To maintain comfortable conditions on balconies, it is necessary to install an insulating layer on the floor slab, ceiling and walls. For finishing, various materials on a natural or synthetic basis are used. The technology of insulating a loggia with isolon, which has good insulating characteristics, does not require special tools; the apartment owner can do the work independently.

To maintain comfortable conditions, you need to insulate the balcony with isolon.

Characteristics of isolon

Thermal-protective material under the registered trademark isolon was developed and produced by Izhevsk Plastics Plant JSC. The coating is a sheet of cross-linked polyethylene that has been processed in an installation that accelerates the movement of electrons.

External influence allows you to create a cross-linked structure, which has a positive effect on strength and resistance to external mechanical or temperature influences.

Main characteristics (using the example of Izolon 500):

- thermal conductivity coefficient - 0.036 W/m*°C;

- density - 33 kg/m³;

- sheet thickness - from 0.8 to 50 mm;

- the material does not absorb moisture, which makes it possible to use isolon for waterproofing;

- the small thickness of the protective layer helps reduce the noise level in the premises;

- increased resistance to petroleum products;

- Possibility of installation on stone and wooden surfaces;

- service life - at least 30 years;

- environmental safety and absence of harmful emissions into the atmosphere.

Izolon is a sheet of cross-linked polyethylene.

Comparison of types of insulation

To avoid problems during the future operation of housing, it is necessary to first familiarize yourself with the technical characteristics of insulating materials and their relationship with the main structures. Only after receiving complete information about the properties of various insulation materials can you safely decide what type of appropriate material can be used to insulate a house.

Currently, mine plate, penoplex and polystyrene foam are used for external insulation.

When analyzing the comparative characteristics of these materials, the main attention is paid to such properties as:

- thermal conductivity;

- density;

- vapor permeability;

- water absorption;

- flammability and so on.

It is necessary that all of the above properties meet the required standards. This, in turn, will help ensure the safety of the house, the formation of its internal climate and a long service life.

In this matter, the type of main material of the house’s structures is important. As you know, it is customary to build housing in a suburban area using wood material, block or brick. The technology for insulating houses directly depends on the main types of materials that were used in the installation of the structure.

For example, for a wooden house, the best insulation option would, of course, be a mine slab. Insulating wooden walls with foam plastic is unprofitable for many reasons. First of all, due to the fact that wood is a breathable material and if polystyrene foam is used, all the important beneficial properties of insulation will simply disappear.

Minslab, in turn, is suitable not only for covering external walls, but also internal partitions, floors and ceilings. Because, together with thermal conductivity, it is an excellent noise-absorbing material.

Polystyrene foam, unlike mine slabs, has excellent contact with wet ground. Therefore, it is more often used as insulation of foundations and various utility networks running underground. Due to its internal properties, polystyrene foam can protect structures for many decades.

In addition to polystyrene foam, many people think of using penoplex. Carrying out a comparative analysis of the properties of materials and finding out their data on thermal conductivity, strength, water absorption, and so on, the majority comes to the conclusion that penoplex is somewhat better. The main disadvantage is the cost.

Insulation with penoplex will cost one and a half times more than using polystyrene foam. It is for this reason that it is often rejected, preferring to deal with cheaper insulation. Such reasoning, when price becomes the dominant component in the choice, can lead to negative consequences.

It is always better to think carefully in advance, what is better, to carry out insulation cheaper, but worse, or to overpay, but in the end get a high-quality insulating, protective coating?

However, polystyrene foam has its advantages over penoplex. The latter, for example, due to insufficiently good adhesion, is not suitable for mounting on walls above the level of the base. Here, preference is given entirely to polystyrene foam or mineral wool, which is even more acceptable, since, unlike mineral slabs, penoplex and polystyrene foam are flammable.

Recently, trends have been observed in Russia aimed at eliminating the use of foam plastic in the construction of houses. It is also worth noting that many European countries have already introduced a ban on the use of such materials due to their toxicity at the time of combustion.

Types of material

The Izhevsk plant uses only cross-linked polyethylene PPE in the production cycle, but some manufacturers use non-cross-linked NPE material to reduce production costs. Refusal to use special equipment allows you to reduce costs while simultaneously degrading performance.

The material is supplied to customers in rolls up to 50 m long or in the form of sheets up to 50 mm thick and up to 2500 mm long.

PPE and NPE

The cross-linked material, which has undergone processing, is distinguished by a 3-dimensional structure of molecular bonds, providing increased strength and resistance to external factors. Izolon of the NPE category has a foam structure and is intended for packaging products; it can be used to protect balconies or loggias, but its service life is 2-3 times lower compared to PPE. An additional disadvantage is poor sound insulation.

PPE differs in the structure of its molecular bonds.

Foil isolon

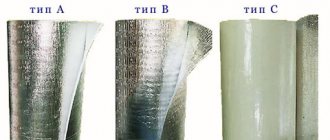

There is a material with aluminum foil applied to the surface:

- category A with 1-sided coating, polyethylene thickness - from 3 to 10 mm;

- class B, characterized by increased strength due to 2-sided foil lining;

- category C, having an additional adhesive backing;

- ALP class with an adhesive backing and an additional layer of polyethylene on top of the foil.

Extruded polystyrene foam

Penoplex is a tile insulation made from extruded polystyrene foam.

Unique thermal insulation characteristics are achieved thanks to the smallest cells filled with air. Penoplex has a bright and recognizable orange color

Penoplex has excellent chemical resistance, but it is important to know that it is absolutely not resistant to gasoline (just like Technoplex). Due to its good strength properties, Penoplex can be used for external insulation

There are different types in the Penoplex line (their names speak for themselves):

- roofing (insulation of attics and roofs of various configurations);

- wall (basement, walls, partitions, facade are insulated);

- foundation (used as insulation for the basement and floor of the first floor);

- comfort (can be used for any work, but is especially well suited for insulating apartments and balconies);

- 45 (has the best characteristics of all types, used in road construction and bridge construction).

. Penoplex is available in standard width and length - 600 mm by 1200 mm, respectively. But the thickness varies - from 20 mm to 150 mm.

Penoplex is used at temperatures from -50 0 C to +75 0 C. Water absorption - 0.4% - slightly worse than Technoplex, but still a very high figure. Thermal conductivity is 0.03 W/(m*K).

Advantages and disadvantages

Main advantages of the material:

- good protection from extraneous noise (regardless of the frequency range);

- resistance to petroleum products (for example, organic solvents);

- low specific gravity;

- elastic structure allows you to compensate for unevenness on the floor;

- ease of machining and installation;

- resistance to moisture (depending on the thickness, water absorption ranges from 0.2 to 0.7 cm³ per m² of surface).

The advantage of the material is good protection from extraneous noise.

Disadvantages noted by craftsmen and owners of insulated premises:

- insufficient mechanical tensile strength;

- deformation of the layer under increased loads;

- difficulties when transporting sheet material;

- predisposition to surface electrification;

- It is not allowed to apply a layer of screed or plaster over the isolon without installing a rigid shield.

Insulation of a balcony or loggia with isolon

Insulating balconies with isolon allows you to maintain a positive indoor temperature in the winter. Before starting installation work, it is necessary to carry out calculations and determine the thickness of the layer. A number of publications indicate that to protect a room from the cold, it is enough to install rolled foil insulation with a thickness of 3-5 mm. But calculations show that to maintain a temperature difference of 10°...15°C it is necessary to install slabs of material up to 100-150 mm thick.

Insulation calculation

Initial data for calculating the insulator layer:

- minimum winter temperature;

- desired indoor temperature;

- duration of the heating season;

- average temperature during the heating season;

- number of degrees/day during operation of heating systems;

- thermal conductivity coefficient for balcony fencing.

Calculation methods and coefficient values are given in SNiP standards (depending on the territorial location of the residential building). For example, in Moscow and the Moscow region, the total thermal resistance of the walls, floor and ceiling on the balcony should not fall below 2.99 W/m*°C. It is possible to achieve the required values in the central zone of the Russian Federation only by installing isolon with a thickness of at least 100 mm.

The use of rolled material 6-10 mm thick with a metallized coating does not protect the room from freezing at temperatures below -15°C.

Required tools and materials

To complete the work you will need:

- perforator;

- hacksaw or electric jigsaw;

- tape measure, square and pencil;

- a set of bits with a flat and cross-shaped tip;

- electric screwdriver;

- chisel and hammer;

- roll or sheet insulation (quantity and thickness depend on the size of the room and climate zone);

- metal tape;

- polyurethane foam;

- construction knife.

To complete the work you will need a hammer drill.

Preparation

Before starting work you must:

- Remove furniture from the balcony and remove foreign objects from the walls.

- If boards are laid on the floor, then it is necessary to dismantle the protective covering.

- Remove dust and debris with a construction or household vacuum cleaner.

- Remove the loose layer of cement from the floor surface and saturate the base with a primer. Places with dips or deep cracks must be filled with liquid solution.

Ceiling

Ceiling insulation algorithm:

- Mount wooden guides in increments of up to 600 mm. Align the elements horizontally using a building level, and place washers under the beams to adjust the position.

- Insert pre-cut sheets of isolon between the sheathing; overlapping fragments is not allowed.

- Seal the joints with aluminum adhesive tape to prevent cold air from penetrating through the cracks.

The owners install isolon on the ceiling.

Some owners install metallized isolon up to 5 mm thick on the ceiling, and then install foam sheets. After sealing the cracks with polyurethane foam, you need to attach the finishing layer of isolon with steel staples to the sheathing, and then proceed to finishing the walls and flooring.

The thickness of the combined thermal insulation depends on climatic conditions and the minimum permissible temperature on the balcony or loggia.

Floor

Algorithm for insulating the floor on the balcony:

- Attach horizontal guide rails to the concrete slab in increments of 500-600 mm, and then lay rolled mineral wool. If the floor slab has a slope, then beacons should be pre-installed and a horizontal screed should be installed.

- Lay rolled insulation on top of the mineral wool, pointing the metal covering towards the room. Stretch the material and attach it to the guide frame with steel staples for a construction stapler.

- Install the top layer of sheathing with cross members oriented at a 90° angle to the bottom frame.

- Mount sheets of waterproof plywood with screws, and then lay down the finishing.

Walls

To insulate walls you need:

- Apply vertical marking lines and attach wooden blocks (the height corresponds to the thickness of the layer), the step between the elements should not exceed 900 mm. For fastening, use screws that should be screwed into the mounted concrete partitions.

- Install pre-cut thermal insulation boards in the gaps between the bars and fill the resulting gaps with foam or sealant.

To insulate the walls, it is necessary to install thermal insulation boards.

Some owners use a combined method of insulating walls, using foil insulation and polystyrene foam. The inner layer consists of foil polyethylene, which is laid with metal towards the wall to protect it from moisture and freezing. Then a foam board is installed and covered with a second layer of isolon, the resulting gaps between the frame and the foam are filled with foam.

After trimming the excess foam, the balcony is finished (for example, with a tongue-and-groove board or plastic panels).

What to choose

If we compare these two insulation materials, then Technoplex is more technologically advanced and has better qualities, but the difference between it and Penoplex is so insignificant that it is impossible to say for sure which one should be chosen.

After the construction of a building, the owners always wonder what kind of insulation is best to use for, strictly speaking, thermal insulation of the home.

And this question is quite reasonable, since the construction market has a colossal number of different insulation materials, which, as it seems to many, only specialists can compare in terms of efficiency.

And given the fact that Penoplex and Technoplex are now the most popular insulation materials, this article will focus on which of these insulation materials is better, and what is the difference between them.

How much does it cost to insulate balconies with isolon?

The cost of Isolon 500 material with a thickness of 8 mm starts from 370 rubles. for 1 m², metallized Isolontape 500 will cost the buyer 290 rubles. for 1 m². A sheet isolon block measuring 1x1 m with a thickness of 100 mm is estimated by the manufacturer at 740-750 rubles. for 1 piece For example, a standard balcony has a floor area of 3 m², the price of material for thermal insulation of the base will be about 2.2-2.3 thousand rubles. (excluding wooden slats, polyurethane foam and fasteners). The cost of completely insulating a room with isolon with your own hands will be at least 12 thousand rubles.

Insulation of balconies with isolon starts from 370 rubles. for 1 m².

Common mistakes

Common mistakes when insulating:

- Insufficient thickness of the thermal insulation layer, which leads to freezing of part of the walls with condensation and the formation of mold on the decorative finish. Izolon has thermal conductivity at the level of foam plastic and is inferior to extruded polystyrene foam, so the thickness of the protective coating should be 100 mm and above.

- Laying 10 mm thick isolon on the floor followed by the use of electric heating. Due to insufficient thermal insulation, the system operates in constant mode, which causes excessive energy consumption. For example, the power of a heated floor for a balcony with an area of 3 m² reaches 500 W, per day the electricity consumption will be 10-12 kW/h, and in a month the parameter will reach 300-370 kW/h. With an average price of 5 rubles. per kW/h, additional costs for the apartment owner will amount to 1.5-1.85 thousand rubles.

Expert opinion

What is better - polystyrene foam or penoplex?

Experts give a clear answer to this question. In terms of its characteristics, penoplex significantly exceeds those of foam plastic. Therefore, this material was able to gain its place in the market. Even at a significantly higher cost, extruded material is often purchased for various construction works. Penoplex also inherited some of the disadvantages of polystyrene foam. This is a vapor-tight and flammable material. However, it fully copes with its thermal insulation functions. This allows us to speak about the high efficiency of penoplex. Polystyrene foam has a fairly limited area of application. This is also a drawback of the presented material.

The house should not only be beautiful and comfortable, but also warm

Therefore, it is very important to choose the right insulation

There are many different insulation materials on the construction market. This article will tell you about such modern insulation materials as Technoplex and Penoplex, how they differ and which one is better to choose.

Let's start with what they consist of. Both insulation is made of extruded polystyrene foam (EPS). EPS is heated polystyrene (the familiar white foam balls) and a foaming agent.

Recommendations from experts

When insulating a wall, it is necessary to provide an air gap between the protection and the finishing. It has a size of 5-10 mm and ensures air circulation and removal of water vapor. When laid tightly, damp areas are formed in which mold and rot appear. In addition to the unpleasant odor, mold fungi release spores into the air, which negatively affect the human immune system and cause allergies.

To reduce heat losses, it is recommended to install plastic or wooden windows with double-glazed windows. There should be no deep cracks on the horizontal or vertical surfaces of the balcony through which cold air enters the room. The edges of the fractures should be cut, and then the voids should be filled with cement mortar (to increase strength, install scraps of thin reinforcement or screws with a cut off head into the mixture).

https://youtube.com/watch?v=G1GqKzxMbIE