Plastic windows are one of the most effective for protection against heat loss and high-quality sound insulation.

In order to preserve the original technical parameters as much as possible, it is important to choose the right size of PVC windows.

Manufacturers precisely set the length, width and depth of window structures.

How is it determined?

The concept of “plastic window size” defines its dimensions, determining the height, width and depth of the glass unit. Standard sizes are taken into account by manufacturers in accordance with GOST requirements.

When designing and manufacturing sashes, common glazing options are taken into account:

- single;

- double;

- triple.

The standard GOST requirements meet the dimensions of most modern new buildings and houses that have been put into operation. Thanks to this, there is no need to order individual plastic windows, since you can choose ready-made PVC windows with the specified parameters.

What sizes can pivot and fixed windows have?

The minimum size of a plastic window sash depends on its functionality. If the window is blind, it can be, for example, 20 by 20, but a tilt-and-turn design requires a slightly different approach. This is due to certain dimensions of the mechanisms, which, even with a strong desire, cannot be reduced in any way, because windows of any design are equipped with standard fittings.

Bathroom with small opening windows

The minimum size of a plastic window with opening is 30 by 30; If you use a smaller frame, the fittings will not fit on it and the window will not be able to open. However, it is worth noting that the size also depends on the brand of fittings. Not every manufacturer produces products that fit such a miniature window. The minimum possible option is given when selecting fittings that can fit on a frame of the minimum size.

What GOSTs and SNiPs regulate the requirements?

Standard GOST standards correspond to the dimensions of a large number of buildings, which becomes a great advantage, even if minor adjustments are required.

In accordance with the requirements of GOST 23166-99, the following important parameters are determined :

- humidity from 8 to 12%;

- standard height sizes - 60, 90, 120, 135, 150 and 180 cm;

- different depth options depending on the number of cameras.

Before buying PVC windows, it is recommended to study all the information on the manufacturers . Experts recommend calling a surveyor who will offer to look at a catalog with ready-made structures and take high-quality measurements.

There is also a description in SNiPs, which describes the standards for glazing adopted in Russia. Standard dimensions are not determined randomly. The necessary parameters for safety and duration of use are taken into account. The installation of an optimal microclimate is also taken into account, which ensures the health of the residents.

Round windows

Round windows made of PVC profiles - how they are produced and how much such plastic windows cost.

Round plastic windows are warm and reliable. They are not only not inferior, but also superior in these indicators to their analogues made of wood and aluminum.

Round plastic windows have become especially fashionable recently with the use of the latest bending technologies, which have made prices for these products more affordable. Round windows look original and emphasize the individuality of the house.

Production of round PVC windows at the Business-M plant

Making round windows from PVC profiles is a process in which, under the influence of high temperature, the plastic profile is softened and given the shape of a rounded arch. To ensure that the geometry is smooth and precise, special bending equipment is used, which allows you to fix the softened profile in the shape of a given radius.

Production stages

- On a bending machine, all plastic elements of the future window are bent: frame, sash, glazing bead.

- The frame is welded: a single round structure is made from two semicircles (arches).

- In accordance with the specifications, a double-glazed window is made for the window, which is then inserted into the structure and secured with beading.

This is interesting:

From a plastic profile you can make windows not only of a classic round shape of a given radius, but also of a free line and almost any color.

Dimensions of round PVC windows

What sizes of plastic windows can be made in the shape of a circle?

— In principle, any, but there are still some limitations associated with the current equipment of production and the limit of the properties of the profile itself.

Minimum size

The desire to make a round dormer window with a minimum size is fraught with the occurrence of excessive bending with profile deformation.

The smallest non-opening round window is ∅800.

The minimum permissible radius of a round plastic window made of PVC profile VEKA Euroline, which can be manufactured at the Moscow Window Construction Plant Business-M: 400 mm.

The smallest opening round window is ∅1080.

A round window with an opening window (transom) will have a smallest radius of 540 mm. This is due to the fact that the minimum bending radius will already be at the sash - the same 400 mm.

Maximum size

The maximum radius of the arched structure is limited to 2300 mm. A similar restriction is imposed on a round product made from a PVC window profile. However, this makes it possible to produce structures of a very impressive size with ∅4600 mm and an area of about 16 square meters!

The cost of plastic windows in the shape of a circle

Prices for windows vary depending on size and configuration.

Standard for a private, panel, brick house (table)

Standard sizes of ordinary windows are determined taking into account the following parameters:

| Selection options | Height in mm | Width in mm |

| By number of doors | From 1350 to 1500 | From 1500 to 1500 |

| In a panel house (Khrushchev) | From 1350 to 1500 | From 1300 to 2040 |

| In a private brick house | From 2040 to 2010 | From 1350 to 1450 |

| In a private wooden house | From 2100 to 2200 | From 700 to 900 |

If the windows do not meet the specified parameters, they will quickly fail due to their high weight or will not withstand high wind loads. Exceeding recommended standards can also result in injury to occupants.

GOST for plastic windows

The standard currently covers window and door structures made from PVC profiles manufactured, sold and used in our country. Standard 30674-99 covers modern metal-plastic windows, which can be white in color, dyed, laminated or made using co-extrusion. Information from such a document, which contains dimensional requirements, is similar to data from the current standard 23166-99.

Differences between various products for the manufacture of which a colored profile is used:

- Colored doors – 2.2 m2

- The maximum weight of structural elements made from colored profiles is 60 kg

- The difference between the diagonals present in PVC windows does not exceed 2-3 mm with a known diagonal length of 1400 mm

The parameters of PVC windows can be changed taking into account the dimensions of the entire manufactured structure. Due to the reliable fastening of profiles by welding, the current GOST 30674-99 specifies the maximum permissible size of a special groove formed during the processing of welds.

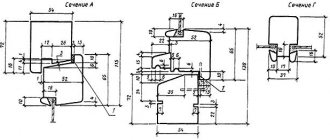

What does thickness depend on?

The key parameter of the profile is its thickness, which differs regardless of the manufacturer.

This indicator affects the preservation of heat in the room, protection from cold air and noise from the street. Manufacturers offer popular options :

- classic or standard width is 5.8 cm;

- additional 0.7 cm;

- increased to 0.9 cm.

In accordance with European standards, a tolerance of 0.2 mm is defined for the internal (2.5 mm) or external (3 mm) thickness.

What are the design features of plastic frames?

The characteristics of the PVC profile allow us to make any structures from it, with different opening methods:

- Single leaf. They are installed in a small opening, for example, 1.0 * 1.5 m and are often performed without an opening sash.

- Tricuspid. It is mounted in the widest openings, with lintels occupying up to 10% of the area. The middle section is often made blind,

and the side ones are opening.

- Deaf. The glass unit is fixed in the profile motionlessly, without the possibility of opening.

- Rotary. Opens inward in the top/bottom direction for easy ventilation and maintenance.

- Folding. The upper part of the sash moves down and inward when opened. The angle of its inclination depends on the installation of the limiter.

- Combined. Equipped with tilt-and-turn mechanics, it provides different ventilation modes.

- Balcony. It can have any dimensions, be equipped with a rotating, folding mechanism or a sliding system.

What are non-standard?

Manufacturers offer custom sizes that are suitable for residential, commercial and industrial buildings. Most users can focus on the following parameters :

- 40x40 cm (400x400 mm);

- 45x45 cm (450x450 mm);

- 50×50 cm (500×500 mm);

- 100×100 cm (1000×1000 mm);

- 200×200 cm (2000×2000 mm, 2 by 2 meters);

- 200×300 cm (2000×3000 mm, 2 by 3 meters);

- 300×300 cm (3000×3000 mm, 3 by 3 meters).

Similar sizes are possible in a private wooden or brick house. They are also allowed during the construction of a monolithic multi-storey building with individual apartment layouts.

Non-standard window designs are products that are manufactured according to an individual project and are not included in the general list of manufacturers’ catalogues. A separate category includes windows with standard equipment, but with non-standard solutions - design, materials, functionality and number of cameras.

Also, non-standard metal-plastic windows include the technical features of double-glazed windows. This applies to the fittings, to the special treatment of the camera glass, and to the composition of the glass itself. We can distinguish a separate type of double-glazed windows, which have distinctive profile dimensions in thickness, depth and color.

It is also worth noting the plastic windows manufactured for a specific design project. Such products differ in size, profile texture and operating modes of mechanical elements.

Where can I order a small window?

The minimum size of a plastic window with opening is, in principle, technically unlimited. You can make a window at least 30 by 30, or even smaller, depending on how thick the profile itself will be. If the design is supposed to have glass, you need to add up the dimensions of the glass you want and the width of the profile, and you will get the minimum allowable size.

A small semi-basement window for ventilation

Do not forget that some space is also occupied by fittings, so the window physically cannot be smaller than the space that the opening mechanism will occupy.

Most often, the smallest plastic windows have a size of 20 by 20; they can only be produced by a qualified craftsman who has sufficient experience with small PVC parts. In large factories, such work is usually not undertaken because it would require distraction from the main production line. You can try to negotiate with a small window company whose production volumes are far from industrial. Most likely they will take on the work there, but again, not every manufacturer is ready to give a quality guarantee. When choosing a manufacturer, you should first of all pay attention to the quality of its main products. After all, the profile will be used exactly the same; from a large piece, they simply cut off what is needed to create your design.

Garage windows

Small plastic windows will cost more than any standard design, despite the fact that they require less material; the point here is not the cost of raw materials, but the cost of effort and time. However, this makes sense if the individual project requires this approach, and installing a larger window would require partially tearing down the wall. This process is expensive, time consuming and leaves behind a lot of waste.

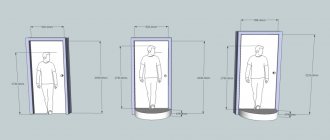

Minimum and maximum dimensions of doors with opening

In many cases, custom-made plastic windows have size restrictions in three planes - height, length and depth.

The main criteria for choosing this parameter are the size of the window openings. Failure to comply with the specified dimensions makes it impossible to install windows in the room.

Don’t forget about technical capabilities, because there are minimum and maximum load thresholds that allow the manufacture of plastic windows for safe operation.

The minimum dimensions of the frame (i.e. the smallest) are practically considered 450x450 mm. A sliding door cannot be made with smaller dimensions due to the fittings. It will not allow the door to open. It is important to accept that approximately 10% of this size will go to the profile and in fact the light opening will be 320x320 mm.

The maximum size depends on the stress ratio of the profile and glass. With a reinforced profile of 1.5 mm, the maximum dimensions are :

- width no more than 900 mm, maximum height 2100 mm;

- width no more than 1200 mm, maximum height 1500 mm.

The main thing is that the area of the entire structure does not exceed 1.8 square meters. m . With profile reinforcement of 2 mm, the maximum recommended size of the sashes should be no more than 1000x2300 mm. It is also worth considering the operation of sliding mechanisms so that they do not damage the interior decoration of the room. The design must include opening stops. They will help to avoid damage to the window opening from impacts from the fittings.

What is the minimum window size you can choose?

Many companies produce products in standard sizes, as this allows them to optimize costs and make the product more affordable, so the smallest plastic windows most often have a size of 50 by 50 cm, less often you can find the 60 by 40 option. These parameters are associated with the features of the equipment producing components for windows. This is the minimum profile size that the machine can cut. That is why smaller windows need to be ordered, and they are more expensive, since they have to be made manually. Such a profile is usually sawed off, after which the parts are joined using a special welding machine.

Soldering iron for manual soldering of windows

Such products have certain disadvantages. Firstly, it does not always look attractive, since even with great experience of the craftsman, the seam will look less neat than one made by machine. Secondly, many enterprises do not agree to produce such windows, since it takes a lot of time and is not financially profitable for the enterprise, since production is conveyor belt and there is simply no time to produce one exclusive, and also inexpensive, part.

Selection of PVC windows

The production technology has practically no limitations in either shape or size. Non-standard designs provide normal glazing of openings, including non-standard designs. At the same time, there are nuances that take into account the weight and capabilities of the profile, and the features of a particular window.

Thus, blind sashes with an area of 1 sq. m. are often supplemented with an impost. This is due to the fact that the profile will not be able to withstand the mass of glass of such dimensions, as a result of which destruction or sagging is possible.

When choosing rotary sashes, it is necessary to strictly observe the proportions , on which the parameters of width and height greatly depend. Otherwise, the fittings will not work properly.

For any deviations of the plastic structure from the shape or size, the product becomes more expensive. Standard models are becoming the most acceptable options for both installation in an apartment and a country house.

If you plan to purchase windows for a private home, take into account the type and purpose of residential premises, the size and location of the building.

An important point is the light transmittance of the glass itself .

The illumination coefficient in the area is limited to latitudes of 45 and 60 degrees. In this case, you can select standard dimensions of window structures. So for an opening of 500x500 mm, a window with dimensions of 470x470 mm is suitable.

If the area borders on the given latitudes, a correction factor is used. In the northern regions, a correction of 1.2 is used, and in the southern regions - by 0.75 . If triple glazing is used, the spacer must be taken into account.

How to correctly set window sizes at the design stage

Only by observing GOST standards and regulations can glazing be made of high quality, reliable and practical. For example, if you decide to build a country house with panoramic glazing, then you should take into account the fact that the windows should be no more than 6 m2.

In this case, you will get rid of many problems, and finding a manufacturer will not be difficult. Almost all companies will be able to offer solutions for glazing such a house.

If you decide to buy ready-made windows in a factory or from a construction company, then pay attention to the area of the opening elements. If it is more than 2.5 m2, then check the availability of certificates for specialized safety tests, because an area exceeding the specified norm is not subject to the standards.

When choosing double-glazed windows, pay attention to the weight of the opening sashes; it should not exceed 80 kg. Otherwise, it may result in exceeding the critical part.

For reference: A three-chamber double-glazed window (3 glasses of 4 mm) with an area of 2.5 m2 weighs about 75 kg.

Casements of casement windows must open inwards in all residential premises, except for those on the first floor and windows facing balconies and loggias. Other cases of opening must be specified in the design documentation.

Why know the parameters of plastic sashes and frames?

Experts recommend that you familiarize yourself with the standard sizes of frames and sashes of plastic windows before purchasing. Knowledge will help you choose blocks that are exactly suitable for specific window openings. This is equally true for owners of apartments in multi-storey buildings and for owners of small dachas or cottages. Particular attention should be paid to the choice when glazing industrial or commercial premises.

When choosing European-made models, you must remember that the maximum dimensions are really large . They can be up to 600 cm in height and more than 320 cm in width. This is due to significant window openings abroad. For glazing of houses and commercial premises in Russia, it is better to focus on compact sizes.

Proper selection of the size of plastic windows provides the following advantages:

- long and reliable operation;

- excellent protection from extraneous sounds;

- heat retention even during long-term use;

- obtaining maximum quality at an affordable cost;

- selection of the required number of cameras and thickness of the glass unit, taking into account climatic conditions.

Thanks to the correct choice of window block dimensions, it is possible to ensure precise installation without the use of additional elements and a large amount of polyurethane foam. This approach ensures correct and trouble-free installation, long-term operation without violating the warranty.

GOST standards

GOST 30971-2002 “Mounting seams of joints connecting window blocks to wall openings” (came into force on March 1, 2003) GOST – 23166-99 “Window blocks. General technical conditions" GOST - 24700-99 "Wooden window blocks with double-glazed windows. Technical specifications" GOST - 30673-99 "Polyvinyl chloride profiles for window and door units. Technical conditions" GOST - 30674-99 "Window blocks made of polyvinyl chloride profiles. Technical conditions" GOST - 24866-99 "Glued double-glazed windows. General technical conditions" GOST 26601-85 Wooden windows and balcony doors for low-rise residential buildings. Types, design and dimensions GOST 11214-86 Wooden windows and balcony doors with double glazing for residential and public buildings. Types, design and dimensions GOST 11214-78 Wooden windows and balcony doors with double glazing for residential and public buildings. Types, design and dimensions GOST 16289-86 Wooden windows and balcony doors with triple glazing for residential and public buildings. Types, design and dimensions GOST 16289-80 Wooden windows and balcony doors with triple glazing for residential and public buildings. Types, design and dimensions GOST 24700-81 Wooden windows and balcony doors with double-glazed windows for residential and public buildings. Types, design and dimensions GOST 24699-81 Wooden windows and balcony doors with double-glazed windows and glass for residential and public buildings. Types, design and dimensions GOST 23344-78 Steel windows. General technical conditions GOST R 54850-2011 Dormer windows and skylights. Method for determining heat transfer resistance GOST R 54861-2011 Windows and external doors. Methods for determining heat transfer resistance GOST 21519-84 Balcony windows and doors, showcases and stained-glass windows made of aluminum alloys. General technical conditions GOST 25062-81 Windows and balcony doors made of aluminum alloys. Types, designs and sizes GOST 27936-88 Wood-aluminum balcony windows and doors for public buildings. Types and designs GOST 23166-78 Wooden windows and balcony doors. General technical conditions

Source: glazingmag.ru

Optimal modular sash sizes

There is another important point - the optimal ratio of the height and width of window structures. These proportions are regulated by GOST 23166-99 and are recommended for the construction of residential and commercial buildings.

It is very easy to decipher information from such a table - all designations are tied to the “M” building module. This value is 100 mm, so all dimensions can be easily calculated by multiplying the numbers from the code by 100. In this case, as can be seen from the table, rounding down or up is allowed.