Stucco molding in a modern interior is always original, relevant and aesthetically beautiful. A wide range allows you to bring any interesting idea to life. In order for the implementation of a design project to meet expectations, special attention must be paid to the installation process and the choice of adhesive. The composition used should ensure simplicity and ease of use, as well as high reliability of fastening. Polyurethane stucco molding belongs to the category of lightweight materials that are easy to install and process. Anyone can cope with the installation process; it is enough to follow the basic recommendations from stucco and adhesive manufacturers.

Main types

Manufacturers offer two main types of glue:

· installation;

· docking.

Depending on the characteristics of the installation process, an adhesive putty or a super-strong fixation composition is selected.

Rating of adhesives for baseboards

When compiling the review, the products of Russian and foreign factories were analyzed. Ease of application, presence of unpleasant odor, and complexity of installation were assessed. User reviews and opinions of professional builders were taken into account. The main attention was paid to the following parameters:

- Material – they produce compositions for working with polystyrene foam, wood, plastic;

- Strength – the ability to withstand load after polymerization;

- Drying speed – affects the finishing rate;

- Safety is an advantage for environmentally friendly and fireproof compositions;

- Economical – consumption affects the cost of work.

Low adhesion to base materials, inability to hold a load for a long time, consistency that does not correspond to the stated characteristics - products with such shortcomings were excluded from our rating.

Sticking to different surfaces

There are some features of attaching baguettes to walls and ceilings, depending on the type of base material. The differences are described below.

On a suspended ceiling

Now stretch ceilings are at the peak of popularity; they are installed everywhere. A smooth surface is achieved without laborious leveling, the design can be varied

Before starting work, you need to pay attention to some features:

- Light weight. It is best to buy foam, polystyrene foam products; plastic and polyurethane products are slightly less preferable.

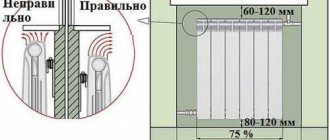

- Special form. The side lying on the ceiling is smaller in size than the side located on the wall. This is due to the specifics of gluing - the substance is applied only to the part of the panel adjacent to the wall. Do not apply glue to the baseboard on the ceiling side!

- Reliable composition. You should choose a product with maximum hold, quick-drying, and durable.

- Additional fastening. If wooden cornices or other massive skirting boards are chosen, they are secured with glue and dowels and anchors.

PVC plinth looks good on a suspended ceiling. It is secured with clips, they must be mounted with self-tapping screws. The corner is decorated with one plank, which is bent. It is necessary to glue the baguettes carefully - if glue stains get on the stretch ceiling, it can cause damage.

For wallpaper

By purchasing high-quality glue, you can install the border in its “rightful” place

It is important to make sure that the wallpaper adheres securely to the wall, especially if the finishing was done a long time ago. If necessary, glue the canvas with wallpaper glue and wait 1-2 days

You can also use PVA glue. When installing cornices, try not to stain the wallpaper. To do this, first make a thin mark with a pencil along the width of the baseboard, then stick masking tape to the border. Upon completion of the work it is removed.

For plaster

Before attaching the baguette, it is important to check how smooth the surface is. Small defects can be sanded down or left unchanged if glued to a putty mixture

She will straighten the wall, eliminating imperfections. You can also purchase skirting boards with soft edges to smooth out uneven surfaces. If there are significant defects, you will have to eliminate them - level the wall, prime and sand.

On drywall

Since drywall is a very smooth material, gluing ceiling panels to it is a pleasure. Only at the joint areas of gypsum board sheets may putty drips remain, which must first be cleaned with sandpaper. Any type of skirting boards is suitable for gypsum plasterboards. Reducing the area of the room when using drywall is inevitable. To visually expand the space, you can attach cornices with the wide side to the ceiling. This will enlarge the room and will look original.

The best liquid nails for baseboards

A special feature of liquid nails is the mandatory presence of mineral fillers. This makes the composition thick and improves adhesion to plaster, brick, and concrete. The best manufacturers use plastic clay as a filler. The composition allows you to make a thick seam, which is important when installing to uneven surfaces. The products are characterized by a high setting speed and increased fixation. Supplied in special tubes for easy application.

Orac Axxent FDP500

The composite is based on acrylic copolymers; water is used as a solvent, which makes it safe for humans. Designed for indoor use on porous surfaces. Designed for fixing polyurethane stucco molding - cornices, moldings, rosettes. Forms a strong, durable connection between decorative elements and a plastered wall or ceiling.

Supplied in a tube, extruded using a construction gun. The composition is economical: a volume of 310 ml is enough for 10-15 meters of surface. If necessary, the product can be easily removed with a wet cloth or sponge. It is not afraid of frost and temperature changes, which simplifies storage and transportation. Stucco can be painted 24 hours after application.

Advantages:

- Strong hold;

- Good adhesion to mineral substrates;

- After application there is enough time for adjustments;

- There is no unpleasant smell.

Flaws:

- Not detected.

The composition has good adhesion to wood, polystyrene foam, gypsum, MDF and chipboard. This expands the scope of application and allows it to be used for working with decorative elements made of different materials. The adhesive seam can withstand high loads.

Tytan Professional Classic Fix

Designed for interior and exterior finishing work. The base is durable and elastic rubber, which allows the seam to withstand temperature changes and linear expansion, and maintain strength even with slight shrinkage of the building. Transparent color allows you to work with different materials when solving complex decorative problems. Fast initial setting ensures strong fixation within 10-15 minutes.

Has good adhesion to most general construction and finishing materials. Can be used for mounting light and heavy decorative elements made of wood, polyurethane, hard and impact-resistant plastic. The seam is resistant to moisture and temperature changes. Does not contain benzene, toluene, safe for health.

Advantages:

- Easy application;

- Wide operating temperature range;

- Good strength;

- Low consumption;

- Environmentally friendly.

Flaws:

- Full strength set 48 hours.

Soudal 48A

Designed for finishing wood panels, a good option for those who decide to glue baseboards to the floor using liquid nails. Supplied in a convenient cartridge, which is convenient to work with in cramped conditions. It has high adhesive strength to materials such as ceramics, natural and artificial stone, and metal. Apply to only one surface, which reduces consumption.

The setting time is 1 minute, which makes it not the best choice for fixing long ceiling skirting boards. Reliably fixes decorative elements to porous and smooth surfaces. Can be used when installing window sills, step edges, floor panels made of wood, chipboard, MDF or polyurethane.

Advantages:

- Durable seam;

- Frost resistance;

- No unpleasant odor;

- Does not emit harmful substances.

Flaws:

- Not suitable for polyethylene, polystyrene.

The best manufacturers of quartz vinyl tiles

Instead of an epilogue

An analysis of the market for adhesives for skirting boards has revealed that for the most part in the Russian Federation there are universal options like “liquid nails”. The remaining samples are unpopular due to their low functional properties, lack of high-quality equipment (for example, a construction spout), as well as outdated chemical composition. At the same time, it is worth noting that, as such, highly specialized compounds will soon fall into oblivion and most adhesives will simply be combined under the simple name of “installation adhesive.” The cost of such goods in Russia is very affordable, and the product range provides the maximum breadth of choice. At the same time, in this segment, up to 80% of goods are presented by foreign manufacturers.

The best adhesives for polyurethane skirting boards

Decorative products made from polyurethane are characterized by high strength, durability, and resistance to aggressive substances. Moldings made from this material are used for interior and exterior decoration. Adhesive for polyurethane skirting boards has good adhesion and forms a durable layer that is resistant to temperature changes.

KIN

Universal liquid composition, ready for use. Has good adhesion to mineral substrates and polyurethane. Capable of gluing porcelain, rubber, hardboard, and will provide good fixation to stone, chipboard and wood. Forms a transparent seam, which helps improve the decorative qualities of the finish. It has water-repellent properties and does not lose its characteristics at high humidity.

It has high tear strength: to perform dismantling, you need to apply a force of 20 kg per square centimeter. Supplied in a convenient plastic bottle with a dispenser. The consumption is small - 500 g is enough for an area of 10 sq.m. It is enough to apply it once to a smooth base; apply it twice to a porous base. Drying takes no more than 20-30 minutes, this allows you to make adjustments. Full strength gain – a day.

Advantages:

- Easy to use;

- Low price;

- Large volume;

- There is no unpleasant odor;

- Durable seam.

Flaws:

- Not detected.

2. Europlast

Made on the basis of aqueous acrylic copolymers, it has a paste-like consistency. Designed for installation of decors made of polyurethane and foam plastic. According to user reviews, it provides good fixation on porous substrates. Recommended for working with treated wood, concrete, brick. A weak base is pre-primed with acrylic or polyurethane primers.

To fix it, just press the decor against the base for 3-4 seconds; you can make adjustments within 10-15 minutes. The seam reaches full strength after 24 hours. Supplied in cartridges for a construction gun. It is characterized by easy application and low consumption. The tube contains detailed instructions for home DIYers.

Advantages:

- Resistance to high humidity;

- No pungent odor;

- Does not move off the surface;

- Can be used as adhesive putty.

Flaws:

- Overcharge.

Installation technology

Necessary tool

- Knife with replaceable blades

universal knife with retractable, replaceable trapezoidal blade

- Carpenter's pencil

- Roulette

- Miter box (device for cutting moldings at a certain angle):

miter box for making cuts from wood, plastic, polyurethane in workpieces of medium and small thickness at angles of 45 and 90

Miter box Matrix 420 mm precision

- Installation gun for sealant:

Assembly gun for glue and sealant

- Rubber spatula

Required material

- Ceiling fillet (plinth) PVC

- Corners for fillets (internal and external)

- Glue or putty

- White acrylic sealant

Basic principles of installation

- It is advisable to start gluing the ceiling plinth from the most visible inner corner.

- We cut the fillet using a miter box, file or knife from one edge at 45%:

plinth trimming

- We install a tube with the selected glue into the mounting gun, then apply the composition in a wave-like motion to both shelves of the plinth:

Applying glue to the baseboard

- We coat the joint of the skirting boards with glue.

- We carefully remove the glue that came out during installation with a damp cloth and carefully smooth the joints with a rubber spatula.

- When working with external corners, first glue long pieces of baseboard, and then make short inserts.

- After the glue has dried, fill all the gaps with acrylic sealant and clean the seams again with a rubber spatula.

cleaning joints using a rubber spatula

The best adhesives for foam and plastic baseboards

Plastic floor skirting boards and foam fillets are the best materials for budget renovations. The products are distinguished by their low price, easy installation, and low weight. Adhesive for foam ceiling plinths may not contain mineral filler. Such substances have proven themselves well when working with plasterboard bases. Liquids for working with PVC may have a mineral filler: a paste-like consistency can fill small cracks.

Moment Installation Express MV-50

Developed on the basis of acrylic copolymers according to recipes from the German company Henkel, intended for interior use. Has good adhesion to styrofoam, PVC, MDF, plaster and wood. Initial setting force 50 kg/sq.m. makes it a good adhesive for ceiling skirting boards and decorative foam tiles. The lifetime is 15 minutes - this is enough to make adjustments. Full strength gain – within 24 hours.

Forms a strong seam that is resistant to moisture and temperature changes. The consumption is small, depending on the degree of porosity of the surface and the material of the decorative elements. Supplied in a cartridge made of elastic plastic. Easily extruded with a gun.

Advantages:

- Cost-effective;

- Low price;

- Does not contain organic solvents;

- Without smell;

- The putty surface can be painted.

Flaws:

- One of the surfaces when gluing must be porous.

Quelyd Mastifix Ultra

Acrylic adhesive for floor plinths is intended for work indoors or under a canopy outdoors. It can be used when decorating walls and ceilings with heavy stucco, since the maximum tensile load reaches 70 kg/sq.cm. It is used for installation of plastic boxes and trays, beams and cornices made of polyurethane, wood products and polystyrene foam. Has good adhesion to substrates such as brick, plaster, cement plaster.

It sets instantly, but within 15 minutes the finisher has the opportunity to make corrections. The composition contains a filler, which allows gluing to the base with differences of up to 5 mm. After polymerization it can be painted with acrylic paints. The frozen seam can withstand temperature changes from minus 30 to plus 130 degrees.

Advantages:

- Ultra-strong fixation;

- Without odor and organic solvents;

- Moisture resistance;

- Convenient cartridge spout.

Flaws:

- Complete drying in 72 hours.

Titan Wild

A gel-like composition based on polymers, which ensures reliable fastening of plastic additional elements. It is used on mineral substrates - cement and gypsum plasters, plasterboard, brick. You can glue fabric, wood and leather. The product is one-component, ready for use. Supplied in a large bottle. The presence of a dispenser helps regulate flow.

The composition forms an elastic seam that retains its characteristics at temperatures down to -30 degrees. Over time, according to user reviews, it does not become fragile and does not flake. The color is transparent, which is important when working with finishing materials that have complex textures.

Advantages:

- Cleanses well from the skin of the hands;

- Short setting time;

- Low consumption;

- Low price.

Flaws:

- Excess has a negative impact on the quality of fixation.

General gluing rules

Any plank, be it molding or baseboard, can be quickly and easily glued using the following procedure:

- The selected segment should be turned with its back, and the adhesive composition should be applied to it in small drops at a distance of 3-5 centimeters from each other (for narrow parts);

- If the width of the part exceeds 6 centimeters, it is preferable to apply the mixture on the back side in the form of a wavy line;

- The lubricated element is unfolded and attached to the desired location of the base - the ceiling, baseboard, wall and pressed tightly (should be held for 10-15 seconds on average);

- The sutures themselves should provide a tight hold within 15-20 minutes;

- It is worth remembering that fillets must be glued from the beginning of the corner;

- If the molding is glued to a stretch ceiling, then the fixation occurs exclusively on the surface of the wall, but not on the unstable surface of the stretch ceiling;

- The ends of the planks should also be coated with a thin layer, then they are attached in the desired corner, and the remaining adhesive is quickly removed with a thin spatula.

How to choose adhesive for skirting boards

Before completing the finishing work, you need to choose what glue to use to glue the baseboards. It is necessary to clarify what type of materials you will be working with, find out the strength and drying speed of the adhesive composition. Not the least important criterion is the safety of the proposed product. The user should pay attention to ease of application. This will allow you to buy a composition that can reliably fix decorative elements.

Material

Skirting boards are made of wood, plastic, foam and polyurethane. All these materials have a working surface with varying degrees of porosity. The surface layer differs in the level of intermolecular interaction with adhesive compositions. For this reason, it is necessary to ensure that the product used matches the adhesion of the material from which the decorative element is made. Acrylic copolymers are considered universal, capable of providing good adhesion to any substrate.

Strength

The tensile strength determines how long the molding will stay on the wall. This is especially important for fillets that are subject to gravity. Ceiling plinths made from foam plastic are lightweight, but polyurethane moldings and wood cornices are heavier. The technical documentation or passport contains data on tensile strength. For foam products, 10-20 kg/sq.cm is enough, for polyurethane 30-40 kg/sq.m. It is better to fix wide cornices with glue, which has a strength of 60-70 kg/sq.cm.

Drying speed

Drying rate affects performance. The decorator cannot press the moldings against the wall for long. It takes away physical strength and makes you waste time. Drying speed should be no more than 10-15 minutes. In this case, the product should set within a few seconds. The rest of the time is necessary for possible adjustments to the location of the decor. If the speed is slow, you will have to use finishing nails for additional fixation. A full set of strength takes from 1 to 3 days; after this time, the decorative elements can be painted.

Safety

In the past, organic solvents were used in the manufacture of adhesives. During operation, the seam released harmful substances into the air - benzene, toluene, acetone. This is unacceptable in residential areas. Most organic solvents are genetic poisons. Today they produce water-based formulations. These are environmentally friendly products without the emission of harmful substances.

Ease of application

The products are offered in cartridges or bottles with a dispenser. This allows you to control the amount of glue applied. To work with the cartridge, you will need a construction gun, which will help you easily squeeze the mixture out of the container. If the product is thick, then physical effort will be required. If you don’t have a construction gun, it’s better to stick with a bottle with a dispenser.

If the joints are cracked

No matter what polyurethane plinth is glued to, they very rarely fall off the wall. But the problem with corners is not uncommon. It usually occurs if the joints were glued with assembly adhesive or any other composition. Then hairline cracks form first, then they can increase to several millimeters. What to do with cracks in the corners of the baseboard? How to fix?

The first thing to do is clean the old glue from the joint. The easiest way to cut is with a knife. Then the joint can be filled:

- Acrylic sealant. After application, try to level it out, repeating the relief. After it dries, we sand it and then paint it. This is the most realistic method and the easiest to implement.

And at the corners the gaps may be larger - If the gap is small, you can apply joint adhesive. Just keep in mind that once it dries, it is difficult to work with. So after applying, remove the excess immediately, wipe off the remaining residue with a rag with acetone. If there are any irregularities left, we try to give the desired shape with sandpaper on a block.

- Seal the joint with polyurethane foam, trim, putty, paint. Foam is the easiest to work with, but you need to use it with a small expansion and make sure that as it increases in size it does not tear the baseboard away from the wall. So the option is still problematic. The truth is not in terms of processing.

All these methods will only give a temporary effect. If cracks appear at the joints, there are reasons for this. And until the causes are eliminated, cracks will appear again. If it is simply an unsuitable composition (not for joints, but for installation), then the normal appearance may last longer. If the joints were glued with the “correct” glue, then the reason is more serious. Possibly - shrinkage of the house, cracks, etc.

Which adhesive for skirting boards is better?

When decorating rooms, decors from different materials are used, which differ in width, length and weight. Therefore, it is worth considering the features of the design project. The VyborExperta.ru team recommends the following brands:

- Orac Axxent FDP500 – for renovation in a city apartment;

- Tytan Professional Classic Fix - the choice of the owner of a country house;

- KIN – for installation of polyurethane moldings;

- Quelyd Mastifix Ultra - for working with floor skirting boards.

All the brands presented in the review are worthy of the attention of finishers, but only the most reliable and easy to use received the status of the best in their categories.

Some advice from experts

So, we hope that we have answered in sufficient detail the question of what to glue first - the ceiling plinth or wallpaper. Below you will find some useful tips from experienced craftsmen, following which you can mount the baguette as quickly and accurately as possible:

- Experts advise buying skirting boards with a small margin. This is especially true in cases where there is no miter box at hand. Trimming baguettes in corners is actually a very complicated procedure. And if you can’t cut it neatly the first time, its ends are simply cut off. Then the procedure starts all over again. As a result, of course, the consumption of skirting boards increases.

- Experienced craftsmen recommend painting the molding only after it has been installed in place. This procedure should not be performed in advance, before gluing. Otherwise, glue stains will remain visible on the baseboard in the future.

By mounting the ceiling plinth on the wallpaper and painting it after that, unfortunately, the walls can get dirty very easily. To prevent this from happening, experienced craftsmen recommend using a clean rag and a long spatula when installing baguettes. Experienced craftsmen advise placing this tool along the bottom edge of the baseboards when painting them. This will prevent paint stains from appearing on the wallpaper.

Of course, you shouldn’t apply too much glue to the planks when fixing them. It should not protrude from under the baseboard when pressed. Drops of glue, if they appear on the wallpaper, should be removed with a rag immediately - before they harden.