The use of plastic windows has important advantages and is therefore becoming more and more widespread. However, it must be remembered that when using them it is important to ensure high-quality ventilation. One of the most convenient ways for this is to install special valves. In order for the owner to make them, he needs to understand the pros and cons, the features of creation, understand what the sequence of actions should be and what needs to be paid attention to during the work process.

Valve installed on a plastic window Source sovet-ingenera.com

How is the valve used in plastic windows?

For ventilation, plastic windows can be opened slightly. For this purpose, a special operating mode is provided. In most cases, using this method provides a sufficient supply of fresh air.

However, there are situations in which such ventilation is unprofitable. This applies, for example, to cases when it is raining, snowing or strong gusts of wind can be observed outside. In winter, during the procedure, a significant cooling of the apartment occurs due to the entry of a large volume of cold air inside. Sometimes dust or insects get in with it, which you would like to avoid. Unregulated inflow contributes to drafts.

Design and principle of operation of the valve

This design includes the following elements:

- The air intake is the outer part of the device. It has a hole that provides ventilation. A special canopy is used here, designed to protect against dust, dirt, various debris and insects.

- A telescopic type through channel is provided for the passage of air. A sleeve is used to secure it.

- Filters are used in the design.

- The device is provided with an adjusting element.

The third, fourth and fifth elements provide internal filling of the valve.

Slot type valve Source sovet-ingenera.com

It works due to the difference in pressure in the apartment and outside. Air enters through the intake hole, moves through a telescopic channel, then exits through the nozzles. Usually there is a battery located next to the window, the heated atmosphere from which rises upward, drawing fresh air from the valve. At the same time, it will additionally warm up, spreading throughout the apartment.

Video on how to properly install a ventilation valve:

Care and maintenance of the valve for PVC windows

One of the important advantages of ventilation valves is the ease of maintenance and care during operation. In most cases, for normal operation of the product, it is enough to clean it periodically, approximately 1-2 times a year. In this case, as a rule, the accumulated dust deposits are removed from the outer grille (using a vacuum cleaner or brush), and the inner surface of the valve is wiped with a damp cloth or soft cloth. Also, a dust spot that sometimes appears on top of the valve is also removed with a napkin.

Under no circumstances should abrasive or chemical detergents or cleaners be used to clean or otherwise maintain valve surfaces. It is also not allowed to wash the ventilation valve with a stream of water or soak its structures and elements.

During operation of the valve, the following point must be taken into account: in severe frosts, it is not recommended to completely close it using the manual type of regulation. This can lead to freezing of some structural elements and failure of the product.

In all other cases, both the care and operation of modern ventilation valves does not present any difficulty or problems.

Rice. 14. Ventilation valve care.

Types of valves

These devices are designed to create a flow of fresh air regardless of whether the windows are open or not. They come in different types depending on their location. There are window and wall structures. The choice is made based on the ventilation characteristics of a particular apartment.

There is also a classification based on their design features. The main valve options are discussed below.

Ventilation diagram in the apartment Source sovet-ingenera.com

Folded

Such models are based on the use of a gap in the frame. They can be installed without dismantling the glass unit. The advantages of using this method are as follows:

- When installing the package, there is no deterioration in the insulating properties of the windows.

- The cost of installation is budget-friendly.

- Carrying out the work is not difficult for the owner.

- The ability to automate the adjustment is available.

The maximum amount of air that can be obtained in this way does not exceed 5 cubic meters. m. Commercially available brands can be equipped with humidity sensors. When purchasing, preference should be given to those models where they are separated from the ventilation duct.

Operating principle of a valve for a plastic window Source sovet-ingenera.com

Types of ventilation valves for plastic windows

Seam systems

These are the simplest designs. The fresh flow enters the apartment through the cutouts in the seals of the vestibule, reaching them along a rather long path (1-2.5 m) along the folds of the frame profiles from the inlet openings. The latter are usually located in the lower part of the frame and are also made in the form of cutouts in the seal of the vestibule or in the folds of special grooves on the frame and sash profiles. The long journey helps the air warm up from the warm plastic - this reduces the risk of icing and dissipates sound energy.

When installing, first remove a fragment of the seal, and then snap or screw the body of the product. The latter is equipped with a petal flap that responds to outside air pressure: when the wind increases, the petal partially blocks the ventilation hole. In addition, the damper can be adjusted manually. Such devices have practically no effect on heat and sound insulation.

The main disadvantage is low throughput. They provide an air exchange of about 5-6 m3/hour, but, according to sanitary and building standards, an influx of 30 m3/hour per person or 3 m3/hour per square meter of area is required. In addition, such systems do not respond to the state of the atmosphere inside the building. The advantage is the possibility of installation on already installed double-glazed windows, the absence of visible elements on the binding. When using them, sound insulation does not deteriorate.

VentoTherm

One example - VentoTherm - provides forced supply and filtration of the flow, as well as heating it through heat recovery (up to 45%). It is mounted above the frame through an expansion profile. Automatic control based on readings from humidity and CO2 sensors. Consumes 1kWh per week.

Mortise systems

They are mounted on the upper profile of the sash, having previously made one or two elongated holes in it. A reasonable question may arise - how to install such a ventilation valve on a plastic window and can this be done independently at home?

Installation is not too labor-intensive and, as a rule, is carried out on an installed double-glazed window. The performance is also quite sufficient, but in severe frosts a draft may appear.

Slot devices

The working channel in them is a through slot 12-16 mm high and 170-400 mm long, made in a horizontal impost or in the upper bar of the sash. From the street it is closed by an inlet block that protects from rain and insects. On the inside, the gap is closed by a control block. The system provides an inflow of 25-35 m3/h (at p=10Pa), which almost meets the standards.

Most of them can be mounted on any profiles made of plastic, wood and aluminum, both when assembling windows at the factory, and on already installed ones. Installation lasts 40-60 minutes. True, on aluminum sashes, if both blocks are also aluminum, a “cold bridge” appears and the channel freezes over. You have to insert a plastic tube into the gap to create a thermal break, which does not always guarantee success.

Firms solve problems of thermal protection, dust and noise control in different ways (various shapes of caponiers, grilles, deflectors, filters). For example, Aerovent and VentAir valves have an adjustment plate installed in the outdoor unit that closes in strong winds. From the outlet block, the damper directs air upward to avoid creating direct drafts. In the Ventec system, the flow is preheated by waste heat in the cavity between the outer glass and the glass unit.

The internal damper-deflector is usually controlled manually, but there are models with a cord drive, a rod, or a motor.

Among slot-hole devices, hygro-controlled automatic ones stand out. They use a special principle for controlling the control damper - depending on the humidity of the room air (in all other valves - on the difference in pressure between the street and room air). The idea is based on energy saving: people appear - the damper opens slightly, life becomes more active - more air is supplied, they fall asleep - less. And all this is automatic.

In Aereco systems, the flap is rotated by deforming a bundle of nylon tapes. It is housed in a chamber where the temperature is maintained below room temperature by incoming cooling. This makes the device less dependent on external conditions. It responds to changes in humidity in the room in the range of RH=30-70% in summer and RH=15-31% in winter, passing through a volume of 5-35 m3/h. In the “off” state, the gap does not close completely and lets through 5 m3/h.

If the house is located on a busy street, slot-hole appliances are not the best way to combat dust and noise. True, special accessories, for example, acoustic visors and sound-absorbing inserts, reduce traffic noise by approximately 5 dB (in terms of sound volume - subjectively by approximately 50%).

Overhead devices

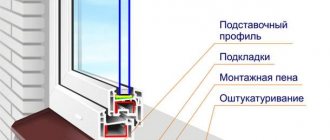

A special feature of the designs is the large area of the working slot channel (up to 200 cm2), extended over the entire length of the profile. Since it is impossible to make a channel without weakening the frame, such systems are made overhead. Installation of ventilation valves on plastic windows can be done in two ways:

- in the gap between the frame and the opening;

- between the sash profile and the end of the glass unit.

They have a large throughput capacity (some - up to 160 m3/h per 1 linear meter of length at p = 10 Pa), but at the same time difficulties arise with sound, dust and heat protection. They are overcome with the help of manually controlled dampers and filters. However, there are also specific problems. This is a considerable building height (60-150 mm) and a box-shaped shape, which changes the appearance of the sash and facade, so their installation may be opposed by the city’s architectural services. Significant depth (95-150 mm) does not add grace to the interior of the room. To give them strength, the cases are made of aluminum profiles, but with a PVC thermal insert and a small width (20-24 mm), therefore, the risk of freezing is increased. And the higher the throughput, the worse the sound insulation.

It is recommended to use such devices in two cases:

- if the draft is small (for example, in country houses with a low exhaust pipe or in apartments on the upper floors of high-rise buildings);

- when using a controlled mechanical hood.

Wall valves

They are usually installed near a heating radiator so that the air coming from the street is heated by the radiator. For this purpose, a hole with a diameter of about 90 mm is drilled in the outer wall (in order not to affect the reinforcement, a construction metal detector is used). The designs offered by Aereco, Hausevent, Marley, SIEGENIA are quite diverse.

The simplest ones do not differ in performance from mortise ones, but are adjusted manually. More complex ones are equipped with a humidity sensor, and the most advanced ones are equipped with a fan, touch control panel and multi-layer filter. Some devices are capable of alternately operating in supply and exhaust modes, with the outgoing stream giving off heat to a special membrane, which then heats the one coming from the street.

If you read the reviews and opinions of experts about ventilation valves for plastic windows, their opinion is unanimous - they approve of such technical solutions. They have more advantages than disadvantages.

Boris Buttsev, head of the technical department of the Aereco representative office

Many residents find themselves in a situation where the apartment uses gas appliances with an open combustion chamber (gas stoves, gas water heaters, boilers), and the premises are “sealed” with sealed double-glazed windows. All the cracks are closed, and oxygen is needed for gas combustion. There have already been sad cases when, during apartment heating with air intake for the burner from the kitchen volume, the oxygen burned out, the flame went out, and the automation did not work. As a result, people died. What to do? It is imperative to use supply devices that, even when closed, would provide an inflow sufficient to maintain combustion. An example is EHA 22-50 (Aereco), in which the damper has a special protrusion that does not allow it to close hermetically - thus ensuring a flow of at least 22 m3/h. It should be installed in the kitchen (according to fire safety requirements).

Video description

Installation of the ventilation valve.

Invoices

These designs resemble slotted window vents. They are distinguished by high throughput. Such models can supply up to 100 cubic meters every hour. m. air. They can be used in both fixed and openable windows. The peculiarity of this design option is that the valve must be installed before the double-glazed windows are installed.

The strength of such valves is their high flow capacity. However, this deteriorates the thermal and sound insulation characteristics of the windows. Therefore, the main areas for installing valves on plastic windows are office and industrial premises.

Air flow through the ventilation valve Source tbmmarket.ru

Criteria for choosing window ventilation valves

The microclimate in the house depends on the choice of the type of ventilation valve, so this issue should be approached taking into account the maximum number of criteria. The following are of greatest importance:

- transmittance of the product. Existing standards recommend the volume of fresh air from outside at 30 cubic meters per hour per person;

- level of sound insulation of the structure after installing the valve. This indicator should not exceed 30-35 dB;

- efficient operation in winter conditions at low outside temperatures. The valve must be made in compliance with the requirements for insulating internal structures, preventing possible icing, as well as the entry of too much cold air into the room;

- regulation mechanism. Automatic, manual and mixed (a combination of the previous two) methods have been developed to regulate the amount of air coming from outside;

- installation location of the product. In addition to mounting directly on the window structure, there are options for wall mounting. They are more expensive and require significant associated work, for example, punching and laying channels to the valve;

- valve installation method. Its installation without removing the window unit is much more convenient and cheaper than alternative options.

Rice. 6. Valve before installation.

Principles of organizing ventilation in an apartment

To constantly update the air in the apartment, it is necessary to provide for the presence of supply and exhaust ducts. At the same time, it is important that they have a cross-section that is sufficient to provide such a volume that the residents are guaranteed good health and a comfortable feeling.

For a long time, builders did not pay enough attention to these issues. This sometimes led to the fact that the apartment had exhaust openings, but practically no supply openings. Intake during window ventilation was provided by open vents and windows or air that passed through cracks when closed loosely. Installing window valves will provide your home with efficient supply channels.

Wall supply valve Source climanova.ru

Installation recommendations

When installing any type of device, you need to work carefully so as not to damage the glass. If a crack occurs on one sheet, it cannot be replaced; you will have to order a new double-glazed window.

To install the valve, prepare materials and equipment :

- the installation template is sold complete with the valve, purchased separately, or prepared independently;

- supply valve set;

- adhesive for gaskets, sealant;

- seal along the length of the product and two pieces 3 cm shorter;

- metal screws with fine thread;

- three plugs for fixing the valve.

Valera

The voice of the construction guru

Ask a Question

The number of valves is determined by the required volume of air exchange. It is recommended to install 1 valve per window unit, then experimentally determine the effectiveness of operation.

Required Tools

Cutters

To remove the gasket section, you will need a construction knife with a retractable and replaceable blade.

Other tools:

- Phillips and slot screwdriver;

- ruler and tape measure;

- level, plumb line, marker;

- electric drill and jigsaw, drills in diameter are 0.5 mm smaller than the size of self-tapping screws;

- file.

Depending on the installation method, you may need a hand cutter to form holes in the window frame.

Preparatory work

Find the area where the valve is located. A single device is installed at the top of the sash, choosing a central location. To do this, measure the length of the profile, divide the resulting value by two, and set aside the value from the edge.

The further position is marked with a tape measure, lines are drawn using a ruler. The area is chosen so as not to catch the edge of the glass unit when drilling or milling. It is important not to weaken the profile structure.

Preparing a metal-plastic frame for valve installation includes the following operations:

- carefully remove the rubber gasket and cut out the area with a knife;

- carefully pull the seal out of the groove on the profile.

If they are working on the sash, it is better to remove it by unscrewing the hinges.

Installation technology

Installation with milling:

- mark the sash, place a template, and make holes on it;

- mark the outline of the slots, remove the template;

- use a jigsaw or cutter to form grooves between the holes;

- close the transom, transfer the holes to the frame;

- Mark the grooves on the box with a template and repeat the milling.

A mounting panel is placed on the inner side, all elements are finally sealed, and the operation of the device is regulated.

the supply unit without milling .

- the valve is applied to the top of the transom, the contours are marked;

- from the inner side the lines are continued until the laying;

- take out the seal, replace it with the one that comes with the kit;

- the valve is fixed with self-tapping screws to the installation site.

Features of valve adjustment

When installing valves on PVC windows, it is necessary to ensure high-quality ventilation. One way to do this is by adjusting the intensity of air intake. These devices use two options:

- Receipt due to the pressure difference between the outside and inside. The owner decides how much air should be supplied. In this case, the required work intensity is set automatically depending on atmospheric conditions.

- In systems where there is a humidity sensor in the apartment, the width of the hole that the ventilation valve for plastic windows has may vary. It increases when there is a significant vapor content and decreases when the air becomes drier.

The lack of adjustment is partially compensated by the budget cost of the devices. When using automatic control, the price per valve will be significantly higher.

Adjusting air access through the valve Source otivent.com

Valve adjustment methods for PVC windows

Practical experience in using various models and types of ventilation valves has shown that for their effective operation it is necessary to have a control mechanism. Options with constant ventilation parameters turned out to be unsuccessful and simply unsuitable for use in domestic conditions.

As noted above, there are three types of regulation: manual, automatic and combined. The most convenient is considered to be an automatic device that uses the readings of a special sensor that monitors the level of humidity in the room. Depending on this, the required operating mode of the ventilation valve is set - from completely closing it to the maximum possible level of air exchange.

Rice. 12. Automatically adjustable valve.

The advantage of an automatic control system is that it reduces heat loss. This effect is achieved by the fact that the valve starts to work only if the humidity rises and there are people in the room. If there is no one in the room for a long time, then the valve operates at a minimum throughput mode or is completely closed.

The manual method of regulating the operation of the ventilation valve is more reliable, but requires constant attention and monitoring.

Valve installation without milling

When creating window ventilation valves, you need to prepare the following tools:

- knife;

- plugs needed to secure the valve;

- several pieces of sealant;

- screwdriver or screwdriver;

- self-tapping screws

In this case, a gap will be used that is formed in place of the cut piece of sealant. To complete the work of installing ventilation on plastic windows, the following actions will be required:

- It is necessary to mark the area of the seal that will need to be cut out.

- Make cuts with a knife and remove the unnecessary area.

- To fix the position of the ventilation valve on a plastic window, you need to screw two self-tapping screws at the edges and one in the center. This is done on the side of the sash where the seal used to be.

- In the place where it was removed, a narrow strip of this material is installed.

- After installation is complete, the valve lever must be adjusted to ensure the desired air flow rate.

After installation is completed, the ventilation valve will be ready for operation.

Air flow through the valve Source oknavik.dp.ua

Advantages and disadvantages of ventilation valves for PVC windows

The disadvantages of using ventilation valves are usually associated either with the use of low-quality products or with installation errors:

- the likelihood of freezing at the valve installation site;

- the possibility of too much cold air entering;

- insufficient level of ventilation provided in hot weather;

- reduction in the level of heat and sound insulation of a window structure associated with the installation of a ventilation valve.

All of the above disadvantages can be eliminated if you comply with the requirements for installing the ventilation valve and use a quality product, for example, the Aereco and Air-Box models described above. In this case, the use of valves for supply ventilation will allow:

- ensure a constant sufficient supply of fresh air from outside;

- maintain the heat and sound insulation of the window structure at the required level;

- prevent the formation of drafts that are dangerous to the health of people in the room;

- reduce heat loss, which is achieved by regulating the level of incoming air.

If the installation rules are followed and high-quality ventilation valves are used, their use will allow you to maintain an optimal microclimate in the room with minimal heat loss.

Rice. 13. Valve design ensuring reliability and quality.