Most of the planned work on replacing PVC windows takes place in the warm season - autumn or spring.

But what if you urgently need to replace a window in winter?

Many experts believe that such a window design can be installed at any time of the year, the main thing is to follow the technology and know the nuances for different installations. In this article we will find out what is the best time for installation and is it worth replacing windows in winter?

What time of year is best?

The technical process of installing PVC windows is essentially completely independent of the time of year. In any season, the installation technology is the same. It is important to approach the installation of window units with special responsibility and know all the nuances.

the time for replacement of window units depending on the existing need and real possibilities. But if he wants to save on installation and get a better quality product as a result, it is better for him to choose the winter time, when installation prices drop by up to 30%, and due to the low volume of work, contractors fulfill the requirements of the PVC window installation flow chart more efficiently .

Experienced installers believe that when choosing an installation period, it is more important to focus on the presence of high wind potential outside the window. When the wind is above 4 m/s, installation, especially on a high floor, is prohibited, regardless of the season. The minimum temperature for work is considered to be -15 C.

Are PVC structures installed in winter?

For some customers,

winter work on installing PVC windows.

For those who are embarrassed by the fact that the apartment can cool down in winter, there is a strong argument - in modern conditions, the installation of PVC windows in apartments and houses proceeds extremely quickly from 25 to 40 minutes, practically during this time period the house will not have time to cool down.

In addition, serious installation companies have special removable barrier shields for these purposes, which do not allow the room to cool down and thereby disrupt the installation process

In winter, two options are used for installing PVC blocks: for heated and unheated rooms.

Let's look at the features of winter installation of PVC windows.

For heated premises

There are no particular difficulties. It is enough to bring window structures and auxiliary consumables the day before installation so that their temperature is equal to the temperature in the room.

When choosing consumables: foam and sealants, especially those that will be applied from the outside, you need to pay attention to the conditions of use; they must be designed for sub-zero installation temperatures.

For unheated

The current provisions of GOST No. 24866, issued in 2014, prohibit the installation of any types of windows at temperatures below plus 5C. This is caused by the sealing conditions of the glass unit; at low temperatures, the air in the glass unit is compressed, creating a vacuum, the glass takes the shape of a concave lens.

When the room is heated, this process is insignificant and does not threaten the glass unit in any way; at negative temperatures inside the room, the glass may burst. Therefore, for unheated rooms, during the installation of a PVC window, you will have to install a temporary heating source to raise the temperature to +5C and above . Also, the PVC profile becomes very fragile at low sub-zero temperatures.

Foams and sealants must be “winter” modifications. Application of PSUL tape. Frames for installation in cold weather must be frost-resistant; the standard defines the maximum negative temperature for such structures -60C.

Spring/autumn

The average daytime temperature in the autumn-spring period is almost always above “0”, so there are no special temperature restrictions for this period of the year regarding the installation of PVC windows. Nevertheless. Installation during this period should be treated with caution as it is characterized by particularly windy and humid atmospheric conditions.

In windy weather above 4 m/s, the installation of any windows is prohibited, and it is also unacceptable during rains. In other cases, there are no special restrictions for construction and installation work during this period.

Features of spring-autumn installation of PVC windows:

For heated rooms. Attention is paid to the purchase of consumables, especially external ones; they must be waterproof and suitable for the air temperature at which construction and installation work is planned.- For unheated rooms when the temperature inside is below 5C, there must be a temporary heating source. Consumables must be designed to work in the operating environment.

- During times of high humidity or fog, external protective screens are used on the window.

Summer

Many people try to install windows during this period of the year, despite the fact that the cost of summer installation is 30% higher than winter installation, the queue for installation is huge, and the quality of work is not the best.

Therefore, a prudent owner will definitely not install windows in the summer. There is another serious reason that almost none of the customers pay attention to - these are restrictions on the maximum temperature not exceeding +35C.

Features of summer installation of PVC windows:

- Attention is paid to the acquisition of consumables, especially external ones; they must be waterproof and suitable for the air temperature at which construction and installation work is planned.

- Consumable building materials must be designed to work in the working environment, above +30C.

- During times of high humidity or fog, external protective screens are used on the window.

Advantageous windows

We order high-quality plastic windows and save money

Plastic windows are attracting more and more people with their technical characteristics and advantages.

True, you can still sometimes hear the opinion that new PVC windows are quite expensive, but a person is quite capable of maintaining old wooden windows in good condition. Even though they were installed a long time ago, they need to be painted and sealed, but you won’t have to invest in glazing with a different profile.

- Why are plastic windows so beneficial?

- Is it possible to save money by ordering inexpensive new windows from a company without losing quality?

- Are companies ready to provide noticeable discounts?

All these questions are easy to answer if you understand a little about the very specifics of plastic windows and certain trends in the market.

- When is it more profitable to install windows?

- What is the difference between deception and an honest offer to save money?

- why plastic structures are the most profitable.

Plastic windows are always beneficial

The features and advantages of plastic windows require special attention. They make even quite expensive profiles truly profitable. It’s just that buyers are accustomed to focusing primarily on the cost of the acquisition itself, and usually no longer think about further operation and repairs - this is “another expense item.”

They always look flawless and are able to maintain their original beauty for decades without needing any updates.

Owners who have decorated their home with modern windows made of plastic profiles practically do not notice the change of seasons. Forget about gluing the frames: simply adjust the sash with a special “comb” to create the desired climate in the room, reduce or increase the air flow. And when closed, PVC windows are practically airtight!

That is why plastic windows from reliable manufacturers, correctly selected and installed, are beneficial in themselves - they are as convenient, reliable and efficient as possible.

Windows at low prices: even more profitable and easier

You can often find fantastic offers that immediately alarm experienced and sensible buyers. Plastic windows, positioned as reliable and durable, are sold at incredibly low prices. Such an offer will most likely turn out to be a hoax.

You can purchase windows at competitive prices, thus they also sell high-quality profiles and install them perfectly. It is important to distinguish an offer from a reputable company from a scam. For example, in Moscow people are already accustomed to receiving discounts and participating in promotions.

Windows can be sold at low prices in a number of cases, and this will not affect the quality in any way.

- Winter time. Seasonal discounts and promotions will allow you to buy windows at a significantly reduced cost. Companies care about a stable level of sales and thus encourage potential buyers not to delay installing windows until spring or summer.

- Good old windows. They are reducing prices for windows, which have already moved a little back in the line of one brand. This does not mean at all that a particular type of window is bad or of poor quality: new models have simply appeared, more modern and functional. It is quite possible that windows that have been on the market longer and cost less will be more suitable for you. It all depends on the specific operating conditions and technical characteristics of the profile.

Suitable temperature: how many degrees is it acceptable to set?

Manufacturers of PVC windows calculate window structures in such a way that they function normally at high/low average Russian air temperatures and relative humidity. For Moscow, these characteristics are +26.3/-15C and 95%, respectively.

This is due to two reasons - the use of consumables: foam, sealants and self-expanding tape, which are designed for their temperature range and the behavior of structural materials and window elements in different temperature conditions.

During the winter season

The minimum winter temperature for installing PVC windows is -15C outside the room and +5C inside. At lower temperatures, the glass unit may crack, and the PVC elements will become brittle; if handled carelessly, they may collapse.

Consumables for installing PVC windows in winter:

“Makroflex” winter foam up to -15 C, excellent adhesion, low secondary expansion, price - 970 rub./piece.- “Soudal” winter foam up to -15C, without toxic additives, odorless, fine-porous and dense structure, cost - 292 rubles / piece.

- “Penosil” winter foam down to -15C, practically odorless, low secondary expansion, high foam yield, price - 665 rubles/piece.

- “Titan” winter foam up to -15C, non-toxic, without shrinkage and with good adhesion, price - 375 rubles / piece.

- Silicone sealants with a working temperature of -50C:

- Belinka Belsil - 300 rubles;

- Ceresit CS 25-150 rub.

- Robiband RF tape PSUL, 6 m - 144 rub.

Spring/autumn

This is the best option for installation. The materials used for installation are called non-seasonal , the permissible temperature of the outside air is -5 to + 20 C, and the inside temperature is above + 5 C.

- Consumables for installing PVC windows in the spring-autumn period: “Moment-installation” off-season foam, temperature range -5 to +20C, good adhesion, dense, homogeneous, tolerates finishing well, price 250 rubles / piece.

- Acrylic sealants with operating temperatures from -5 to 20C:

- Makroflex FA131, Germany - 360 rubles;

- Dow Corning 7091, USA - 1500 rub.

- Polyurethane mixtures:

- TYTAN PROFESSIONAL PU 40, Poland - 700 rubles;

- Dow Corning, USA - 1800 rub.

- Robiband RF tape PSUL, 5.6 m - 290 rub.

In summer

Summer temperatures have a maximum limit of +35C. this is due to the fact that due to thermal expansion, the windows will behave unpredictably, for example, the sashes will not be able to close or the fittings will not function.

In this temperature regime, it is impossible to perform the correct post-installation adjustment of such a window. Therefore, if it happens that it is necessary to install a PVC window during high summer temperatures, you need to choose morning or evening hours for installation, when the mercury column on the thermometer is below 35C.

Consumables for installing PVC windows in summer:

- Stroypena:

- Makroflex, 750ml, price - 800 rubles;

- TYTAN Professional, price - 360 rubles;

- Penosil Max /Premium/PRO, 750 ml price - 500 rub.;

- Makroflex ShakeTec, 750 ml. price - 1500 rub.

- Polyurethane sealant, used at temperatures above +35C:

- “Moment” 600 ml, price - 460 rubles;

- “Izhora” 12.5 kg, price - 2188 rubles;

- Olin 600 ml, price - 200 rubles;

- Retel 310 ml, price - 110 rub.

- Robiband RF tape PSUL, 6 m - 144 rub.

Is it possible to glue wallpaper before installing windows?

If you're thinking of putting up new wallpaper, you shouldn't do it with old windows. Window installation is a whole complex of “dirty” work on the structure. ... It will be necessary to remove the old windows, which naturally damages the internal slopes.

Interesting materials:

When did Saturday become a day off? When is Myron's angel day? When is Family Day 2022? When is Railwayman's Day this year? When is Republic Day in LPR? When is Family Day in May? When is St. Andrew's Day in Russia? When is Accountant's Day in Russia? When is Accountant's Day celebrated in Russia? When is Chief Accountant Day in Ukraine?

Installation features

The construction organization must choose the technology for installing PVC windows and consumables depending on the season of work.

Manufacturers of PVC window blocks suggest installing them in the autumn-winter period, since it will be possible to immediately check the window for energy efficiency.

If during installation drafts or fogging of the glass unit is detected, the quality of the installation work is unsatisfactory, and the window leakage must be repaired by the company that carried out the installation.

During the cold season

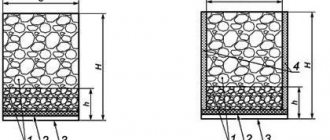

Installation of PVC blocks in winter is complicated by negative temperatures and high humidity. In order to level out such negative conditions, installers use 2 methods of winter installation.

Winter installation of PVC windows in heated rooms:

To protect the workplace on the street side, a protective heat shield is attached, which retains heated air in the room, preventing the installed double-glazed windows from freezing and protecting them from moisture.- Frost-resistant polyurethane foam is used.

- The joints are sealed indoors.

- Inside the room, the layers of the seam are distributed in this way: silicone sealant, polyurethane foam and joint insulation.

- On the outside, all seams are covered with waterproof tape.

This method, as a rule, costs more than a conventional installation, but it is the one that can smooth out the influence of negative winter factors.

Winter installation of PVC windows in unheated rooms:

- Construction foam with frost-resistant characteristics is used.

- Turn on the heat gun.

- Warm up the outer layer of applied foam.

- Fill the gaps from the inside with foam. This method gives good results in filling all voids with foam.

- The mounting tape is fixed in warm conditions.

- During the installation process, the PSUL hydro- and vapor barrier tape is also heated by a “heat” gun together with the joint surface.

This method is one of the most labor-intensive “winter” options for installing PVC windows, but ensures high quality work.

In the warm

In the warm season, when sealing the installation seams of PVC windows, preparatory work is carried out to dismantle old blocks and prepare the surface of the opening.

In order to create an installation seam in three layers, you will need to purchase PSUL tape for the outer vapor-permeable layer, the central one is filled with summer or inter-seasonal mounting foam with a heat-protective effect, and the inner vapor barrier is made of waterproof tape. This protection design does not allow moisture and vapor to penetrate either from the room into the seam, or from the street into the room.

With this scheme, the seam can be ventilated from the street side, removing the moisture accumulated in it outside, and not inside the room.

Sealing seams when installing PVC windows:

- Paste the PSUL tape before installing the PVC frame, avoiding creases, and also make sure that no mortars get on it.

- Apply foam in a continuous line, leaving no voids or gaps.

- Excess foam is cut off to install vapor barrier.

- If the installation gap is very large, the foam is applied in layers, waiting for the previous layer to polymerize.

- On the room side, a vapor barrier tape is glued over the created seam, with overlaps in the corners.

Preparatory work

OKNO.ru - Quality comes first!

Call +7 (495) 278-1-888

Only until the end of the month there are special discounts of 30% on windows and balconies!

I want a discount

This stage of glazing should be taken seriously. By well preparing the openings for installation, you can increase the service life of the window by 5-15 years. In most cases, it is impossible to glaze a loggia without first preparing the base. For example, before installing an aluminum “slider”, a masonry of foam blocks is installed or the existing metal parapet is strengthened.

It is more difficult to prepare a PVC profile for installation. It is necessary to carefully consider the heat exchange in the room. As a rule, plastic on a loggia is mounted on a support made of foam blocks. It perfectly holds large weights, protects from cold, and is resistant to strong winds. The disadvantage of foam blocks is their vulnerability to precipitation. Foam block masonry must be cleaned from environmental influences.

Pros and cons for different seasons

Experts believe that all seasons are good for installing such windows; the main contractor must withstand the work technology and temperature characteristics. Among users there are supporters of both winter and summer options for installing such a window structure.

Advantages of different options for installing PVC windows:

- Summer : Low volumes of preparatory work, low cost of installation work, low-cost consumable building materials, low labor costs for installation, high quality of installation and adjustment work, high quality of sealing work.

- Winter : a good level of diagnostics of the quality of functioning of all window elements - any draft will be identified and eliminated in a timely manner by installers, a high level of adjustment work, shorter waiting times for installation, due to the unloaded winter service market, low cost of construction and installation works.

Disadvantages of different options for installing PVC windows:

- Summer : It is difficult to diagnose the quality of installation work due to the lack of cold air, the high cost of construction and installation work, the congestion of the market for installation services of PVC windows, the low quality of work and the level of adjustment.

- Winter : High labor intensity of work, high cost of consumables designed for work in winter.

When performing work in both cold and hot weather, it is very important to take into account the thermal expansion of the PVC frame and sashes, so it is recommended to bring them to the site at least 24 hours in advance for “acclimatization.”

Reviews

Before choosing the preferred season for installing PVC windows, the user needs to read on the Internet the opinions of the owners of such structures who have already installed them.

Advantages of installing PVC windows in different seasons according to forum materials:

- Summer period:

- quick installation;

- good selection of consumables.

- Winter period:

- significant discount on installation;

- the ability to choose professionals;

- work gets done faster;

- It is better to install it in winter so that you have time to check the operation of the unit during the one-year warranty period;

- excellent result of the work, the main thing is to make sure that the installers install winter foam and sealants;

- in Siberia, windows were installed in winter and no problems for 5 years;

- The work was completed in no more than an hour; the apartment did not have time to cool down.

Disadvantages of installing PVC windows in different seasons, according to users, based on forum materials:

- Summer: low quality of work due to the fact that the craftsmen are in a hurry or have low qualifications.

- Winter period:

- possible damage to the structure from frost;

- it is difficult to properly prepare openings;

- liquid plastic does not harden and is not attached to the construction material;

- when it got warmer, one of the doors sagged.

You can read the reviews in detail here and here.

Useful tips

Removal of old windows must be done on a windless day. Construction waste must be removed immediately so that it does not interfere with the work. In addition, it is useful to adhere to the following recommendations:

- There is no need to save on the number of opening doors. The more there are, the easier it is to clean the window unit.

- You should not be tempted to install plastic windows with wide sashes because they are cheap. Such structures may sag after two years of use. Preference should be given to standard sashes.

- If there are plans to independently insulate the balcony, you need to inform the workers about this. They will install additional profiles that will allow you to further secure the insulation and perform finishing work.

ryazan.satels-okna.ru

Preparation for glazing

Why should you take it seriously? The service life and efficiency of glazing increases significantly. As an example: an aluminum frame lasts three years on average, and if a loggia or balcony is properly prepared, then all 15. And the price of preparation is an order of magnitude lower than the cost of the most budget glazing. However, sometimes the question of whether it is needed or not is simply not worth it. In 80% of cases, it is impossible to install the structure on the average balcony or loggia without preparation.

To install an aluminum “slider”, a frame is assembled from timber (50×70mm), which forms the correct installation plane and has minimal weight, without taking up useful space.

Pros:

- This is aluminum - it conducts heat perfectly, which will be distributed evenly throughout the frame. The heat will also be at the bottom, unlike plastic, which will only be warm at the top.

- Twice cheaper.

- More compact.

Minuses:

- Poor sound insulation.

- Compared to plastic, it retains heat inside a balcony or loggia worse.

Preparing for the installation of warm (plastic) glazing is more difficult, because it is important to think through the heat exchange inside the balcony or loggia. Typically, the structure is installed on a supporting masonry made of foam blocks, which perfectly supports large weights, retains heat and withstands extreme wind loads. But foam blocks have a disadvantage - they do not tolerate rain or snow, so they need to be protected from environmental influences.

A warm loggia increases the cost of housing. Even if you don’t plan to sell the apartment or add a loggia to it, warm square meters have never hurt anyone.

Is it possible to glass a balcony in winter and in the rain?

If it is not possible to insulate and glaze the loggia in the summer, this work will have to be done in the off-season or in winter. Arranging a balcony on a rainy or cold day will have its own special features.

- Dismantling of the old structure can be done at any time, except in windy weather and extremely low temperatures. In the first case, some part may fall and injure passers-by; in the second, the builders themselves risk slipping.

- Neither rain, nor wind, nor frost will interfere with welding work.

- Installation of a wooden frame (sheathing) in winter should be done from dried wood. Damp wood will crack when screws are screwed into it.

- Installing a canopy in rain and snow is also allowed. However, you will have to make sure that moisture does not get between the joints, otherwise the connections will be loose.

- In winter, lining a balcony can only be done with siding - a material that is easy to handle and frost-resistant. Finishing the structure with PVC panels and clapboard if there is snow and ice around is extremely undesirable: the casing will burst.

Thermal insulation

There are two options for thermal insulation: warm and cold structures. The first are intended for balconies, which are a full-fledged part of the living space, the second are suitable for an isolated balcony, their main function is protection from weather conditions.

Cold glazing

If there is no goal of turning a balcony into a living space, structures made of light profiles, such as aluminum, will suffice. Typically this is single glass or double glazing. In this case, additional insulation is not used or is used to a minimum. This option is cheaper and weighs less, which is important for the load on load-bearing balcony slabs, especially in old houses. Cold glazing does not provide thermal insulation - in winter the temperature on the balcony will be only a few degrees higher than outside.