house is made of ceramic brick, cinder block, shell rock, etc. weak material, but dry, and the opening is impeccable, it is advisable to install the window with a fastening through and through. To do this, first of all, holes are drilled in the frame for fasteners: mounting nails with a diameter of 6 mm; hole diameter – 5 mm. The length of the nail-dowel should be 80 mm + gap width + frame thickness. For example, if the frame is made of magpie timber and the gap is 20 mm, then the length of the nails is 140 mm.

There should be 3 holes per side of the frame up to 1.5 m long: two with a distance of 150-200 mm from the corners; the third is in the middle. In frame elements more than 1.5 m long, 4 holes are drilled: two extreme ones with the same distance from the corners, the rest - evenly along the length. For very long or high frames, the spacing between mounting holes should be no more than 600 mm.

Then the frame is placed in the opening, leveled with blocks, as already described, and on the wall, through the holes in the frame, places for holes for the nail sleeves are marked. The holes for the sleeves are drilled by removing the frame, according to the diameter of the sleeve and the depth of its length + 30 mm for dust and crumbs. There is no need to drill holes in the window sill: the frame is simply nailed to it with ordinary nails.

Attention! The holes for fasteners must not go through the pads. If any of them landed on the block, it needs to be moved.

After drilling, the sleeves are driven into the holes, the frame is placed again and, without removing the pads, they are secured with nails. Then they take out the pads, fill the cracks with foam, make slopes and install the sashes. This completes the installation.

Note: if the pads had to be adjusted, they are marked at the ends before being removed. When installing in a skewed opening, this must be done.

Option 3: oblique opening in any wall

Wooden windows can only be securely placed in a skewed opening using anchors - metal strips with holes. You can make the anchors yourself from strips of tin or galvanized steel, but it’s not worth the trouble: the price of factory anchors is a pittance, but working with them is much more convenient.

The anchors are attached to the ends with self-tapping screws along the outer perimeter of the frame so that they stick out inward. These “tails” will then disappear under the slopes. The number and location of anchors is the same as the holes for through fastening.

Note: it is often advised to first attach small intermediate fastening strips to the frame, and then use them to secure the frame to the anchors. This is justified in large-scale professional construction: one worker quickly, without losing the rhythm, attaches anchors to empty openings, and then two, also without losing the rhythm, push in and screw the windows. When installing one or several windows yourself, there is no point in spending money on extra fasteners.

The frame with anchors is pushed into place into the opening and leveled with blocks (do not forget about the level with plumb lines - the opening is slanted!). Then a drill hole is marked on the wall through the holes of the anchors, the anchors are bent, holes are drilled for dowel-nails, the anchors are bent back and secured with dowel-nails.

After this, you MUST remove the pads; the window frame must hang in the opening on anchors. An oblique opening indicates either the negligence of the builders, or the natural uneven shrinkage of the building, so there should be no rigid connections between the window frame and the walls.

Finally, the gap is filled with foam, a window sill is installed (in a slanting opening the window sill will be hanging - nothing can be done) and, as always, slopes are made and sashes are installed.

Note: sometimes there is advice - to level the opening with a cement screed. Martyshkin's work. No screed will stop uneven shrinkage. Even the most notorious schemers still do not lay homemade crooked bricks. The carelessness of the builders, which led to uneven shrinkage, was hidden even during the design. But uneven shrinkage can begin later, when the properties of the soil change, even if the project has been completed in good faith.

Buy a change house from the manufacturer

The Stroy-Gid company is engaged in the production and sale of construction cabins of standard and individual modifications. You can order the production of a change house according to your own planning solution with an individual arrangement of windows, doors, partitions and the use of various finishing materials.

Sale of cabins for builders and foremen

The main type that is most popular in sales are metal cabins (block containers). Based on them, various temporary buildings are made - a security post, a tire shop, construction workers' trailers, a modular building up to three floors high. The metal frame creates a monolithic structure of the entire structure and protects the cabin from damage during frequent loading and moving.

Prices from 45,000 to 87,000 rubles.

Construction cabins from Stroy-gid We produce and sell construction cabins

Buying a frame or timber cabin

Structures based on frame-panel construction have the second place in popularity of sales and applications. In most cases, these cabins are used to accommodate construction crews for the summer, autumn and spring periods. Also, cabins of this class can be used in summer cottages as a room for storing garden tools, organizing recreation or overnight accommodation. Change houses made of profiled timber serve for more comfortable living in the country.

Prices from 30,000 to 120,000 rubles.

Wooden and metal sheds store

The advantage of the Stroy-Gid company is a wide range of ready-made trailers, as well as the ability to build a custom-made cabin. Buying a change house from us is as easy as going to the supermarket for groceries. Our employees, who have extensive experience in selling cabins, will offer you the best equipment and advise you on the optimal design option based on your requirements.

Ordering a change house from Stroy-Gid LLC is the right decision!

Wooden window in wood

In a wooden house, installing windows comes down to planting them in a casing using liquid nails. For strength, you can grab it through with nails or screws. The cracks inside and outside and holes with fastener heads are sealed with the same irreplaceable liquid nails, and platbands are attached to them. But the platbands also need to be strengthened additionally, with ordinary nails or self-tapping screws - there is wind outside.

What to do if the casing is oblique or not the right size? In this case, the casing needs to be adjusted to size and leveled. This is done with beams, planks or slats on liquid nails. For leveling, the necessary ones are driven, as needed, onto a wedge - on a jointing machine, with a small circular saw with a toothed circle or manually, with a hacksaw for metal (yes, yes - you need a very fine tooth, and so that you can cut the fibers obliquely) or with a bow saw or a plane. The latter, of course, requires the working skills of a carpenter.

LOG HOUSES: INTERIOR AND EXTERIOR DESIGN

Houses made of timber successfully compete with brick buildings. Customers have the opportunity to obtain durable, environmentally friendly housing at an affordable price without the painful wait for construction to be completed. The interior of a log house is created taking into account the requirements of modern design and customer preferences.

In this case, it is first necessary to resolve the issue of conducting communications, since the wiring will have to be hidden under finishing materials. Such houses are insulated using natural materials (as a rule, moss and tow are used) or no less high-quality analogues. When choosing insulation means, you should focus on the nature of the construction and the specifics of operation.

Wood is an excellent material for interior or exterior decoration; it does not require additional decoration. Our craftsmen will treat the timber with special means that can enhance its strength and prevent the appearance of mold. This design will last for many decades if the rules of use are followed.

About fixed windows

Windows are ready-made for installation in homes. Making a good and beautiful window is not an easy task even for an experienced carpenter. But sometimes - in an attic, in a barn, a garage or in a country house - you need to make a small blind window. You can make such a window yourself by making a frame from beams and slats.

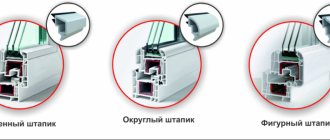

What the profile of the window frame should be can be seen in the figure. Note the highlighted protrusions at the bottom that are the lightest. These are teardroppers. Their purpose is to prevent water from flowing into the frame. They must be made on the lower cross member of the frame, but in no case should they be done on the top: there they will turn into moisture traps. But they are useless on the sides.

***

So, now you know how to install a wooden window in any window opening of any building. As you can see, the work itself is not complicated or difficult, but it requires preliminary consideration of many different factors, and when performing it, intelligence and accuracy.

Basic DIY installation steps

The production of wooden window products sold on construction markets is of high quality and meets international standards. Often these products have a high cost, but the technology of installing wooden windows yourself is a simple process and reduces costs by up to 10%.

To install a window in compliance with building codes, you need to know the stages of work on installing window frames. Its quality benefits and service life depend on how correctly we install the window.

The recommended stages of work on installing window structures are set out in the product manufacturer's instructions, but there are many nuances that you need to know in order to install wooden windows efficiently. The main features of installing wooden windows are the following:

- dismantling the old frame;

- cleaning the window opening;

- taking correct measurements;

- installation of window sills and ebbs;

- installing a window in the opening;

- fixing the box in the opening;

- insulating the space between the frame and the opening;

- setting and adjusting window closing/opening elements;

- design of window perimeter slopes;

- finishing of the outer perimeter.