Brick is one of the most common materials, widely used in construction. It is used in the construction of houses in cottage villages and dachas. With its help, openings on the facade are beautifully designed. Let's look at why windows are decorated with brick. Let's talk about the types of material used. Read and learn the features of expanding, creating lintels and decorative framing of openings, including the method of facing quarter bricks.

Option for decorating openings in the facade with brick Source sdelai-lestnicu.ru

Why are windows framed?

When erecting the walls of the designed building, all masonry work is carried out according to the drawings.

Surely, there will be no disproportions in such a structure, which cannot be said about houses that are built “by eye.” Those who are engaged in construction themselves should keep in mind that the appearance of the facade largely depends on the size and symmetry of the openings, and this is what you need to pay the main attention to

The role of openings in the aesthetics of the facade

The dimensions of windows, the width of the walls between them, the height of the window sill area - all this is regulated by standards. But even if the dimensions of the openings do not correspond to them, there is no big problem in this - any company today will manufacture window blocks according to individual sizes.

The key to the harmony of the facade is that the windows are located symmetrically on the walls and are themselves proportional. To understand what we are talking about, just look at the photo below. In our opinion, the shapes and sizes of the windows here are extremely poor, as well as their location on the wall, which is why the façade is not at all pleasing to the eye.

- In such situations, decorative lining of the opening with brick will only aggravate the dissonance, and the asymmetry will be even more striking. In any case, finishing of openings is carried out not during the process of laying the wall, but after it has already been completely raised to the designed height.

- It happens that the frame of the house was built earlier, and other work, including the design of brick window openings, is carried out after the house has settled. If this is exactly the situation you have, then before you begin this work, you need to check whether the window openings are located symmetrically in the brickwork.

Expansion of the opening

So, removing 6 cm of the wall - namely, the size of a quarter of a brick - does not imply any measures to provide support for the lintel. It’s a completely different matter if you need to radically expand an existing window, combine two openings into one - or even cut an opening in the masonry where there was not one originally.

- Cladding a window opening with brick is not always done in a house under construction. Sometimes a building is simply rebuilt, overhauled, and the expansion of openings becomes an integral part of the work. Therefore, this chapter will provide short instructions on this topic.

- With a significant expansion of the opening, not only the window block is dismantled. To make a new, longer jumper, the old jumper most often has to be removed. The number one task that needs to be solved is to provide reliable supports for the new lintel.

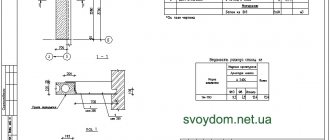

Reinforcing an opening cut into brickwork with a steel lintel

After the surface of the heels has hardened, a beam is installed in the grooves, wedged and supports are arranged. Next, the same thing is done from the side of the room, after which the wall is dismantled; the supporting posts are removed; the nests formed in the wall are sealed; and install the new window frame. Of course, it is impossible to make beautiful brick lintels in such a situation - this is done during the process of building a house. When expanding openings, either reinforced concrete products or rolled steel are used

In private construction, the second option is most often used, which is why we focus on it.

Brickwork of a window opening

- After the metal beam is installed, it and the brickwork above the window opening are jammed, and only then the dismantling of the old slopes begins. The lintel for a new large opening, combining two small old windows, is mounted in the same way. Only here, in addition to the side slopes, you also need to support the central partition.

- After the grooves for the new lintel are cut out and the heels are cemented, the wall between the two openings is trimmed. It is completely disassembled, removing racks and supports along the way, after the lintel beams have been installed. If the wall is thick, then the lintel should consist of three beams: two along the outer contours, and one central, which is inserted from the side of the opening, from below.

Then all this is pulled together with crossbars and the window opening is lined with bricks

Please note that new slopes are laid out using M50 mortar, tying them to the existing wall by all available means

In this case, one of the most popular options for framing the opening today is most often used, which is called a “quarter”. In any case, this is the simplest option.

Layout of decorative elements

The design of quarter-brick openings can be done both during the construction of a wall and during the process of replacing windows. To make quarters on a rectangular window, the easiest way is to use a steel lintel, and it’s most convenient if it’s a corner measuring 120*120 mm.

The metal, by the way, must be coated with an anti-corrosion compound before installation.

If the window needs to be given a spherical shape, then instead of rolled steel, wooden circular templates are used - it is on them that the brick is laid over the window opening.

Brick window opening

- To make a quarter, the brick is pushed beyond the general plane of the wall, poking forward, by 5-6 cm. This is a quarter of the length of the brick, which gives the name to this architectural element. By the way, with the advent of plastic windows, it began to be performed not just as decoration. The quarter on the opening allows you to cover the joints between the masonry and the window frame, thereby improving the quality of thermal insulation of the opening.

- The presence of quarters on the opening is an excellent option not only from an aesthetic point of view. They allow you to use any seals and heat-insulating materials to seal the gaps between the window frame and the wall. Although, in order to highlight window openings on the facade, there are other, more decorative ways of laying bricks.

Simple framing of openings against the background of decorative wall masonry

When constructing masonry, not only the butt side, but also the spoon side can move forward. In this case, the brick itself may not lie on the edge, but be positioned vertically. The position of the bricks, as well as their color, and even shape, can alternate, creating a pattern similar to battlements or a chessboard.

What can I say: an experienced mason can lay out not only the window areas, but also the entire wall, as it is now fashionable to say: in “3D format”. This is exactly the kind of art, without exaggeration, that we see in the picture above.

All about the material, its advantages and types

Thanks to the use of facing bricks, the external defects of the building are hidden. If facade brick is used for old buildings, then it perfectly hides the presence of cracks on the walls of the house that appear due to load. But not only old houses require finishing - the brick facade of a new house looks even more impressive. Previously, many buildings were erected using brick, but now it is customary to use facing bricks specifically as a finishing element for the facade.

Facade bricks are:

Thanks to the use of facing bricks, external defects of the building are hidden

Both are used to decorate the exterior walls of the house and give it a beautiful appearance. The use of clinker is necessary for houses that are made using three-layer wall technology. Of course, the expenses for such a facade will be greater, but the benefits will also increase. A favorable microclimate is created inside houses with three-layer walls, and all thanks to the fact that the thermal insulation is distributed as evenly as possible between the load-bearing and outer walls.

The use of clinker bricks has a number of advantages:

- The material has high mechanical strength

- Frost-resistant and non-flammable, and also serves as a barrier to fire

- Not afraid of corrosion and pollution

- A huge selection of clinker facing material allows you to perform a variety of finishes, which allows you to make your house beautiful and attractive

Clinker brick facade

In addition to a large selection of shades, the facing material is also available in black and white. And if you take advantage of this and make the facade of your house from facing bricks of different colors, you can achieve incredible effects and show everyone that you have taste and imagination. The shapes of clinker bricks are varied; they can have rounded edges or chamfered edges. Clinker facing bricks can be perfectly combined with wood, stone and metal, so various combinations of clinker material and other facade elements will give an original appearance.

Nowadays it is customary to use facing bricks as a finishing element for the facade.

Repairing the brick façade is a major challenge. The cause of cracks on the wall can be not only time, but also shrinkage of the house or improper design. Sometimes it is possible to use overlays and metal belts - they strengthen the wall of the house and prevent further destruction.

Important! Outwardly, it can be difficult to understand whether a crack is growing or not. In order to understand this, glue a sheet of paper onto the damaged brick - if after time the sheet remains intact, then the crack does not increase and you can begin to carry out repair work and restoration

When it is impossible or you do not want to use such a finishing element as brick, you can use other options. For example, brick siding will be a cost-effective solution that you can implement yourself. Siding is lightweight, and thanks to this there is no unnecessary load on the house. Siding can be easily processed, and it is applicable for a curtain wall.

Brick siding panels: original and inexpensive facade design

Of all the advantages of using, the following can be highlighted:

- Brick siding is so similar to natural material that from afar it can be very difficult to understand whether a building is built of brick or lined with siding

- The ideal appearance is obtained by making a mold based on a cast of masonry from natural material

- A brick wall requires restoration, and facing siding just needs to be washed with water

- The service life of the finish reaches 30 years or even more - it is not afraid of precipitation and does not fade in the sun

- Light siding panels can be used to cover not only the walls of a house, but also its individual elements.

- A wide selection of colors, along with the lightness and low price of the panel, made it one of the most popular cladding elements

A hinged ventilated facade is used to cover the house with siding. The panels are fastened to the sheathing after the thermal insulation layer is laid. The ability to decorate your home yourself using such panels is a huge advantage. And the fact that this work is clean and dry, unlike “wet” facades, makes it even more pleasing and enticing to do it yourself.

Siding panels imitating brickwork

We offer:

Hurry up to buy

Popular goods

presents its online store of building materials in Kaluga. Now everything you need during construction and repair work can be purchased not only in our sales offices or warehouse, but also online, without leaving your home. Your order will be accepted, processed and delivered directly to the site.

The purchasing time is significantly reduced, since thanks to the systematized catalog you can immediately find the products you need.

Our company's assortment

We offer building materials for different types of work. This:

- hydro- and thermal insulation;

- insulation;

- metal tiles;

- profiled sheet;

- flexible tiles;

- dry mixes;

- brick, blocks;

- facade panels;

- Hauberk facade tiles and much more.

All products are certified and have undergone strict control for quality and environmental safety. We cooperate only with trusted domestic and foreign manufacturers, therefore we guarantee the reliability of the products we offer.

How to buy building materials profitably in Kaluga

Our company works with both retail and wholesale buyers: construction organizations, enterprises. We can take full responsibility for providing the construction site with materials: you provide us with an estimate, and we deliver everything you need on time. We strictly adhere to the agreed delivery times.

Framing options

Homeowners and professional builders use a variety of window framing options.

Wooden elements

Framing windows on the façade of a building using wooden elements is a very common option today. Their use allows you to decorate windows in a unique Russian style. This method of framing has come down to us since time immemorial and is still very popular.

The disadvantages of such finishing include significant cost, difficulty in manufacturing design elements in the same style, fragility of wood and high requirements for finishing care.

Related article: Window insulation using Swedish technology

Brick

Very convenient material to use. It is most often used in brick buildings, since in this case the framing of the windows of the house can be done directly at the construction stage.

Stone

Decorating window openings with stone is quite a labor-intensive job, which requires the use of a significant number of elements. They can be represented by cornices, platbands, keystones, carved brackets, window and door slopes made of stone, and window sills.

Decorating window openings with stone is quite a labor-intensive job, during which a significant number of elements should be used

Plaster stucco

This option for finishing windows on the facade of a building is very expensive not only in terms of cost, but also in terms of labor intensity at the stage of installation work. In recent years, the popularity of gypsum stucco has declined significantly. It has been replaced by modern and more affordable materials.

Plastic profile panels

A very affordable option in terms of price and installation for finishing windows on a facade made of various materials, including brick, wood and others. The only, but quite noticeable, disadvantage of using profile panels is the low decorative effect of the resulting cladding.

Plastic profile panels are a very affordable option for finishing windows on the facade in terms of price and installation.

Wood-polymer composite

Recently, this material has received close attention. Its undoubted advantages are low cost, simple installation and guaranteed durability.

Self-installation

Independent window framing using decorative elements made of polyurethane does not fall into the category of difficult work.

The variety of options for designing openings using polyurethane is reflected in numerous design projects with different levels of complexity. Installation on the facade is carried out in the shortest possible time, which is due to the ease of processing and installation of polyurethane elements. Fastening polyurethane parts to the facade can be done using glue or self-tapping screws.

For polyurethane decoration on the facade, you will need to purchase elements, the type and quantity of which will depend on the number, size and shape of the windows. Manufacturers of ready-made frames produce the following elements:

- sandriks of various sizes;

- arches of different sizes;

- round windows;

- wall panels and various false shutters;

- polyurethane moldings;

- cornice strips;

- radius moldings and cornice strips.

Independent window framing using decorative elements made of polyurethane does not fall into the category of difficult work.

A decorative element of a façade window frame in the form of a platband is intended for finishing a window from the sides and top. As a rule, the type of platband is selected in accordance with the stylization of the entire building.

Platbands in the style of the Greek order system have been very popular lately. The use of platbands in the framing of window openings contributes to the visual expansion of space.

For the facade of a house in a classic style, you can choose a platband that will stand out with its protrusions above the wall plane. It is allowed to color the element.

A very interesting and original option is the use of window framing elements in the form of columns and pilasters. This design creates an overall impression of nobility and grace.

A very interesting and original option is the use of window framing elements in the form of columns and pilasters

Material selection

First of all, you need to decide on the material that you want to use for finishing. Very often, in brick houses, windows are also framed with brick of the same or a different color. It’s not difficult to make simple brickwork, and this option will always look simple and stylish. The material is easy to use, beautiful and durable. Framing can be done both during the construction of your home and after its completion.

For a brick house, you can also use stonework around the windows. The decor of window frames with facing stones can be very diverse - sometimes the stone is laid evenly on the frame, and sometimes an interesting design or mosaic is created from several types of stones.

Metal framing looks interesting and is suitable for both modern and traditional home designs. The design of such structures can be extremely diverse. The advantage is their durability, but you need to remember that the metal quickly heats up in the sun and becomes extremely cold in the cold - in some cases this can cause discomfort.

Framing with wood is typical for both brick and wooden houses. You can make both laconic frames and carved versions in the Russian style. At the same time, it is very important to properly treat the wood from moisture and contamination so that the frame really lasts you a long time.

Concrete structures are also quite simple. Concrete can look quite interesting if the structures are covered with plaster and paint. This option looks good in a house with a painted facade, and it is most convenient to make such window framing during the construction stage.

For houses in a classic style, moldings with a wide variety of designs are often used. They are usually made from polyurethane. The molding is usually a white structure that imitates columns or stucco: this option can look very elegant, but it will only be appropriate if the design of the entire house is appropriate.

If you want to save money, you can use siding, plastic structures and even foam. If you choose an artificial material, you need to carefully consider its quality. The advantage is that from artificial materials you can create quite a few options for unusual design framing - this solution is suitable for modern cottages and country-style houses.

General information

The construction industry is developing very rapidly, and the market for construction and finishing materials is regularly replenished with new high-tech materials, which allow expanding the field of activity of designers and architects.

New and modern finishing materials make it possible to make the framing of your home's windows stylish, original, attractive and durable. For decorative window framing, materials such as brick, natural stone, gypsum, polyurethane panels, wood and other materials can be successfully used. Most often you can see the framing of openings on the facade with brick and wood.

The choice of material directly depends on the goals that the home owner achieves. In addition, it should be remembered that framing with brick, wood, polyurethane slabs and other materials allows you to create an original style of window framing.

For decorative framing of windows, materials such as brick, natural stone, gypsum, wood and other materials can be successfully used.

The nuances of facing a house with bricks

Finishing the facade with brick has features that must be taken into account to obtain a high-quality result.

Strengthening the foundation

If you intend to cover a structure that was erected quite a long time ago or is a frame structure, then it is necessary to obtain reliable and durable support for the cladding layer. The fact is that the brick puts a serious load on the building itself and on the area where it is located. In the absence of a strong base, the surface will sag and become deformed. To strengthen the foundation, a solution in the form of a reinforced tape is additionally poured over the entire area of the house.

If there is no space for external brickwork on the main foundation, then it is necessary to install a reinforced concrete frame nearby

Bunch

The lining needs to be securely connected to the main walls; for this purpose, metal mesh, anchors or wire are used. The bottom line is that there must be at least 4 points per 1 m2. The selected material is installed in load-bearing walls and located along the seams of the masonry, while the minimum depth should not be less than 8–9 cm.

When arranging decorative masonry during the construction of walls, the tie is carried out using a mesh; for finished buildings, anchors are used

Creating window openings

Window openings in brickwork require a very responsible approach. To install them, it is necessary to carry out markings in advance and draw up a layout diagram. That is why most often surfaces are covered in parallel with the construction of load-bearing structures. The laying of window openings is carried out as follows:

- Initially, the main part of the walls is erected according to the chosen method.

- The creation of the opening begins as soon as the height of the areas located nearby is equal to the height of the window. The main thing is to make sure that all openings have a uniform structure.

- The masonry is carried out using the end method; for this purpose, the brick is cut to length. First, the lower section of the opening is laid out, and then the vertical posts.

- The upper part needs strengthening. For this purpose, a metal corner of suitable thickness, treated with a protective anti-corrosion solution, is used.

- The corner is located exactly above the window; one of the corners of the brick is cut off. First, the elements are placed without mortar to ensure the accuracy of their location, and then they are mounted on the composition. The masonry can be made protruding or flush with the main walls. To avoid deformation, the corner is propped up with a wooden strip.

- If it is planned to line the opening without removing it, then the bricks are laid close to the frame with the elements trimmed to the required size.

Of course, if you lack experience, window design may require more time and effort, but the main thing is to install the parts exactly to the level. Doorways are created using a similar principle.

In the absence of experience, it is advisable to check each level of masonry with a template

Video description

The video compares five types of lintels in private houses:

Laying wedge-shaped bricks is also done using formwork. It is made in the form of a template with a straight or curved bottom. It is this formwork that allows you to build a lintel of the desired shape.

The laying of wedge-shaped bricks begins from the edge of the window and leads towards the center of the opening. It is performed with a slight slope to ensure the expansion of the building material. The wedge-shaped brick is mounted vertically. Its narrow side always points down. Because of this, the thickness of the seam between adjacent bricks is different at the lower and upper points. The standard value is 5 and 25 mm, respectively.

The laying of wedge-shaped bricks begins with markings. It is made on a formwork template, which is placed above the window opening. Marking is needed to accurately calculate the number of bricks. When calculating, be sure to take into account the thickness of the seams, since it is necessary to have an odd number of rows. The last brick is mounted exactly in the middle of the lintel. It is this one that is odd and is called the castle one.

Installation algorithm in an already finished wall

The second option for arranging a window opening involves performing work on an existing wall. The workflow looks like this:

- First the marking is done. This stage involves identifying zones for placing jumpers and technological holes. The working stage is carried out using the triangle method, the lintel is marked so that its top is in the lower masonry row;

- Having made such marks, fifteen centimeters are added for each edge of the jumper. This distance is necessary to install supports that secure the lintel made of metal structures or reinforced concrete;

- installation of the support begins. It is necessary to provide a distance of seventy to eighty centimeters between the load-bearing wall and the supporting element;

- as soon as the support is placed, a wooden beam is laid on it, which is necessary to redistribute the load effects;

- a mark is made along the outer surface of the wall corresponding to the placement of the beams;

- in order to place these marks on the inside of the wall, drill holes into which studs are installed, supporting them on each side with supporting elements;

- the next stage is fixing the support. This can be done with ordinary nails, driving them into boards and studs;

- Using a hammer and a sharp chisel, the plaster layer is removed from the surface of the wall. The cleared area should correspond to the size of the future window opening. An additional three centimeters are added on each side;

- Having removed the plaster material, we begin dismantling the brickwork section. It is best to move from the place where the jumper is located, after that all that remains is to install it;

- all protruding bricks are adjusted;

- Having finished installing the jumper, use a grinder to make a cut. This will help to level the edges of the brickwork of the opening area, remove irregularities above the window, and facilitate subsequent processing of the slopes;

- At this stage, the design is completed, it is allowed to proceed with the installation of the window structure.

Finishing doorways

When renovating or remodeling houses and apartments, there is often a need to relocate door openings. In order to move an opening in a wall ceiling you need:

An example of a doorway trimmed with brick

- mark the future opening according to the size of the door block, taking into account gaps of 15 cm.

- dismantle the baseboard.

- knock out a row of wall blocks under an iron or concrete lintel.

- install the jumper and secure with mortar.

- Leave for two weeks until firm.

- knock out brick blocks according to the markings.

- level the floor with a screed.

But such work requires maximum precision and accuracy from the performer, but can still lead to damage to the wall partition. A more suitable option for making holes in a brick wall would be diamond cutting, its advantages are as follows:

- accuracy of cutting line;

- speed of work performed;

- minimal impact on the supporting wall;

- reduced noise level;

If work is required to reduce the doorway, the sequence of work will be as follows:

- It is necessary to perform brickwork in one brick.

- Plastering of the sides is carried out three days after installation.

- After a week, you can install the door block.

It is also necessary to take into account the moment of strengthening with metal structures if the strength of the hole under the door is insufficient.

The work on finishing the doorway is carried out by a master

Peculiarities

Exterior window framing is a process that must be approached carefully. Framing is preceded by the installation of the windows themselves - wooden or plastic. If you have never encountered this, it is better to seek help from professionals

It is especially important that the work is carried out by specialists if you have a ventilated facade

Once the windows are installed, you can think about the exterior decor and take into account several nuances.

Modern finishing options are extremely diverse

At the same time, when choosing synthetic options, make sure that the material does not have any foreign odor when heated and does not deform - the quality of the material is important for your health and comfort

Before installing frames made of stone or other heavy materials on the facade of the house, calculate whether the weight of the structure is too large

In rare cases, particularly heavy structures lead to deformation of the walls. Pay attention to the rules for working with different materials and think about whether you will do the finishing yourself. While siding can be easily fixed with your own hands, stone framing will require special knowledge, and the work of specialists can be expensive. Consider what style of framing will suit your home

The finishing should be organically combined with both the exterior of the house and the decorative elements on your site.

Cladding methods

Varieties of finishing design

Laying window openings from facing bricks will not cause any particular difficulties if you initially plan everything correctly, use high-quality tools and materials, and maintain proportions and symmetry.

There are the following methods for lining window openings with brick:

- Chernova. It is used when masonry is carried out by an inexperienced worker, when using stones from an uneven surface or creating a complex figure with gaps. Once the solution has hardened, the structure is finished using decorative plaster.

- Finishing. Assumes precise work with high quality materials. The masonry is carried out with millimeter precision; no additional finishing is required upon completion.

The choice of method is determined by your own abilities and the configuration of the purchased brick.

Homemade run

When designing window openings of non-standard sizes, the production of the lintel (its filling) is carried out at the location. To do this you will need to perform the following typical operations:

- first of all, the masonry surfaces on the sides of the window opening are cleaned of mortar residues;

- after this they are thoroughly primed;

- At the final stage of work, formwork is installed at the location of the lintel.

Formwork

Reinforcement

Upon completion of these procedures, a thin layer of pre-prepared concrete mixture is poured into the formwork, after which a reinforcing mesh is immediately placed there. After this, you can continue pouring the lintel, followed by placing another reinforcing fill in the concrete. When dismantling the formwork, it should be taken into account that it is not always possible to dismantle its lower part.

Supports for formworkLintel laying

When decorating window openings lined with facing bricks (the so-called facing brickwork), in order to preserve its decorative advantages, it is allowed to use channels (wide metal corners). In this case, the visible part of the purlin will be located only on the inside of the load-bearing wall.

Laying a figured window opening

At the same time, there should not be any noticeable traces of the presence of a lintel on its façade surface.

Style and design

It is very important that the design of the entire house looks like a single whole. For a harmonious style, not only the material is important - the color design is also of great importance, as well as the design itself

Depending on your preferred materials, consider tips for stylish exterior window treatments.

Very often, for the facades of houses in the Russian style, windows are framed from wood with traditional floral patterns. At the same time, more modern options can also look great: you can create a wooden frame with an asymmetrical streamlined shape, or make a strict geometric pattern on it. It will look very good to add a second wooden element of a different color - for example, light wood can be combined with wenge or red wood decor.

Stonework can be very diverse. Sometimes neat identical stones are used to lay out an even frame around the window in the same way as with bricks. Nevertheless, the material allows you to try more interesting designs. For example, you can make masonry that smoothly transitions into the masonry of a facade of a different color if your house is entirely trimmed with stone. You can use two or three stones to frame one window. Contrasting colors such as black and white can look good, or, on the contrary, options that are similar in tone: for example, shades of beige, brown and terracotta.

Often frames made of artificial materials also highlight windows in an interesting way. You can choose an unusual siding color or make a plastic structure of an interesting shape.

Frame-type slopes

So, if plaster is a continuous covering of a slope, then there is also a frame type, when there is empty space inside that can be additionally insulated. The choice of material for such solutions directly depends on the type of building cladding. Slopes can be made of plastic, wooden lining, vinyl or metal siding, window profile, metal cassette element. The installation of these materials is almost identical, so we did not separate them.

View the following photographs showing similar slopes.

Metal cassettes with matching façade cladding

Slopes made of wooden lining

Siding slopes with external frame

Special window profile

Slopes made of plastic with a metallic sheen

Each of the listed materials has its own set of characteristics, but none of them provides the window system with additional thermal protection, like special compositions of plaster mixtures. However, there are methods for insulating such slopes: the internal space is filled with polyurethane foam or mineral wool.

External insulation of window slopes and walls

Installation proceeds according to the following scheme:

- A frame is exposed, which can be external and internal, or only external. In the first case, a belt of slats or metal profiles is attached near the window frame and the same along the outer perimeter of the slope. In the second - only the outer element - the inner one is replaced with a starting profile, which is attached directly to the frame. The last solution is suitable for plastic and thin lining.

- All frame elements are set clearly in level, since they completely determine the geometry of the future slope.

- They are attached differently, depending on the material. Most often, anchors and metal hangers are used as fasteners.

- The finishing material is installed according to the fastening scheme of the specific material. For example, wooden lining can be held in place by nails and self-tapping screws directly or through metal clamps, and siding is held in place by self-tapping screws and a special fastening profile.

- The outer corner of the slope is covered with a decorative element. Usually these are overhead corners, examples of which you could see in the photographs shown above.

Determining the width of the slope

Galvanized profile frame

Sheathing for lining

Slopes made of fiber cement siding can also be installed over the sheathing.

It is much easier to make a frame slope than a plaster slope, and in 90% of cases it does not require additional processing. The product begins its service life immediately after installation. Everything would be great, but not every material will last long. Painted elements fade over time in the sun, wood can rot and change color. You can repeat the coloring, but it will not look like the factory one, and the slopes will definitely lose their attractiveness. But plaster surfaces can be renewed an unlimited number of times.

Peculiarities

Exterior window framing is a process that must be approached carefully. Framing is preceded by the installation of the windows themselves - wooden or plastic. If you have never encountered this, it is better to seek help from professionals

It is especially important that the work is carried out by specialists if you have a ventilated facade

Once the windows are installed, you can think about the exterior decor and take into account several nuances.

Modern finishing options are extremely diverse

At the same time, when choosing synthetic options, make sure that the material does not have any foreign odor when heated and does not deform - the quality of the material is important for your health and comfort

Before installing frames made of stone or other heavy materials on the facade of the house, calculate whether the weight of the structure is too large

In rare cases, particularly heavy structures lead to deformation of the walls. Pay attention to the rules for working with different materials and think about whether you will do the finishing yourself. While siding can be easily fixed with your own hands, stone framing will require special knowledge, and the work of specialists can be expensive. Consider what style of framing will suit your home

The finishing should be organically combined with both the exterior of the house and the decorative elements on your site.

How to decorate a facade with decorative bricks?

Façade finishing is a responsible and quality-demanding job. Without having special knowledge and experience, it is better to leave this work to qualified craftsmen. But if you follow all the technologies, you can do the work yourself.

If you decide to do decorative masonry, follow the basic rules:

First. Calculate the exact amount of material needed. An emergency purchase of brick may result in a different shade. Take 10% more material than needed.

Second. Start with a trial laying. It will help you determine the quality of the mortar texture and joint filling.

Third. Soak the brick in water. Water will clean the brick from dust. This technology will improve interaction with the mortar mixture.

Fourth. Do not hurry. During breaks, you can assess the quality of the work being done with fresh eyes and eliminate shortcomings in a timely manner.

Cladding brick windows

It emphasizes the contour, adds volume and highlights the windows on the façade of the building. Cladding a window with contrasting or relief brick allows you to almost completely change the facade. Facing brick gives the building a more neat and elegant look.

The surroundings of the windows must be carefully calculated and symmetrical in relation to the masonry of the main walls and the corners of the building. Original, beautiful windows will complete the look of the facade, provided that the cracks are carefully sealed using special masonry or using brick platbands.

The harmonious appearance of the facade directly depends on the size and shape of the windows, or more precisely, on how symmetrical they are relative to the corners of the building and the width of the partitions. It is necessary to comply with certain standards when constructing the walls of buildings, but in practice it is often possible to observe inconsistencies that it is advisable to eliminate before laying facing bricks.

General information

Like other facing materials, brick performs protective and decorative functions. It reduces heat loss in the building, prevents the penetration of moisture into internal structures, and partially protects windows from mechanical influences, increasing their strength .

The decorative function is manifested in the ability to create various patterns, adjust the thickness of the layer of materials, thereby changing the amount of sunlight entering the rooms. The frame visually highlights the windows against the background of the walls.

In most cases, polyurethane foam is used to secure window frames. Without external protection, it becomes deformed and becomes covered with cracks. This happens within 1-2 months after its application; exposure to moisture accelerates the process. Timely framing helps prevent such negative phenomena.

Window frame made of polyurethane - advantages

The first (main) advantage is the original design.

Almost no other material for decorative framing of windows and doors has such variability and the ability to combine various components. Here you can create compositions from moldings and cornices, arches and rustications, rosettes, consoles and keystones; you can “play” with the length of elements, the distances between them, patterns of alternation, color and style.

The ability to cut any decorative elements in any place and at any angle without compromising quality, easy assembly of stucco molding allows you to create individual compositions from finished elements or their parts. For greater expressiveness, you can use individual stucco details with small patterns - bas-reliefs, rosettes, panels, door trims. The result is a truly exclusive frame for a door or window, one of a kind, since the designer’s imagination is limited solely by the size of the opening and the financial capabilities of the customer.

Related article: Do-it-yourself repair of plastic swing windows

The second advantage is the durability of polyurethane stucco molding and its ability to hold its shape even for small artistic detailing.

Indeed, the ease of care and durability of polyurethane products can hardly be overestimated. Facade decor made from it is not afraid of snow, rain, or frost; it can be washed with both ordinary water and detergents. Frames of windows and doors made of polyurethane on the facade of the house do not need to be restored, like wooden decor - it is enough to paint it and it will look like new. As for durability, the service life of polyurethane stucco is comparable to the service life of a building - more than 25 years.

The third advantage is ease of installation.

As you know, polyurethane stucco is very easy to process. It can be sawed, cut, drilled, and glued. Therefore, the installation of frames for openings is greatly simplified. Elements - door and window frames, sandstones, rusticated stones and so on can be put together almost like a mosaic; they just need to be fastened together and fixed to the load-bearing surface with glue and self-tapping screws: the decor will hold firmly.

Another advantage is the lightness of polyurethane stucco.

Due to its low weight, it can be attached to any flat surface, including plastered walls and houses of lightweight construction (for example, those made using frame technology). Stucco molding is also convenient to work with: even large decorative trims and moldings can be lifted by installers without the use of special equipment, and this is a direct reduction in the costs of construction work. Our website presents original architectural solutions for decorative framing of windows and doors with polyurethane stucco, developed by the FACADE PROJECT company.

Tips for working with the material

Strength, durability and visual attractiveness of a brick facade can only be achieved by working in strict accordance with existing technologies:

Brick cladding is always a ventilated facade. It is better to use “breathable” mineral wool as insulation (if necessary). The use of polyurethane foam and polystyrene foam sheets is impractical, since in this case they cannot be avoided becoming damp, which means the materials will lose their thermal insulation properties. Their use is permissible only if there is no ventilation gap between the facade and the walls.

- The service life of mineral wool insulation can be increased by using a moisture-proof, vapor-permeable membrane.

- Brick cladding, especially a combined facade (when different materials are used for the walls and the façade) requires mandatory connection with load-bearing walls. Outdated “old-fashioned” methods of connection (reinforcement, steel mesh and other improvised materials) usually cause cracking of the facade in the area of connection.

- If it is necessary to cut brick, the only tool that will allow you to make an even cut without destroying the material is a grinder with a disk for cutting dry stone with a diameter of 230 mm.

- Before laying the facade, load-bearing walls must be cleaned, dried and coated with at least two layers of primer, and wooden buildings require additional treatment with antiseptics and fire retardants.

- Using products from several batches at once will help to avoid the effect of a striped facade, the appearance of which is due to differences in brick shades. To do this, you should take 3-5 pallets with bricks from different batches and use them alternately when laying rows.

- When using not special masonry mixtures, but self-made cement mortar, the bricks are soaked in water for several minutes before laying. This is done to prevent the material from taking moisture from the solution.

It is important to make vertical ventilation gaps every 3 rows of cladding. They are not filled with solution; when it gets there, it is immediately removed with a wooden stick.

You can also create ventilation gaps using plastic boxes. Their width is 10 mm, and their height corresponds to the height of the brick. Their use is much more convenient, especially since the boxes are inexpensive. At least 2 ventilation gaps must remain in the lower part of the windows when facing.

Video description

The video clearly shows the process of creating a straight wedge lintel:

Important! In brick lintels, the seams are made without voids. They are completely filled with cement-sand mortar, since such masonry works in bending. They are practically not affected by compressive forces. If you do not follow this rule, then the bricks will move over time. This can lead to complete destruction of the brick lintel.

Complex run options also include an arched brick lintel. It is created in the form of a semicircle. This design will decorate any facade.

The construction of an arched girder is also carried out using formwork. It is made in the shape of a semicircle. This structure is placed on pre-prepared wooden fortifications. The construction of the arch is carried out in strict accordance with the formwork shape.

To make a template of the correct shape, craftsmen use a construction compass. The construction of the arch itself is carried out by specialists quite quickly, because it is necessary to ensure uniform hardening of the mortar in all places of the structure. The quality of the arched window opening depends on this.