Speaking about plastic doors, you should know that they have only the name in common with plastic windows. The first products still have higher requirements. The device for plastic doors is quite simple.

Diagram of a plastic door: 1 - Door frame; 2 - Door leaf; 3 - Hinge; 4 — Translucent filling; 5 - Opaque filling.

In modern production, plastic is used in the manufacture of entrance, interior and balcony doors. Each of these types has its own requirements: balcony door - thermal insulation, interior door - space delimitation, entrance door - security.

How to adjust a plastic balcony door: recommendations

Speaking about plastic doors, you should know that they have only the name in common with plastic windows. The first products still have higher requirements. The device for plastic doors is quite simple.

Diagram of a plastic door: 1 - Door frame; 2 - Door leaf; 3 - Hinge; 4 — Translucent filling; 5 - Opaque filling.

In modern production, plastic is used in the manufacture of entrance, interior and balcony doors. Each of these types has its own requirements: balcony door - thermal insulation, interior door - space delimitation, entrance door - security.

Plastic doors laminated to look like wood

Like other products of a similar nature, the designs we are considering have both their pros and cons. Let's consider the positive qualities of the plastic solution.

- Light weight . Due to the fact that the mass of the material used is relatively small, the likelihood of sagging of the canvas is minimized.

- Excellent strength . Thanks to the use of a durable combined profile, the basis of which is aluminum and plastic, manufacturers of metal-plastic doors have managed to achieve the ability of their products to withstand impressive loads.

- Sealed shutter . The use of a special seal in combination with high-quality clamps provides the structures with a good closing tightness.

- Excellent heat and sound insulation . Manufacturers of plastic doors were able to ensure the presence of similar properties in products due to the properties of the material from which the door leaf is made and the possibility of hermetically sealed locking (clause 3).

- Easy repair and adjustment . These qualities allow you to get rid of most of the problems with doors that inevitably arise during their long-term use.

Thanks to the above advantages, plastic solutions firmly occupy a leading position for use in non-residential premises.

Varieties

Despite the fact that balcony openings have standard parameters, there are 4 main types of plastic doors:

- standard - the simplest possible design, low price and ease of manufacture, consists of a plastic bottom part and glazing at the top;

- system for an insulated balcony;

- non-standard blocks - the difference lies in the dimensions and interesting designs;

- French doors are the name given to a fully glazed unit.

There are other types of plastic balcony doors. The classification is based on the number of valves: single or multi-leaf, which consist of two or more parts. Depending on the type of opening, doors can be hinged, sliding or folding (the so-called “accordion”). A wide range of choices is provided by the fittings - one of the elements that make up the balcony system.

Many of us have plastic doors on our balconies, and I think they need to be able to be adjusted because...

Fittings - this concept includes all kinds of hinges, with the help of which the structure is securely and firmly fixed, locks responsible for tightly locking the window, plastic or metal parts - special covers to protect connections, micro-lift, strips. angular gears, etc. Most of these mechanisms can only be considered with a complete disassembly of the system. All of the listed components are necessary to connect the frame and sashes. If it is not dense enough, drafts will occur. It is these elements that allow you to select the desired ventilation mode and secure the structure in a certain position.

It is necessary to monitor the condition of all parts and regularly carry out the necessary preventive maintenance: lubricate hinges, adjust pins in grooves, etc.

There are the following types of profiles that are actively used by well-known companies (Veka, KBO, Rehau)

- O-shaped - represents a closed contour. Such designs are used in various systems. Many companies run promotions that claim they provide greater insulation so your apartment will always be warm and cozy. In fact, this statement cannot be confirmed, but it is easy to refute. It is not metal, but plastic that is responsible for maintaining a stable temperature in the room. Such a profile cools quickly, which leads to a sharp cooling of the surfaces. What is the door made of? Door terms and their description. Window owners may find such an unpleasant surprise on frosty days. completely closed circuit can change its size: this is why prudent manufacturers make a minimal gap.

- U-shaped - copes with its responsibilities better than the sample already described, and is actively used in the manufacture of plastic window profile designs.

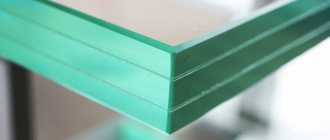

The glass unit is an important part of the window. Thanks to it, we see the space located outside the house, and it also protects us from cold and moisture. This element is contained in a frame assembled from plastic parts and is fixed in the opening. This design most often consists of 2 or 3 glasses, the distance between which is provided by an air chamber, the width of which varies depending on the features of the model: from 10 mm and more. What is a plastic door made of? Its value cannot be arbitrary: it depends on the parameters of the rectangular section of the profile.

There are several types of this element:

- Single-chamber - consists of two glasses of 4 mm each. The width is 24 mm, and the cross-sectional dimensions are 16 mm. This type is increasingly being installed on windows and balcony doors. The advantage is an affordable price, which allows you to save on purchasing the necessary design.

- Double-chamber – the number of glasses increases: there are three of them with two chambers between them. The most popular samples are those whose width ranges from 32-40 mm. Such models retain heat better, and with them your home will always be

quiet and cozy: the additional surface reliably protects from extraneous noise. However, such models also have their drawback: they transmit sunlight much worse, being a real barrier to ultraviolet rays.

- Noise-isolating - with it you will not hear screams from the street or the roar of engines of cars rushing along the freeway. What is special about this product? Glass that provides reliable sound insulation varies in thickness and quality. Additional materials affect the functionality: a special film reduces the noise level several times.

- Energy saving - it includes a unique i-glass, the operating principle of which can be compared to the action of a thermal mirror. The surface of this structure is coated using an original sputtering of silver ions.

- Protective - a shockproof and safe model, when destroyed, the resulting fragments remain behind a special film. Such double-glazed windows are installed in shop windows and kiosks.

- Tinted - a light-proof surface for rooms whose windows are located on the sunny side.

Types of plastic doors

Any architectural, technical and residential building is characterized by door and window structures of various design developments. Whether it is a new building or an old building with an entrance to the veranda, there is always an entrance door. When choosing one or another door design, each model has its own type, design and technical purpose, divided into several types.

3 types of plastic doors:

- Input;

- Balcony;

- Interior models made of PVC.

The main types of plastic structures have many technological differences in the opening method and partitions.

Types of plastic doors:

- Double or double leaf;

- Single leaf;

- Arched;

- Sliding;

- Swing;

- Foldable.

Such models have the best design options and are manufactured using the best technology. Almost every family has metal-plastic structures, be it windows or doors. Manufacturers guarantee safety and reliability for many years of operation. Most buyers choose metal-plastic structures because they are of high quality and quite inexpensive, which almost everyone can afford.

Differences between plastic street doors

All doors have a generally similar structure: frame and leaf, filling, lock and handle. However, each door element has its own resource, in particular, fittings, which impose restrictions on the use of the entire structure.

Plastic door fittings are elements with a given number of guaranteed opening and closing cycles (10,000 - 20,000). They are not suitable for stores with a large flow of visitors - the power reserve can run out in a few months, so their use is justified in individual housing construction and on sites with low throughput. In cases of high traffic, we recommend choosing aluminum doors. Aluminum doors are lighter and more resistant to intense loads, although they are somewhat more expensive than plastic ones.

Having understood the filling of windows, let’s understand the main types of blocks

- Rotary - according to the type of opening and locking of the valves;

- Folding models;

- Combined;

- Suspended - the turn is carried out around the upper axis;

- Rotating – vertically or horizontally;

- Sliding – easily retracted into the wall;

- Folding;

- Deaf (static).

A detailed story about the composition of a durable and multifunctional system allows you to verify its complex structure. It is important not to forget that each element performs a specific function and requires inspection and special care. In the picture on the right you can see the design of plastic windows in section.

Remember the rules for using these irreplaceable products. Only your care and attention to the condition of all parts guarantee a long service life of the structure.

Types of plastic entrance doors

Types of doors should be distinguished according to the following criteria:

Number of sashes. Mostly, single-leaf doors are installed as entrance structures, but there are also double-leaf doors. Moreover, the second ones can either be the same width, or one part can be wider, and the second narrower.

Opening method. Entrance doors can be sliding, hinged, folding, or accordion-type. More often, a swing version is installed in a country house, which opens either inside the room or outside.

To keep the house warm, double doors with a vestibule are installed. The distance between them is very small, but they can be made from more than one material and differ in both stylistic design and color: it all depends on the preferences of the owners. This type of construction is not suitable for apartments. To install it, you must have a porch, veranda, etc.

The sliding version of the design will also look good on the facade of the house, but it is better to install the “accordion” design not as the main door, but at the exit to the garden or veranda. Such a door does not function well in cold weather and folds like a book when opened.

Variety of canvas. A plastic door can be either fiberglass, made of impact-resistant material, or solid. If a country house offers stunning views of the sea, mountains, garden and other interesting places, then the option of installing an all-glass panel is relevant, which will allow you to enjoy all this beauty every day. Moreover, the glass can be not only transparent, but also matte, corrugated, with or without any pattern.

Structure thickness. It all depends on the manufacturer and door manufacturing technology (the thickness of the aluminum profile, the presence of air chambers and glass inserts). On average, the thickness of the finished structure ranges from 90 to 120 mm.

What types of plastic entrance doors there are for a private home can be seen in the photos presented in this article.

Advantages and disadvantages

The main function of the design is to separate the balcony from the room. However, this is only part of the task, since the same role can be performed, for example, by a curtain, which, of course, will not suit the inhabitants of city apartments. In addition, such a module must guarantee thermal insulation, sound insulation, be quite aesthetically pleasing and last a long time.

A plastic door, like a window, meets all requirements and even exceeds them:

- absolute tightness - the composition of aluminum profile and PVC plastic ensures a very tight connection between the sash and the frame. So dense that the level of thermal insulation of a metal-plastic window cannot be compared with any other building structure;

- strength – the profile frame has high rigidity. If desired, impact-resistant glass can also be installed;

- moisture resistance - plastic is not afraid of water or dampness and is insensitive to rain and snow;

- tilt and turn sashes are easily adjustable, light in weight, and the control mechanism is very simple;

- all components of the structure - glass, locks, hinges, handles, awnings, everything is replaced and repaired;

- The installation of a plastic balcony door guarantees several decades of service. The leaf is designed, for example, for 5000 openings.

The disadvantages of the solution include cost, but only when compared with an aluminum structure. In addition, high tightness can result in a disadvantage: if the room is dominated by synthetic finishes and there is no hood, moisture may accumulate.

Mandatory door hardware

Loops

This is the most loaded structural element. The hinges ensure reliable fastening of the door leaf to the frame and sufficient rotation of the hinged door when opening it. The door and the openable window sash in metal-plastic structures differ in size, but they perform the same tasks. Therefore, for balcony doors, standard anti-corrosion (zinc-aluminum-magnesium alloy) hinges are used, which are also suitable for windows. They can withstand loads of up to 80-130 kg.

Bottom hinge of balcony door

The frame frame and door leaf are connected with hinges during the production of the balcony block according to individual dimensions at the manufacturer. Therefore, you will not have to install the hinges yourself and adjust the operation of the door during installation. If during operation after the warranty period there is a need to adjust the door, the following knowledge will help:

- Hinges are used to adjust the location of the door relative to the opening when it rubs against any frame profile.

- To move the door vertically, the lower hinge is released from the decorative cap. At the top of the hinge there is access to a bolt that is located inside the canopy. Using a hexagon, you can raise (clockwise) or lower (counterclockwise) the door.

Bottom Hinge Adjustment

- The shift to the right and left is carried out by rotating the second bolt of the lower hinge. It is located in its lower part parallel to the door leaf. When the door leaf is attracted to the hinge (the hexagon is rotated clockwise), the top of the door opposite the hinge is lowered. And vice versa. The top hinge allows you to make similar adjustments, but only when the door is open.

- isolates the room from noise, drafts, moisture, odors, dust;

- protects the room from cold and heat, helps maintain a comfortable microclimate;

- saves metal fittings from dangerous condensation.

Sealant

The use of an expensive multi-chamber profile and special energy-saving double-glazed windows does not guarantee that the declared performance characteristics of the door correspond to the actual ones. For the correct “working” of a metal-plastic structure, the role of a conventional seal is invaluable - an elastic band with a relief cross-section profile, which is fixed in special recesses along the perimeter of the plastic door profile. When the door is closed, the seal is pressed tightly against the frame and performs the following functions:

Modern seal materials are non-toxic, suitable for long-term use, resistant to deformation loads, maintain performance characteristics over a wide temperature range and are almost resistant to ultraviolet radiation. For the production of seals, polyvinyl chloride, ethylene propylene rubber, thermoplastic elastomer, vulcanized rubber (classical rubber), and silicone are used.

You need to get acquainted with the characteristics of various materials and select the necessary sealant at the stage of ordering a balcony block or before replacing the old material yourself. The need for replacement will be warned by emerging drafts, increased street noise, noticeable cracks and other mechanical damage to the sealing material, the appearance of condensation, fungus or mold on the seal. Sometimes problems are eliminated by adjusting the position of the sash and the force of its pressing against the frame. In other cases, the seal is changed.

Replacing worn-out material yourself does not cause difficulties and is performed in the following order:

- The rubber band to be replaced is hooked and removed from the groove in the profile along the perimeter of the door leaf.

- The groove is cleared of dust.

- In the corners of the frame, glue is applied to the groove to securely fix the seal.

- A new sealing cord is inserted into the groove along the entire perimeter, and the excess is cut off.

- The joint of the seal (preferably located in any corner of the perimeter) is carefully glued.

Door knob

Force is constantly applied to this element of the door structure, sometimes excessive, to influence other mechanisms. The handle will work correctly and reliably with careful use and timely elimination of emerging problems, which can be easily solved by a caring home craftsman on his own:

- If the handle is loose, tighten the fastening screws. Under any handle there is a plastic cover. It is easy to pry with your fingers and rotate in any direction. There are screws under the bar. Now access to them is free. After tightening the screws, the bar is rotated into place.

- If the handle breaks, the screws are unscrewed. With a slight rocking, the handle is removed from the connector. With the orientation respected, a new one is placed in this place. We tighten the screws, turn the plastic cover to a vertical position and use a working new handle. If it is necessary to install a handle with a lock (child protection), the operating sequence is the same.

- The handle works with jamming, it has to be brought into working positions with effort. Reasons for this type of work: dirty and unlubricated handle mechanism; the door leaf is subject to a large pressing force against the frame; the door sagged relative to the opening. Problems can be solved with lubrication and necessary adjustments. In all the cases considered, the handle is not the cause of trouble and cannot be repaired.

- Sometimes the handle jams due to the inattention of users. When an already open door is moved to the “ventilation” position, a (false) locking occurs. The situation can be easily corrected. A metal spring-loaded tongue, located at the end of the door slightly below the level of the handle, is moved by pressing to a vertical position. After this, the handle becomes movable again.

Fittings

There is a fitting around the perimeter of the door leaf. Its task is to transmit mechanical force from the handle to the pins, which will block the door in the “closed” position. If necessary, the harness includes “scissors”, with the help of which the function of tilting the door to the “ventilation” position is realized. Replacing fittings is extremely rare and is usually entrusted to specialists from a specialized company. But it is useful to know the sequence of actions for dismantling old fittings to understand the principle of its functioning:

- Remove the plastic cover from the top hinge.

- The handle is set to “closed” so that the door does not fall in the future. Using the mounting handle, remove the pin from the top loop.

- The handle turns to “open”. Holding the door leaf, we tilt it towards ourselves and lift it until it exits the lower canopy.

- The removed door is placed on the floor (the handle is located at the top). The handle is removed first.

- All screws are unscrewed around the perimeter.

- The central lock in which the handle was secured is dismantled.

- Then the middle locks are removed at the bottom and top of the sash.

- The corner gears are removed last.

Attaching the door leaf with new fittings is done in the reverse order.

Self-repair rules

Regardless of the reason that led to the malfunction, to adjust the plastic balcony door you need to take a tape measure, pliers, and a set of screwdrivers (flat and Phillips). You should also prepare hex keys and plastic spacers.

Correcting sagging

To return to its normal position, the blade must be shifted towards the upper loop. The work is carried out in several stages:

Some models have screws that can only be adjusted with a five-point wrench, so it is important to check the type of hardware in advance and stock up on the appropriate tools.

Midsection Pull Up

In this case, you need to move the sash towards the hinges. You can do this as follows:

Pressure correction

The force with which the door leaf is pressed against the frame is regulated using locking elements attached to the leaf. Most often, profiles are equipped with parts in the shape of eccentrics. They must be grabbed with pliers or an adjusting wrench and rotated until the clamp is adjusted. Manufacturers of balcony profiles recommend carrying out this procedure twice a year. Before the onset of cold weather, you can install a tight clamp, and in the summer, loosen it so that fresh air can enter the room.

Eliminating handle looseness

This is the simplest task, the solution of which does not require significant effort. The adjustment is performed as follows:

Lubricating the mechanism

In order for the balcony door to function correctly, it is necessary to lubricate the seal and fittings at least once a year. Experts recommend performing this procedure before the onset of frost.

If the rubber seal is not lubricated in a timely manner, cracks may appear on it, and after 2-3 years the material will become unusable. In addition, dry tape sticks to the plastic, which causes an unpleasant sound when opening the door. With good care, the seal can last up to 10 years.

Liquid silicone must be applied to previously cleaned and dried rubber and evenly distributed over its surface using a soft cloth or sponge. You can also use an aerosol, but in this case the composition will get on nearby interior items.

What are plastic entrance doors for a private home made of: photos and design examples

To create plastic entrance doors for a private home, photo examples of which you will see in this review, special profiles are used. These parts are divided into special air chambers and have stiffening ribs.

Plastic models fit any facade

Profiles can be made using metal reinforcement. All components are connected by mortgages. Closers and power loops are installed on many entrance structures. Special locking mechanisms are installed around the perimeter to ensure a good fit of the door.

Similar products can have different types of coatings

Plastic products consist of the following parts:

- The box consists of a profile frame. The structure is reinforced with a steel frame.

- The canvas is additionally insulated with heat-insulating material. The door is partially made of armored glass.

- Bolt locks are used as fitting elements.

- The threshold is made of aluminum or steel.

Sectional profile of a plastic product

Plastic doors can be hinged, sliding or tilting. Such products are well suited to brick, concrete, stone or wooden walls.

Plastic structure on a stone facade

Components of a plastic door

Metal-plastic entrance doors can be solid and transparent, the photo shows this perfectly. Sandwich panels are used for blind structures. Glass filling can be combined. In this case, the area in the upper part is equipped with double-glazed windows, and the lower part remains blank. The glass used can be frosted, grooved, colored or transparent.

Canvas filling options

The door design can be double-leaf, single-leaf or equipped with a transom. Double-leaf leaves are shtulpovy. Locks can be mounted under an arc handle or under a push handle. The structures are also equipped with closers.

Plastic door device

Design nuances

The general style of the building is complemented by plastic entrance doors with glass for a private home, photos of which are presented below. Such designs are characterized by reliable soundproofing qualities and provide good thermal insulation. They look great with buildings covered with siding, brick or stone walls.

Variety of glass filling options

The advantages of plastic products include the ability to use curved configurations. In this case, it is possible to create arched structures.

An example of a harmonious combination of plastic construction in the exterior

Various mechanisms can be used:

- Swing structures in which the sashes are driven by rotating hinges.

Swing structures are more suitable for verandas and terraces

- Pendulum ones can open in two directions.

The pendulum mechanism is more often used for public spaces

- Sliding types help free up space in front of the door.

- Semicircular models that move using rail devices look interesting.

The semicircular design is impressive and high cost

- The telescopic mechanism uses many doors that slide on top of each other.

In the production of entrance structures, different types of glass are used. In this case, relief models, triplex, matte are used, and mirror surfaces are also mounted.