If you are offered to produce plastic windows in a couple of days, you should be wary of such offers. We will tell you about the main stages and terms of production of PVC structures, so that it is clear why companies usually fulfill orders within 7-10 days. It is not easy to make windows in 2-3 days: craftsmen with such short deadlines can offer ready-made products that are stored in a warehouse and for some reason did not suit the first customer, but it is unlikely that individual production will be carried out according to your project.

What to do if the contractor violates the deadline for starting work or the work is done poorly?

If an advance payment for services was made, but the work was not completed or was performed poorly, Article 395 of the Civil Code of the Russian Federation – “Use of other people’s funds” – comes into force.

Under this article, interest accrues in favor of the injured party from the moment the claim is filed. In this case, it is necessary to save and present in court the work acceptance certificate (if the deadlines specified in the contract are not met, then the customer should not sign the certificate specified in the contract). What penalties may there be? Penalties for each day the contract is overdue. A penalty that is paid either according to the agreement, or at the refinancing interest rate of the Central Bank, or in accordance with Article 395 of the Civil Code. Lawyers charge from 7 to 12 percent of the amount of the claim (the amount of the claim is determined by the victim himself). But keep in mind: the higher the amount, the lower the percentage. And most importantly: be more careful when drawing up a contract.

Interior Balcony Entrance groups Warm windows "AGS" Warm doors "AGS" Entrance group "AGS" Glazing of balconies and loggias "Provedal" Continuous glazing Stained-glass windows Rooflights Winter gardens PVC and aluminum partitions PVC slopes Fittings Mosquito nets Double-glazed windows Window sills Ebbs Catalog "Renolit" Catalog "Ral" Contacts Production time Delivery Questions and answers Terminology Useful information

December 24, 2022 12:25

All our products made from pvc profiles “Veka” “Rehau” “KBE” are certified and fully comply with all hygienic and fire safety standards ISO GOST SNIiP.

Our windows and doors are chosen for their safety and affordable price!

Replacing windows in winter

You will be surprised, but installing windows in winter has many more advantages than in summer!

Let's consider all the advantages of this installation:

- When replacing windows in winter, all the shortcomings and shortcomings of such work will be immediately noticeable: you can check for freezing, blowing and other defects in the structure, the installation itself or the walls.

- An attractive bonus: window companies (including) often organize promotions and make discounts in the winter, therefore, prices for windows installed in winter are often reduced without compromising quality.

- Due to the lack of rush in winter, you can rest assured that more time will be spent on your order and all your wishes and preferences will be taken into account.

Perhaps there is only one disadvantage to replacing PVC windows in winter - at temperatures below -25 degrees, installing windows will be fraught with certain difficulties. In this case, it is necessary to use special polyurethane foam.

Production time for PVC windows

Back

03.02.2021

The production time of PVC windows depends on many factors, including the volume of work and complexity of the order, time of year, and the competence of employees working in production. The manufacturing process of plastic window structures includes several stages, each of which takes a certain time. Let's look at these steps:

- Preparation of technical documentation. This is carried out after measurements have been taken. Based on this documentation, work will be carried out in the workshops. Registration may take from several hours to two days. The deadline depends on the volume of a specific order and the workload of the design department. Today, technical documentation does not imply paper drawings and sketches. Special programs are used for detailing.

- Profile cutting. This process also takes no more than two days if we are talking about standard rectangular structures. Cutting is carried out on an automated line. Manufacturing of double-glazed windows. If you follow the technology, this may take 3-4 days. If the window manufacturer does not manufacture double-glazed windows, but orders them from another company, the period will also be several days.

- Assembly of the structure. This is done after the parts are cut and the glass unit is ready. It can take from a couple of hours to two days.

- Checking the finished product for stability of shape and absence of defects. This is the final stage, which usually occurs 6-7 days after the order has been put into operation.

As we can see, high-quality PVC windows are manufactured within a period of 7 to 10 days. The time of year also affects the order fulfillment time - in the period from June to September it can increase to 12-15 days. This is the “high season” when producers are at their busiest. Also, the production time will be longer for structures with complex shapes or laminated profiles.

You should be wary of companies that promise to fulfill your order in a very short time. This is not possible, so the window manufacturing time will still increase during the process. In addition, there is a risk of the manufacturer using low-quality components. Or you are dealing with scammers who are just going to take your advance payment and disappear. The exception is the sale of finished windows. In this case, it is possible to receive the goods in a few days.

Although most homeowners still prefer to order plastic windows in the warm season, today they can do this in winter. Modern PVC profiles and special polyurethane foam allow installation at sub-zero temperatures. Moreover, in winter, not only the order fulfillment time decreases, but often its cost as well.

The time during which the window will be manufactured must be specified in the contract. Most companies prefer to specify a period of two weeks. This is the manufacturer's insurance in case of force majeure. In reality, the order may be completed earlier. But even if you really have to wait two weeks, this is not a reason to worry. Doing quality work takes time and responsible manufacturers understand this.

Next article

Previous article

Window with guarantee

How long it takes to install plastic windows also depends on the professionalism of the team. On average, it takes about half an hour to remove an old window and prepare it. The rest of the time is spent installing a new window, slopes, window sill and waiting time for the polyurethane foam to harden. Typically, installing a typical window costs 15–20 percent of the cost of the window.

To begin with, workers are dismantling old structures. This takes a lot of time especially if the windows are old, with tightly screwed frames and frozen streaks of old paint. When dismantling an old window, the frame most often breaks, since removing it intact is problematic, and residents usually do not have such a need.

The quality of work largely depends on the thoroughness of the preparatory procedures. In place of the removed window, a lot of debris remains, which must be cleaned and prepared for installation of the window frame. It is set exactly to size and secured with anchor bolts. At the same time, it is necessary to ensure that the frame is at the building level, and not at the opening, because in many houses the lines, which supposedly should be perfectly straight, suffer from various distortions. And if you look at the window opening from afar, then in many houses you will notice that the horizontal line in the windows is broken.

All cracks are treated with polyurethane foam, and the question of how long it takes to install plastic windows stretches out for another forty minutes so that the material sets and hardens properly. Only then is a window sill made of plastic or other material fitted under the box

For proper installation, it is also important to measure and strictly install window sills. Window slopes consist of plastic panels, which are secured with a facing corner or platbands. By the way, if the apartment is undergoing renovation, then it is better to install the platbands yourself after wallpapering, so the windows will look better

Throughout the entire window installation process, owners should observe the work of the team to be sure of the quality.

By the way, if the apartment is undergoing renovation, then it is better to install the platbands yourself after wallpapering, so the windows will look better. Throughout the entire window installation process, owners should observe the work of the team to be sure of the quality.

At the final stage, installers install the double-glazed window itself, if it was previously pulled out of the frame, mount it and regulate the direction and degree of opening of the sashes. If necessary, you can include the installation of additional parts, for example, fittings, mosquito nets or clamps.

After completing all the work, you must remember to remove the protective film from the window; this can be done by workers, or by owners. But you should not expect that this film will extend the life of the window, and you can leave it until it falls off on its own. When heated in the sun, it breaks down and can damage the window, leaving streaks and micro-scratches on it.

Window installation instructions

I will try to outline instructions for installing plastic windows in questions and answers.

How long does it take to install one window? It will take a specialist no more than two hours (this is without slopes); for a non-professional, installing metal-plastic windows may turn out to be an overwhelming task and end in calling a specialist and no instructions will save you.

How many people does it take to install a metal-plastic window? If we are talking about an ordinary window, for example, in a panel house, then one person can do the installation. With a large glass unit, for example, a shop window, a whole team of workers may be needed.

What do you need to know to install a window yourself, with your own hands, without the help of a specialist? It is necessary to have “straight hands”, a suitable tool, the window itself, and correctly follow the steps of installing the window.

Can you tell me more about the stages of window installation? Please:

- Measuring a window opening, ordering and manufacturing a window. As a rule, most window manufacturers provide measurement and subsequent installation services. But if you want to save money, then you can refuse these services and measure, dismantle and install the window yourself. Sometimes large companies sell ready-made window blocks of the most popular sizes. But in any case, you should move on to the next stage only after you have the window of the required size. Oh yes, before installation, do not forget to check the actual dimensions of your new window and the old opening under it.

- Removing the old window. If we are talking about old wooden windows, then you must first dismantle the glass (to reduce the risk of suffering from fragments if something goes wrong), then remove the sashes, then use a handsaw or reciprocating saw to make an incision in the window frame in any convenient place , thus, the frame beam can be broken into the opening; do not forget to clean the window opening after dismantling.

- Preparing windows for installation. Installing an entire window is usually very difficult due to its considerable weight and design features. For proper installation, you must first remove the sashes and interfering double-glazed windows in the places where the anchors will be. Usually the frame is left “bare”. For ease of reassembly, mark the appropriate places with a dry erase marker. It is necessary to remove the protective film from the profiles, but only from the outside of the window. The film should be left on the inside, for example, in case of finishing work. Then you need to prepare the opening for installing the window sill and lay the support profile.

- The window installation itself. The frame is leveled in the opening (strictly vertical) and holes are drilled for the anchors, usually on the sides of the window opening. The anchors are screwed in, but not all the way yet. Full tightening of the fasteners is done after the window is installed exactly vertically; if necessary, the level can be adjusted. Next, all the removed parts are returned to the frame: sashes, double-glazed windows, fittings, and fastenings for the mosquito net, if any, are installed. The fittings (handles and hinges) are adjusted. Now you need to “blow out” the frame around the perimeter with polyurethane foam, the main thing is not to overdo it, the excess will be difficult to remove. After foaming, we install the window sill in a special recess in the stand profile, which, if necessary, can be “foamed” from below. We install the drainage drain last, screwing it with self-tapping screws to the stand profile.

- Installation or improvement of slopes. This is a separate topic for discussion, let’s not get ahead of ourselves.

VN:F

we are waiting...

Rating: 5.0/5 (1 vote)

Window installation instructions, 5.0 out of 5 based on 1 rating

- Filling a fence with concrete - cheap and cheerful or reliable...

- Types and advantages of automatic swing and…

- What is more profitable – to buy a ready-made sauna stove or...

- Is it worth installing a “Smart Home” system at the dacha (in...

- Features of paying state duty for Unified State Register documents

- Expanded clay blocks in construction: description and characteristics

Memo to the consumer when purchasing and installing plastic windows

Nowadays, it is not difficult to find a company engaged in the manufacture and installation of windows. But not all companies responsibly fulfill their obligations. But the warmth and comfort of your home depends on the quality of the window and compliance with all installation rules.

In order not to come face to face with a fly-by-night company, pay attention to the period during which the company has been operating on the market, consult with friends who have contacted this company.

Find out if the company installing plastic windows has its own production and how far from your city it is located.

Check out the sample window. Any self-respecting company should have a full-size and cross-sectional sample of a window in its office. If you find it difficult to choose, ask the company manager to clearly show and talk about the differences and advantages of the proposed profile. Pay attention to samples of components (window sill, mosquito net, fittings, etc.).

What information should be brought to the attention of the consumer when choosing window designs?

Information must be presented in Russian and must contain:

list of work performed;

designation of standards whose mandatory requirements must be met by window structures and installation joints (GOSTs, etc.);

turnaround time;

warranty periods;

prices for structures and work performed;

information about the procedure and form of payment;

In addition, it would be a good idea to ask the seller (manufacturer, etc.) about the availability of documents confirming the quality and safety of the materials used in the manufacture of window structures (certificates of conformity, sanitary and epidemiological reports).

What should you pay attention to when concluding a contract?

Before signing the contract, read the text carefully!

As a rule, a contract for the manufacture and installation of a window is a contract, and not a purchase and sale agreement. Therefore, the contract must indicate: conditions on the timing of the work, as well as the price of the work, since these conditions are essential for the work contract. In the absence of agreement on the specified conditions, the contract is considered not concluded.

The contract also states:

date of conclusion of the contract,

full company name and location (legal address) of the manufacturer; for an individual entrepreneur (last name, first name, patronymic, information about state registration);

type of work;

liability of the contractor in case of poor quality work;

warranty obligations;

rules and conditions for the effective and safe use of window structures.

The contract is drawn up in two copies - for the buyer and the contractor.

Carefully check the annexes to the contract, descriptions and drawings of your future windows. Payment of the agreed amount must be confirmed by a payment document, otherwise the fact of payment will be difficult to prove.

What are the most common violations that occur during window installation?

First of all, these are incorrectly taken dimensions and installation in violation of the requirements established by law (as a result - a decrease in thermal insulation or windows begin to “freeze”). In any case, when accepting the window, make sure that there are no scratches, chips in the plastic, or other visible defects. The window should open and close without effort.

The main difficulty at the installation stage of the product is that it is difficult for a “non-specialist” to assess the correctness of installation.

Therefore, before signing the acceptance certificate, it is necessary to carefully examine the result of the work and, if any shortcomings are identified, reflect them in the certificate.

What rights do consumers have if the contractor violates the deadlines for completing the work?

In accordance with Art. 28 of the Law of the Russian Federation “On the Protection of Consumer Rights” No. 2300-1 of 02/07/1992 (hereinafter referred to as the Law), the consumer, in the event of a violation by the contractor of the deadlines for completing the work, has the right, at his own discretion, to:

assign a new term to the executor;

entrust the work to third parties for a reasonable price and require the contractor to reimburse the expenses incurred;

demand a reduction in the price for work performed;

refuse to fulfill the contract for the performance of work;

demand full compensation for losses caused to him in connection with violation of the deadlines for completing the work, as well as payment of a penalty in the amount of 3% for each day of delay.

What rights does the consumer have when discovering deficiencies in the work performed?

Defect of work - non-compliance of the work with either mandatory requirements provided for by law, or the terms of the contract (in their absence or incompleteness of the requirements usually presented), or the purposes for which work of this kind is usually used, or the purposes of which the contractor was informed by the consumer at the time of conclusion agreement.

A significant defect in work is an irreparable defect or deficiency that cannot be eliminated without disproportionate costs or time, or appears repeatedly, or appears again after its elimination, or other similar deficiencies.

Hidden defects are defects that could not be identified using the usual method of acceptance or were deliberately hidden by the contractor.

In accordance with Art. 29 of the Law, the consumer, upon discovery of deficiencies in the work performed, has the right, at his own discretion, to demand:

free elimination of deficiencies in the work performed;

a corresponding reduction in the price of the work performed;

repeating the work;

refuse to fulfill the contract for the performance of work and demand full compensation for losses if significant deficiencies are discovered or if the deficiencies were not eliminated by the contractor within the prescribed period.

demand a penalty in the amount of 3% of the price for violating the deadlines for satisfying consumer requirements.

What should a consumer do if defects are discovered?

If a deficiency is discovered, you must immediately notify the company by preparing a written claim, drawn up in two copies, which must indicate one of the requirements provided for by the Law of the Russian Federation “On the Protection of Consumer Rights”. This can be done if the defect is discovered during the warranty period, and in its absence, within a reasonable period, within 2 years from the date of acceptance of the work performed.

Warranty period is the period during which, if defects are discovered in the work performed, the manufacturer (performer, etc.) is responsible for the defects.

Service life is the period during which the manufacturer undertakes to provide the consumer with the opportunity to use the work for its intended purpose and bear responsibility for significant deficiencies.

In the event of a dispute about the causes of defects, the contractor is obliged to conduct an examination at his own expense (if defects are discovered during the warranty period). The consumer has the right to be present during the examination and, in case of disagreement with its results, to challenge the conclusion in court.

Legal adviser O.A. Moshensky - Citizen F. contacted the Consultation Center for the Protection of Consumer Rights about the fact that she had plastic windows installed. Representatives brought windows without slopes, window sills and mosquito nets. Representatives of the individual entrepreneur no longer came and did not answer phone calls. No windows were installed. Although the cost of the order was paid in full. The consumer had to turn to another entrepreneur to install windows, which entailed additional costs. The entrepreneur did not respond to the demand. As a result, a statement of claim was drawn up and sent to court.

Case two. Citizen M. installed plastic windows, interior doors and an entrance door. No agreement was drawn up. After some time, shortcomings became apparent, the windows began to fog up, water began to accumulate on the window sills, and the interior doors began to close poorly. The consumer began to call the contractor on the phone, but the contractor did not answer the phone calls. The consumer does not know the last name or where to find the performer.

To avoid negative situations when concluding contracts for window installation, the Consultation Center for the Protection of Consumer Rights recommends:

Choose to have the measurements, manufacturing of windows, their delivery, installation and warranty service handled by one organization with an installation guarantee of at least 5 years (as per standard).

Demand that a purchase and sale agreement for the window structure and an agreement for installation work be concluded in writing and separately, indicating the quantity, name and size of the window, price, payment procedure, delivery period of the window structure and warranty obligations for the quality of the window.

The contract for installation work must include a list of work performed with calculation of materials and their costs, the deadline for installation work and a quality guarantee for installation. The liability of the parties for violation of the established deadlines under the contract in the form of payment of a penalty must comply with the norms of the Law of the Russian Federation “On the Protection of Consumer Rights” (for violation of the deadline for the transfer of a window - 0.5% for each day of delay of the prepaid amount, but not more than that, for delay installation - 3% for each day of delay from the price of the work, but not more than the established price). Inexpensive windows and free installation, as a rule, are offered by fly-by-night artisans who work on cheap, low-quality materials, without following proven technologies. Low prices for components provide them with profit, and you with problems and additional costs for eliminating the consequences of incorrect installation or poor quality of the window.

If, when transferring a window structure, you are required to sign a Transfer and Acceptance Certificate, then first of all, carefully inspect the window so that it is not skewed, there are no mechanical damages, bubbles, chips, scratches, cracks on the profile and glass, etc.

Check the contents and accessories. If you find that the window does not correspond to the sample, the terms of the contract, or defects are found, do not agree to the persuasion of the company’s employees that everything is removable, replaceable and solvable. The installers may persuade: “Just sign the document!” Don't believe it! Demand that a bilateral act be drawn up with a list of all comments and defects; if employees refuse, then write in both copies of the acts offered to you that the window has been accepted with comments and defects and describe them in detail. Specify the deadline for eliminating defects, only then sign the acts.

Be sure to have a second copy of the act in your hands, signed by an employee of the company. After completing the installation work, require the signing of a bilateral work acceptance certificate. Pay attention to the implementation of the main stages of installation work. Before installation, the surfaces of window openings and structures must be cleaned of dust and dirt, oil contamination must be degreased, loose, crumbling areas must be strengthened (treated with binding compounds or special film materials). The frame of a standard block (1500x1500) must be fastened to the wall at no less than 12 points (3 on each side). The installation seam must consist of three layers (outer-waterproofing, central-heat-insulating, inner-air-insulating).

On the outside, a vapor-permeable self-expanding tape PSUL is placed between the frame and the quarter (but not sealant). Then the installation gap is filled with professional (pistol) foam (for heat and sound insulation). From the outside, installation seams can be protected with special profile parts (rainproof strips, soundproofing pads). On the inside, the installation seams can be covered with a layer of plaster or cladding parts for window slopes. It is recommended to finish the internal slopes with plastic slopes, which eliminates the appearance of cracks, gives the window a finished and modern look, and also reduces the time required for installation work.

The sale of plastic windows and their installation must comply with the requirements of the following documents:

Law of the Russian Federation dated 02/07/1992 No. 2300-I “On the protection of consumer rights”.

Rules for the sale of goods based on samples, approved by Decree of the Government of the Russian Federation of July 21, 1997 No. 918.

Rules for consumer services for the population in the Russian Federation, approved by Decree of the Government of the Russian Federation of August 15, 1997 No. 1025.

GOST 23166-99 “Window blocks. General technical conditions".

GOST 30674-99 “Window blocks of polyvinyl chloride profiles. THAT".

GOST 30971-2002 “Mounting seams of junctions of window blocks to wall openings.”

CONSUMER DICTIONARY WHEN SELECTING PLASTIC WINDOWS

Window is an element of a wall or roof structure, designed to connect the interior with the surrounding space, provide natural lighting to the premises, their ventilation, protection from atmospheric and noise influences and consisting of a window opening with slopes, a window block, a system for sealing assembly seams, window sill boards, and parts drain and facings.

Accessories:

A profile (bar is allowed) is a measured section of a product produced by extrusion, with a given shape and cross-sectional dimensions.

Profile system is a set (set) of profiles that form a complete structural system of window (door) units.

A double-glazed window is a sealed product consisting of two or three sheets of glass connected to each other along the contour using spacer frames and sealants, filled with dried air or other gas. There are single-chamber (two glasses) and double-chamber (three glasses) double-glazed windows. Very often, plastic windows are called double-glazed windows, whereas a double-glazed window is just a part of a plastic window.

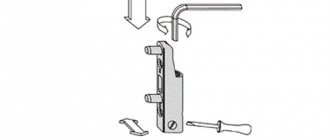

Fittings - fittings are handles, hinges, opening, locking, ventilation mechanisms, etc. That is, what allows a modern window to perform many functions that are impossible in old wooden frames.

Slopes - the distance from the inner wall to the window frame. Slopes are divided into side and top.

Window sill is a slab installed at the level of the bottom of the window block. Plastic window sills are usually used.

Flashing is a sheet of coated metal installed on the outside of a window and designed to drain rainwater. Previously, drainage systems were traditionally made of galvanized sheet metal, but today other materials are used.

An assembly seam is an element of an abutment assembly, which is a combination of various insulating materials intended to fill the installation gap and has specified characteristics.

zab-gealan

So what do we see? The greatest interest in windows, that is, the peak load on window companies in 2013, occurred in July and September. Consequently, window companies gave the longest lead times for order fulfillment at this time. The lowest rates were in January and December, respectively, the shortest periods were at this time.

This graph can be considered a reference for window companies; the statistical results will be repeated from year to year. Now let's figure it out together. From the above, it is clear that if the deadline for completing an order is fundamentally important to you when choosing a window company, focus on the time in which you plan to purchase plastic windows or glazing, this will allow you not to find yourself out of a pleasant situation. For example, you decided to install windows before the end of your vacation or before leaving, you chose a company, discussed the deadlines, the deadlines passed, but they arrange red tape for you, they postpone the installation from day to day, citing heavy workload. What should you do? Don't go on vacation now? or maybe take time off from work every day and wait for the installers? All this is very unpleasant and very tiring. By the way, this is one of the main indicators of customer loyalty to the company. Even if in the end everything is done EXCELLENTLY, you are still unlikely to contact such a company again after such hassle. Companies operating for the first season do not conduct a qualitative analysis and, when concluding a contract, mistakenly set deadlines within which they will later be unable to fulfill their obligations. In some cases, unscrupulous companies do this on purpose, they promise the customer very short terms, they work on the principle that the main thing is to conclude an agreement, and then we’ll see, it will be necessary, they’ll wait, they won’t go anywhere.

Another scenario is also possible. If you have been measured, and when concluding the contract they set an installation date almost the next day, don’t be too happy, perhaps the illiquid window that has been collecting dust in the warehouse for so long has finally fit your size. Unmarketable windows are those products that for some reason did not fit during installation or were abandoned, or even worse, a window that had already stood for some time, and then was dismantled and restored.

Precautionary measures

1. Firstly, it is advisable to understand that the order completion time directly depends on the time of year. 2. Secondly, make sure that the installation terms are specified in the contract. Preferably with a clause under which the company is responsible for failure to meet deadlines. 3. Also, when concluding an agreement, please do not force the manager to shorten the period; under your pressure, in order to conclude an agreement, he may make concessions to you, but later this will come back to haunt you, two days before the installation they will call you back and politely apologize, they will postpone the installation date , which will most likely have a negative impact on your plans. The manager is the first person who will be covered by a wave of your righteous anger if the deadlines are not met and he knows about it, so do not persuade him to change the deadline, let a real installation date be set, not a mythical one. 4. When concluding a contract, immediately inform the manager that the installation date cannot be later postponed due to, for example, departure. Let him make a corresponding note for himself. This will force the manager to take your order more seriously regarding the timing.

And so, let’s, based on the data displayed on the graph and our own statistics, draw up an approximate map of order completion times in different periods:

- January: 4-5 days

- February: 4-5 days

- March: 6-7 days

- April: 12-14 days

- May: 12-14 days

- June: 14-16 days

- July: 20-22 days

- August: 18-20 days

- September: up to 25 days

- October: 12-14 days

- November: 8-9 days

- December: 6-7 days

Also, do not forget to clarify how many days the work will be carried out for you, if this is important to you and may affect your plans, for example, a loggia with complex finishing may take 3 days. The information is relevant for the city of Chita and may differ from company to company.

The information is relevant for the city of Chita and may differ from company to company.

Windows without double glazing can be produced faster

Technically, the process of hardening of adhesive and sealing compounds used in double-glazed windows does not allow speeding up window assembly. For a double-glazed window glued according to all the rules to harden into a rigid structure, a day must pass (preliminary hardening of the sealants takes place in 2-3 hours, and the final hardening takes place in about 24 hours).

If the window does not require double glazing, the window production time can be reduced by a day

When one glass of glazing is sufficient, the timing problem is solved by the availability of the required glass in stock. If it is a typical one, the window's readiness time is reduced by 24 hours.

“When it is urgently necessary to close window openings, the delivery time of finished products can be reduced by installing window blocks with installed technical filling.

As a technical alternative to a double-glazed window, a sandwich panel of a given thickness is used, which must correspond to the thickness of the future double-glazed window. Then, when the glass unit is ready, the technical filling is replaced with the finished glass unit. Replacing the infill on site is a simple step that does not require much labor.”

Important!

It is not recommended to speed up the production of double-glazed windows, since a double-glazed window that has not gained strength may become deformed, which will lead to its damage during installation or operation.

Order for the production of double-glazed windows

You can order quick production of double-glazed windows from us. Our region of work is Moscow and the Moscow region. Our company employs experienced employees who will take accurate measurements and urgently produce double-glazed windows.

We provide a guarantee, which once again confirms the high quality. Our double-glazed windows are durable, have increased resistance to heat transfer and breathability, and are scratch-resistant.

In our company you can order the production of non-standard sizes. Specialists will advise on all issues so that clients can choose the optimal double-glazed window option. We have additional services - a technician visiting for measurements, professional consultation, replacement of damaged fittings.

Official agreement

The contract specifies the timing of production of window structures and delivery, so customers know when PVC products will be ready, even before payment. Managers additionally inform the customer about the readiness of the products and coordinate the time of delivery of the windows. The production time for structures usually does not depend on the volume of the order: it is the complexity of the project that does. Sometimes window systems for an entire balcony are produced faster than assembling one complex window. And yet, structures of any complexity are manufactured in no more than 2 weeks, while at the factory the assembly itself lasts from 2 to 7 days.

Main stages

After the specialist takes measurements, it is necessary to draw up a layout. Usually the master does this in the office or at home, then sends the project to the manager and to the production workshop. In automated production, but manual labor is not excluded. Preparation is carried out, since windows have their own parameters: size, type of profile, type of double-glazed window. From the moment the measurements are taken, it takes about 2 days.

In any production there is the concept of a queue, and in large companies, even if there are several conveyor lines, they are usually in operation. The production time for plastic windows can be up to 14 days during the high season, but this is still rare. Thanks to modern technologies, PVC products are manufactured quickly, so we do not delay production deadlines. Plastic windows are assembled after the profile is cut and the glass unit is made. This is carried out 5-6 days after placing the order.

An important point is checking the quality of PVC products. Windows are checked for chips and damage; it is important that the client is satisfied with our products. The check is carried out approximately 6-7 days after the order. Thus, after a week, the plastic structures are picked up by the delivery service and delivered to the customer. So it turns out that the average order completion time is 7-10 days.

If it is necessary to produce windows of non-standard sizes (shaped, dimensional or very small), then the production time increases due to the fact that more time is required for the production of the frame and glass unit, and assembly of the structure. If windows are produced for standard apartments, the work is completed faster. No additional preparation is required; the production already has the dimensions of all window openings. The order fulfillment time for standard houses does not exceed a week.

How to install plastic windows correctly?

The need to glaze a living space does not cause any problems. The only thing that may cause any difficulties is choosing from the variety of options offered. The first criterion to consider when making a decision is the material.

As a basis for the manufacture of windows, a variety of components are used, which differ in many characteristics. For example, aluminum structures are unanimously recognized as the most durable, strong and wear-resistant, and the hallmark of wooden profiles can be considered aesthetic properties that are successfully combined with technical characteristics. However, the unanimous leader in this market is plastic.

How to install plastic windows?

Installing the selected structures will not take you much time, especially if you decide to handle this process with the help of a specialist. Extremely persistent and inquisitive owners who, for one reason or another, decided to conquer this peak on their own, can be given some advice

First of all, it is important to thoroughly and consistently take measurements of window openings. This is necessary in order not to make a mistake with the dimensions of the required structures when ordering

At the next stage, it is worth starting a difficult task - dismantling the old window and preparing the opening for installation. After the preliminary steps are completed, you can proceed directly to the installation of plastic profiles. You can get detailed information on any thematic site, for example, on the one listed above.

When is it better to install plastic windows?

It is better to come up with many questions in advance. This applies to the season in which the installation work will be carried out. According to experts, there are two equal options – winter and summer. The cold period is supported by the cost of products, which is noticeably reduced due to the small number of potential customers. In summer, the danger of drafts is practically eliminated.

How long does it take to install plastic windows?

As for the installation time, it all depends on the mechanism that the home owner chooses. If he chose to install it himself, the result depends on his skills, intervals between jobs and other factors. Professionals usually complete the task in two hours (time for one window). Plastic windows in our time have long ceased to be considered a luxury. This is an essential attribute of every modern home. Due to the emergence of a large number of different-scale companies specializing in the production of this type of product, prices for goods are quite flexible, which allows even people with low incomes to glaze their home with high-quality and durable material. The editors of uznayvse.ru recommend seeking help from specialists.

uznayvse.ru

How long can installation of plastic windows take?

May 14, 2019

The issue of installation time for one plastic window worries customers not out of idle curiosity. As a rule, people have to take time off from work, send their children to grandma, prepare the premises for the upcoming installation, etc. And if the installation of PVC windows also takes place in the winter, all the above concerns are added to the fear of freezing the living space with an open window opening. In general, the installation process brings a slight chaos into the customer’s life, and the sooner it ends, the better. At the same time, we must remember that there is an inverse relationship between the speed and quality of window installation. The faster the installation, the worse the quality. And vice versa. So, you just need to be patient and let the installation crew do everything as expected, without unnecessary haste. Next, we will use specific examples to analyze what can determine the speed of installation of a plastic window in modern houses and apartments.

First, it’s worth deciding what is meant by the term “ installation of a plastic window .” As a rule, we are talking about the procedure for dismantling an old window, installing a new window block, aligning it in 3 planes, securely fastening it and creating a high-quality installation seam, as well as collecting and removing waste remaining after dismantling and installation procedures. Additionally, the process of delivering windows and bringing them into the room could be attributed here, but we will not do this, since delivery and installation are carried out on different days.

The condition of the room where installation procedures will be carried out is of great importance for the timing of installation. It's quite simple to explain. All dismantling and installation processes are accompanied by the use of physical force, lifting heavy parts, elements and tools, which significantly increases the risk of touching, damaging, breaking or scratching something.

It is immediately worth noting that it is the customer who, before the installers arrive, must take care to protect furniture, coverings and furnishings from damage and contamination, as well as clear free space for the convenience of the installation team. After all, it's in his best interest. You need to set aside tables and chairs, remove everything from the windowsill, protect upholstered furniture with cellophane, lay newspapers on the floor in front of the window, etc. Some customers do not do this, believing that the installers themselves should do this. And installers, as understanding people, can actually take a number of actions to protect the premises from damage, although this is not their responsibility. As you understand, the preparatory procedures plus the need to work extremely carefully and slowly, all this will certainly affect the installation time, which is not at all in your interests.

House under construction

It will be easiest for the installation team if the house is at the construction stage. There is no need to clean anything, there is no risk of damaging anything, there are no old window units that have to be dismantled in residential buildings and apartments. Even the debris that is generated during installation can be removed by the builders working on site. Considering the absence of a dismantling procedure, it will be several times less than under normal conditions. In general, if the measurements are carried out correctly and there are no additional complications, the entire process of installing one window can take a maximum of an hour. If installers are free, they can glaze the entire house in two to three days, provided they are fully employed at one site.

Room being renovated

The second option is to install windows in a house or apartment that is being renovated. In principle, everything is the same as in the previous case, but the process of dismantling the old window is added. And this process, I must say, is purely individual. Removing the old window unit can take anywhere from one to six hours, depending on conditions, which we'll talk about a little later. We also add to the total installation time the process of collecting and removing waste remaining after dismantling. In some cases, about a dozen bags of brick, concrete and plaster can be collected from one single window.

Living space

We have everything the same as in the case of a room being renovated, plus we add the need for more careful actions in a residential environment. As we have already said, installers will do everything possible to prevent damage to furniture and other surfaces. But only you can completely eliminate the risk of possible troubles by properly preparing the room for installation procedures. With proper preparation, the installation process can speed up significantly, amounting to about an hour and a half per window.

Panel and brick houses

The difference between the speed of installation of plastic windows in panel and brick houses is very, very significant. It is much easier for installation teams to work in panel-type buildings, where there is no need to drill into the plaster with a hammer drill, where pieces of brick walls are not broken out, etc. Dismantling procedures here, as a rule, last no more than half an hour. And there is very little garbage left. The treasured hour and a half for installing windows in panel high-rise buildings is not a myth, but a reality. Of course, in the absence of additional difficulties that we talked about above. As for brick houses, even the dismantling process can take several hours. Installation crews have to remove the plaster layer, the thickness of which can be from 20 centimeters. And brick tends to deteriorate over time, which leads to the need to be extremely careful during the dismantling process. So, if the process of installing plastic windows in a brick house takes a whole working day, don’t be surprised.

conclusions

As you can see, the installation time for PVC windows can be very different. And don’t think that installers are simply lazy to do everything quickly and efficiently. Be patient, and the installation of plastic windows will go exactly as needed for their effective and long-term service.

Services and service Warranty

- Guarantee

- Payment Methods

- Production time

- Calculator

- Order from A to Z

- Certificates and licenses

- May 24, 2019

If your dacha needs new windows

No matter how much the weather resists the onset of heat, nature takes its toll. Today no one doubts: there will be a mass opening of the dacha season! And this blessed time is already within sight. And some of the luckiest (in terms of the location of the dacha) owners have probably already visited their property and even outlined priority tasks that require a priority solution.

- May 21, 2019

Do I need to change plastic windows from the developer?

When you move into a new apartment located in a recently built new building, you get a so-called “box” in which there is practically nothing except doors, windows and wiring. And this is not so bad, because at the same time you get the apartment at a minimal cost, and you can do whatever you want here without having to deal with the removal of traces of the repairs made. You will have to invest a lot of money in new renovations, but at least you won’t have to install plastic windows. After all, caring developers rent out a property with PVC windows already installed. However, do not rush to rejoice. In 9 out of 10 cases, you will have to part with plastic windows from the developer in the very near future. For the benefit of your comfort, health and safety. This article will discuss the moments when it is necessary to replace PVC windows from the developer, and when you can get by with cosmetic repairs to bring the window structures into proper form.

- May 07, 2019

Features of installing balcony glazing in Khrushchev buildings

It is worth recognizing that Khrushchev-era apartment buildings are not the most comfortable and high-quality type of housing in our country. Created in conditions of a total housing shortage, Khrushchev's high-rise buildings were built in an emergency mode, using far from the highest quality building materials and using not the most successful design and planning solutions. As a result, half a century after their construction, such houses appear before us in a very unpleasant form. But housing is housing, and many people simply have no other choice but to live in their native Khrushchev. And some citizens specifically buy houses in Khrushchev-era buildings, rightly believing that the prices for such housing will be among the lowest.

- April 30, 2019

Window cost: what factors influence its formation

A modern plastic window is a complex structure. Its final version consists of many components. The more components and the higher their quality, the higher the cost of the finished product. But we should not forget that in order for the window structure to take its intended place, it must be delivered and installed properly with the right of warranty service. Thus, the final cost increases by the cost of delivery, installation and warranty service.

All news and publications

| Calculation of your project | or call a surveyor |

Installation quality

Glazing of new buildings is often carried out in emergency mode. If you want to complete the work as quickly as possible and meet the deadline, the developer may make critical errors and violations. The most common of these is installing windows in rainy or wet weather. In this case, it is easy to create ideal conditions for the development of fungi in the space between the window frame and the wall.

Haste also leads to poor foaming, missing gaps that allow air, moisture and sunlight to enter the foam. As a result, after a few seasons the material will completely collapse. There will be drafts in the room, and fungi and mold will begin to develop.

Where in the depth of the opening should the window frame be located?

If the thickness of the wall (window opening) is conditionally divided into three equal parts, then the frame of the window being installed should be at 1/3 of the wall thickness on the street side. This is especially true for windows with a frame width of about 60 mm, since a narrow frame contributes to increased heat loss through the slopes, which is associated with condensation both on the surface of the slopes themselves and on the surface of the frame, sashes and double-glazed windows. Proper installation and insulation of the gap (assembly seam) between the window frame and the outer wall while simultaneously insulating the slopes will allow you to avoid troubles. To solve the problem of freezing of a narrow frame, a method of installing the frame offset to the center of the window opening is also used.

The best option is to use wider structures with a profile width of over 70 mm. The likelihood of frame freezing is reduced, but only if the window slopes have been insulated.

What shapes and colors can plastic window frames have?

One of the reasons explaining the high popularity of plastic windows is the ability to manufacture structures in a wide variety of shapes and colors. A high-quality window profile is easy to bend, the profiles can be welded to each other at any angle, and therefore the windows can be trapezoidal, triangular and arched.

Technology and installation stages

Our company’s employees perform work of any complexity using two technologies:

- Installation of plastic windows with disassembly - involves disassembling the window structure into its component elements. Performed sequentially, it allows you to give the window strength, especially when carrying out work in multi-storey buildings at high altitudes.

- Installing an entire window simplifies the work of the installation team because it does not require disassembling the window into parts. Prevents incorrect installation of double-glazed windows and glazing beads, reduces operating time. This technique can be used when carrying out work at low heights (maximum up to the 12th floor, provided that the window height does not exceed 2 m).

The dismountable installation system is more complicated because it requires a specialist to know the window manufacturing technology and its structural features. If such a technique is used by a non-professional, the likelihood of window damage increases significantly. On the other hand, there are situations when it is impossible to use another installation technology, which means that you should trust the work only to experienced craftsmen who have the appropriate education and skills.

From us, clients will be able to inexpensively order the installation of window systems in any preferred way. We have the necessary technical, material and personnel base to carry out work on time, inexpensively and in strict compliance with rules and regulations.

Duration of operation of PVC windows according to GOST

The history of the triumphant development of plastic windows began in Germany, more than half a century ago. Much time has passed since then, but to this day the windows that were installed first are still in use. Despite the fact that the structures still perform their functions, there are certain standards established by technical regulations, including GOST. Some restrictions also apply to the service life of PVC structures.

Expert commentary Vladislav Dobronravov Leading technical specialist of the Okna-Media company Important! In this case, we are not talking about the time that the window will last without the need for repair work, but the final loss of qualities that make it impossible for the window to perform its functions

Calculation of average indicators will depend on the following product parameters:

- the quality of the profile from which frames, sashes, and load-bearing elements of the product are made;

- involved fittings that ensure the functioning of sashes and other moving elements;

- double-glazed windows that provide access to natural light into the room and protection against heat loss;

- seals ensuring tightness and tight clamping of structural elements.

Answering the question about how long plastic windows will last, we can say that in Russia they proceed from the basic requirements established by GOST 30674-99. However, it does not stipulate the service life, but the warranty period for the product to maintain its consumer properties.

Distance frame in a double-glazed window. White balls are an absorbent that absorbs moistureTo increase the strength of structures, special substances are added to PVC, making the product especially resistant to mechanical stress and resistance to penetrating rays of the sun.

The calculation of the operating time of the structure includes the parameters of wall thickness, installation depth, and properties of the metal amplifier.

Distance frame close

According to regulatory documents, the service life of PVC windows reaches 40 years. In reality, the working period is determined taking into account the following parameters:

- the presence of a protective film that prevents the harmful effects of ultraviolet radiation on plastic surfaces and its thickness;

- the possibility of external influence, including mechanical damage and exposure to an aggressive environment;

- environmental operating conditions.

The environmental issue is one of the significant factors, since if harmful impurities are found in the air, they will settle on the window structure. Both rain and snow are parameters that negatively affect service life.

How to extend service life?

Plastic windows will faithfully last for many years if you take proper care of them. What is meant by this concept?

So, the plastic profile should be washed regularly, ridding it of dirt and dust. Do not use abrasive substances. A soapy solution of warm water and a sponge are enough.

When washing double-glazed windows, you can use special products or just water.

The fittings on PVC windows need to be lubricated regularly. Only in this case can we talk about a long, long service life.

Seals also require maintenance. First of all, it means a timely change of regime from summer to winter and vice versa. If, of course, the products themselves provide such an opportunity. This will allow you to protect the room from drafts and cold in winter, and in summer it will reduce the load on the rubber component.

Every owner of PVC windows and doors wants this expensive product to last as long as possible. And here not only quality is of great importance, but also appropriate care, as well as proper operation.

It is also important to choose a reliable installation company. How many years the window will delight you with impeccable performance depends on the correct installation - 1 year or 40 years

Plastic window production technology

Process stages:

- In accordance with the measurements taken, a drawing is created in electronic version

- Impost blanks, frames and PVC profiles are manufactured

- The master makes holes for moisture removal, as well as for inserting fittings into the PVC window

- Reinforcing profiles are manufactured and installed, seams are sanded

- Imposts are milled in accordance with the templates, then they are attached to the block

- Handles and fittings are installed

- The frame is equipped with rubber seals

- The sashes are installed in the frame

- Double-glazed windows are being installed and sealed

- The manufacturing process ends with careful quality control.

Next, after the technician is convinced that the plastic window is working, it is prepared for transportation for further installation.

Standard production times for a standard window

To make decisions about the stages of construction and repair, you can operate with standard production times for plastic window and door units.

A window made of a white PVC profile with conventional fittings and a standard single-chamber or double-glazed window can be produced in a period of 3 days. Mandatory conditions for order fulfillment within a standard time frame: availability of all components in stock and no queue of orders. If production is heavily loaded with orders, the production queue may be several days, which will need to be added to the standard time.

What can affect the increase in standard production time:

- Production workload;

- Lack of necessary components in stock;

- Inclusion of a time-consuming additional processing process (for example, lamination or painting of a PVC profile, stained glass in a double-glazed window);

- Circumstances of force majeure or force majeure.