Tightness is the most important characteristic of a plastic window.

It largely depends on the tight fit of the sashes to the window frame and the uniform pressure of the seal along the entire perimeter of the glass unit.

If you make mistakes when installing fittings, you will not be able to achieve high-quality sealing of the structure.

It is necessary not only to comply with the requirements of the regulations, but also to know how to improve the fit after installing plastic windows.

In what case are they required?

The main factor is the appearance of drafts and poor window sealing. If noise, moisture, dust and cold air enter the room, this indicates the need to install additional parts. Especially when this happens with maximum pressure on the sashes.

In a window design,

three technological elements are responsible for downforce :

- awnings;

- response hooks;

- trunnions.

The clamp should provide :

- lack of blowing;

- comfortable opening/closing of the window without effort;

- long service life of the structure without repairs or adjustments.

Therefore, the pressure on the seal must be uniform around the perimeter of the sash and sufficient to prevent the penetration of cold air. A “standard” sash has at least three clamping pins, opposite which there are strikers. If a regular set of fittings is not enough to achieve these parameters, then you can install an additional one.

Installing an additional clamp is recommended on large windows, as well as terraces and balconies.

Design Features

To understand how the window pressure is adjusted, it is recommended to study the structure of the window and its component elements combined into an overall window structure. The main elements of the product are:

- frame;

- doors;

- glass unit;

- accessories;

- sealing and sealing agents;

Complementary structural elements include glazing beads, frames and imposts.

Blitz survey: Do you know what a frame window is? From our last article you can find out: What is a frame window and its design features.

The basis of the frame is a profile with a plastic base, equipped with reinforced steel reinforcement on the inside. The connection between window profiles is made by special welding, which is characterized by high strength and the ability to withstand significant loads. Self-tapping screws serve as connecting elements. The purpose of the frame is to ensure structural strength that can withstand significant loads.

Basic elements of PVC windows

The doors have a steel profile on the inside. These parts are used to perform the opening and closing functions during operation. The fittings for window structures include a wide variety of steel elements - awnings, handles, etc. The purpose of the fittings is to ventilate the room and provide the opening function. The operation of plastic windows largely depends on how high-quality fittings were used in the manufacture of the product.

The purpose of double-glazed windows is light transmittance, providing natural lighting to the premises. Plastic window designs can contain from one to several double-glazed windows. The glass in the bag forms an air chamber. High-quality characteristics are ensured by pumping special gas into the chamber. To hold the glass, glazing beads are used, which are most often made of plastic.

What does a double glazed window consist of?

Increased tightness is ensured by the use of seals. They serve to protect the internal space from moisture and cold. If the window opening is made of several structural parts, it is necessary to install an impost between them. The material for the impost is a reinforcing galvanized steel profile or plastic. With the help of a plastic element, the window opening is completely freed. If the elements are made of steel, they are installed permanently in the opening, allowing the opening to be divided into many component parts.

links to materials that complement this article: How to check the quality of plastic windows. What should you pay attention to?

Windows with blinds inside double glazing

Colored PVC windows in the interior of the apartment. Photo

Types of parts for installation

The tightness of the fit is greatly influenced by the number of pressure points and the correctness of their location around the perimeter of the opening. The tight fit is ensured by clamps and hardware locks. The first type is independent mechanisms, and the locks are controlled by a handle.

During long-term operation of the structure or when exposed to sudden temperature changes, softening of the profile may occur. The sash begins to sag and does not adhere tightly to the frame . As a result, the main parts become insufficient, so there is a need to install additional middle clamps.

There are the following types of products.

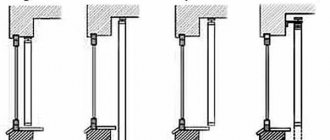

External middle

The clamp consists of two metal parts. One is located on the frame, the second on the sash. Such elements are visible when the sash is closed, so decorative trims are used to improve the aesthetics of the window. External clamps are installed on the sash between the upper and lower hinges .

They have the same principle of operation, although the design differs depending on the manufacturer. When turning the sash, the part serves as a lever, which ensures a tighter fit. The number of levers depends on the length of the sash. Such products are installed only on rotary sashes.

Hidden

Also suitable only for windows with a turning mechanism, they work on the principle of a lever. The quantity depends on the size of the sash. Some models are adjustable, which distinguishes them from external clamps. The disadvantage of this type of clamp is manifested in its strong sensitivity to deformation of the window sash.

Middle loop

This type is installed on high sashes. The loop is visible from the outside and is also decorated with overlays. The softer the profile, the smaller the distance between the two trunnions should be.

Checking the pressure

After installing the windows, you need to immediately check the pressure. Sometimes this is done using a candle or lighter to detect blowing with the help of a flame. However, this method is not always effective, so it is better to use the paper test method. To do this, a regular sheet is placed between the frame and the sash, after which the window is closed by turning the handle to the “Closed” position. If the paper is firmly held between the profile and the sealing contour, the seal is normal. Otherwise, you will need to adjust the pressure of the plastic windows. If after this procedure the sheet still slides along the profile, it is necessary to add additional elements.

For the fittings to function properly, the eccentrics must be in the correct position. There are 2 modes – “winter” and “summer”, about switching which you can read in the article on OknaTrade.

Rules for selecting an additional element

Installing additional elements lengthens the fittings. Therefore, you need to approach the purchase of an additional clamp responsibly. When choosing parts for a plastic window, you need to be guided by the following rules :

- Manufacturer's name. Ideally, the window structure and fittings will be manufactured by the same company.

- Material. Usually it is metal or plastic. Metal ones are durable and have the ability to adjust the clamping force; they require annual lubrication. Plastic ones have a simpler design and shorter service life. Very rarely are models produced that provide adjustment of the clamping force.

One more nuance. Before purchasing external clamps, you need to check whether the slopes allow you to screw the striker to the frame. If they go far into the profile, then you should take a hidden model.

Adjusting plastic doors yourself: instructions

Before you start adjusting the entrance or balcony plastic doors, check the integrity of the seal. Often its defects become the cause of drafts and leaks. If the seal is damaged, replace it with a new one. In this case, there is no need to disassemble and adjust the mechanisms.

Before starting repair work, close the doorway and outline the frame around the perimeter. The contour should be parallel to the inner edges of the door frame. If there are curvatures, you need to eliminate the sagging of the sash and adjust the canvas in height.

First remove the decorative trims from the hinges, this will provide access to the screws.

Door pressure adjustment

Loosely fitting doors lead to drafts in the house and the formation of condensation on the glass. Before you start adjusting the door pressure, you need to determine the place where the gap appears.

If there are areas where the sashes do not fit tightly, you need to correct the defect by turning the axles. These are bushings at the end of the door frame, located along its perimeter. When the door opens and closes, they move.

On one side of the pins there is a mark or a stamped point - this is a mark. It should be directed upwards. To make the clamp tighter, turn the axle with the hexagon mesh towards the room. So the door is switched to “winter” mode. To loosen the fit, turn the mechanism towards the street.

Adjust the position of the door using the pin and hinges. Source: https://www.okno-moskva.ru/

The pressure of the sashes is also adjusted using the lower hinges. Open the door and look at the door leaf: you will see a screw at the bottom. Rotate it to obtain the required pressure on the door leaves.

Turn the bolt in the bottom hinge until the door fits snugly. Source: https://remontokon777.ru/

If both methods of adjusting plastic doors did not help, the problem lies in deformation of the structure or incorrect installation. To eliminate the defect, move the strike plate 1–2 mm closer to the street and secure it.

Adjusting the plastic door height

Sagging of the sashes more often occurs with double-chamber double-glazed windows - they have more weight and more load. To lift the sash, you need to rotate the screw on the bottom hinge. To do this, take a 4 mm hexagon and turn it clockwise - the canvas will rise, counterclockwise - it will fall. This method helps if the canvas has sunk evenly around the entire perimeter.

Scheme for adjusting the height of a plastic door. Source: https://balkonka24.ru/

The skew of the door leaf is indicated by the sagging of one side relative to the bottom edge of the opening. To level the defect, adjust the upper and lower side loops. Turn the screw with a hexagon. If you turn to the right, the canvas moves in the direction of the key, if you turn to the left, in the opposite direction.

To eliminate skew, adjust the top and bottom loops. Source: https://www.ivd.ru/

Displacement of the blade leads to an increase in the load on the glass. If the defect is not corrected, the glass unit will burst.

If moving the adjusting screws does not help, the sagging is corrected with pads under the glass unit. To install them, the glazing beads are dismantled and calibrated wedges are installed. Leave repair work to the masters: you must strictly follow the technology so that the door does not become deformed.

Adjusting plastic door hinges

The hinges of the door panels are adjusted if their lower part catches the frame or does not fit tightly. The problem arises in the autumn-winter period, if the fittings are relegated to a corner. To eliminate the defect, the sash is moved horizontally: the position of the top and bottom hinges is adjusted.

Attention! To adjust the plastic profile, tighten the upper and lower hinges. If you adjust only one, then the position will change only at this point. The entire profile may become deformed.

The sequence of actions is as follows.

Open the door and trace the outline of the canvas with a simple pencil. If both edges are equidistant from the inside of the installation box, you can complete the adjustment of the plastic door.

Tighten both loops to avoid distortion. Source: https://stroychik.ru/

The back adjusting screw may be located in the corner or above the door leaf.

Adjusting plastic door fittings: handle repair

The handle is attached to the door with two screws. Over time, the structure becomes loose, the fastening needs to be tightened. To do this, turn the plastic plug hiding the screws 90°. Screw the screws until they stop.

Two screws are hidden under the plastic plug.

If you cannot turn the plastic plug, pull the door handle towards you and try again. Loose screws may rest against the plug and interfere with rotation.

If the handle turns worse after repair, remove the plastic plug again and loosen the screws a little. Try opening and closing the door again.

If the handle closes poorly, does not turn completely or creaks, you need to correct the coupling of the pin with the strike plate. The principle of operation is the same as in the case of the clamp: turn the axle with the mark towards the street, that is, move it to the “summer” position.

Breakage of the handle may be the result of incorrect adjustment of the balcony door. In this case, the sequence of actions is as follows.

If the above adjustment methods did not help, this means that the problem lies in the wear of the belt mechanism.

Adjusting the fittings of a plastic door includes working with hinges. If during operation they become loose and begin to wobble, you need to tighten them with a hex wrench. If the lower fastening is torn out, you need to change the hinge. There are two reasons for the breakdown.

If the handle makes sharp sounds when opening and closing the front door, remove the handle and lubricate the mechanism. If lubrication of the moving parts does not help, you need to change the locking system.

To lubricate handles and other moving parts, use machine oil. Source https://legkovmeste.ru/

3 replacement of seal

If after adjusting the pressure the drafts do not disappear, you need to change the seal. This part lasts no more than ten years: it is destroyed by external damage and careless operation. Door gaskets cannot be repaired, they are only replaced.

There are three types of seals.

Rubber and rubber are wear-resistant models. Resists temperature changes and humidity changes.

Plastic rubber seals have the longest service life. Source: https://www.plastok.ee/

Polymer - made on a PBX basis. We do not recommend installing in regions with cold winters; seals do not tolerate low temperatures.

Polymer sealants are used only in mild climates. Source: https://www.oknakomforta.ru/img/

Polyethylene - produced on the basis of foam. The insulating material is not elastic enough, it does not recover well after compression.

The foam-based sealant is short-lived. Source: https://remont-book.com/

You can change the seal yourself. To do this, purchase a layer of insulating material, which you will place in the doorway, and silicone glue.

The sequence of work is as follows.

Source

How to install correctly?

You can do the installation yourself. It is important to follow the instructions and follow the manufacturers' recommendations.

Installation of main types

This includes installing trunnions and strikers. When installing the window structure, you should check the location of the strikers. Carry out the check when the sash slams shut. If the trunnion engages the mating parts incorrectly or rests against them, then the sash will not be able to slam shut. Another possible problem is that the strikers are screwed in such a way that the trunnions do not reach them. In both cases, it is necessary to install the strikers correctly.

First of all, you will need:

- Determine the range of travel of the trunnions and the direction of their movement when locking. It is necessary to install the mating parts in front of the trunnions in the direction of movement of the sash for locking.

- It should be installed at such a distance that the trunnions do not rest against the middle part of the slats, but slide behind them. Otherwise, the handle will not be able to move down completely.

To ensure an optimal degree of fit, you need to install at least 2 strips on each side of the sash.

Additional

Hidden models can be installed without removing the sash :

- Mark the location of the strikers on the frame. They must coincide with the press-in part on the sash.

- Insert the components of the clamp into the fitting grooves of the profile.

- Screw on with self-tapping screws.

The fittings are included in the window unit.

External models are mounted by removing the window sash:

- Remove the decorative trim from the top hinge.

- Use a screwdriver to pry off the finger and remove it.

- Slightly tilt the sash forward, then lift it up and remove the part.

- Apply a thin part of the clamp to the middle of the side end of the sash and screw the part with metal screws.

- Return the sash to its place.

- Screw the mating part to the frame.

Additional eccentrics are installed when it is necessary to install trunnions on the upper and lower profile of the sash. This work must be entrusted to professionals. The number of eccentrics can be increased by replacing the middle locking bar with a long one.

The successful process of installing additional pressure points requires knowledge of the features of fittings from different manufacturers. You should also be able to determine the type of underlying constipation. In some cases, it may be necessary to replace the corner elements to ensure proper functioning of the system after the update.

Repair of possible hardware breakdowns

Various types of problems may arise with accessories during operation. Among all the possible difficulties, two are the most common.

- If the latch does not fix the position of the door, then a pair of metal washers can be added under its cylinder. If the locking is correct, but even the slightest wind tears the doors off, you should add another latch.

- A common problem is a tight latch, which complicates the process of opening and closing doors. To get rid of this problem, it is recommended to lubricate the mechanism with oil.

Proper installation reduces the likelihood of latch problems

Sagging doors

To deal with this problem, you need to adhere to the following algorithm.

- Place a mark where the door leaf meets the frame.

- Move the door in the opposite direction.

- Using a hex key, turn the screw located on the top hinge clockwise - continue until it is pressed tightly.

- Carry out similar actions with the bottom loop.

The hinges can be adjusted horizontally and vertically

Loss of tightness due to wear and tear of the insulation

Fixing this problem is quite simple.

- First you need to buy a new seal. It should be the same as spoiled.

- The old seal should be removed from the groove using any available tool, such as a screwdriver, and a new one should be put in its place.

- For better fixation, you can add rubberized glue to the groove.

The seal is a short-lived accessory that needs to be changed periodically

Problems with opening and closing doors

This problem often occurs when the function of the pen is disrupted, because it:

- tightened too tightly;

- does not turn completely.

To fix the problem, make horizontal adjustments to the hinges. If there is a malfunction of the handle with a core, you should:

- dismantle every part of it;

- check how the pin is secured (it connects the handle and the core).

If the connecting pin has any defects, it must be replaced. In some cases, the entire handle may need to be replaced.

If you can’t solve the problem yourself, it’s better to call a specialist

Difficulties and errors

When installing clamps on plastic windows, some difficulties may arise :

Wrong choice of part type. In this case, it will be difficult to achieve a good fit.- Self-installation of additional eccentrics. Lack of experience and knowledge can lead to a violation of the window geometry.

- Use of low-quality tools. This will damage the profile.

In addition to installation, it is necessary to adjust the fit.

Handle malfunctions

Sometimes there is a problem with the operation of the pen. This part is most susceptible to wear and requires frequent maintenance. In order to secure or change the handle, you need to rotate it 90 degrees. Afterwards you will need to remove the decorative trim: you will see the screws that hold the handle. Unscrew them; After this, the handle can be easily removed. It can be replaced with a new one, which will need to be secured with screws in the reverse order.

If a comb is needed, it can be fixed to the base of the handle. In construction supermarkets you can buy a child-resistant handle.

Required Tools

In order to adjust plastic windows with your own hands without much effort, you need to have or purchase some tools. During the work you will have to use:

- hex key, size 4mm;

- bits for a star screwdriver;

- Phillips screwdriver with No. 3 or No. 4;

- pliers;

- technical oil or WD40.

Regarding the attachments that are used for a screwdriver, they will be necessary only in certain types of windows; in general, you can do without them, but having them will not hurt, because it is impossible to know in advance that they will be useful without special knowledge of the type of window.

Using a furniture key, which is called a hex key, will be much more convenient if, in addition to its characteristic shape (the letter G), it has an additional curved upper edge, but you can also use such a regular-looking key.

It is impossible to do this without a regular Phillips-type screwdriver, because all the available parts of the fittings are attached to the retractable window frame with bolts that are designed for a Phillips-head screwdriver. In most cases, windows have to be adjusted only in roller-type carriages, where the distance required for work is set.

In addition to the tool, without which you cannot adjust plastic windows yourself, it is better to additionally familiarize yourself with the main adjustment points in advance, this will greatly facilitate the work.

| Element | Adjustment |

| Bottom loop | This mechanism contains an adjusting element in order to adjust the position of the open window in the vertical plane, as well as the angle at the bottom of the sash in the horizontal plane. |

| Top loop | In this mechanism, the sash is adjusted in its upper part. |

| Locking pin | The force with which one part of the window is pressed against another occurs in one of the specified parts of the mechanism. |