Even if low-power heaters are used in the room, properly selected insulation will help maintain a comfortable temperature. When answering the question of what Izolon is, what first comes to mind is its improved capabilities in creating high-quality thermal insulation. Let's figure out what the features of the canvas are, what characteristics it has and how to choose the right option.

A popular variety is foil Izolon Source sevparitet.ru

Material and its varieties

Isolon is a brand of insulation. The name hides foamed polyethylene foam with a closed-type fine-cell structure (the cells are closed, separated from each other). The structure determines the improved physical and mechanical characteristics of the canvas. The industry produces the following types of Izolon insulation:

- Izolon PPE (polyethylene foam). Multifunctional material, heat, sound and vapor barrier. The abbreviation PPN refers to the production method - it is an ethylene polymer with cross-linked molecules (physically cross-linked foam or cross-linked polyethylene). It is found on sale in the form of rolls of different windings or sheets (100x200, 140x200 mm).

- Izolon adhesive (self-adhesive). Foamed polyethylene with an adhesive layer, sold in rolls of different windings, the thickness of the material also varies (2, 4, 10 mm). A physically cross-linked structure of cross-linked molecules improves performance properties.

Above – uncrosslinked PPE, below – crosslinked Source cdn-ru.bitrix24.ru

- Izolon foil. A thin layer of aluminum foil is applied to one side, and the other is sometimes additionally coated with glue. Foil insulation is sold in the form of rolls; the foil can have different thicknesses.

- Colored isolon. The insulation initially had two colors: white and gray, but today multi-colored versions are produced, known as foamiran. The material is produced in the form of rolls and sheets of different thicknesses and qualities, and is used in decoration, design, and handicrafts.

- Izolon block (slab). It is used not only in construction, but also as flooring in sports halls, and also as a target for arrows.

Stages of production of isolon

- Polyethylene granules and foaming agent are mixed in a common container. To obtain PPE, it is necessary to add “cross-linking” agents.

- Extrusion. Formation of future sheets of material by heating and melting the polymer mass.

- Foaming. A conveyor net feeds the formed sheets into the oven. High temperature activates the foaming agent. As a result, the structure of the material becomes porous.

- If foil-coated isolon is produced, the next step is gluing the aluminum foil using the lamination method.

Subscribe

Advantages and disadvantages

The porous structure with cross-linked molecules provides the following properties of the Izolon material:

- Excellent ability to retain heat and sounds. A polymer with a thickness of 1 cm in terms of thermal insulation properties corresponds to 15 cm of brickwork or 5 cm of solid pine timber; slightly superior to polystyrene foam and mineral wool (they will need 1.5 cm).

Foamiran is a decorative variety of PPE Source shopify.com

- High level of waterproofing. Thanks to the closed pores filled with air, the material practically does not absorb moisture and remains vapor-tight.

- High inertness in contact with oil and petroleum products, with chemical compounds; Izolon is compatible with most building materials.

- Impressive service life: manufacturers talk about 80-90 years without loss of performance properties.

- Health safety. The material does not emit substances that are hazardous to health or cause allergies, does not rot and does not become a haven for microorganisms and fungi.

Builders note the following advantages of Izolon:

- Elastic and lightweight insulation makes installation simple and quick. It is easy to process - just a sharp knife is enough to cut the workpieces to the desired size.

- Reasonable price and no waste make it an economical insulation option.

- The polymer is resistant to atmospheric factors and solar ultraviolet radiation, so it is used for facade (external) insulation.

Isolon blocks serve as a reliable shock absorber Source prom.st

See also: Catalog of companies that specialize in home insulation

The following features of foil insulation can turn into disadvantages:

- Low strength. It is also typical for other insulators of this class: any of them is easy to pierce, so care is required during installation.

- Foil materials require a ventilation gap of 1-2 cm; this helps to avoid the formation of condensation, but at the same time increases the cost of insulation.

- With constant high humidity, the aluminum coating begins to corrode, and over time the thermal insulation ceases to perform its functions.

Features of using isolon

Sealing isolon

To ensure that the material does not lose the properties declared by the manufacturer during operation, its sheets are laid end-to-end without overlapping. To reliably seal butt seams, special aluminum tape is used. When insulating the surfaces of building structures, always leave gaps for ventilation between the insulated element and the isolon used. This will prevent the formation of condensation, which is destructive for many materials. For safe operation, it is prohibited to lay conductive foil insulation directly next to electrical wiring.

Safety of using isolon

There is no release of any toxic substances into the environment even if the isolon is heated to +140°C. The material is hypoallergenic, environmentally friendly, hygienically safe. Its operation allows contact with food and human skin. During the production of foamed polyethylene, there are no emissions that destroy the ozone layer of the atmosphere, because the freon included in the gas mixture for foaming is successfully replaced with isobutane, propane-butane and other gases. When disposed of, buried, or accidentally released into the soil, no harmful substances and gases are released that pollute water bodies and groundwater. Resistance to aggressive petroleum products and organic solvents makes isolon a reliable insulator for various products and surfaces. Polyethylene foam is fireproof (due to the inclusion of fire retardants - fire extinguishing additives) - it does not burn, but decomposes into carbon dioxide and water.

Scope of application

A universal set of characteristics contributes to the widespread use of Izolon; Application covers the following areas of the economy:

- In construction. With its help, heat and waterproofing of walls, floors, floors and ceilings is arranged. It is needed for waterproofing communication systems, basements and foundations, for insulating balconies and loggias. The fabric copes well with thermal insulation of saunas and baths - objects with regular fluctuations in temperature and humidity.

PPE in floor insulation Source stroyfora.ru

- Automotive industry. Thermal fabric is used for interior trim; it not only reduces heat loss, but also reduces vibrations and protects against noise. It is also used to make various sealants to protect against corrosion.

- Mechanical engineering. Izolon is used to insulate the surfaces of refrigeration equipment, air conditioners, and heat-reflecting screens. It is used to produce seals and vibration isolators.

- Manufacturing of medical products. These include a variety of thermal blankets and orthopedic products (for example, insoles).

- Production of consumer goods (household goods), including for recreation, sports and tourism. Polymer is used to make fillings for life jackets, mats, helmets, shields, gloves and punching bags.

- In the furniture, leather goods and footwear industries.

- As packaging material. Its shock-absorbing properties are important here, protecting the finished product from deformation.

High-quality sound insulation of the car interior Source recn.ru

Laying foil insulation

The next step is the installation of the first layer of insulation. But before this, you need to cut the isolon to size, and there should be no gaps between the pieces of sheets. At the joints, the material is fixed with tape. If one layer of thermal insulation is enough, then you need to lay more waterproofing on top of the isolon, and then proceed to installing the finished floor.

It should be taken into account that when insulating walls and ceilings, good ventilation in the room must be ensured

When laying several layers of insulation, it is necessary to install logs after the first layer. For such purposes, timber pre-treated with an antiseptic is cut and mounted above the thermal insulation. At the edges, it is recommended to install these beams near the walls. During such work, you need to constantly monitor the evenness of the position of the lag using a level. After eliminating the differences, the elements can be secured with dowels or self-tapping screws.

Isolon is laid with foil down in the space between the joists. It must completely occupy the void. Thermal insulation material should be installed as tightly as possible, leaving no gaps. After the work is completed, all that remains is to lay the finishing floor.

Performance characteristics

The overall dimensions of the insulation are as follows:

- Roll material. Winding (length) – 10-220 m, width 150-200 cm, thickness 2-20 mm.

- Plate material parameters: 1×1 m, 1.4×2 m.

Foil insulation has an additional letter classification:

- "A". This polymer is coated with a metallized layer on one side. The thickness is in the range of 3-10 mm.

- "B". There is a foil layer on both sides. The material is more resistant to mechanical deformation.

- "WITH". Cross-linked polyethylene foam with an adhesive layer on one surface. Thermal insulator with a self-adhesive base is popular in private construction due to its convenient use.

- "ALP" Self-adhesive insulation, on one side of which there is an adhesive layer, on the other - aluminum foil. The metallized layer is additionally protected by a transparent polymer film 1-3 mm thick.

Isolon is used in construction with the following technical characteristics:

- The application range is limited to operating temperatures from -80 to +80 °C. The fabric retains its elasticity at temperatures from -60 to +80 °C.

Installation of a heated floor with a heat-reflecting substrate Source stroyfora.ru

- Average density 25-45 kg/m³.

- Thermal conductivity coefficient: 0.031 – 0.04 W/m·S.

- Infrared radiation reflectance (for products with a foil layer): 95 – 97%.

- Water absorption. Does not exceed 1%, by volume – up to 0.2%.

- Vapor permeability: 0.001 mg/m·h·Pa.

- Noise insulation. The strength of sound absorption depends on the thickness of the material. Depending on the desired suppression of external sound, a material with a thickness of 8 to 50 mm is selected. The level decreases by 60-80%.

- Isolon is considered a moderately flammable insulation and is included in group G2-G4 (flammability class according to GOST 30244). Its properties can be improved if treated with a fire retardant. Foil heat insulator is a moderately flammable material (B2).

- The melting point is 105-130 °C (depending on the manufacturing method).

Thin Izolon does not reduce the free space of the balcony Source cottage-lux.com

Advantages of insulation

Izolon is an environmentally friendly and safe material. It is characterized by elasticity and ease of processing. To cut this insulation, you can use a stationery knife or regular scissors. It is easy to lay on surfaces of any configuration, since the material is very light.

By properly insulating your walls with isolon, you will protect your home from the penetration of cold wind and dampness.

The advantages include high thermal insulation qualities. The main operational property of isolon is its low thermal conductivity coefficient, which ranges from 0.03 W/m*K and higher (the indicator depends on the manufacturer and variety). Moreover, the material has good vapor permeability and moisture resistance, because each cell in the insulation is closed, so the material does not absorb water, thereby protecting the surface.

Isolon can be fixed with staples, glue, screws or nails. It instantly restores its shape and is wear-resistant. Thermal insulation material can be used repeatedly, since it is not afraid of temperature fluctuations, precipitation and ultraviolet rays. Manufacturers of isolon assure that such a product will last at least 80 years.

How to choose

When choosing, it is important to pay attention not only to the type of Izolon, but also to its thickness, since this parameter depends on the area of application. The following ratios are recommended:

- If you want to additionally insulate the floor, PPE with a thickness of 2-5 mm is suitable as a substrate. You can use regular or foil polymer.

- Insulation of concrete or wood floors is made from 8-10 mm fabric.

- Rolled Izolon 4-10 mm thick will help to reliably isolate the roof and premises from external noise.

- Izolon in the form of blocks is suitable for internal thermal insulation of rooms and interfloor ceilings. With its help it is convenient to insulate the foundation and roof of any type (flat, pitched).

Heat and sound insulation of a residential building Source vesta-teplij-pol.ru

- Pipes located underground are insulated with 15-45 mm polyethylene foam.

- To install heated floors, you need thin (up to 2-4 mm) material.

- Foil fabric is chosen for insulating pipes and dry screed. If you want to level the floor using a wet cement-sand screed, use a sheet with a double-sided metallized layer.

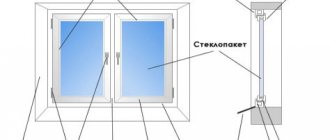

- For small jobs, Izolon, produced in the form of a tape, is suitable. It is used to glue cracks and seal door and window openings.

Facade insulation works Source znatoktepla.ru

Floor insulation technologies

The technology for installing isolon on the floor has 2 options for carrying out the work.

Option 1 - insulation with isolon together with another insulation (most often mineral wool). Stages of work:

- Removing old flooring and cleaning the subfloor.

- The slats are attached to the cleaned base with dowels. This provides the necessary ventilation gap. The distance between the bars is 50-60 cm.

- Sheets of mineral wool are laid between the bars, and then sheets of isolon are laid on top under tension with a layer of foil in the middle of the room, attaching them to the slats with dowels.

Important: the joints of the isolon sheets must be placed on slats and taped with metallized tape, which ensures complete sealing of the sheets.

- Next, a second row of slats is mounted on the PPE isolon layer perpendicular to the first.

- At the next stage, sheets of plywood are laid on the slats, securing them with self-tapping screws.

- Finally, the floor covering is installed.

Option 2 - insulation with PPE isolon without the use of a second insulation . Stages of work:

- Isolon is laid directly on the wooden flooring.

- The sheets are laid end to end in one layer.

- The seams between the sheets are taped with metallized tape.

- Plywood sheets are placed on the layer of isolon PPE, screwing them with self-tapping screws.

- A floor covering (usually parquet or laminate) is installed on the plywood.

Briefly about the main thing

Isolon is a universal insulation material that is widely used not only in construction, but also in other areas of the economy. Thanks to its closed porous structure, it has improved performance characteristics: plasticity, minimal water absorption, high levels of noise and heat protection.

The chemically neutral material is produced in the form of canvas (roll), plates and construction tape; There are colored varieties for creative needs. The canvas may have an adhesive and/or foil layer. The choice of the appropriate PPE option depends on the type of work to be done.

Wall insulation technology

Insulation technology:

- The bars are attached to the cleaned walls with dowels in increments of 50-60 cm. Sheets of isolon PPE are laid on them end-to-end with the foil side inside the room and attached to the bars using a construction stapler.

- Then a 2nd row of slats is placed on the PPE isolon layer perpendicular to the first row located under the insulation.

Important: the second row of slats serves as the basis for attaching the final finish - plastic or wood panels, or plasterboard sheets.

The latter need to be puttied and then painted or wallpapered .

Nikifor Agafonov from Nizhny Novgorod is interested in:

I set out to insulate a private house in order to save energy resources. I decided to use modern technologies, but a dilemma arose: is penofol used as a vapor barrier and insulation at the same time, or should two layers of different materials be laid?

Our expert's answer:

Among modern insulation materials, penofol occupies one of the leading positions in popularity. This is due to the many advantages that the material in question has.

Harmlessness and environmental friendliness: the main components of penofol - polyethylene and foil - are widely used in the food industry and do not pose any danger to human health.

Lightness combined with strength - these qualities allow any type of transportation after rolling the foam foam into a roll.

Moisture resistance – absolute exclusion of moisture absorption and transmission.

Compliance with sanitary and epidemiological requirements - the product is certified, as evidenced by the relevant conclusions.

The presence of soundproofing properties.

Another advantage of the material is its availability - prices do not exceed, and sometimes compare favorably with, the cost of other well-known insulation materials (mineral wool, expanded polystyrene, etc.).

Due to its moisture resistance, the material is universal. In addition to its main task - insulation, it provides complete vapor barrier, since it has a high density and does not allow water to pass through in all its states of aggregation, including steam.

However, there are some nuances that can sometimes radically affect the decision to use penofol as insulation.

The material is too soft - it excludes the possibility of applying wallpaper or plaster on top, which will become a significant problem if insulation is carried out inside the building, since the aesthetic design of the wall is impossible

If you use penofol for outdoor use, it plays the role of an additional layer. Foam plastic is best used as the main insulation material, while penofol will reflect thermal energy and protect the walls from moisture.

Recommendations for selection

To solve different problems it is necessary to use different types of insulation. To increase the thermal insulation properties of parquet flooring, you should choose a solution with a thickness of 25 mm. Isolon is often used for thermal insulation of wooden and concrete floors. For high-quality work, insulation with a thickness of 80 mm should be used.

To carry out measures to create high-quality sound insulation between floors, it is best to use 80 mm material. Such a layer will be quite enough to prevent you from hearing soft music and speech coming from your neighbors. In case of severe acoustic discomfort, to eliminate it, it is necessary to install a more powerful layer.

Izolon is a fairly effective solution for high-quality thermal insulation. With its help you can well insulate any room. Certain types of material provide protection from steam and temperature changes. Proper execution of the work allows you to count on a long service life of the installed layer. If violations were made during the procedure, the process of destruction of the thermal insulation layer will begin quite quickly. In this case, the installation of the isolon will have to be done again.

Advantages

Advantages of isolon:

- Thermal insulation. Indispensable in the construction field.

- Steam and moisture protection. Allows use in wet objects such as baths, swimming pools, saunas.

- Soundproofing isolon.

- UV resistance, which allows its use for external coatings;

- Fire safety.

- Light weight. Does not create additional load.

- Elasticity, which gives isolon its “flexible character”. It can easily take the shape of any object to which it is attached.

- Elasticity. Restores original shape. There is an opportunity to use it again.

- Rot resistant.

- Damping the force of blows.

- Easy installation.

- Safety for people. There are no releases of toxic materials.

- Environmentally friendly material.

- A thin layer of insulation does not reduce the internal dimensions of the insulated object.

The disadvantage of isolon is usually its cost. But if you consider that the service life is 90-100 years, then the investment in its purchase may not seem that big.

What is penofol?

Penofol is a foamed, foil-coated polyethylene with a closed-cell structure. Today you can buy the following types of this material:

The thickness of the pillow may vary.

Penofol has the following characteristics:

How to make long-burning stoves with your own hands: diagram, necessary materials and tools, useful tips.

About where a long-burning furnace can be useful during mining is written here.

By the way! It will be interesting to know: Delta-Dawi GP vapor barrier