MesterulManole

7135 0 0

MesterulManole September 18, 2016Specialization: many years of experience in finishing works of residential and office premises, dachas, country cottages, etc. Hobby: cycling in all its forms

A typical example of the use of reflective glazing cladding on the sunny side of a façade

Greetings. Today I’ll talk about how mirror film is installed on windows , what it is and why it is needed at all.

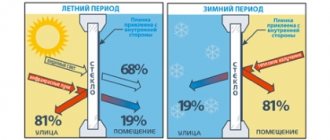

With the onset of the warm season, mirror reflective films are in particular demand. This is not surprising, since the sun's rays are reflected from the mirror surface and, as a result, the air in the room warms up less in comparison with those rooms in which the windows do not have a protective film covering.

Let's take a closer look at the characteristics of the protective film

Which film is right for you?

And sun protection comes in different forms!

- To ensure privacy in the house - mirror film . It not only protects from the sun and shades, but also closes the room from the street from prying eyes.

- To absorb blinding rays and glare - tinting film . It provides natural light in the room, without wallpaper, curtains, furniture fading in the sun, and without glare on monitors.

- To protect against overheating of the house and harmful UV radiation - athermal film . It shades, reflects IR and UV rays, and this solar control film for windows also reduces stuffiness and heat in the room.

Reflective glasses

The effect of mirror coating on glass is obtained under the influence of high temperature. The transparent coating blanks are placed in an oven, which is heated to 650 C. The molten raw material is first rolled out with rollers, then treated with metal oxides. At the last stage, the material is hardened with air, increasing strength and light absorption parameters.

What are there

The characteristics of the structures depend on the type of raw materials in the package. Mirror glass for windows is available in three types:

- Absorbing. Treated with metal oxides. The material “absorbs” ultraviolet radiation, so only 1/3 of the radiation enters the room. Made in blue and greenish tones.

- Reflective. Sputtering consists of ceramic, metal oxide or polymer particles. Glass surfaces repel the sun's rays from the windows, maintaining a comfortable microclimate. The color is silver.

- Combined. First, layers of metal oxide are applied, and after cooling, a silver coating is applied. The models simultaneously absorb and reflect ultraviolet radiation from structures.

Mirror-coated glass is inserted into a standard window frame. The products are able to block up to 60% of solar radiation from entering the room. The thickness of the transparent material varies between 6-10 mm.

Reflective glasses Source windowssearch-exp.com

Prices for covering windows with solar control film

| Color | vendor code | Price, rub/m2 | |

| Film type: sun protection | |||

| Silver mirror | Silver 15/20 | 650 | |

| Silver mirror | Silver 35 | 650 | |

| Silver mirror | Silver 50 | 650 | |

| Gray-mirror | Gray 10 | 750 | |

| Gold-mirror | Gold 15 | 750 | |

| Bronze mirror | Bronze 15 | 750 | |

| Blue-mirror | Blue 15 | 750 | |

| Green-mirror | Green 15 | 750 | |

*prices are valid for orders of at least 10 m2. Discounts are calculated individually for orders over 50 m2.

For faster ordering, please call

+7

LEAVE A REQUEST FOR SERVICE

Examples of our work

Video description

Mirror coating on glass

Disadvantages of raw materials

High cost is the main disadvantage of mirror glass units. The raw materials have a complex manufacturing technology, consisting of several stages. The length and painstaking nature of production is reflected in the final price, which is why not everyone can afford high-quality material. Most often, the products are installed in administrative and shopping and entertainment buildings, less often in high-rise buildings and cottages.

High price Source ba-bamail.com

It is better to order glass with mirror coating at the glazing stage. Of course, you can replace the transparent material in existing bags. The quality of such structures is much worse than that of new ones, which will negatively affect the microclimate of the room.

Absorbing mirror glass units for plastic windows get hot. Due to its absorbent properties, during solar activity the surface becomes very hot, and in the evening it cools down sharply. With such fluctuations, the material cools unevenly, so it gradually loses its properties and may crack. The model should not be used on south-facing balconies.

Disadvantages of reflex types Source stihi.ru

What effect to expect

Professionally applied solar protection film provides you with the following:

- Comfortable temperature in the apartment/house/office even in the summer heat.

- Long-term preservation of the color of wallpaper, curtains, furniture, plants on window sills.

- Effective work at the computer at any time of the day, without glare.

- Protecting your privacy and privacy.

- Protection from sharp fragments in case of damage to windows and display cases.

- In summer, reduce the load on the air conditioner and fan.

- Pleasant microclimate in every room.

But just remember - the film must be applied very high quality, carefully, without the slightest defects that reduce its service life. The most correct option is to buy solar control film for windows with installation, so as not to worry about its further installation. Our company offers a variety of films with installation and guarantees the quality of all operations performed! You can even choose the color of the future film.

How to make a mirror surface on glass at home

The ability to create mirrors with your own hands is a fascinating activity. Even though furniture stores are full of mirrors of every shape and size, creating something with your own hands brings special pleasure. From a practical point of view, this is even a useful activity. Because it can be useful in repairing optics and lighting devices containing mirror elements. However, this will require a separate room with the functions of a chemical laboratory.

Necessary materials

To work you will need the following elements:

- Goggles, rubber gloves, respirator;

- Vessels or containers for working with solutions, glass rod;

- Silver nitrate;

- Caustic potassium;

- Ammonia;

- Spray;

- The piece of glass is high quality, beautifully shaped, smooth;

- formalin in solution;

- Paint of any color;

- Chalk;

- Cuvette;

- Distilled water.

Useful: You can obtain silver nitrate yourself from an old silver coin by dissolving it in a 10% silver solution. Be sure to follow protective precautions when doing this.

Procedure

To create a mirror, the technique of chemical silvering of glass is used. First, you should properly prepare the glass surface of the future mirror, always holding it only by the edges so as not to leave stains on the smooth surface. For this:

- it is washed well on both sides, as well as the ends, with distilled water and crushed chalk;

- the entire area of the glass is degreased by wiping it with a napkin containing an alkali solution of 10 - 15% consistency;

- wash again with distilled water;

- dried;

- immersed in heated distilled water (the glass blank should be 10 degrees hotter than the silvering solution).

Next, a silvering solution is prepared. This is a two-step process:

- Stage one. Distilled water is mixed with silver nitrate in a proportion of 30 ml per 1.6 g. 25% ammonia is dripped into the resulting composition until the sediment disappears. As soon as there is no precipitate, add 100 ml of distilled water.

- Stage two, final. The resulting solution and 5 ml of formalin solution of 40% consistency are mixed. The solution for silvering is ready.

The glass is removed from the warm aqueous environment and placed on a special flask or cuvette. The silvering solution is poured into the middle and rolled out in an even layer using a glass rod. You can lower the glass blank directly into the solution, but so that the opposite side is not flooded with it. The chemical reaction takes three to ten minutes. After finishing, the resulting mirror surface should be washed with distilled water.

Next, the process of making the mirror continues with two hours of drying of the silver-plated surface. In this case, the temperature is maintained at a level of 100 to 150 degrees. The glass must be vertical. After the specified time has passed, the cooled surface is coated with transparent varnish using a spray bottle. If you get silver streaks, you should wipe them off with a cloth with a weak solution of nitric acid before applying the varnish. The silvering process is completed by horizontal drying of the mirror.

If the inner surface of the glass is endowed with the properties of a mirror, opaque paint of any color is applied on top of the silver layer. In order for the outer surface to serve as a mirror, the glass blank is kept completely lowered into a special container with a silver composition for 5-10 minutes.

Important: When working with chemicals, be sure to use goggles, a respirator and rubber gloves. It is forbidden to breathe the fumes of the resulting solutions. If it gets into eyes, rinse with clean water and consult a doctor.

Recommended reading

How to improve a wooden house using drywall Choosing plywood - all the selection and search criteria Artificial lawn and some of its features Choosing and purchasing an IP camera: key features and comparison of models

Add a comment Cancel reply

Manufacturing technology

Rice. 5. Examples of using mirror film

The main component in the manufacture of mirror film is polyester. Raw materials must be thoroughly cleaned and sorted. The material is multi-layered, each layer in thickness does not exceed 20 microns. Additional functions can be added by adding additional spraying. The manufacturing company rolls the layers until a homogeneous base is created. After the necessary actions under high temperature, a single structure is obtained.

It is important to choose a high-quality base so that the final material meets all requirements. One of the necessary conditions for the finished product is the absence of distorted reflection when looking at the surface. The condition is achieved by selecting layers of equal thickness. Manufacturing technology is constantly being improved, and the physical and chemical properties of the components used are improving.

Nowadays it is difficult to find a film on which scratches appear when washed with abrasive substances, although previously there was no other option. When the concentration of one of the constituent substances decreases, the properties of the coating also change, for example, the degree of light transmission. The glue used is one of the important components. It acts at the molecular level, connecting all elements together. If you buy a high-quality mirror coating, its use will last for several decades.

Why you should trust us with the installation

- We do it with high quality: without peeling, bubbles, cracks or stains.

- Measurements and consultations are free.

- We will help you choose the film to suit your needs.

- We calculate the cost and include it in the contract.

- We comply with deadlines and all terms of cooperation.

- We guarantee our work.

If you are looking for something to shade your balcony, then tinting with a mirror film is the most reliable, durable and economical way. Contact us to receive quality service and professional advice!

SUBMIT YOUR APPLICATION

Balcony tinting with film - what to look for

Today it is probably difficult to imagine a house that would not have glazed balconies or loggias. But just recently, some twenty years ago, representatives of a housing office could fine the owner of an apartment for unauthorized glazing of a balcony, since it was believed that in this way the opportunity to leave the premises in the event of a fire was blocked.

But, despite all the prohibitions, people continued to glass their balconies, because they were primarily concerned about preserving heat in their home, and of course, a glass balcony looked more attractive compared to its “naked” counterparts.

In addition, the skilled owners managed to equip a kind of workshop on the balconies, and also built in cabinets for storing preserved food or various things that were unnecessary now, but so necessary on occasion.

Today everything has changed, and it is no longer possible to imagine a new building in which the loggia would not be glazed. But with the installation of double-glazed windows on balconies (loggias), a new problem appeared.

Heat and stuffiness, these eternal companions of panel high-rise buildings. The fact is that a glazed balcony essentially turns into a greenhouse, accumulating the sun's rays indoors, and being in such a room in the hot summer becomes not very comfortable, especially if it is not possible to install an air conditioner.

But unfortunately, not all people can stay in a stuffy room or apartment with air conditioning for a long time, since due to the weakness of the body they are susceptible to various kinds of diseases, from hypertension to colds.

What should these people do? Should we resign ourselves and suffer in silence, waiting for cloudy days, or should we look for ways to solve the problem?

Disadvantages of mirror glass units

Rice. 12. Pasting the film

Mirror double-glazed windows are made in a special way. They are able to reflect ultraviolet rays well. Infrared radiation, which is harmful to the human body, is almost completely absorbed. A high sun protection effect does not interfere with the penetration of a sufficient amount of light into the room, or the choice of the degree of penetration of sunlight. Natural lighting ceases to be harsh and becomes pleasant and warm.

In addition to the listed properties, the external characteristics of the building are improved, due to which the materials are increasingly used in the construction of entertainment centers or sports complexes. The price depends on the properties of the surface. There are a certain number of disadvantages that you should know before purchasing products:

- Reflective double glazed windows can deteriorate if exposed to excessive heat. Visible stains appear on the surface, spoiling the appearance.

- Using film as a protective coating for double-glazed windows requires time for pasting and investment of money. Artificial coating costs an order of magnitude more than film.

- If the protective film is applied incorrectly, the appearance may be damaged. Leaving burrs along the edges (applies to the protective film) is unacceptable, as they will begin to curl up, spoiling the attractive appearance.

- The reflective properties disappear at night, when the inside of the room becomes an order of magnitude lighter than outside.

Can protective film replace grilles?

Yes, if the purpose of installing bars is to prevent unauthorized entry into the premises. A blow with a hard object to glass with an impact-resistant film punches a hole in it approximately the same size as the impact weapon. It will take considerable time to widen the gap necessary to gain access to the interior of the room. This means that security staff have the opportunity to respond to an alarm and prevent a crime. In addition, any object thrown into glass with an armor film, be it a stone, a grenade or a Molotov cocktail, bounces off and remains outside. If there is a need to leave the room through a window (for example, in case of fire), then such glass can be easily squeezed out from the inside.

Advantages of vacuum deposition of titanium

When applied in a vacuum, titanium is deposited, resulting in a uniform and reliable thin-film coating. In addition, titanium deposition in a vacuum environment on glass and mirrors has other advantages:

- High degree of adhesion between titanium and workpiece.

- High chemical resistance of titanium coatings.

- Possibility of adjusting coating properties.

- Obtaining coatings with a given degree of reflection and transmission.

- Reasonable price for mirrored and tinted products obtained in this way.

What are your benefits when tinting a balcony or loggia?

Protection from prying eyes and vandals.

Savings - Reduce your energy costs.

Comfort - no more blinding sun and heat on the balcony.

Safety - if the glass is damaged, the fragments remain on the film and do not injure.

Comfort - at any time of the day, summer and winter.

Lightness - the interior of the balcony will not have thick curtains or rattling blinds.

Durability - tinting a loggia with mirror film can last for many years.

You do not need special care for the film coating! It's simple: it is washed with liquid detergent and wiped dry. The film does not fade or lose its properties, and can easily withstand a wide range of temperatures and any humidity.

What is window tinting?

Windows are an integral part of every home. It is through them that sunlight penetrates into our houses and apartments. But sometimes there is a lot of this sunlight, which causes the air to warm up too much.

In addition, under the influence of direct sunlight, furniture and appliances deteriorate, wallpaper fades, etc. In order to avoid all these troubles, use window tinting on balconies and loggias.

Tinted windows not only look much more attractive against the background of ordinary ones, but also give the apartment’s inhabitants long-awaited coolness

Window tinting involves covering the glass with special films. At your discretion, you can choose the degree of darkening, preferring a darker/lighter option.

This service is quite expensive, but you can do the tinting on your own without resorting to the services of specialists. To do this, you will need to choose the appropriate material and do the pasting yourself, but more on that below. First, let's look at the types of tint films.

Features of film selection

In order not to be disappointed with the result, when choosing a tint film, be sure to pay attention to such an indicator as light transmittance . It is expressed as a percentage and the higher this value, the higher the ability of the material to transmit light.

The next thing you need to pay attention to is the color of the film . Of course, choosing the color of the film that suits the interior of the room is not so difficult, but do not forget that the color is directly related to the ability of the material to transmit sunlight.

| Film color | Transparency level, % |

| Silver | 15-50 |

| Violet | 15 |

| Gold | 15-35 |

| Bronze | 15 |

| Smoky | 20 |

| Green | 15 |

| Grey | 15-35 |

| Blue | 15-35 |

| Solar Bronze | 20-35 |

Brand and price . You should also not save on material by purchasing cheap and low-quality products. It will be money wasted. Such material will not provide sufficient protection from sunlight, and is unlikely to last long.

Therefore, it is better to give preference to well-established manufacturers. Among which are: Armolan, Professional Window Film, Sun Control, Ultra Vision, Eastman Chemical.

In today's market, the choice of tinting films is huge. Everyone can find a suitable option, but you shouldn’t save on your purchase. It's better to pay a little more and buy really high-quality products

A protective layer against scratches is also important . Most cheap materials simply do not have it, so leaving a mark on such a coating will not be difficult, which cannot be said about branded films that have reliable protection against mechanical damage.

If you live on the ground floor, it would be a good idea to purchase a protective film of class A1 - A3. With such a coating, double-glazed windows will be almost impossible to break.