More recently, door structures made of plastic and aluminum were installed only on balcony blocks, or in retail and office premises. Modern technologies make it possible to produce street doors from a wider, more reliable profile for a private home or cottage. Plastic entrance doors do not swell from excess moisture and do not require regular updating of the coating with paints and varnishes, unlike their wooden counterparts, and the polymer coating allows you to identically imitate the texture and color of natural wood. Plastic doors are significantly inferior to metal ones in terms of reliability of protection from intruders who can get into a private home through windows. In addition, high fences are increasingly being built around cottages to protect privacy. Therefore, plastic door structures are the optimal solution for individual housing.

What are plastic doors?

Doors made of PVC profiles are structures made of plastic; For rigidity, aluminum liners are placed inside. The customer can adjust the size and shape of the structure, which allows it to be used universally for any type of premises.

There are GOST requirements for the material, valid since 2003. The standard divides structures according to the following classification:

- Purpose.

- Profile features.

- Design features.

- Type of filling.

- Finishing.

The standard for PVC external doors has been developed for their manufacturers. The information contained in GOST will help the buyer obtain reliable information about what quality products should be like. This knowledge will help you choose a quality product.

How to choose good fittings for plastic doors and windows, read our article “Choosing a fitting mechanism for plastic windows”. What are the ways to remove a PVC door from its hinges, see the link https://oknanagoda.com/steklo/vchodbie-gruppi/sposoby-snyat-dver-iz-pvkh-s-petel.html.

Read how to adjust plastic balcony doors in our material on the website.

Manufacturing materials

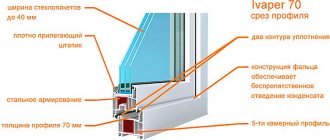

The quality of a product directly depends on the materials from which it is made. An outdoor plastic door is made from a special door profile, the thickness and width of which is much greater than that of the profile for balcony blocks or windows. Inside, the profile along its entire length is reinforced with durable plastic for door structures made of plastic or an aluminum contour for structures made of metal-plastic. The profile of doors for a country house made of metal and plastic belongs to the class A category, the characteristic parameters for it are: thickness 7.0 - 11.8 cm, thickness of the outer wall more than 0.3 cm. Inside the profile there are many chambers and a mandatory reinforcing contour made of more thick aluminum.

The thickness of the profile depends on the place where the product is used. For example, in climatic conditions with low/high temperatures, it is recommended to choose structures from a thicker profile. A thick profile is also necessary if the door is installed first, and not second, or if there is a vestibule in front of it.

The insulated chambers inside and the thickness of the outer wall are also responsible for the thermal insulation properties and strength of the plastic profile. The number of cameras should be at least 3, ideally 5.

Please note that there is a PVC door profile with a thermal break, the increased sound and heat insulation properties of which allow the finished product to be installed in the harshest conditions. When installing such a plastic entrance door, it is important to take into account the high level of tightness and provide the room with forced ventilation.

For strengthening and stability, the plastic door is reinforced from the inside along the entire perimeter with a metal profile, onto which corner reinforcing elements are attached, allowing the structure to maintain its shape during operation.

Purpose of blocks

The PVC door block can be used both indoors and outdoors. External doors include doors bordering the street or located in the vestibule. Indoor units are structures installed in rooms, bathrooms, kitchens, that is, located directly inside the building.

The design of door blocks may differ. Most often you can find two types of it:

- Single-leaf: it can open to the right or left, has the appropriate fittings, in other words, it is similar to a conventional door.

- The double-leaf model can open in both directions; this also requires the installation of a hinged system. Most often, such doors are used in rooms with high traffic.

- The threshold may or may not be present.

- The door transom can be on the side or on top.

Types of door blocks by purpose

GOST 30970-2002 for plastic entrance and interior doors

The spread of technology for manufacturing door blocks from polyvinyl chloride has led to the need to develop generally accepted standards for these products. Therefore, in 2002, an interstate standard (GOST 30970-2002) was published, regulating the requirements for door blocks made of PVC profiles. This regulatory document regulates the standards by which swing plastic doors are produced. The requirements of GOST 30970-2002 do not apply to plastic models for special purposes, including balcony doors.

The development and implementation of state standards is the only opportunity to oblige manufacturers to produce products that meet certain requirements. In the absence of a generally accepted GOST, manufacturers work according to specifications developed independently. As a result, similar products produced at different enterprises may have different properties and vary greatly in quality.

The implementation of GOST for products used in the construction industry is very important. After all, the reliability of the structures being built, and, consequently, the safety of people, depends on the properties and qualities of the manufactured products.

Type of door leaf filling, differences and features

External plastic doors, like internal ones, may differ in the type of filling. They can be of the following types:

- The plastic blind door does not have glass; there is insulation inside it.

- Glazed structure, which includes a double-glazed window.

- Light glazing: in this case, the top is made of double-glazed glass, and the lower part of the door is blank. Most often, this design is used for balconies.

Door leaf options by filling type

The PVC door profile itself can differ significantly in the number of chambers (from one to three or more) , and the type of profile finishing. The following types are found:

- Standard white or colored. This profile is considered painted.

- Painted with paint or varnish.

- Laminated.

Typology of PVC doors according to GOST

In accordance with GOST 30970–2002, metal-plastic doors are divided into:

- Regarding the purpose, the door can be external or internal. An internal door can be an interior door, an entrance door to an apartment or for a bathroom;

- Regarding the type of filling of the door frame:

- glazed PVC door, into the frame of which a double-glazed window or transparent glass of any type is inserted;

- a blind door whose door leaf is opaque. It can also be: light (when the lower part of the door is not transparent, but the upper part allows light to pass through) and decorative (when the PVC door leaf is equipped with an architectural pattern);

- Regarding its design, a metal-plastic door can be:

- with one canvas (right or left) and with two canvases (the same or different widths);

- with a fixed sash or one that opens;

- with or without a threshold, with or without a frame box;

- regarding the type of PVC profile.

Here the classification occurs according to the number of chambers of the profile system from which the door is made. Profiles come with two, three or more cameras;

- Regarding the profile finishing option, the PVC door can be white or another color, covered with a laminating film or with a co-extruded front covering.

What do the letters on plastic structures mean?

When purchasing a finished door, you can note that it is marked with a certain set of numbers and letters. It's worth knowing the following about this data:

- The letters DPV mean that you are looking at doors for indoor use. DPN – respectively, external doors made of PVC .

- If the letters are complemented by M, then the door should be used as an interior door.

- The space is followed by symbols that let you know how the canvas is filled. For example, the letter G means that the door is plastic and solid. .

- The presence of the letter B indicates the absence of a threshold in the design.

- L – single-field design. In addition, the direction of movement of the web must be indicated.

- Дв – designation of a double-field structure.

- Next you can see the numbers. They mean the dimensions of the door, its height and width.

Most residential premises have a standard doorway; this size is dictated by generally accepted building codes, so its height can vary between 2170 - 2419 mm. The width of the opening can also vary between 70 – 910 mm.

The entrance opening, corresponding to GOST, should not be less than 91 cm. The maximum possible dimensions of the door leaf can be regulated by the technical conditions developed for the product; Each door will have them individually.

Technical characteristics and GOST for PVC doors

Today there is no person who has not heard of PVC doors, also called metal-plastic or simply plastic. Using them in everyday life, how often have we wondered what it is?

Such doors are usually made from polyvinyl chloride (PVC) material reinforced inside with aluminum structures. Hence the name - metal-plastic. PVC is a difficult to ignite and self-extinguishing material, resistant to atmospheric influences, as well as the destructive effects of alkalis and acids, and not subject to rapid wear. It is these characteristics that allow it to be used for the manufacture of door frames. Also, a PVC door is much cheaper and often more beautiful, as evidenced by customer reviews.

Anyone who buys a PVC door should know that the opportunity to choose a truly high-quality product is regulated by law. Since 2002, the State Standard for metal-plastic doors has been in use. It is called “Door blocks made of polyvinyl chloride profiles” (GOST 30970–2002).

This standard describes the main types of metal-plastic doors and their technical characteristics required by production. GOST obliges manufacturers to adhere to all quality standards described in it. Therefore, when purchasing a metal-plastic door, in order not to blindly trust the seller, it is important to understand the basic concepts of GOST.

Are there any requirements for the operation of doors?

Companies produce a variety of PVC door blocks, the technical characteristics of which differ significantly from each other. If you use the door as a balcony or entrance door, an important condition is the product’s ability to insulate heat and noise. A good door should be durable, withstand a large number of openings, and also have a ventilation mode for the room.

GOST regulates the amount of heat transfer. It depends on the thickness of the product. For example, if the width of the panel layer is from 16 to 24 mm, the door should have a resistance within the range: 0.8-1.2 m2C/W. The sound insulation of this design does not exceed 26 dBA. There are also requirements for air permeability - they are 35 m2/(h m2).

If the product is made in accordance with GOST requirements, it must withstand at least half a million opening cycles.

Find out on our website what modern doors there are for a private home. Features of entrance doors. Sliding doors in your home will help save space and improve the design of your home.

In some rooms it is convenient to use accordion doors. Read more about this at the link https://oknanagoda.com/steklo/vchodbie-gruppi/razdvizhnye-dveri-garmoshka-vidy-osob.html

How to choose a PVC door

When choosing a PVC profile product, several factors are taken into account.

- A brand – no matter how you look at it, the products of a renowned manufacturer with extensive experience, using high-quality materials and components, will always outperform a door block assembled in a homemade environment from who knows what.

- Profile – for entrance doors a special PVC profile is used, which ensures the use of reinforcement with special steel liners and the installation of welded hooves in them. If a window-door is used, a standard window profile can also be used.

- Profile width – the wider it is, the “warmer” it is, all other parameters being equal. For the entrance door to a house, especially in cold regions, the optimal installation width is 70-82 mm.

- Compaction - as with width, the more contours, the better. But at least two sealing circuits.

- Reinforcement, welded hooves into the sash - in accordance with the recommendations of the developer of the profile system.

In addition, the door configuration is selected for specific operating conditions.

MopozFORUMHOUSE Member

I built a house, I need a door and window with access to an open veranda, we will use it mostly in the summer. The opening width is 1.6 m, height is 2.6 m, I plan to make the door 2 meters high. Please tell me:

- Is one side blind or two opening sides (which is better)?

- Is it better for the door to open inward or outward?

- which threshold is better?

- What else is needed to open a door (window) well?

The kitchen will have heated floors and a radiator on the wall next to the door.

Sergey Elnikov Technical specialist at VEKA

From the point of view of ease of use, it will be convenient to make a frame French window.

- The working sash (active) through which you plan to mainly exit, is 900 or 1000 mm wide, the second sash (passive) is narrower. Or symmetrical sashes. Both doors can be tilt-and-turn, as they are the most convenient to use and maintain. The peculiarity will be that the active leaf will always open first, and the passive one will open later. This window design will provide the maximum amount of light while maintaining airtightness. And the window height can be increased (sash height up to 2400 mm) and not limited to 2000 mm.

- Since the sashes will be tilt-and-turn, it is necessary to use internal opening.

- As a rule, all system suppliers (developers of their PVC profile systems) have aluminum thresholds with thermal inserts that prevent freezing. But in this design I recommend using not a threshold (although this is possible), but a solid frame with perimeter fittings. In this case, the tightness will be higher than that of a structure with a threshold.

- Depending on the double-glazed window used (soundproofing, triplex, child safety, or burglar-proof) and its weight, you may have to glue the double-glazed window in order to improve the performance characteristics of the French window. The fittings must be from leading European brands. Each of the fittings has its own interesting features. Including the possibility of fixing the sash in any place in the open state.

To ensure better performance, the window must be heated with warm air from heating systems. The heat from the side battery will go up and not onto the window, which will not be the best solution. The same applies to heated floors, since it does not create warm air movement in the window area. As a recommendation, I would advise you to consider a combination of underfloor heating and a converter in the floor near the window. This solution would be the most optimal.

Service life of the structure

The standard provides for different service lives for different structural elements. For example, a high-quality profile should last at least 40 years, a double-glazed window should last at least 25 years, and the gasket is the most short-lived: its service life is only 10 years. However, these are only approximate requirements; the quality of some manufacturers' products may exceed them.

PVC door blocks can have different strengths depending on the class to which they belong. Products of categories A, B and C differ. A-class is the most durable and high-quality product, the wall width is 3 mm. If the canvases are welded, the width of the walls will exceed 600 mm. Typically, such a structure needs to be reinforced with metal liners to make it more rigid.

Features of PVC balcony doors

Traditionally, balcony doors are made in the same design as the window. Therefore, the manufacture of balcony structures has its own characteristics. The advantage of PVC products over other materials is:

- tight fit of the canvas to the frame and ease of opening/closing;

- resistance to temperature changes;

- airtightness and low heat transfer, so that there is no heat leakage in the room through the balcony door;

- ease of care.

Hacking protection

In order to make the door secure from intruders, you can use the following methods:

- Install additional locking mechanisms that will make it more difficult for a criminal to enter the premises.

- The double-glazed window can be equipped with glass 10 mm thick. This will not only make it durable, but will also greatly improve its ability to insulate noise and retain heat. There is another way to increase the strength of glass. To do this, you will need to install a double-glazed window with tempered or armored glass. Breaking such glass is extremely difficult or even impossible. This design will not only prevent a criminal from entering the house, but will also last for many years, since it is practically not subject to mechanical stress.

- There are special anti-removal devices on sale that are installed on PVC door blocks . This will prevent the criminal from removing the door and entering.

- Reinforced hinges not only resist burglary, but also increase the service life of the structure as a whole.

Features of balcony doors

GOST requirements for PVC balcony doors are somewhat different. They are described in detail in GOST 30673 - 99.

- These blocks use various channels and valves that can improve the humidity conditions of an apartment or house.

- To enhance sound insulation, special valves are installed in the products, which absorb noise.

- Balcony doors can withstand increased operating loads, for example, strong winds, as required by established standards. Increased attention is paid to resistance to static loads.

- In the technical designations of the block passport you can see the letter M, which is added when using a frost-resistant version of the product.

- The design of balcony blocks is installed with increased attention to fire safety.

- To increase the heat-insulating properties, balcony double-glazed windows are filled with a special gas.

- GOST for plastic balcony doors provides for strengthening the profile of products with liners coated with an anti-corrosion compound.

Fire safety

Plastic doors themselves do not burn. They can melt at very high temperatures, but will not allow the fire to spread throughout the room. If you are afraid of fire or are going to install a door in a room with a high fire hazard, then it makes sense to purchase fire doors made of PVC profile .

This profile differs from the usual one in that it has a higher fire resistance coefficient. In the event of a fire, such a door will provide adequate resistance, survive and prevent the flames from spreading. It is important to note that when exposed to high temperatures, plastic will not emit harmful volatile substances that can cause poisoning.

Structural design of the vestibules

Double-floor structures can be closed using an impost or a frame structure. An impost is a plastic partition dividing a door or window in which a groove is installed for closing. The modern hinged design allows both halves of the door to be opened without creating obstacles or disrupting the view.

The frame design is relevant for offices, shops and entrance doors to the house. In this case, one half can be fixed to the latch and opened if necessary to carry furniture or other bulky things. Old interior or balcony doors with two leaves will perfectly replace plastic ones with a hinge that swing wide open outward. In the case of a balcony design, this design allows for more efficient use of the room area.

The hinged design is especially relevant for balcony doors

Gradually, the impost is becoming a thing of the past, giving way to a more rational design - the shulpovoy. In addition to improving the appearance, saving material, increasing the luminous flux, the frame system has increased anti-burglary resistance. Two plastic sashes are connected by snapping and are quite difficult to break open from the outside, unlike an impost structure. The locking mechanism can be attached to one leaf or two, and only a specialist can notice it.

Users also note the good tight fit of door leaves with a latch latch. This is especially true for a balcony door, as it allows you to retain heat in the apartment. Among the mechanisms of the latch design, the simple and economical latch version stands out. There are latches on the passive leaf at the bottom and top, and on the active leaf there is a handle that operates the door opening system.

Features of doors designed for balconies

A balcony door differs from a regular door in that it is often produced in the same block as the window. When choosing such a design, it is important to pay attention to the following features:

- When closing, the canvas should be pressed tightly against the frame and no gaps should form.

- The material must be able to withstand temperature changes and the difference between indoor and outdoor temperatures.

- Doors made of PVC profiles should insulate heat well and not let cold air into the room.

It is worth noting that the fittings for balcony doors are most often used the same as for plastic windows.

When ordering a door, ask to install a double-sided handle, this will protect you from accidentally slamming the door.

In order to make the room brighter and the door structure itself invisible, it is recommended to glaze not only the upper part of the door, but also the lower part. This option will fit perfectly into any interior.

If you install a door without a threshold, it will be much more convenient to use, but there is a risk that cold air will start to blow in.

Knowing GOST standards for metal-plastic structures, you can choose an excellent solution for an office or apartment. A manufacturer that complies with the requirements of the standards will offer only high-quality products.

Characteristics of PVC door blocks

For metal-plastic doors, GOST 30970-2014 Door blocks made of polyvinyl chloride profiles applies, which regulates their technical characteristics.

| Index | Meaning |

| Heat transfer resistance of sheets (m²·˚С/W, not less) | 0,60 |

| Sound insulation (dBA, not less) | 26 |

| Air permeability (m³/(h m²), no more) | 3,5 |

| Reliability (opening cycles, no less) | 500000 |

The performance characteristics of doors made from PVC profiles are also excellent.

- Increased thermal insulation and sound insulation is achieved due to the multi-chamber profile, the absence of cold bridges and several sealing circuits. In blind panels there is thermal insulation material inside with a minimum thermal conductivity coefficient (PPU), in translucent panels, a two-chamber energy-saving double-glazed window (filled with inert gas, low-emissivity glass). In terms of energy efficiency and sound insulation, plastic doors are superior not only to metal, but also to wooden ones.

- Functionality - a PVC entrance door, depending on the task at hand, can combine the functions of both doors and windows if equipped with a tilt-and-turn mechanism. Such doors are often placed on the second exit (to the garden, to the terrace, to the balcony, etc.). At the same time, in terms of thermal insulation and noise insulation, the door-window is comparable to a conventional swing structure.

- Practicality - plastic is highly resistant to wear, abrasion and fading and does not require specialized care. To maintain the original appearance throughout its entire service life, regular wet cleaning and maintenance of the seals and fittings are sufficient.

- Durability – polyvinyl chloride does not corrode, does not rot, is resistant to heat and frost, and can withstand intensive use and high traffic. The durability of the PVC profile and double-glazed windows is more than 20 years and almost the same durability of the seal ensures a long service life of the door block. The exact warranty period for the product depends on the specific manufacturer, but not less than three years.

- Aesthetics - initially only white profiles and sandwich panels were produced, but with the advent of lamination and thermal printing technology, the decorative properties of PVC doors increased significantly. You can choose any shade and texture, as well as combine them, and with glass filling the designs look not just beautiful, but elegant. Glass can be either transparent or frosted, mirrored, with a variety of patterns. Plus, design possibilities have expanded many times with the advent of decorative panels.

- Versatility - modern metal-plastic doors are equally harmoniously combined with wooden log houses, and with stone cottages, and with frames of all formats. Lamination imitates the texture of wood or other materials as accurately as possible. And the ability to produce blocks of almost any shape, including curved ones, allows you to select a design for buildings in any architectural style, even the most original.

- Convenience and comfort of use - the relatively small weight and fittings make it easy to operate the sash without any effort. True, only when we are talking about a high-quality product and compliance with installation technology.

id236086965FORUMHOUSE Member

My experience installing a plastic entrance door with glass. Before this, there was a metal one, which was far from the cheapest, but it sweated in winter and froze in severe frost, so we decided to change it to plastic. We ordered a measurement, a specialist arrived, measured everything, and installed it two weeks later. I tried to close it (with the handle up so that it would attract along the contour), it seemed a bit harsh, the attraction was almost at the very end and barely, I made a comment and they said it seemed like it was normal. Well, okay, I think, if anything happens, I’ll call them and they’ll fix it...

Over the course of a week, closing became very stressful, I called, they seemed to tighten it up a little, set it to summer mode, it became a little easier, but still not the same. It feels as if something is missing and in the end you really need to help with your other hand so that the lock can be closed, even the handle is a little loose. Then they sent someone from the factory and again they sang the same thing, like, this is the design, we can’t do anything. Why does a PVC door close so poorly and what to do?

Sergey Elnikov Technical specialist at VEKA

It is difficult to make a diagnosis in absentia. The reason may be either in the configuration of the door (profile, fittings, hinge group), or in the correct wedging of the double-glazed window in the sash, or in the installation of the structure. The door manufacturer should have told you about different door designs, shown samples of such doors, and helped you choose the best solution for you. You have every right to demand that the door manufacturer fulfill its warranty obligations.

- Reliability – if you want, you can break down absolutely any door, the only difference is the exposure time, the skill of the “performer” and the tool base. In terms of anti-burglary characteristics, doors made from PVC profiles are not inferior to metal structures. To a greater extent, how long a door will last before being broken into is influenced not by the material of the door block, but by its design and the presence of specialized fittings (multi-point locks with central piping).

NewHomeForumHouse Member

We are designing a frame house, with a large number of windows, including panoramic ones, from floor to ceiling, and a portal door to the veranda. With this approach, it seems absurd to make a powerful burglary-resistant steel entrance door - if anyone needs it, they will open the window. How are plastic doors in terms of tightness, sagging and safety?

Sergey Elnikov Technical specialist at VEKA

If the manufacturer complies with the rules and restrictions prescribed by the developer of PVC profile systems, the door will have high deformation resistance and tightness. In addition, the door configuration, including special profiles, reinforcement, welded corner connectors and additional profiles, as well as special fittings, will ensure compliance with both basic and anti-burglary requirements.

PVC doors have one drawback and it is due to the properties of the material itself.

Significant linear expansion/contraction due to temperature changes - to avoid deformation and depressurization, the PVC profile is reinforced with steel liners, and multi-point locks with perimeter piping are used to ensure a tight fit. If the manufacturer saves on both the profile and fittings, the design may fail, so you need to choose not from the position of the minimum price, but from the position of price-quality ratio, among proven brands.

Current regulatory documents

The beginning of mass production of doors and windows made of plastic occurred at the end of the last century. In 1999, GOST 30673-99 was adopted, which regulated the requirements for PVC profiles from which window and door units were assembled. The state standard made it possible to restore order in the production of plastic products, which were previously produced according to specifications developed by each company independently.

Today, according to the requirements of GOST 30674-99 and GOST 232166-99, PVC balcony doors are produced.

For external door plastic blocks and interior doors made of PVC, GOST 30970-2002 is used. This regulatory document describes the manufacturing technology of plastic doors, the standard values of the parameters and possible deviations from the standards.

Features of the production of plastic doors

Plastic balcony doors are made using the same technology as PVC profile windows. Essentially, a balcony door is just a large plastic window with hinged or (less commonly) swing doors.

There are different requirements for interior and entrance doors, so in 2002 a regulatory document was adopted regulating the production of these products. Interior and especially facade plastic doors should be more burglar-resistant and reliable than models installed on a balcony block.

Specifications

Basic requirements for plastic doors, regulated by GOST:

- Heat transfer resistance – 0.8-1.2 m²*C/W (depending on the type of insulation).

- Sound insulation – not less than 26 dB;

- Air permeability – no more than 3.5 m³/h*m²

What is considered a defective plastic door?

A serious violation of GOST requirements or, in other words, a defective plastic door is considered to be:

- Significant deviations in dimensions from those stated in the documentation. The permissible deviation in dimensions is -1 mm/+0.2 mm.

Advice! There is a limited tolerance for measurement differences in the diagonal length of the door leaf. For doors with a total area of up to 1.5 m², this tolerance is 2 mm; if plastic doors have an area of more than 1.5 m², then the tolerance for measurement mismatch is 3 mm.

- A defective plastic door is considered to have various surface defects - chips, dents, scratches. Unacceptable surface defects include differences in the degree of gloss and shade that are visible to the naked eye.

- Quality doors should be easy to close and lock if they are equipped with latches or locks. According to GOST requirements, when closing the door, ensuring the required deformation of the seals, the force should not exceed 120N.

- The presence of deviations in the actual technical characteristics of the doors from the values stated in the documents is considered a defect.

Advice! GOST regulates not only the standards for the manufacture and characteristics of plastic doors, but also the rules for their installation. Plastic doors are installed taking into account the requirements of GOST 30971.