Finished with white plastic lining

White PVC lining is an excellent budget option for repairing balconies and loggias. The white color of the finish increases the space and adds sophistication to the room.

Why order from us:

- We carry out professional work of any complexity;

- Installation only in accordance with GOST and TU;

- There are certificates for all materials;

- 5 year warranty!

Advantages of white PVC lining:

✔ Economical option; ✔ Not afraid of moisture, condensation, sunlight; ✔ Simple and quick installation.

From 800 rubles per 1 m2

Only high quality!

Installation time – 1-2 days!

Finishing with colored plastic lining

Colored PVC lining - thanks to the large range of colors of plastic, you can choose any combination of colors. And the pricing policy will please every loggia owner.

Why order from us:

- We carry out professional work of any complexity;

- Installation only in accordance with GOST and TU;

- There are certificates for all materials;

- 5 year warranty!

Advantages of colored PVC lining:

✔ Economical option; ✔ Not afraid of moisture, condensation, sunlight; ✔ Simple and quick installation.

From 850 rubles per 1 m2

Only high quality!

Installation time – 1-2 days!

In order for the apartment to acquire a finished look from the inside and outside, it is necessary to pay professional attention to all rooms, including the balcony or loggia. Our company has extensive experience in finishing balconies, creating unique projects in this very specific space. Such a service as finishing a balcony with plastic lining in Moscow is very popular among our clients. It is practical, efficient, varied in design and inexpensive in price.

Types of lining

Plastic lining is an excellent material used for finishing.

It is made from polyvinyl chloride with the addition of chalk and plasticizers. The production process is carried out using the extrusion method. Disposable tableware and syringes are currently made from similar raw materials, which indicates its safety and quality control, which are confirmed by various certificates.

In its finished form, the type of material under study consists of long strips of PVC, which have a double internal structure. Thanks to it, the surface contains a high degree of heat and sound insulation.

The service life of such products is at least 30 years, and their color range is very diverse. However, how to choose lining among its many varieties?

Seamless lining

Before purchasing a facing material, you need to know that the surface has differences. It happens:

- glossy;

- matte.

It also differs according to the type of connection:

- seamless;

- suture

The second type does not provide for any type of connection; the constituent elements are simply attached to each other.

The suture version has a tongue-and-groove locking system at the ends, thanks to which connections are made.

High-quality interior finishing of balconies and loggias with clapboard from specialists “WITH A BALCONY”

We have one of the most affordable prices in the capital and region for finishing a loggia with clapboards and the price for the work of specialists. At the same time, we guarantee the high quality of the materials used, fasteners and components, as well as the efficiency of the project. Many companies attract customers with reduced prices, which are actually much higher: the real picture becomes known to the customer after placing an order and starting work. We do not hide anything from our clients and speak openly about how much it costs to finish a balcony with PVC lining. Prices are formed from many factors, and we inform the client about everything and consult with him. Believe me: where you can save money - we will tell you, and where you should not do this - we will explain why.

Seamless plastic panels

Along with the presented classification, suture models are divided into:

- embossed (excellent imitation of wood texture);

- with rustication (these models are a cross between seam and seamless panels).

Depending on the need, the material under study can be textured or smooth.

The first type has a rough and uneven surface, while the second has a smooth surface. Each of these types can be pastel colors, very bright, natural, as well as muted and many others.

Manufactured PVC lining has several types, which differ in color, surface type and size. The most common:

- covered with offset printing;

- painted (more than 100 colors);

- with thermal transfer film;

- laminated to look like granite, wood or marble.

Do-it-yourself clapboard cladding: step-by-step instructions for preparation and installation

Preparatory work step by step using the example of eurolining:

- Seal joints, cracks, in external fencing and walls.

- Remove protruding pieces of reinforcement and significant bumps.

- Waterproof all walls, flooring, ceiling.

- Insulate if necessary by choosing foam foil or polyethylene.

- Make a sheathing.

- Place lighting fixtures, switches, sockets, i.e., at the required points. conduct electrical wiring, mount it on the sheathing.

- Place insulation between the frame slats.

- Additionally, lay a layer of membrane vapor barrier.

- If the frame and adjacent elements are wooden, then it is necessary to treat it with fire retardants and antiseptics to enhance the protective properties.

- Check the degree of dryness of the room, whether there are any risks of fire when finishing the balcony with panels of wooden lining, MDF.

If the room is prepared for cladding, restoration work has been carried out on the dilapidated balcony, all frame elements have been treated with a protective compound, then you can proceed directly to finishing the balcony with lining on your own.

It is more expedient to start the cladding from the ceiling

Step by step steps:

- Start installation from the ceiling. Attach the first lamella to the corner of the wall using screws and nails.

- Secure all subsequent slats with clamps. Connect tightly using a block of optimal length so that there are no gaps.

- Lay 5-7 lamellas, check the evenness with a level, tap with a hammer to avoid leaving gaps.

- Trim the last column so that it matches the width of the balcony (cut the slats if necessary).

- Secure with nails and self-tapping screws all the way through.

- After covering the ceiling, you can move on to the walls using the same technology, installing the first batch of slats from the corner, checking the vertical position with a level.

- Cover the entire area of the walls with slats, leading the wires under the socket of the lamp (switch).

- Move on to cladding door and window openings, adjusting the boards to size, aligning them using a level. If desired, use polymer or modular slopes to match the shade of the lining.

- Lay the floor, starting from the most distant wall, moving to the exit from the loggia using the same technology as for the ceiling with walls.

- Cover the laid eurolining with a protective tinting varnish at the final stage.

Installation of lining on walls

The eurolining is held well by clamps, fixed on one side to the ledge, and on the other to the sheathing.

It is important to adjust all elements with a hammer, tightly joining each other. Lastly, horizontal joints are covered with skirting boards, and vertical joints with corners.

Application options for lining

Lining can be used to decorate not only the walls, but also the ceiling of the balcony.

In its appearance, the material resembles eurolining, which contains ridges and grooves for a high-quality connection. But inside it has a void with longitudinal stiffeners.

The width of the plastic raw material is, as a rule, 10 cm. This parameter and the shape of the profile distinguishes such lining from other materials that create smooth and seamless joints. Although those that have a wider ridge allow you to create a relief and quite interesting surface.

Lining for external use must be frost-resistant

They use lining for interior and exterior decoration. The type intended for interior work is distinguished by a large number of colors.

Plain panels are most often used for the ceiling surface, and for wall coverings - those with ornaments or imitation of various woods.

The second type, used for external installation, must first of all be frost-resistant, since this type of product, if it does not contain special plasticizers, can simply crack.

However, after appropriate processing, the material becomes more resistant to various temperature changes; in this regard, for external finishing it is important to carefully study the attached documentation for the product and check the level of content of these substances.

PVC lining is an excellent material for finishing

Why is finishing the balcony with clapboard so popular ? As professionals, we will answer this question point by point:

- plastic for such work is presented in a wide range of colors,

- with the help of lining you can create any interior of a balcony or loggia,

- installation of panels does not require preliminary preparation of walls and ceilings,

- installation is carried out within one day,

- caring for the lining is very simple,

- PVC lining is durable, safe, withstands temperature fluctuations, is not afraid of moisture, is not subject to corrosion, and is not affected by mold and fungi.

pvc paneling for finishing your balcony from us the best price for services and many pleasant bonuses.

Features of choosing lining

Before purchasing a product, it is important to pay attention to the following main points, on which the choice of plastic lining will depend:

- Surface. It is necessary to find out whether the outer or inner surface will need treatment.

- Laying method. How the panels will be placed horizontally or vertically.

- Quantity. Panels should always be taken with a reserve.

- Color. The tone and uniformity of the color shade of the material are selected depending on the purpose of the room and the interior of the adjacent room.

- Size. When determining this parameter, it is important to take into account the following fact: the thicker the panel, the greater the load it will withstand.

- Quality. A well-made panel should have smooth edges and the same width around the perimeter of the entire product.

- The rigidity of the structure is given by the number of ribs: the more there are, the more the lining can withstand mechanical damage. For information on what you need to know before purchasing and installing lining, watch this video:

When choosing one type or another, you should pay attention to the fact that there is no distance between the ribs greater than 1 cm. In addition, you can notice that some manufacturers do not mix the color pigment with the paint, but apply it only to the front part.

This can result in scratches and rapid fading of the surface color.

Assembly and installation of a frame for cladding a balcony with plastic

In turn, galvanized profiles are very easy to install, they practically do not rust, they are standardized, and much smoother than wooden ones, but they do not seem very convenient for fastening the lining. After all, you can’t drive a nail into galvanized iron. However, this is exactly the version of the frame structure that we offer you for implementation; a small trick that will help you is a magnetic attachment for a screwdriver.

A galvanized screw with an extended head (the so-called “press washer”) sticks to the bit inserted into the magnetic attachment, and easily twists into the profile, fixing the plastic lining much better than a nail. Of course, screwing in a self-tapping screw takes longer than driving in a nail, but the fact that you need half as many of them more than compensates for this disadvantage.

I recommend: Working with drywall with your own hands, how to work with drywall

We assemble the frame using CD and UD profiles and attach it to the wall with a standard direct hanger (you can learn more about these profiles from the material on working with drywall). Of course, you can’t do without a hammer drill. If the walls of the house are brick, you can use an impact drill, but this replacement will not bring much joy. For each direct hanger, two holes with a diameter of 6 mm must be drilled. It is best to fasten with “quick installation” nails. These convenient screws also have another name, which in our opinion is quite apt - dowel-nail

.

The figure shows options for attaching plastic to the profile with self-tapping screws and to the rail with nails.

The dowel-nail is convenient because after drilling a hole and inserting a plastic dowel into it, the metal anchor does not need to be screwed in; a gentle blow with a hammer is enough for it to fit into the plastic plug, securely fixing the structure. At the same time, the inherent ability of the screw to be disassembled by unscrewing is preserved.

A dowel-nail allows you to not make preliminary markings, but, having temporarily fixed the part, drill a hole directly through it. How the direct suspension is attached to the wall, and the profile to the direct suspension is shown in the section in the figure above.

Important aspects when purchasing

Some types of panels produced by unverified manufacturers may contain toxic substances, so it is advisable to ask the seller for the appropriate quality certificates before purchasing the product. To learn about the dangers plastic can pose, watch this video:

In addition, the presence of chalk in the finished lining should not be more than 20%. Exceeding this indicator in production can lead to excessive fragility of the material. To check the contents of this component, you can slightly bend the corner of the lining. If it has plasticity and does not break, then the material is of high quality. If a crack or white stripe appears at the bend, it indicates that the norm has been exceeded.

To avoid problems during the operation of plastic lining, it is important to purchase products from manufacturers of well-known brands that specialize in the quality of the material and value their reputation.

Our craftsmen will do turnkey finishing

Another significant advantage of our company is finishing the balcony with turnkey clapboards at the best price. This is especially convenient when you are busy at work all day and cannot devote time to participating in the process of finishing work on a balcony or loggia. We enter into an agreement that details all aspects of the service. After all, organizing the internal space of a balcony is not just about installing plastic panels. This includes the conduction of electricity, the installation of flooring – including warm flooring, and the selection and installation of furniture. And some projects even involve placing heating radiators on the balcony and other large-scale solutions. By entrusting the finishing of your balcony with clapboard to our company, you will get the best price in Moscow!

No. 2. What should be the thickness of the plastic lining?

Based on thickness, plastic lining is conventionally divided into wall and ceiling . Of course, no one prohibits the use of wall lining for ceiling cladding and vice versa, but often this is impractical. The thickness of the material intended for finishing the ceiling is about 8 mm , and now there is a tendency for manufacturers to reduce this indicator, so you can often find material with a thickness of 7 mm, and even 4-5 mm.

The normal thickness of the lining intended for wall finishing is 10 mm. In this case, we can already talk about an acceptable level of strength. The length may also differ: lining for walls, as a rule, is made with a length of 2.7 or 3 m, less often 6 m, and the same indicator for ceiling material is usually 6 or 12 meters, but the specific figures depend on the manufacturer.

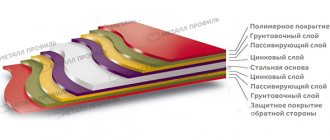

You also need to take into account the thickness of the front surface . If we look at a section of plastic lining, we will see that between the two outer sheets there are so-called stiffening ribs, located at an equal distance from each other and forming a hollow structure. Stiffening ribs not only connect two sheets, but also take on the entire impact of external influences. These stiffeners should not be visible through the front side of the lining. It should be as thick as possible, which determines both the aesthetics of the material and its strength.

No. 3. Number of stiffeners and distance between them

As for the number of stiffeners , the more there are, the better and the more resistant the lining will be to mechanical damage. The distance between the stiffeners is also important . It should be no more than 10 mm . Make sure that the stiffeners are not dented and that they are not deformed during transportation and installation. Even if the front panel remains intact, a dent will be visible on its surface.

How to cover the lining on the balcony

Finishing balconies with wood involves not only applying a protective mixture, but also further applying substances to the material that will give the wood a more attractive appearance. This issue can be solved very easily, and use the mixture that you like best.

Experts advise using regular stain. It is quite easy to apply and really highlights the wood grain. There are many shades of this mixture on the market, and it all depends on your tastes and preferences.