At the beginning of the 19th century, no one could have imagined that a strange material called “plastic” would become one of the most popular materials in production, and certainly no one would have thought that it would become the main material for the production of windows. The idea of creating PVC windows belongs to the Americans; it is in the USA that a record for the production and sale of plastic windows will be set - 15 million copies in 1997. Today, the market is dominated by plastic windows, which are easy to buy, but previously people did not accept this product for a long time and treated it with disdain. This is a short story about the most competitive type of business and three resourceful entrepreneurs and their long, difficult path to recognition.

History of PVC

Since ancient times, people have tried to create a synthetic material that would surpass any natural raw material in all physical characteristics, be cheaper and help save resources. Polyvinyl chloride (PVC) is one of the oldest synthesized materials used in industry. Many sources confirm its appearance and use (often to no avail) in different parts of the world at different times. The earliest mentions date back to the mid-19th century. The first dates back to 1838, when, in the course of various experiments, PVC was discovered by the French chemist Henry Victor Regnault, the second - the German chemist Eugen Bauman achieved a similar result in 1872. In both cases, the resulting material was described as hard white granules that formed accidentally when vinyl chloride reacted with sunlight. But the resulting material was difficult to work with, and no one tried to use it for industrial purposes. In 1913, German inventor Frederick Heinrich August Klatte patented polyvinyl chloride. In 1920, there was a real PVC breakthrough in the United States, which is associated with BFGoodrich and manufacturing scientist Waldo Semon. Waldo was faced with the task of finding a worthy alternative to natural rubber, which is very expensive to produce. All experiments led to polyvinyl chloride, which met all the company's requirements - the material had waterproof properties like rubber, provided the opportunity not to use natural resources and had low cost. The product quickly gained enormous popularity and found wide application in many industrial sectors. During World War II, PVC was used as an insulating material for wiring on warships.

In 1926, Waldo Semon proposed PVC as an alternative to natural rubber.

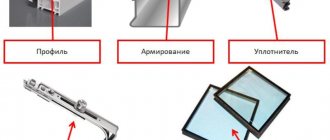

Assembly and disassembly

When disassembling a plastic window you need :

- lower the rotary mechanism handle completely down (to the closed position);

- use a screwdriver to pry off the plastic casing on the lower and upper hinges;

- Use a flat screwdriver to remove the pin on the top hinge;

- Unscrew the lock on the bottom hinge with a hexagon;

- lift the handle up halfway (open position, not ventilation) and pull the sash towards you.

To install the sash back, you need to do all the steps in reverse order.

In order to remove the glass unit you need:

- remove all unnecessary parts from the window sill and remove the sash;

- insert the knife into the gap between the profile and the bead, with the sharp end and gently knocking on the handle, drive the nose to a depth of 10-15 mm;

- carefully turn the knife towards the glazing;

- during rotation, the gap will begin to widen, so the previous action must be repeated along the entire length of the bead until it is completely disconnected;

- you need to press on the glass on one side so that it begins to come out of the grooves. It is recommended to do this in pairs: one holds the frame and presses, and the second accepts the double-glazed window.

Reinstalling the glass occurs in the reverse order. It is recommended to replace the seal on the beads, then install the top one first, then the side ones, and the bottom one last.

About disassembling windows in detail here.

How it all began

It's 1950. The world has recovered from the war, and as the economy grows, the population increases. New families need new homes, they need new windows that are inexpensive and durable. We need new technologies. In those days, no one thought much about energy saving; people simply needed high-quality windows and comfort in their home. The trend in the mid-20th century was aluminum windows, which were much stronger than conventional ones, but did not retain heat well.

“I was producing aluminum profiles and selling them to window companies. “In 1957, I seriously wanted to connect my life with aluminum windows,” said David Weiss, who founded Modem White Mfg. in Pittsburgh in 1959, “Someone showed me a piece of PVC product from BF Goodrich, I knew about all the problems with aluminum windows and immediately realized that this material was the future.” Some time later, Weiss decided to focus on promising new material. His company was renamed Thermal Industries, and it was under this name that the company became world famous.

Another person who was looking for an alternative to aluminum profiles was Paul Mancuso: “In 1950, I founded the Fiberlux company in New York State, which produced fiberglass. My subsidiary, Westchester Window, produced profiles for aluminum windows, and already in those years I was concerned about the unpromising nature of this product. I was very interested in the new material from BF Goodrich."

And the third person, Leon Slocombe, who meanwhile worked for the large chemical company DuPont, was inspired by the new horizons that plastic opened up. In addition, Slocombe's father was engaged in the production of aluminum windows. “Thanks to my father, I learned a lot about windows,” said Leon. “Because of its high thermal conductivity, aluminum is not at all suitable for windows.” A little later, Slocomb founded Slocomb Industries in Washington state and began collaborating with Goodrich.

A plastic window that withstood the weight of a bulldozer. Demonstration of the durability and reliability of the new product.

Window market prospects

The history of window development is strikingly diverse. Thus, Venetian and French windows appeared in parallel. With the advent of PVC in “collaboration” with aluminum profiles, it became possible to develop and produce the most fantastic glazing projects, including panoramic and other options.

No one can be surprised by the most different types of structures: wind, auditorium, attic, second lighting, structures made of metal-plastic, wood, fiberglass (fiberglass). What will the window of the future be like? Future generations will see this.

The first problems of plastic windows

“Fools walk where wise men fear to tread,” said David Weiss. “Having released a new product, I was faced with new problems.” Americans were biased towards the first plastic windows. At that time, plastic seemed to everyone to be a cheap, short-lived, fragile material.

“For people, plastic means children’s toys and trash cans,” said Paul Mancuso. “They had no idea how practical plastic windows are, which require virtually no maintenance. Instead, they bought aluminum windows, which cost twice as much.”

“We fought for 20 years and could not break through the wall of popular rejection of plastic windows until 1980,” recalled Leon Slocombe.

But public rejection and low sales were not the only problems. “There were a lot of people who were satisfied after the presentation and understood that PVC windows were a great product,” says Mancuso. “The main problem was the lack of understanding among salespeople, delivery services and installation specialists about what a new product they were dealing with. We had a great sales manager, but he had previously sold shoes and was having a hard time learning and promoting a new product. Delivery services lost the necessary parts, without which the window simply would not function, and the craftsmen, due to ignorance of the technology, often performed the assembly incorrectly, which led to breakdowns and spoiled the image of the new product. It was a real nightmare."

Weiss: “The technology for producing PVC profiles was not perfected; not long after installing the window, the plastic began to turn yellow. Plastic windows are produced by welding all parts of the profile together; at that time, specialized equipment that was presented in Europe had not yet appeared on the US market. We made everything with improvised tools in our garages and this way we produced several thousand windows!” To create the specialized welding machines, Weiss and Mancuso collaborated with American tool manufacturers.

Specialized European equipment for the production of plastic windows, which was sorely lacking in the USA.

What were the first window openings?

The history of windows goes back more than 4 thousand years. But the first designs were as primitive as possible. They were made in the form of an opening for air exchange and natural lighting.

Even Beelzebub was “involved” in the history of the creation of windows - however, then he was called Bal Zebub, and he was the god of thunder and fertility. He was sent to earth by the supreme deity to live among people. As the legend says, he lived in a golden palace with silver decorations. There were also windows in that castle.

How have window shapes changed?

Historically, it can be seen that the role of a window (air duct and natural light) was first played by the chimney. If you have ever seen a sauna that is heated in the black, then most likely it had a very small window or none at all. A hole in the ceiling of a yurt, wigwam, or other simple dwellings is also a kind of window.

The most unusual windows were preserved among the northern peoples. The window opening also serves as an entrance and is covered, if necessary, with animal skins.

However, already in the time of Pompeii, which was later destroyed by the volcano Vesuvius, the first glazed windows are discovered. They were installed in thermal baths (baths), and the dimensions of the opening were quite decent 90x120 cm.

Due to the complexity of production and the high cost of materials, windows were first installed in temples and “administrative buildings” and palaces. And stained glass became the most popular in terms of form and aesthetics. It was easier to make a “canvas” from many colored glass pieces. Thus, one of the very first known stained glass windows is the windows of the St. Sophia Cathedral in distant Constantinople (Constantinople). The colored glazing in the Byzantine capital dates back to 330 AD.

Russian windows: technology and diversity

In Kievan Rus, finds indicating the use of window glass date back to the 10th century. Archaeologists have found blown glass with “cakes” (“pies”), blown specifically to decorate the window opening. In Europe, these began to be used only in the 13th century. However, there was no full-fledged, modern glass window in Rus' yet.

To close the window opening, mica plates, fish press, oiled canvas or a wooden plug were used. In winter, they could even insert ice. Although the window was not so expensive, and they made it small, the heat loss was significant. This is how other window systems were invented: the so-called fiberglass windows.

The history of wooden windows has been impressive. Even the original design of closing (“closing”) windows was not at all primitive:

- a window frame (window frame) was installed;

- The end was set into it during the cold season (in addition to glass, peritoneum or bull bladders were common;

- a portico (sliding shutter) was installed inside the house;

- for convenience, window inserts were placed (like slopes);

- shutters completed the decoration and protected the window.

It was considered customary to have windows in the upper room on two walls, and in the light room (“women’s” room) on three or four sides. It is believed that this facilitated typical women's work - from spinning to sewing, knitting.

In the 17th century, the history of the appearance of windows took a new turn. An innovation was spreading across Europe - enlarged window openings with large glass that let in a lot of light. Tsar Peter I saw the new product and ordered this fashion to be introduced here too. It also had to be planted, but this was also hampered by an objective limitation - a lack of glass. Russia's own glass factory appeared only in 1635, and the capacity of manufacturers increased to 6 factories only by the 18th century.

First success

Thermal Industries took into account and corrected all the shortcomings, and soon the first major sales began. “The first success greatly encouraged me and gave me an incentive for further development,” Weiss shared his impressions. “In 1966, we sold windows with one glass and a window frame thickness of one inch. There was no balancing in these designs, and everything was quite primitive, but despite this, we sold 30 thousand copies.”

But gradually the demand for more complex, convenient and technologically advanced designs begins to grow on the market. Especially in 1973, during the Oil Crisis, a serious problem arose with resource consumption and energy conservation. It was thanks to this event that a breakthrough occurred in the world of plastic windows. The enterprising Paul Mancuso held a major exhibition of PVC windows in New Jersey, where all the heat-saving properties were demonstrated. This had a huge public outcry. In addition, the cost of plastic was significantly lower than aluminum, and in the 70s. A huge number of aluminum window production companies have closed.

An advertisement for the window company Fiberlux, founded by Paul Mancuso.

Who invented the world's most durable double-glazed window

The famous triplex window (specially strong glass) was also the merit of the French scientist. But no research was carried out for its production; the invention happened by accident. The French chemist Benedictus was engaged in research of a completely different kind in his laboratory. For one of them, he wrapped a glass flask in cellulose and accidentally dropped it. Despite the hard floor and height, the flask did not break. After this, inspired by Benedictus, he developed the technology to create the world's strongest glass. His invention immediately found application in military affairs - glass for gas masks began to be made from durable triplex.

European intervention

The American and European markets for plastic windows developed in parallel, independently of each other. With the increase in the number of manufacturers in the USA in the 70-80s. European brands began to penetrate the market. “The Germans had a strange sales tactic,” recalls Weiss. “In the US, the walls of most houses were very thin, and they were trying to sell their massive, super-durable, expensive windows... but for such windows you would have to build a new house. Therefore, it took them several years to adapt their products to our market. We had to take into account all the nuances and sell plastic windows cheaply.”

Sigi Valentin, a representative of the European company Komcraft, which was later sold to LBPlastics: “The windows were not at all suitable for the American market, they were very heavy and expensive. We didn't understand the Americans at all. In Europe, everything that is technologically advanced automatically becomes in demand, and the US market requires technological and practical solutions that will be affordable for the majority of the population.” Trocal, Rehau, Veka windows, and LB Plastics all had to adapt.

In 1980, only about 600,000 PVC windows were sold in the United States; over the course of several years, this figure slowly grew, and by 1984, 10% of the window market was made up of plastic structures, and by the end of the decade, the number of units sold reached 6 million.

Windows from the 90s: how the first plastic window appeared in Russia

Each era has its own iconic symbols and differences. If we are talking about photography, we understand that we are talking about the middle or end of the 19th century, and if we have an iPhone in front of us, then it is obvious that this gadget was released no more than 10-15 years ago. Likewise, when we mention the 90s, a certain associative series pops up in our heads. For example, the first McDonald's in Russia, Tetris and... the appearance of plastic windows. We would like to dwell on the latter in more detail and tell you who was the pioneer in the field of plastic windows in Russia and how production technologies have changed since that time.

Photo: Russia's first McDonald's caused a huge stir

It’s hard to believe, but such familiar PVC windows, which are installed in almost every home in our country, were once a great luxury that only wealthy people could buy. Yes, we are talking about those famous 90s. And even more surprising is the fact that about 50 years ago no one had heard of such an invention as plastic windows in Russia. Where did they come from?

How it all began. History of plastic windows in Russia

One of the first who decided to conquer the Russian PVC window market was the German company producing KBE profiles. They began importing products in 1995, and in February 1996, KBE officially registered its representative office in Moscow. Two years later - in Yekaterinburg and Rostov-on-Don. Back then, all manufacturing orders were sent directly to Germany and required considerable time and money.

Photo: one of the tasks of post-Soviet fashion in the nineties was to be as different as possible from what came before

Over time, demand nevertheless exceeded supply, and in October 2000, the company's management decided to open its own plant in the town of Voskresensk near Moscow. This event marked a fundamentally new level of development for the company and showed clients the long-term and serious intentions to develop the Russian market.

The system that was the first to roll off the production line in Voskresensk exactly 20 years ago was the three-chamber KBE_Etalon. It was so competently and accurately designed, taking into account all the conditions and requirements of the Russian market, that over the past 20 years it has not undergone any major changes.

Photo: three-chamber KBE_Etalon

It is interesting that at the same time there was another important milestone in the history of KBE, namely the participation of its specialists in the development of the first Russian GOST window standards. As a result, 80% of GOST standards were illustrated with drawings and cross-sectional diagrams of KBE profiles. This gives us the right to say that KBE is the first standard of Russian windows.

How a new type of plastic windows appeared

Time does not stand still. Of course, since the 90s, both the design of the profiles and the technologies used to manufacture them have improved. In addition, windows have ceased to be a luxury item and have become an everyday product.

Photo: Voskresensk KBE plant is the largest in Russia

Today, the offer on the market includes systems for every taste and color - from narrow three-chamber 58 mm to profiles with seven chambers and an installation width of 88 mm. This means that no matter where you live - in Siberia or the Far East, Crimea or Moscow - you can easily choose the best option based on your individual preferences and the climate of the region.

Photo: KBE production lines are equipped with modern equipment

In the field of technology, the German brand KBE has also become one of the market pioneers. Having become part of the profine concern, the brand was able to produce systems using the unique greenline technology: based on calcium-zinc stabilizers, without harmful lead in the composition. Thus, the first and to this day only windows made of environmentally friendly profiles appeared on the Russian market, the production of which passed voluntary certification and received the international eco-label “Leaf of Life”.

A completely new type of window

The reason for the enormous success of plastic windows was the invention of single-chamber double-glazed windows, which appeared on the market in 1983. “In those days, everything depended on construction companies,” recalled Mancuso. “It was they who set the trend and decided what windows would be installed in houses, and PVC still seemed to them a dubious product. New buildings were being fitted with timber windows, so we decided to design the windows with beveled edges to resemble traditional windows as closely as possible. We tried to convince construction companies to install metal-plastic windows at their sites for free, try it and try to find all the disadvantages. But they didn't find it. It was after this that the new type of windows became an incredible success.” From that moment on, an unprecedented increase in the production and sales of plastic windows began all over the world. In 1997, 14.5 million copies were sold in America.

One of the first public presentations of single-chamber double-glazed windows.

Hello Guest! Offer from "Clerk"

Online professional retraining “Accountant on the simplified tax system” with a diploma for 250 academic hours . Learn everything new to avoid mistakes. Online training for 2 months, the stream starts on March 1.

Sign up

How many years of warranty?

The warranty for windows made of polyvinyl chloride profiles is established in accordance with GOST 23166 and standards for specific types of products. Most often, the warranty period is based on the intensity of use, conditions of use (for example, weather), and also on the basis of customer service provided by the manufacturer or seller.

The warranty period for windows and balconies (profiles, fittings, assembly units) is at least 3 years, taking into account compliance with all regulatory documents , as well as intended use. For special blocks (stairwells, technical floors), the warranty period must be at least 2 years. The service life of a double-glazed window must be at least 5 years from the date of installation.

But Federal Law of the Russian Federation N 2300-1 “On the Protection of Consumer Rights” in Article 19 states that the buyer can return the goods within 2 years from the date of purchase if relevant manufacturing defects are identified. Given the service life of up to 40 years, such measures are based on the fact that an error was made in the production of the window or fittings (a part was defective), as a result of which it does not perform its functions.

XX century

From the very beginning until the middle of the 20th century, ordinary standard houses with the same identical wooden windows were built in Russia. That is, mass and fairly cheap production began, which could not but lead to a loss of quality. That is, these windows contribute to energy loss - from 40 to 80 percent of the heat comes out through the windows.

In the 60s of the last century, the first PVC (polyvinyl chloride) windows were manufactured. These windows are resistant to various atmospheric conditions, they are light-resistant, and have a high quality surface.

The advantages of plastic windows include such properties as sound insulation, tightness, heat protection (which is important, given the huge heat losses through ordinary windows). Such windows do not require repairs or painting during operation. The PVC profile is very flexible, so architects have unlimited freedom to give windows any shape. In turn, consumers do not have to wait long for their order to be completed, as is the case when ordering wooden windows of complex configurations.

We can say that modern plastic windows are the ideal result of such a long history of window development - they provide excellent illumination, protect the home from heat loss, allow you to regulate the flow of fresh air into the home, provide visual comfort and sound insulation.

Door opening mechanisms

Manufacturers now offer two types of window units: American (sliding) and European (tilt-and-turn).

Sliding window units are most successful when glazing loggias and balconies. They will not take up a single extra centimeter of space, as is the case with conventional frames that open inwards. Tilt-and-turn blocks allow the doors to open in two planes: on vertical hinges, like conventional windows, and on horizontal hinges, like transoms. The last option is the most convenient for ventilation: it does not blow.

What does the price depend on?

The main factors that determine the price of PVC windows are:

- frame size and shape;

- fittings (burglary-resistant or high-strength ones cost more);

- shape and width of the profile (number of chambers, as well as their filling);

- number of doors;

- window shape;

- the glass unit used (shockproof or with insulating film), as well as the number of cameras in it;

- presence of gas in double-glazed windows;

- window automation;

- window sills and ebbs;

- the presence of blinds;

- number of sealing circuits;

- decoration and availability of sprats.

More details about pricing here.

Insulation

To insulate a plastic window, you can use a special glass film that reduces heat loss. Also, to remove cold bridges on the walls around the profile, you can insulate the outer part of the walls, slopes and window sills.

This is done using polystyrene foam, special glue, fiberglass mounting mesh, and plaster. In some cases, slopes can be insulated using mineral or basalt wool, as well as fiberglass.

All information about insulation is here.