When decorating the facade of a house with siding panels, window and door openings require a frame made of appropriate material to complete the appearance. For this purpose, a window siding strip is used. Let's look at the main features of its design, dimensions, conditions of use, what requirements must be met during installation, as well as what are the main nuances, stages and options for its installation.

An example of a house with a window framed in a window strip Source pofasadam.ru

Window strip - design features, dimensions, conditions of use, purpose

The window profile is intended to be an additional element of siding lamellas. As a rule, the product is included in the standard package of this type of finishing materials from all well-known manufacturers. Therefore, a consumer who uses products from official manufacturers will never face the problem of finding suitable components.

Design features and dimensions

The plank, manufactured according to the European standard, consists of the following main parts:

- Wide edge - located on the inside for direct overlay on the slope. The surface structure can be smooth or grooved and have different widths. Combines with finishing strip.

- Narrow edge - separated from the above part by bending. Performs the function of a platband and is located on the outside. The width is 2-3 times smaller than the inner area.

- Fastening area or J-component. It has a U-shaped structure and oblong fastening holes along the edge for strong fixation and joining with siding slats.

Construction of a near-window strip Source mkif12.ru

The dimensions of the parts of the near-window strip depend on the location of installation of the profile and combination with the siding, as well as on the brand that manufactures it, and vary within the following limits:

- The length of the profile is 305 cm, the width of the internal part is 14.4 cm, the external part is 8 cm.

- The length of the plank is 305 and 381 cm, the width of the inner area is 24 cm, the outer area is 8 cm.

- Product length – 305 cm, width inside – 22.8 cm, outside – 7.5 cm.

Moreover, if the slope area reaches 16 cm or more, the product is considered wide and is used for finishing slopes up to 20 cm, if less than 16 cm - small.

Conditions of use and purpose

The type of slope strip in question can be used under the following conditions:

- Installation is possible with a slope depth of 20 cm (plus or minus 1.5 cm).

- When the window is located at the level of the facade, only the platband is installed.

- When the opening is located to a depth of more than 20 cm, the surface of the slope is sheathed with siding or soffit.

- The installation of the plank elements is carried out before the installation of the lamellas begins, which allows for more precise finishing.

An example of installation work on finishing a facade with siding with a window profile Source rubankom.com

The main purpose of the window trim is to protect the structure, as well as the connection points with the wall, from precipitation. Additionally, the plank performs a decorative function, and with an artistic selection of multi-colored elements, it allows you to decorate the facade of the house in an original way in accordance with the design ideas.

See also: Catalog of companies that specialize in finishing materials and related work

Rules for cutting near-window profiles for designing slopes

In order for the finishing material to accurately follow the contours of the window opening, it is necessary to perform a series of measurements and calculations. The cost of additional elements is quite high, so before cutting, you need to double-check the accuracy of the measurements taken.

If, upon completion of installation, flaws in the cutting of components are revealed, do not despair. It is impossible to correct errors, but there is a way to disguise problem areas using plastic corners. As a rule, errors in calculations and measurements lead to the appearance of cracks at the joints of panels.

The shortcoming is eliminated like this:

- use metal scissors to cut off a plastic corner of the required length;

- Super glue is applied pointwise to both of its shelves;

- press the corner tightly against the cladding.

Marking and cutting the side strips of the window profile

First of all, measurements are taken and the following indicators are determined:

- the height of the window opening from its inside. When taking measurements, the tape measure is pressed directly against the window block. The resulting figure is the length of the inner end of the side window strip;

- the height of the outer side of the window opening. As a rule, it is greater than the height of the inner one. This is due to the fact that the window covering is performed with a slight slope of the slopes outward, towards the wall cladding. The tape measure is applied to the lower corner point formed by the intersection of the siding panels that frame the window opening. Stretch the measuring tape to the upper corner point;

- width of the slope (also known as the depth of the opening). Measure the distance between the corner of the window block and the intersection of the siding panels.

For the convenience of work, all indicators are not only recorded, but also a kind of drawing is drawn on which all distances are marked.

Determining the bevel angle of the window strip

An important step is measuring the slope of the slopes in their upper and lower parts. As a rule, the bevel is shallower at the top than at the bottom. For measurements, use a square and a pencil. The square is applied to the lower corner of the window block and a mark is made. Measure the distance from this point to low tide.

Using the data obtained, the shape of the future slope is drawn on the near-window strip. It is trapezoidal. The side part of the additional element, which is the platband, must remain rectangular in shape. For ease of installation, the inner corner of the nail strip is cut off.

Prices for platbands and accessories for windows and doors

Platbands and trims for windows and doors

Installation requirements

In order for the near-window strip to fulfill its tasks and serve no less than the siding itself, all installation work must meet the following series of requirements:

- When attaching both metal and vinyl elements, you should leave a small gap. This is necessary to compensate for the expansion of the material under the influence of temperature changes between seasons. So, the self-tapping screw should never be tightened to the limit - even if there is a press washer.

- The hardware should be screwed into the center of the hole and perpendicular to the base.

- It is recommended to use galvanized self-tapping screws as the main elements for fastening.

- Installation of the strip should be carried out at the stage of installation of the frame structure.

The window strip was installed before the panels were installed Source prom.st

- To form a high-quality frame and a tight fit of the connecting sides (to avoid the penetration of dampness), corner trimming and edge trimming should be performed, respectively.

- It is recommended to carry out installation work at positive ambient temperatures. Otherwise, during operation there is a high probability of defects due to expansion of the material during a thaw.

Advice! To avoid problems of components not matching the main material during installation, and to avoid defects and damage during operation, it is necessary to purchase accessories from the manufacturer that produces the main product.

Professional advice

Both metal siding and vinyl panels are characterized by linear expansion, so professional craftsmen adhere to several rules that will not only help to install the finish efficiently, but also to avoid deformation:

- It is best to perform the installation process only at an air temperature of at least 5 degrees Celsius. Although manufacturers claim that siding can be installed at any time of the year, the material becomes brittle at subzero temperatures.

- When joining parts, including window strips, it is necessary to leave a gap for expansion.

- The fastener is fixed only in the center of a special hole on the perforated side of the part, while it is not tightened all the way, but a gap of 1–1.5 mm is left. Installed parts can be moved from side to side.

- Window trims should be used only when necessary; in other cases it is better to replace them with other elements.

When installing iron or vinyl siding, special additional elements are provided. Without them, it will not be possible to perform high-quality installation

Special attention is paid to the finishing of doors and windows. In order for the window opening to look carefully, a window strip was designed

In this article we will look at how to attach window siding strips.

Installation nuances - calculation, preparation, installation, processing

Before installing the window strip, you need to install the sheathing along the entire profile of the house for siding, take measurements and other preparatory procedures according to the following algorithm:

- Replacing old frames with new ones (if necessary).

- Renewing the surface of the slope - cleaning, covering cracks and cracks.

- Treatment of the external part with an anti-fungus and mold remover.

- Installation of sheathing on the house facade.

Scheme of preparation, trimming and installation of window trim Source vseprosiding.ru

Preparatory and calculation work

Finishing activities include the following stages of preparing the opening:

- The window is cleaned of everything unnecessary, the slopes are checked, cracks and crevices are covered. Treatment is carried out with protective compounds against mold and mildew. If you plan to replace old frames, then this is done in advance.

- The general sheathing of the house is being erected.

- After framing the window with frame elements from the outside, the location of the ebb is determined. For these purposes, a special additional part is used. It is placed at a distance from the facade, ensuring uniform drainage. But it can not be used, then a near-window strip installed at a slope is used as a drainage system. For it, a beam is pre-set, cut at the desired angle.

- The outer part of the opening is also framed with a wooden strip; it will serve as the basis for installing the finishing profile. For these purposes, it is better to use parts made from hardwood with minimal thermal expansion. Such fragments must be treated with antiseptic compounds.

The frame for window cladding can be either metal or wood.

After preparation is completed, the material for the cladding is calculated. The internal and external perimeter of the opening and the width of the slopes are measured. To do this, it is advisable to use at least 3 points on one side, which will avoid distortions due to changes. All parameters are transferred to the window diagram. According to the dimensions, the optimal type of profile is selected and purchased or the existing one is adjusted.

Opening finishing options

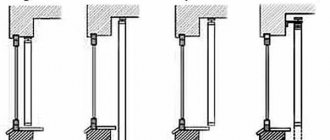

The technology for installing window strips near window and door openings when decorating a house with siding, as well as the set of materials used, depend on the depth of the slope and have the following variations:

- The depth of the slope is 20 cm. Installation is carried out according to the above standard instructions.

- The depth of the slope is more than 20 cm. The cladding is carried out using siding panels adjusted to the size of the slope. In this case, the finishing profile is mounted inside, and the corner profile is mounted on the outside.

- Opening without slope. The framing is done using a J-profile.

On a note! The use of window strips for siding is possible only if the opening dimensions correspond to standard parameters. In other cases, alternative methods and materials are used. Therefore, when planning a house, it is necessary to think in advance about what and how the facade will be finished.

What is siding

Siding is a cladding material that imitates various types of finishing, consisting of long narrow strips connected into a single homogeneous coating.

Each strip has a stamped profile that repeats the structure of a particular coating - logs, stone, etc. The surface has a textured pattern, making the imitation completely reliable.

There are several types of siding made from different materials.

Can be found:

In addition, siding can be classified according to its intended purpose:

By panel arrangement:

Profile types:

Each of these types has several varieties with different colors, width, panel length and other parameters.

Briefly about the main thing

A window strip is an additional element for framing window or door openings when finishing the siding of the facade of a house. It consists of three main parts - the wide and narrow sides and the J-component. The dimensions of the product are strictly specified by production standards, so it is used for openings with a depth of about 20 cm. Its main purpose is to protect window joints from precipitation and decor.

Installation of the profile must be carried out strictly in accordance with the requirements:

- When fixing the material, a technological gap must be left taking into account interseasonal temperature changes.

- Screwing in the hardware strictly in the center of the mounting hole and at a right angle.

- The best fastening element is a galvanized self-tapping screw.

- Framing should be done during the installation phase of the frame under the facade.

- The installation technology must necessarily include trimming and trimming procedures.

- Installation is recommended to be done at positive air temperatures.

The installation of a window strip when finishing a house with siding is preceded by preparation, calculation and processing procedures. Depending on the depth of the slope, a window or doorway can be framed not only with a specialized profile, but also with a J-profile or lamellas adjusted to size.

Why are siding accessories needed?

The starting strip for siding must interact with many finishing elements. Siding manufacturers produce a certain set of components necessary for installation (see).

They may differ slightly in color, size, profile, have different names, but are necessary for the same needs. This is the protection of weak points of the facade from moisture, wind and other atmospheric influences, as well as the design of facade components.

The starting strip for metal siding is the element with which it is customary to begin wall cladding. It is installed with the upper edge along a pre-marked line, which is located forty millimeters above the lower border of the finish. The siding panel is then inserted with its lower edge into the starting strip, and the upper edge is secured to the sheathing or wall.

- H-profile

or is necessary to hide the seams between the panels and their connections when increasing the length. - A drain or hanging siding strip

is necessary to protect the base and windows of the building from water flows. It is installed in the upper part of the opening or at the junction of the plinth with the siding. - The external and internal corner

(see) are the elements necessary for joining the panels. - The wind strip

is necessary for finishing the eaves of the roofs. - Platbands and near-window strips

are used as finishing material for openings and are installed around the entire perimeter. - Soffit

is an element intended for finishing roofs and facades. - The finishing strip

is the final element of panel finishing. Installed under the eaves before installing the outer siding panel, disguising it as a trimmed or perforated edge.

Most of these accessories are installed on the façade of the building before the panels are installed. These are connecting and starting strips, elements for framing openings, corner parts.

All parts are attached to the frame, which is where the finishing process begins. Let's look at the main points of finishing siding, what to do and what not to do.

How to Set a Starting Bar or Starting Strip

Element installation features:

- The starting strip is attached around the perimeter of the house where the cladding is planned.

- After installation, the element is covered with panels, so there are no special requirements here. The part can be joined from scraps, or strips of even a different color can be taken.

- Setting the initial bar sets the tone for subsequent work. It is better to spend more time on leveling it during installation than to correct even the slightest slope when performing work in the future.

- Before you start fixing it, you should mark the place where the element will be attached. To do this, drive a nail or screw in a self-tapping screw at the very bottom of the wall.

- The distance from the nail to the ground should be equal to the width of the starting plank.

- A thread is pulled between the nails. The correctness of its tension is controlled by the building level.

- A line between the elements is drawn with chalk along a thread. This will be the attachment line for the starting strip.

Attaching the starting bar

How to fix siding to the wall of a building

When attaching vinyl siding elements, you should adhere to the following rules:

- The distance between two screws should be approximately 250 millimeters.

- It is necessary to wrap hardware or drive nails strictly perpendicular to the plane of the wall.

- Self-tapping screws are installed only in the middle of the oval hole, which allows the panel to slide as it expands.

- The self-tapping screw does not tighten completely. There is a gap of approximately one millimeter between the material and the cap. This can be done in two ways:

- by attaching a coin;

- tighten it completely, and then loosen it one turn.

- There should always be a gap of up to seven millimeters between adjacent starting strips, which compensates for the linear expansion of the siding panels.

- The corner strip is not completely installed in place.

- When attaching the bracket, it is necessary to maintain a gap of approximately one millimeter.

How to attach vertical strips, corners and H-connectors

The corners are placed before installing the main planks.

The vinyl corner is attached with the following features:

- The angle should not touch the ground by 5-7 millimeters. Heating the element will cause it to expand vertically, and the gap will prevent it from deforming.

- It is necessary to fasten the screws correctly. The corner is attached from the top hole (see External corner for siding and options for performing the work). In this case, the self-tapping screw is screwed into its upper part. In this case, the entire corner hangs on the screw in the air, and the material can only expand downwards or to the sides.

- All other screws are screwed in the same way as the starting strip - in the center of the oval hole for the nail.

- The lower ends of the corner are cut to the width of the starting element, which helps prevent the material from deforming when heated.

When arranging sharp or obtuse corners:

- The corners of vinyl siding are quite flexible, which allows them to trim sharp and obtuse corners of the structure.

- In this case, elements for acute angles must be narrowed, and elements for obtuse angles must be expanded.

- The internal corner is done in the same way.

- Considering that the price of the corners is high, you can install two J-bars in their place, as shown in the photo.

Installing the corner of the house

When installing the H-profile, it is important to correctly calculate the location of the strip. Then the fastening is done in the same way as the corners:

Then the fastening is done in the same way as the corners:

- The bottom bar is installed.

- The top bar is installed.

- If it is necessary to perform an extension, pieces up to seven millimeters long with perforation are cut off.

- The profiles are overlapped. It must be borne in mind that the starting strips must be adjacent to the H-connector, and not vice versa.

Connecting the starting strips to the H-connector

Calculation of materials

Before starting work, you need to calculate the amount of materials that will be required. To do this, you need to calculate each window separately, since in most cases, in practice, even an ideal structure has errors in volumes that are invisible at first glance.

The calculation process is simple - measure the length of all sides of the window. Don’t forget to add 6 mm extra on all sides; they will be needed for joining corners and cutting off excess for maximum fit of elements.

If there is a ebb in the lower part, its length is not taken into account, since it usually replaces the window strip.

In addition, it is important not to forget that the window strip should be installed as a solid mass, because the window is the first thing that guests and passers-by see. The aesthetic appearance of the windows creates the first impression of the house as a whole, and if the decoration consists of several parts, then the appearance will be appropriate. Such oversights cannot be hidden even in a photo, and even more so, it is impossible not to notice when you are nearby.

Which window slopes are better - let’s look into the details

So, the installation of windows with your own hands is completed, and you are thinking, which window slopes are better? After all, you need to know both the pros and cons? Let's ask the experts!

To understand this issue, you need to find out what advantages and disadvantages each type of finish has.

Plaster slopes

The “oldest” type of window opening has a number of advantages:

- Acceptable price. If you order work from craftsmen, now only the work is assessed, without taking into account the materials. In addition, you can easily install this type of slope yourself;

- Resistance to mechanical stress. Unlike plastic and plasterboard analogues, plastered slopes are not so fragile, and this is a very decisive factor for owners who decide which slopes are best for a window;

- Seamless installation. When installing a plastered slope, there are no seams or edgings, there is no need to worry about joining the sheets, and the process of puttying the window brings the surface to an almost perfectly flat layer.

- Easy to install. Even a beginner, in principle, can independently plaster a slope; this requires a minimum of tools, materials, and labor costs;

- Versatility of use. This type of slope can be used in any room, at any temperature.

However, like every type of finish, these window slopes also have disadvantages:

- Installation duration. The installation principle is to apply the mixture layer by layer. In addition, the next layer can be laid only when the previous one has dried, and this automatically extends the production time to 5 days, which is not very convenient;

- Formation of condensation. This type of slopes for windows is “cold”, since it does not contain materials with heat-insulating properties, which leads to moisture condensation and the subsequent formation of mold;

- Cracks. The plaster slopes do not adhere closely to the plastic windows, which ultimately leads to peeling.

Plasterboard slopes

When deciding which window slopes are better, many choose the plasterboard option. Let's look at what exactly attracts them so much:

- Simple device technology. Without a doubt, any beginner can make such slopes for windows; it will only be enough to purchase the material;

- Installation speed. With skill, installation of one slope takes no more than 2 hours;

- Low cost. Materials for work are quite accessible to all consumers, and this is often the most decisive argument when deciding which slopes for windows are better.

- Exposure to moisture. In the presence of excess moisture, this slope, unfortunately, can collapse, and the same moisture can cause the formation of mold, which simply cannot be removed from the plasterboard sheet; the damaged sheet will need to be replaced;

- Major renovation. If for other types a partial replacement is possible, then here, as already written above, a complete rework of the slope will have to be carried out.

- Indoor use only. While plastered window slopes can also be installed outdoors, plasterboard ones are intended exclusively for “working” indoors.

Plastic slopes

This option for slopes is the “youngest”, and now more than half of consumers are in favor of this finish when deciding which slope is best for a window.

So, the undeniable advantages:

- Smooth surface. Of course, no one will argue about the smoothness and evenness of the surface of the plastic being produced today;

- Quick installation. The simplest type of installation that you can imagine, if you are not yet a master of your craft, and you are choosing which slope for the window is best. We advise you to opt for plastic options;

- Clean work. There will not be as much dirt and debris as when working with plastered window slopes and drywall;

- No finishing work. There is no need for painting or puttying of the seams - it’s installed and that’s it, the work is finished;

- Color selection. Manufacturers today can please consumers with a wide variety of product colors;

- Additional thermal insulation. This material provides additional thermal insulation to the slopes, which is also a very tangible advantage when deciding which slopes are better for windows;

- Possibility of replacement. If in the case of gypsum craton it is necessary to completely repair the slope, then a partial replacement can be completely sufficient.

Disadvantages of plastic slopes for windows:

- Damage. These slopes do not “tolerate” mechanical damage;

- Price. Despite the affordable price for this type of finishing, it is still worth choosing more expensively, since cheaper analogues may change color when exposed to sunlight, and your boiling white slopes may become dirty yellow after six months, and hidden ones may also become visible stiffening rib;

- Inconsistency between the colors of the panels themselves and the fittings. Often there is no available color of fittings that would match the shade of the panels themselves, especially if you have chosen some exotic option;

- Inconsistency with the interior. Often, this option for window decoration does not suit the designer’s idea, especially if the interior is designed in a classic style;

- Number of additional extras. Only all purchased planks, profiles and corners will guarantee your room an ideal look.

So, here is a fairly detailed analysis of the most common finishing options, read, think, and then you will find your own answer as to which window slopes are better.