A correctly selected window is durable and low maintenance, helping to create coziness and a favorable microclimate in the room.

Every component is important - profile, fittings, double-glazed windows. Since the main area of the window is the transparent part, the heat-insulating and noise-insulating characteristics of the window depend 90% on the properties of the selected glass unit. Of course, the light transmission of the window largely depends on the glass unit. How a double-glazed window works, what parameters to choose, what its cost depends on - you will find answers to these and other questions below.

What does a plastic window consist of, design features

The material from which plastic windows are made is called polyvinyl chloride, abbreviated PVC. It was not chosen by chance; its main property is complete chemical neutrality. The frame and double-glazed windows do not form a chemical reaction with air, rain and other atmospheric phenomena. They can be washed with any cleaning properties without damaging or dissolving the surface.

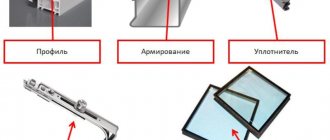

Construction of a plastic window:

- Frame (profile) . This part of the structure is located around the perimeter and is inserted into the window opening. A glass unit is fixed in it. The material from which it is made has various modifications (to protect against burglary, to be reinforced with metal, etc.).

- Double-glazed window. This is the transparent part that allows sunlight into the house. They differ in the number of glasses, their tightness, properties regarding the conductivity of heat and sunlight.

- Sash . The part (usually half) that can open is attached to the fittings. It is made from the same material as the frame. Beading is installed on all sides of the sash. The junction with the frame is sealed with insulation so that the air does not cool the room. This material needs to be replaced periodically; it wears out over time. It can be made as a full-size part or in the form of a window. The presence of fittings allows you to fix the sash and ventilate the home.

- Glazing bead . This is a plastic cover on the end of the sash with a rubberized base. With its help, a tightness is created; wind, dust, and moisture do not penetrate into the room. The sash fits tightly to the profile.

- Impost. Plastic profile reinforced with reinforcement. It divides the window in half (or into several parts). With its help, several doors are held tightly.

- Accessories . This includes all small components that help in operation. These are elements such as: handle, bar, hinges, etc. Since it receives the greatest load, the manufacturer and materials must be reliable. Types of fittings: burglary-proof, child-safe, etc.

- Windowsill . It is attached at the bottom; inside, in the standard version, it is left hollow. It has high heat-insulating properties and has a multi-chamber design.

- Low tide . It is attached from the outside, at the bottom. Its task is to drain water down from the outside so that it does not flow under the frame.

- Slopes. They are installed inside the window opening along the perimeter, made both in the classic white color and in other options, depending on the design of the room.

- Platbands . They are attached to the slopes from the side of the wall, they cover the window structure, and they finally decorate the window opening.

The frame for PVZ windows, in comparison with those made of wood or metal, has improved mechanical properties.

Essential elements

The design of PVC window blocks differs significantly from those made of wood. For the convenience of mass production, the company's developers use a modular approach, which allows them to assemble finished products like a construction set. Let's look at the main elements of plastic glazing:

- Frame. Each window must have a supporting frame made of PVC profile reinforced with metal.

- Sash . In order for the window to open, sashes (also made of reinforced profile) are placed inside the frame. If opening is not provided, the glazing is installed directly into the frame.

- Impost . The internal part of the frame, designed to separate it and provide the necessary rigidity.

- Glazing bead . As in traditional wooden windows, it is necessary to fix the filling elements (double glazed windows, sandwich panels). The removable element is made from the same PVC profile and is equipped with a rubber seal.

- Double-glazed window . Element of transparent filling of frame openings. Usually consists of two or three glasses, separated by a spacer frame with moisture-absorbing material. There are also options with single glass (sometimes several) and opaque filling (sandwich panel).

- Accessories . A set of components and mechanisms designed to ensure fixation and opening/closing of window sashes in various positions. Most PVC windows are equipped with a tilt-and-turn system, which includes hinges, a handle, strikers, etc.

- Windowsill . A mounting element with which the internal space at the bottom of the window block is blocked. The most common products are made from hollow plastic profiles. Despite their comparative cheapness, they have sufficient strength characteristics, are practical and look good. More sophisticated options, made from solid reinforced polymers, are much more expensive.

- Low tides . A metal or polymer plate of a certain profile, which is mounted on the street side and is necessary for draining water.

- Additional accessories . Such important little things as mosquito nets, elements of fresh air ventilation, blinds, roller blinds, etc.

During installation work, special profiles are also used to correctly connect parts of the block, panels that form slopes (both external and internal). Some junctions are covered with strips or decorative overlays. The presence or absence of these parts largely depends on the design of the windows of a particular manufacturer and installation features.

Plastic window frame

Positive performance characteristics include:

- high-quality thermal insulation;

- simple manufacturing process;

- easy installation;

- effective protection from atmospheric phenomena: heat, cold, wind, moisture;

- the ability to use any chemical reagents for cleaning;

- variety of design ideas;

- low cost.

Main disadvantage: flammability. Negative reviews are mainly related to improper installation of the structure.

Sectional view of a plastic window

Externally, the design of plastic windows looks the same. Hundreds of manufacturers present window models that are impossible for an inexperienced buyer to distinguish. If you don’t know about the basic characteristics, a bad choice becomes obvious only over time, when the frame ceases to cope with its functionality: it begins to let in moisture, wind, etc.

To avoid disappointment, you need to familiarize yourself in advance with the description of the options for constructing a PVC profile and the main parameters in detail.

Energy efficient glass

Today, glass with a special selective coating is increasingly used to make warm windows. A metallized layer applied to the surface transmits visible rays of sunlight and blocks thermal ones. Thanks to this separation, it was possible to provide windows with high energy efficiency without reducing light transmission. Currently available:

- i-glass

– have a soft coating; - k-glass

– have a hard coating.

A detailed comparison of the characteristics of these two modifications is given in a special article on OknaTrade. Energy-efficient glass for plastic windows allows not only to better retain heat in winter, but also to retain coolness in summer - that is, it fully functions in 2 directions.

Energy-efficient double-glazed windows have approximately the same heat transfer resistance coefficient as conventional two-chamber models. An additional benefit from their use is that they can significantly reduce the weight of windows and prevent interior spaces from quickly warming up in the summer.

Material thickness

The inside frame design is hollow with partitions. Reinforced reinforcement is also installed around the perimeter of the frame for density. The air is left inside for better thermal conductivity. In this case, the length and width of the walls on the inside and outside matter.

Manufacturers divide frames according to the width of the walls into 3 classes:

- Class A. It is considered the best and provides ideal thermal insulation. The thickness of the outer wall is from 2.8 mm. Inner box from 2.5 mm.

- Class B. Subject to deformation, used in the construction of public premises (entrances, shops, etc.). The outer wall here has a thickness of 2.5 mm, the inner one from 2.0 mm.

- Class C. This includes structures with thin frames that are used in non-residential buildings: warehouses, industrial premises. The thickness of the lines here is less than 2.4 mm on the outer wall and 1.9 mm on the inner.

The design of the reinforced profile ensures its rigidity, so the thickness of the walls is of fundamental importance.

Triplex glass

Since ordinary float glass easily breaks even as a result of a slight impact, in the production of windows there was a need for an impact-resistant material with good light transmittance and a high level of safety. This is how triplex appeared. It was obtained by combining ordinary glass and a polymer film, which is located between two sheets. This combination made it possible to simultaneously increase both strength and safety. Even if triplex glass manages to break, thanks to the film, the fragments will not scatter throughout the room. At the same time, the number of layers in triplex can be more than three, which makes it possible to further increase the impact resistance of products. Today, technologies make it possible to produce triplex with four layers of polymer film, the total thickness of which is 32 mm.

Frame width

This indicator determines the type of double-glazed window that the profile can withstand without problems. The wider the window frame, the thicker the glass unit will fit into it. This means it will better maintain the temperature in the room.

Also, the width of the window frame affects the installation dimensions; they matter during installation. Wide profiles increase the overall weight of the structure. When installing on a balcony, this is one of the most important indicators that need to be taken into account.

The standard width is 58-80 mm, this is enough for the climate in central Russia. For severe cold regions, widths up to 120 mm are used. They also isolate from sounds from the street.

Strained glass

If ordinary float glass is subjected to heat treatment at a temperature of 650-680 °C and at the same time rapid two-way cooling is provided, it will become tempered. This means that such sheets will be much more difficult to break. It also increases thermal resistance and improves safety - tempered glass fragments have blunt edges, making it almost impossible to get hurt by them. Such products are most vulnerable to impacts at the end, and this should be taken into account when designing glass structures.

Double-glazed window installation

The glass that we are used to seeing consists of several transparent plates connected to each other. A small space remains between them, which is either left untouched or filled with inert gas to maintain thermal insulation characteristics. The last method is used only in the premium class.

The packages are divided into chambers, for example, 2 glasses and the empty space between them - this is a single-chamber double-glazed window. If 3 glasses and 2 spaces are installed - two-chamber and so on.

Metal reinforcement

To ensure that the structure is rigid and the plastic does not give in to deformation, a metal frame is installed inside along the perimeter. Thanks to it, the shape of the window frame is preserved, and dents do not form due to the use of window sashes or exposure to temperature.

Reinforcement is carried out in accordance with the dimensions:

- if the frame is small, it is sufficient to strengthen the components of 2 sashes - L-shaped reinforcement;

- if the size is up to 1.9 m in height, a U-shaped frame is used;

- for panoramic metal-plastic windows, in large areas, loggias, etc., reinforcement is carried out along the perimeter, the frame is called closed and has the greatest rigidity.

Types of glass

For the manufacture of double-glazed windows, float glass, tempered glass or triplex are used. In some cases, reinforced glass is used in windows.

To obtain a double-glazed window with the specified characteristics, glass of different thicknesses and types, various coatings on the glass surface, and films can be used.

Float glass

Float glass (from the English float - to float) is made by pouring molten glass onto the surface of a molten low-melting metal, for example, tin. This method allows us to obtain high quality glass with uniform thickness, smooth surface and good light transmission.

In most cases, the strength of 4mm glass is sufficient. Greater strength may be required for large glass units. Thick glass absorbs sound better, which can be useful in a noisy area. For windows on the upper floors of high-rise buildings, thicker glass is also preferable - they better withstand wind loads.

Shockproof glass

When ordinary glass is heated to a certain temperature and then quickly cooled in a flow of cold air, residual mechanical stresses arise in it at the micro level, which give it new properties. Glass strengthened in this way is called tempered. It is stronger than usual, resists impact better, and when broken, it crumbles into small fragments that cannot cause serious injury to a person.

Triplex is made of two thin glasses, between which a film is glued. It is much stronger than ordinary glass and absorbs sound waves better. Thanks to the film, broken triplex does not crumble into fragments, which makes such glass especially safe. If you need the most durable window with high burglary resistance, order a triplex glass unit for it.

Glass with special coating

To give glass special properties, special films or spraying are used:

- To protect from excess sun, tinting films are applied to the surface of the glass or it is painted in bulk;

- a reflective mirror layer will hide your room from prying eyes;

- a dirt-repellent coating will reduce the need for frequent window cleaning - this option is in demand for windows on the upper floors of high-rise buildings;

- spraying a thin layer of metal creates a surface that reflects thermal infrared rays - such a double-glazed window is highly energy efficient and can significantly reduce heating costs;

- films with patterns allow you to turn glass into stained glass.

Profile cameras

They should not be confused with double-glazed windows. The internal cross-section of the frame is hollow and divided by a wall and partitions. The more separated voids inside the components, the warmer and quieter the room will be. Accordingly, the thinner the width of the frame, the fewer cameras it contains. For a 58mm width, the norm is 3 cameras. If the width is 90 mm, the norm is 6 chambers.

Each empty space has its own functionality as part of the structure: attaches fittings, removes moisture, etc. They are located according to technology. Most often, 3-5 chamber profiles are used. The difference between 3 and 4 chambers is almost not felt, but in comparison with 6 chambers it will be noticeable.

Tinted windows

Tinting allows you to darken rooms, protect them from overheating and, in some cases, reduce heat loss. This type of glass is presented in 4 modifications:

- tinted in bulk;

- with pyrolysis coating;

- covered with polymer films;

- coated with metal oxides applied in a vacuum chamber.

The characteristics of these products and the method of care depend on the type of tinting. Glass tinted in the mass is considered the most resistant to mechanical damage, but they themselves quickly heat up in the sun and begin to transfer heat to the interior. As a result, it is recommended to give preference to glass with pyrolysis or vacuum coating.

White frosted glass for windows does not belong to tinted products, since they are made using other technologies - sandblasting or chemical etching.

Material homogeneity

The plastic itself should be smooth, without gluing. The surface of low-quality material may be grainy, streaky, or uneven in color. In this case, there is a high probability that a fake was purchased and such frames will perform poorly in operation.

To distinguish an unscrupulous manufacturer, you need to look at the printed inscription inside. On quality materials, the name of the manufacturer and a series of numbers indicating the number of the machine that stamped the profile and the date of production are indicated.

Reflective glass with reflective coating

These glasses are somewhat similar to energy efficient ones, but are designed for different purposes - reflection or segregation of solar rays. The protective metallized coating can also be soft or hard and differs in its degree of resistance to external influences. Some types of reflective glass can protect against overheating while maintaining high light transmittance of windows.

Solar control reflective glasses have a mirror surface, so in some cases they can be used to ensure privacy.

The best manufacturing brands

Germany is considered the leading country in this area. Their designs are distinguished by high-quality materials and the latest assembly technologies. The appearance of such frames is preserved for a long time; over time, the plastic does not change color and looks beautiful. This also applies to colored material; it does not fade. Some leading companies have factories in Russia, so the price is not too high and is affordable for most citizens.

Rehau

The products of this company are of excellent quality, have the best characteristics, and the profiles look beautiful. It has existed for more than 50 years, regularly updating production technology, improving build quality.

There are 6 types of Rehau profiles on the Russian market. They have from 3 to 6 cameras installed, width from 60 to 80 mm. The latest models have a reduced frame height, which means more light penetrates the room, without affecting the quality of the structure. Prices are average and affordable.

KBE

One of the most widespread companies in Russia. Uses durable materials that can withstand temperatures from -50 to +50 degrees. The plastic used is environmentally friendly; KBE products are recommended for use in medical and educational institutions. The width of the frames is from 58 to 70 mm, there are expensive and economy class models, produced using German technologies.

Proplex

A young Russian company that works using innovative technologies. Successfully applies the developments of Austrian specialists. It pleases customers with high-quality assembly of structures, uses the best materials and tries to keep prices reasonable. Width from 58 to 127 mm. Constantly working on modernizing production technology.

VEKA

Another company from Germany that has proven itself over decades of impeccable work. It produces traditional and multi-colored frames that are not susceptible to changes in outdoor temperature, do not turn yellow and do not lose color over time, and are painted according to the RAL scale. The design uses a rubber seal that is not deformed or destroyed under the influence of atmospheric conditions. Frames can be installed in any Russian regions. Width from 58 to 90 mm.

Trocal

Appeared on the market in 1954. One of the first companies to engage in the production of PVC windows. It produces many models with decorative finishes, laminates frames, covers them with acrylic paint, etc. In the manufacturing process, it uses innovative Greenline technologies and materials. The products provide high-quality thermal insulation, do not allow noise from the street, dust and moisture to pass through. Width 70 mm.

Salamander

They are produced directly in Germany, hence the price is slightly higher than that of analog companies with production in the Russian Federation. The materials and build quality are no worse than Veka or Rehau. Width from 60 to 76 mm.

Plastic windows Salamander

Knowing about the structural features of PVC profiles in detail, making a choice is much easier. Now there are several hundred manufacturers, among which there are many worthy ones.