Window trims are installed regardless of the type of profile used for their production. Today, these protective elements are presented in a wide range of models, which makes it possible to improve the sealing of frames made of any material. In addition to providing additional protection, with the help of strips it is possible to effectively decorate all problem areas around the perimeter of window and door units. Currently, these inexpensive and simple products are the best option to improve the aesthetic and performance characteristics of structures made from plastic, metal and wooden profile systems.

Why are they needed and what are they?

Needed for decorating a window opening. They cover the mounting foam between the window frame and the wall. During installation, other defects appear, to cover which a PVC strip is used.

The peculiarity of the element is that the element can be used both inside and outside the building. Not exposed to moisture or sunlight.

A practical flashing is not only a decorative element, but also a fitting that allows you to protect the room from drafts.

There are several main types of flashings.

Why are we needing stripes?

Flashings are special decorative strips that are placed in the joint between the frame and the window opening. Thanks to this, it is possible to close the slopes after they are filled with polyurethane foam (or other material). The result is a complete, harmonious design that looks attractive.

The functional purpose is based on the implementation of two main options:

- Decorative. Inside and outside the house, slopes are filled with various materials. Even if you use ultra-modern materials, for example PSUL, its external data will still be much inferior to any decorative design. Therefore, it is extremely important to use additional materials and products designed to enhance and improve aesthetic properties, which is what strippers do;

- Protective. The device is placed in the cracks between the filled slopes. Accordingly, it additionally protects all those materials that are located behind it, providing them with durability and the ability to cope with assigned tasks much longer.

For example, if direct sunlight hits the joints filled with polyurethane foam from outside the window opening, the material will quickly deteriorate and crumble. This will invariably lead to the fact that the slopes will need to be filled again with polyurethane foam after a year (or even several months, if nothing interferes with the sun’s rays). And the flaps take the entire “sunstroke” on themselves, thanks to which the foam will last much longer.

balconman

Ask a Question

It is recommended to use window strips for several reasons: 1. They make the device beautiful and aesthetically pleasing; 2. Allows you to hide seams and protect them from negative external influences; 3. They are not so expensive that you would try to do without them; 4. Supplied to the market by many manufacturers, in particular, trusted companies and well-known brands. It should also be noted that installing the bar can be done completely independently. There is no need to involve a specialist for this, which further reduces the cost of the installation process.

Kinds

In order to make a choice, the pros and cons of each type are studied separately.

Metal

They can be made of galvanized steel, aluminum and have a flexible edge. The advantages of such elements, according to experts, are that metal strips demonstrate high durability and reliability.

The ease of installation is due to the fact that the simplest self-tapping screws with a press washer are used for installation.

As for the flexible edge, with its help it is possible to effectively close almost all unevenness on the slopes and effectively protect the room from drafts.

As for galvanized steel flashings, they are used mainly for arranging garages or hangars.

Recommended for use in brick or panel buildings.

Wooden

They are made mainly from pine. It is distinguished by high quality and environmental safety.

Experts recommend installing this exclusively on wooden windows.

Outwardly it resembles a regular rail.

Wood-look plastic cover

Wooden cover

Plastic

The PVC hard strip is an accessory that is installed exclusively on plastic windows. Suitable for hiding external and internal seams.

It has a silicone coating, which allows you to effectively smooth out all the unevenness on the slopes.

To make installation of flashings easy, they are produced in a wide variety of variations. It is better to purchase material in the form of reels, thereby reducing the amount of waste.

Self-adhesive

Such models have a special self-adhesive layer. Therefore, the self-adhesive PVC strip is the easiest to install. Such models may also have a silicone seal.

Criterias of choice

For the ideal combination of the flashing with the window, you should follow a number of points when choosing and purchasing. In this case, you can not only ensure an elegant appearance of the window group, but also effectively protect the seams from the effects of ultraviolet radiation and dampness.

- The trim strips should be selected to match the color of the window frame, the color of the façade or the interior decoration. In this case, the flashings will not discord with the surrounding colors, looking like eye-catching patches.

- The texture of the material should also match the window. For example, wooden flashings will look bad on white plastic windows. They are best used for finishing frames made of natural wood, or plastic, stylized to resemble the texture of wood. In the same way, white additional elements made of metal or PVC are not suitable for wooden frames.

- Before purchasing, you need to measure the width of the joining seam between the window and the wall opening. The width of the plank should completely cover the seam, extending onto the facade wall.

- When choosing, you should give preference to products from companies that have proven themselves in the market. The price of such flashings will be slightly higher, but all costs are compensated in the long term, thanks to their long service life.

As practice shows, the highest quality flashings, as well as other additional components, are produced by well-known companies that produce profiles for plastic windows. Some of these brands include:

- "Centuries".

- "Rehau".

- "KVE".

- "Mont Blanc".

- "Proplex".

It is recommended to purchase sash strips in specialized stores that sell components for plastic windows. Or directly from official representatives of window profile manufacturers. The cost of flashings depends on the material of manufacture and the manufacturer. Flexible plastic self-adhesive elements will cost an average of 20-50 rubles per linear meter. Rigid PVC planks will cost from 50 to 300 rubles per meter. The price for wooden and metal ones, depending on the width, decorative finish and type of wood/type of metal, ranges from 100 to 1000 or more rubles per linear meter.

How to choose the right one

In order to choose the right corner strip for plastic windows or a straight shape, you should follow certain rules:

- First of all, attention is drawn to the manufacturer’s company, namely, what kind of reputation the company has. It would be foolish to choose high-quality and advertised kona, but at the same time buy flashings of dubious production. In this case, you can study reviews about the company.

- Paying attention to the cost, it is worth saying that saving on this accessory is not advisable. There is no need to purchase too cheap models, since the cost of the most expensive options is quite acceptable. High-quality and reliable options have a long service life and are not subject to deformation. There is only one principle here: you have to pay for quality.

- You should definitely pay attention to the material. If windows are installed exclusively from natural wood, then the trims must also be made of wood. This will ensure the necessary environmental safety and create a harmonious design of the window space.

- Must be chosen to match the overall design of the window. To determine, attention is paid to the material, color and shape. In general, it should not highlight too much, harmoniously hiding flaws.

Important! Flashings are accessories that, although not too noticeable, need to be paid attention to their appearance with great care. If there are doubts about the correctness of the choice, the opinion of a specialist is used.

Product types

There are three types of flashings on sale:

- Wooden crafts;

- Metal elements;

- Plastic options.

Each option has its pros and cons and is suitable for certain conditions.

Wooden elements

Wooden flashing is a traditional option, which was the most popular a few decades ago, because then windows were also made of wood. But these days, PVC windows occupy a leading position, so this type of product is not used often, however, in some cases it fits perfectly.

The main features of wooden flashings are:

Wood products do not fit well with PVC windows, so they are used infrequently

- Made from pine . Ideally, the raw materials should be dried in a chamber so that the elements do not subsequently crack or bend due to drying;

- May have different sizes and shapes . The width is selected depending on the size of the joints. The style of execution can be very different, wood lends itself well to processing and, if desired, they can make you almost any profile;

Strips can have different designs and sizes

- Can be painted . You can choose a ready-made version of the desired color, its price is higher, but you do not have to paint the product, you can install it right away;

Painted products are completely ready for installation

- Used primarily indoors . Wood, even with excellent treatment, cracks over time in the open air. Therefore, such strips are used exclusively inside. They are best suited for windows whose surface imitates wood. Another option is elements painted white; they are also suitable for ordinary PVC structures;

Wooden flashing is installed outside in houses made of logs and timber

A linear meter of such a cover costs from 30 to 100 rubles, depending on the design and material of manufacture.

Fastening wooden products is best done using liquid nails; the composition reliably fixes the elements on the plastic frame, and you do not need to damage the window profile.

Metal version

This type of product can be made of steel or aluminum, but the second option is much less common.

The metal strip for plastic windows has the following features:

- Wide selection of standard sizes . Products differ mainly in width and are selected depending on the size of the gap between the window frame and the opening;

Metal products are rigid and durable

- Wide selection of colors . The elements are painted according to RAL markings in a variety of colors, so you can choose the best option for any window;

- Different profile shapes . If you need to close a protrusion in an opening or other non-standard elements, then flashings of any configuration will be made to order. This is very convenient if you need to close joints in old buildings, where there may be protrusions in the openings;

In a specialized workshop, products of the required size and shape will be bent for you.

- High strength . Metal elements are not afraid of atmospheric influences, ultraviolet radiation and temperature changes. They are resistant to deformation and have a long service life. The only negative is that if the paint layer is damaged, metal corrosion may begin.

The price of products depends on the configuration and size; a linear meter can cost from 50 to 200 rubles.

Most often, metal products are used outside, as they do not look very presentable. Installation is carried out using self-tapping screws; they are screwed into the window profile as shown in the photo below. You can use either galvanized fasteners or colored ones, in which the caps are painted in the desired color.

Metal flashing is strong and durable, so it is well suited for the outside of openings

PVC strips

This is the most popular option today. Products are in great demand due to the following reasons:

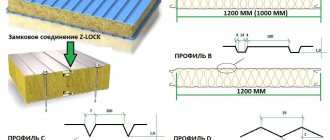

| Illustration | Description |

| Large selection of sizes. PVC flashing can have a width from 30 to 70 mm and even more. This allows you to choose the best option for any joints. | |

| Flexibility . PVC flashings bend, which allows you to reliably close even uneven joints and ensure a tight fit of the element along the entire length of the opening. The product levels out all irregularities very well and protects the connection in the best possible way. | |

| Self-adhesive strip on the back side. This option is self-adhesive, you just need to peel off the protective layer from the glue line and press the product firmly onto a clean surface. This completes the installation. At the same time, the glue holds the elements very well; they come off only with great force.

| |

Easy to install. The instructions for doing the work yourself are very simple:

| |

| Versatility . PVC window trim can be used both inside and outside. It is not afraid of moisture and low temperatures and does not crack over time. Products are sold in linear meters, you purchase as much as you need. The price per linear meter depends on the width, so the 30 mm option costs 20 rubles, and the 100 mm option costs 80 rubles. |

Installation

In order to install the flashings, despite the simplicity of the design, certain nuances are taken into account.

Tools and materials

In order to install flashings, you do not need to use too many tools and equipment. It all depends on the material from which they are made and the configuration.

If non-self-adhesive options are used, then liquid nails and sealant are additionally used.

To measure, you will need a tape measure and a knife to cut the material to a certain length.

Preparatory work

As for the preparation of the window, the surface where the flashing will adhere must be clean and not have any additional materials.

Step-by-step instruction

For PVC models it is as follows:

- the window opening and assembly seam are measured;

- measure and cut a piece of a certain length from the purchased roll;

- Carefully removing the film, glue the strip to the opening;

- If there is no adhesive tape, I use liquid nails for installation.

Important! If you have to use liquid nails, it is important that when gluing the liquid material does not extend beyond the flashing, so that you do not have to remove dried nails in the future. In this case, you can ruin the appearance of the plastic.

Metal strips are installed as follows:

- It’s worth noting right away that the model can be installed at almost any temperature, even if it’s an arched window covering;

- start gluing from the bottom edge, and then make “overlapping” fasteners;

- In those places where there is overlap, apply sealant.

Types of strips and their sizes

According to the type of material, strips are divided into: plastic (in the form of strips or tape); metal (steel or aluminum); wooden _

Wooden strips are flat strips, corner strips or strips with a triangular cross-section. Mostly, flashings are made from pine, but oak, birch, linden, aspen, larch or beech are also used for their production. You can find out what requirements apply to wood depending on the type of work here.

The sizes of the strips are varied and depend on the installation location; the length is usually from 2.5 meters to 3 meters. The width of the slats is in the range of 20-50 mm.

Benefits of use

Despite all the obvious advantages of using flashings, it is worth mentioning them again:

- Easy to transport and store. They are made in special rolls or reels and fit into any vehicle.

- Has high resistance to external factors. Not afraid of radiation and do not deteriorate from exposure to moisture. Accessories can be installed both internally and externally.

- The material from which the strips are made does not scratch and is quite difficult to spoil. In this regard, the window opening will not lose its appearance.

- Installation does not require complex tools and requires little installation time.

- High durability and reliability.

In what cases should you use flashings?

These protective elements are recommended to be used even when the slopes are lined with putty and plasterboard structures. Almost always, due to thermal expansion and even slight shrinkage of buildings, cracks that widen over time appear in the places where they join the frames, and the putty gradually breaks off and crumbles. A metal, wooden or plastic flashing completely covers the expanding gap with a reserve, protects the mounting foam from external influences and prevents depressurization of the window structure.

The exception is situations when internal and external slope systems are used for finishing. These protective and decorative structures are equipped with a special starting strip, which serves as a cover plate. Find out more at OknaTrade about these excellent systems for decorating internal and external slopes.

How to get rid of traces of shingles

Windows often require repairs. The strips are removed for work. Problems with such actions do not arise when self-tapping screws are used for fastening. If we are talking about installation on an adhesive layer, then after dismantling all the glue remains on the window profile. It needs to be removed. How to do it?

There are several basic methods for removing glue:

- Eraser. This device is used if there is little glue left and it can be removed quite easily.

- Vegetable oil. The method seems funny, but in fact the strip is glued to the surface using an adhesive composition that includes acrylic. For clarity, like on tape. If vegetable oil is mixed with acrylic glue, its main property disappears. This method is effective and is best suited for removing glue from a large surface. In this case, the area is lubricated with oil and wiped after a few hours with a paper napkin. But you should be careful, since it will not be possible to glue a new strip to the place that has been treated with vegetable oil. He just won't hold on. This option will be suitable if in the future you install a new flashing with self-tapping screws.

- If the windows are of high quality, then you can try to remove the adhesive solution using white spirit, as well as using any other solvent. In order to determine that the solvent will not harm the plastic. It is worth first testing its effect in a separate place and seeing what happens. Low quality plastic will begin to dissolve.

Important! Don't think that an eraser will help remove any amount of glue. This work is labor-intensive and the method is not suitable for large volumes.

Installing skirting boards for the ceiling

Figure 5. The profile or molding is attached directly to the wall using glue. At the same time, the ceiling canvas takes on a completely different look.

Installing a plinth is not difficult, but you need to approach it with the utmost care and precision. A video on installing skirting boards made from various materials will help with this.

After the choice of baguette is made, begin installation. It is carried out in three stages: preparatory, fastening the plinth, painting.

Preparatory stage

The best option is when the molding is attached after preparing the walls for wallpapering. The canvas itself is already located on the frame. The reason for this is simple, because after attaching the lamellas, gaps may remain that spoil the appearance of the structure. At this stage, you can get rid of them by using ordinary finishing putty. When the openings are sealed, all that remains is to level the surface and prime the place where the plinth will be attached. After the primer has dried, you can begin attaching the moldings to the wall.

Fastening the baguette

Figure 6. Fastening the profile in the corners requires precision. When the installation task is carried out correctly, it resembles a baguette in appearance, due to which the ceiling and walls become attractive

Since the molding is sold in two-meter sections, you should look at the end parts of the planks. If necessary, the deformed parts can be cut off using a sharp construction knife. To adjust them at the joint, you can use fine-grained sandpaper.

Important! To accurately join the lamellas at the corners, special corner parts are used. If these are not on sale, then a hacksaw and a miter box will help you.

When purchasing molding, select an adhesive that is suitable for such material. As a rule, the glue and molding should be accompanied by instructions that state compatibility with different types of components. If in doubt, consult the store manager.

To position the molding accurately, you need to make a marking - this is a horizontal line on which the lower box of the part will be located.

Coloring

This is the final stage, which is performed after the material is fastened. To avoid staining the film, use a polyethylene or cardboard spacer. After the paint on the molding material has dried, the lighting is installed and the wallpaper is glued.

A profile in the form of a baguette is an interesting option for hiding gaps at the joints between the ceiling and walls

Molding for stretch ceiling fabric is an excellent option for decoration. Thanks to a wide variety of colors and textures, you can transform the interior of the room and give it a finished look.

Tips in the video: