In any region, they try to protect residential premises from insects from the street, be it flocks of mosquitoes or single individuals. The most environmentally friendly and safest method of protection is mechanical - equipping window and door openings with mesh structures, permanently placed or removable, compactly folding or rigid - in the form of frame sashes of a certain size.

Types of devices for protecting homes from mosquitoes

To know how to install a mosquito net - a necessary additional accessory for window frames, let's take a closer look at the most common designs of these protective devices and their characteristics.

Requirements for mosquito nets

The main task of such nets is to create a barrier to the path of insects from the street to the apartment. Based on this, window and door openings of housing for protection against mosquitoes were previously equipped with any mesh material that was suitable at first glance - gauze, tulle, gauze fabric, fine-mesh steel construction mesh, etc. However, it soon became clear that due to certain factors these materials lose their functionality and require repair or replacement.

Some functions of mosquito net devices

To choose the right fabric for mosquito protection, we list the necessary characteristics that it must have:

- the optimal combination of mesh size and the thickness of the base material - creating a barrier in the path of insects while allowing the unhindered passage of air and maintaining sufficient transparency for viewing;

- strength - the ability to withstand random mechanical impacts and wind;

- moisture and heat resistance, ultraviolet resistance - the material preserves the strength characteristics and geometry of the canvas under the influence of atmospheric moisture, summer air temperature and sunlight;

- antistatic properties - to prevent clogging of cell openings with dust attracted by static electricity;

- ease of daily care to maintain the necessary sanitary and hygienic condition;

- safety – absence of harmful emissions into the air.

Based on the above requirements, not all mesh materials are suitable for durable and effective equipping of window and door openings with protection against insects: gauze quickly becomes dirty, stretches and impairs visibility, uncoated steel wire mesh rusts, and fine-mesh nylon mesh accumulates static electricity and becomes clogged. dust. These materials can only be used for a temporary solution to the problem, and for high-quality furnishing of housing with mosquito protection, special fine-mesh mesh canvases are used.

Framed or without?

Anti-mosquito canvases without a frame, made by yourself, do not adhere very well to windows. They are also limited in use due to the impossibility of their frequent removal.

The most budget option for such a mesh (will cost about 100 rubles) is when the tailored panel is placed in place of the standard window seal (which is previously removed), where it is fixed using a regular linen cord. True, in this case you may encounter a situation where the sealant “sticks” to the grooves in PVC windows over time. But even if the window structures are new, after a season or two there is a possibility that you will encounter the problem of unsealed windows, which means leaks and air leaks. And then the repairs will cost an amount that is many times more than what we managed to save on the mosquito net by undertaking to create it with our own hands without a frame. That is why it is better to make a frame mosquito net for residential premises.

Types of mesh for mosquito repellent devices

Mosquito repellent mesh has certain characteristics.

The first of these is the cell size, which is in the range of 0.5 - 1.2 mm. As the cell lumen decreases, the protective ability of the mesh increases - less dust will penetrate into the room. But it should be borne in mind that fabric with cells of minimal sizes needs to be washed more often - as it becomes dirty, its permeability to air and light quickly deteriorates. A canvas with a maximum mesh size is almost no barrier to dust. Therefore, the best option when choosing the degree of protection would be a mesh with a medium-sized cell - from 0.8 to 1 mm.

The second most important characteristic of a mesh fabric, which is also tied to the cell size, is the material from which the canvas is made:

- cotton - with high resistance to ultraviolet radiation and retention capacity (lint on threads), cotton netting for protection against mosquitoes from the outside is rarely used, since the lack of resistance to moisture and mold causes its fragility;

- polyester (nylon) - in the absence of any outstanding individual characteristics, canvas made of thread up to 0.8 mm thick, supporting a weight of up to 4 kg, is quite strong, durable, cheap and therefore most common for external protection against mosquitoes;

Fine mesh mosquito repellent fabrics: on the left – made of cotton, on the right – made of polyester.

- nylon – a polymer for the production of anti-allergenic mesh of complex fine-mesh “anti-dust” weaving, which traps even flower pollen;

- steel thread - fabric woven from steel wire is widely used due to its high strength, but the price of material with a protective zinc coating or stainless steel is quite high;

Mesh material: on the left – “anti-dust”, on the right – “anti-cat” made of stainless steel

- fiberglass (fiberglass coated with PVC) is the best choice due to the high transparency and strength of the fabric, which does not support combustion and is resistant to all atmospheric factors.

A significant factor when choosing a mesh is also its color, which affects light transmission, transparency and compliance with the interior. A gray canvas is the most transparent for viewing, but if the window is not panoramic, this factor can be sacrificed in favor of the aesthetics of the canvas and choose a mesh of a different color.

Colored mesh fabrics for mosquito protection

If there are pets in the house, the strength of the cellular canvas, which must withstand the impact of claws, teeth or the weight of pets, is of particular importance. Meshes that can withstand these factors are combined into the “anti-cat” group and are produced from polyester, fiberglass and metal (woven steel and expanded aluminum).

Types of metal mesh of the "anti-cat" class: 1 - woven steel, 2, 3 - aluminum perforated.

The strength of cellular canvases of this class allows them to be used for mosquito control devices installed both on large-format windows and on doorways.

Among the products offered on the modern market, mosquito repellent sheets from foreign manufacturers such as the German Roto (Roto Frank AG), the Danish Velux Group, the Polish Fakro Group and the American Pfeiffer have proven themselves well. Phifer & Company).

Installation of a frame with cellular fabric on Z-shaped brackets

The metal clamps with their profile resemble the Latin letter Z. The height of the lower overlays is 2.5 cm, and the upper elements are 4 cm. This is necessary so that the frame can first be inserted into the upper openings of the brackets, and then lowered into the lower grooves.

Type and position of Z-brackets

Step-by-step instructions for installing MS on Z-brackets

Attaching curved brackets to the outside of your home will require some skill. If the window openings are located above the 1st floor, then it is better to entrust this work to specialists. Installation of the mosquito net on the brackets occurs in a certain order.

- First, fasten the clamps at the bottom of the window frame with self-tapping screws.

- From the shelves of the lower brackets, measure the height of the frame vertically on both sides of the block and make marks.

- 20 mm above the marks mark the position of the shelves of the upper brackets.

- The fasteners are screwed in with self-tapping screws.

- The mesh is taken by the handles with both hands and taken out of the opening, unfolded and inserted into the upper brackets. Then strictly vertically lower the MS down until it stops at the lower shelves of the brackets.

- When dismantling the mesh, proceed in the reverse order.

Designs of mesh devices for protection against mosquitoes

Mechanical mosquito protection devices are produced today in many varieties, the difference from each other is often not even noticeable visually. But there are two main groups of such devices:

- frame (frame);

- frameless.

Frame ones are a frame of a fixed size and format, onto which a mesh fabric is attached. Such a sash can be installed on a window or door block in an opening using the following devices:

- plungers (pins on springs);

- loops;

- Z-shaped fastenings;

- corner clamps;

- rotary flag clamps;

- guide rails.

Frameless designs of mosquito repellent devices include the following types:

- on sticky mounting tape;

- roll (roller);

- pleated.

If you have basic installation skills, all types of protective devices can be installed independently; each of them is simply installed taking into account the individual design nuances.

Fastening the mesh sash with plungers in the window block

Fastening a mosquito net (MS) using movable rods is a reliable option for fixing the protective sheet. A plunger is a movable metal rod supported by a spring. Installation of the MS occurs as follows:

- in the side ends of the plastic frame of the mesh, two holes are drilled on each side;

- The MS is inserted into the opening, and marks are made in the window block through the holes with a marker;

- In the center of the points, recesses are drilled into which mating sleeves are inserted. They must fit tightly into the block array. Before installing the mosquito net, they can be coated with glue.

- plungers are inserted into the mesh frame with their sharp ends facing outward, and handles are screwed to their reverse ends;

- a sealing cord is glued along the perimeter of the mosquito frame from the inside;

- place the mesh by pulling the plungers by the handles. Then they are released so that the ends fit into the sleeves.

Installing the plunger

Attention . In some cases, spring rods are inserted only on one side, and fixed rods are placed in the opposite bar. This makes it possible to easily install the MS yourself without involving others.

Methods for installing mosquito repellent devices and necessary accessories

Let's look at how to install a mosquito net on a plastic window yourself if the protective device is ready or semi-ready (mesh canvas with Velcro).

Installation of a mosquito sash in a window block on plungers

Plungers are a system of movable pins (rods) with closer springs, installed around the perimeter of the sash at its end and holding the frame with the mesh in the window opening by resting on the inner edge.

Important! With the plunger method of fastening, the frame with the mesh is installed not as an overlay on the window block, but in the opening between the sealing rubber bands, so the accuracy of the measurements of the future frame is especially important - the distance between opposite points between the seal is measured in several places and the average value is taken as the design value. Measurements are usually carried out by the protection manufacturer.

Of all the methods for installing mosquito protection, the plunger method is the most reliable and therefore expensive, but still affordable mounting option.

The manufacturer installs 4 plungers on the protection frame - 2 on each side. Having placed the frame in the window opening at the installation site, use a marker to mark the drilling points along the pins for installing the mating sleeves. Having drilled 2 holes on one side and installed sleeves in them, install the frame rods in the sockets and rest the pins against the window block on the other side. Once again checking the correct location of the marks applied, make the remaining two holes.

A brush seal is glued along the outer contour of the sash with a mesh to fill the gaps between the window block and the mosquito protection sash.

Locations of spacer plungers and sealing brushes

After installing the remaining mating sleeves, the frame with the mesh is installed in place, pushing the plungers into the sockets.

Installing mosquito protection in a window opening on hinges

Window sashes, as a rule, open inward, so a frame with a mosquito net is installed on the window block from the outside - on the trim using self-tapping screws.

Hinges are installed on the protection frame in such a way that their supporting half remains removable downwards when the pins are directed upwards.

Important! If the apartment is on the first floor, then the hinges on the sash can be installed so that the axes of their supporting halves are located towards each other or directed in opposite directions - with this fastening, the frame from the street side can only be removed by unscrewing the screws.

Accessories for swinging the sash: hinges, lock (magnetic and latch)

Having secured the latch and hinges to the frame with screws, the sash is applied to the window block and centered, after which their axial halves and the lock are fixed with self-tapping screws on the frame - it is more convenient to perform this operation together and using an electric screwdriver.

Installation of hinges and lock on the sash

A swing installation of mosquito protection is indispensable when equipping doorways with mesh, but it is better to install 3 hinges on the door.

Fastening the frame with a protective mesh to Z-shaped brackets

For this method of installing a sash with a mesh, metal fasteners of a Z-shaped configuration are used, and the elements of the upper location differ from the lower brackets in the size of the pressure shelf.

Z-shaped brackets and their location on the window block

This method of attaching frame mosquito protection is also quite reliable, but the location of the clamps must be precisely adjusted to the height. In addition, it is sometimes necessary to glue additional gaskets into the brackets to ensure a tighter fit of the sash to the block.

Installation begins by fastening the lower clamps with self-tapping screws at a distance of 25 mm from the lower edge of the window opening. Then the height of the frame is set upward from the brackets and another 12-15 mm is added to the risks, after which the upper Z-elements are mounted, which for aesthetics should be located exactly opposite the lower ones.

Z-clamps: lower and upper (with technological gap)

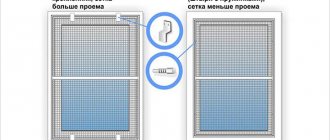

As can be seen from the figures illustrating the plunger and two subsequent methods of installing mosquito shutters, the dimensions of the protective frames of the rod fixation with the same dimensions of the window opening will differ to a smaller extent, which must be taken into account if a decision is suddenly made to change the mounting option.

Linking the size of the mesh sash to the dimensions of the opening, depending on the method of installing the protection

Fixing frame protection to corner stops

This method of fastening is a variation of the previous one and differs from it in the location of the brackets and, accordingly, in their design.

Installation of a mosquito frame on the corners - “pockets”

Corner stops, also called pockets, by definition are mounted in places where the corners of the protective frame adjoin the window block, and the elements of the top row differ from the bottom stops. Measurements of the location are made identical to the layout of the Z-brackets.

The location of the top and bottom row of “pockets”

Mounting the frame on “pockets” is a reliable fixation technology and even has an advantage over installation on Z-brackets - the protection frame cannot be moved to the side by a gust of wind.

Mosquito frame with flag clips

The essence of the fixation method is to use rotating brackets, the durability of which depends on their design and material of manufacture.

The sash, equipped for convenience with a crossbar or handles, is located outside the window block. After installing the frame in place, the flags are turned outward beyond the contour and press the frame profile to the binding.

Metal version of flag clamps

Attaching the flags to the frame is not difficult - using self-tapping screws along the perimeter of the sash in increments depending on the size of the opening and the wind load on the window.

Plastic version of rotary flags

This fastening method is inferior in reliability to the previous ones, since the fit of the flags on the sash and the tightness of the frame fixation weaken over time, and therefore the brackets require periodic tightening of the screws.

Installation of a protective sash with a mesh on the guide rails

Currently, plastic window blocks are produced, the design of which includes a movable sash with a mesh that moves in the opening along guides located outside or inside and which are part of the profile. But such window frames are much more expensive than conventional ones, so it is more advisable to equip the window with a sliding frame yourself.

Window blocks made from a profile designed for industrial installation with mosquito sashes

To equip a window with a sliding sash, you must order the frame itself with a mesh and guides. The height of the protection frame is taken in such a way that there is space left at the top and bottom of the horizontal sections of the window block for mounting the runners, and the width depends on the size of the opening.

The guides can be made of aluminum or plastic and, depending on preference, are attached to the block from the outside or inside.

Important! The slats are installed between each other at a distance that provides a gap of 1-2 mm with the sash on top for free movement of the frame at any time of the year, and strictly parallel to each other.

Samples of installed sliding mosquito protection doors

For easy sliding, the sash is equipped with rollers on the bottom and sliders on top, and the contour of its junction with the guide is finished on the back side with a brush seal.

Using a tape measure and a building level, the installation of the guides is marked, after which they are fastened with self-tapping screws. Roller fittings and handles are installed on the shutters for ease of movement, after which the protection assembly is inserted into the runners. If the frame moves easily after installation and adheres well to the block, then restrictive plugs are attached to the ends of the guides.

The idea of sliding doors will be more complete if you watch this video:

Installing frameless mosquito net protection on adhesive tape

Of all the existing ways to protect your home from insects and dust, this method is the simplest.

The principle of attaching a protective mesh without a frame to a window opening

Purchase adhesive tape with a length equal to the perimeter of the window opening, and a mesh canvas with the necessary characteristics for the size of the window block with a margin of 3-5 cm in both directions.

Ready-made protection kits of a certain size are also sold, including fabric, Velcro and glue.

The components are available in various colors so that the mounted device fits optimally into the interior of the room.

Kit for installing mosquito protection with adhesive tape

Velcro is attached to the profile of the block from the inside with glue - after preparing the base (degreasing and marking along a ruler). It is better to stitch the tape to the fabric using a sewing machine, first tucking the edges of the mesh inward.

The technology is simple, functional, cheap and safe.

Rolled (roller) design of a mosquito protection device

This type of device is the most modern both in technical design and visually, which determines its high cost - from 5 thousand rubles. per square meter.

The design consists of a horizontally mounted cylindrical box, in which a blade is placed on an axis with a return spring, which extends along guides with brush seals to the required length if you pull the handle located on the outside.

External view and internal design of roll-up mosquito protection

Roller shutter devices are produced in industrial conditions, but there are restrictions on dimensions: height - up to 250 cm, width - up to 200 cm.

Important! Despite many advantages, this design has a serious drawback - only a regular mesh can be installed in it, and “anti-dust”, “anti-pollen” and “anti-cat” canvases cannot be used.

Roller shutter protection against insects: on the left - at the installation stage, on the right - installed in place.

Anti-mosquito net of the pleated system

This type of protection is new on the domestic market. Each device is manufactured for a specific size of window opening, while the maximum dimensions are limited to 5 meters in width and 3 m in height, which allows them to equip public, administrative or sports premises with large glazed areas.

Schemes of possible canvas movement depending on the design of the protection

The operating principle of the device is to cover the opening with a mesh folded in the shape of an “accordion” in a vertical or horizontal direction (depending on the design).

The design solution of the device imposes restrictions on the material of the canvas - the “pleated” protection uses polyamide canvas, the characteristics of which, however, are quite high.

Types of cellular canvas for pleated protection

Advantages of the pleated device:

- the ability to service large openings;

- high degree of compactness when folded;

- durability;

- wide choice of colors.

Pleated type of protection in working condition

Despite the apparent complexity of the internal structure, the “plisse” is quite possible to install independently, since when assembled it is a rectangular block, ready for installation on a window frame.

Installation diagram of one of the types of mosquito protection of the “pleated” type from domestic (SKF).

In addition to high technical and aesthetic characteristics, “pleated” stands out among other types of protection and is priced from 8 thousand rubles. for 1 square meter.

Watching this video will help you install pleated protection yourself:

Homemade frames

To assemble such a mosquito net you will need the following set of parts:

- 2 drains;

- 2 crossbars;

- impost (additional transverse beam);

- impost connector;

- metal or plastic corners, 4 sets;

- detailed fasteners in the required quantity;

- cord.

Imposts and fasteners for them are ordered optionally - one such element is placed every 60-80 cm in height of the frame.

The material from which the fastening units and profiles are made matters. For example, steel corners are cheap, but susceptible to corrosion over time. The PVC coating, which soon wears out, does not save them either. It is better to use plastic ones - they are good in all respects.

As for frame profiles, they can be made of PVC or propylene . The former are cheaper and not so durable, the latter are more expensive, but they last up to 10 years if the anti-mosquito inserts are changed in a timely manner.

Frames on steel corners are fastened with through bolts, and on plastic ones - with self-tapping screws or standard latches. Additionally, they can be secured using hardware.

Plastic profiles for frames can also be purchased in long lengths - 3 or 6 m each. If you need to install frame mosquitoes on several windows at once, this is the best option. Sold by the meter and a special elastic ribbed cord, which allows you to place the mesh panel in the grooves in the most reliable way, with even pressure.

An excellent frame for a mosquito net is made from plastic cable channels (boxes) with a width of 10 to 60 mm. The cross-section of such boxes for external mosquito nets in Z-profiles should be square, then the frame will be strong and rigid. If the frame is supposed to be mounted on brackets, channels with an oblong cross-section are suitable. These frames are assembled on steel corners and secured with bolts by removing the box covers.

An impost, if required, is made from the same cable channel (the required length is cut off), its lid is sealed with stronger glue (say, construction Moment or Titan), and the ends are caulked with wood plugs. Such an impost is placed into the frame using through wood screws.

Movable mesh doors on guide rails

Movable panels with anti-mosquito fabric are installed to protect openings with sliding glazed frames. Modern plastic sliding systems are equipped with factory-made MS. The protective screens have rollers in the upper and lower transverse bars of the mesh.

Movement of the MS along an additional guide rail

Step-by-step instructions for installing a movable mosquito net

If the sliding window system has been installed for a long time, you can make a movable frame with a mosquito net yourself. You need to do it like this:

- Sections of the cable channel without covers are glued to the window sill and ceiling close to the guides of the sliding system. To do this, it is better to use Liquid Nails glue.

- You can make a mosquito net yourself or order it according to the measurements of the window opening. The frame can be made of wooden slats with a width equal to the groove of the cable channel;

- An adhesive tape is glued or stapled onto the vertical elements (it is used in wardrobes and is commercially available). The brush seal is needed in order to eliminate the slightest gaps on the sides of the mesh;

- For ease of handling, handles are screwed onto the vertical bars of the mesh;

- Carefully bending the sides of the guides at the top and bottom, insert the mesh into the channels. The protection is installed and ready for use.

- In order not to deform the plastic box each time, you can install spring-loaded rollers, which are mounted in the doors of sliding wardrobes.

Installation of a roller or pleated mosquito net

When figuring out how to install a mosquito net that is not framed, but roller shutter or pleated, you need to refer to the manufacturer’s instructions, since the process can vary greatly for different types of structures.

In fact, the roller shutter model consists of three main parts - a roller shutter with a mesh assembly (pictured on the left) and guides for it. A closed box with a roller, on which a mesh cloth is wound and where the braking mechanism is installed, is attached from the outside to the window frame using self-tapping screws. The mounting height is chosen so that the protective sheet completely covers the opening from above and below - that is, the length of the sheet should be enough for the entire opening with a small margin.

The guides are also attached using self-tapping screws, the heads of which are then hidden with protective inserts. Often the kit also includes a lower support bar, against which the edge of the mesh rests when fully lowered. This option is convenient because there is no gap at the bottom.

For pleated mesh, a similar scheme is used, only instead of a roller for winding the panel there is a place where the mesh is folded. For products with pleated fabric expanding in one direction (in the illustration on the left), this place is hidden by the box at the top or on the left/right (picture in the center). If the panel moves apart in both directions (picture on the right), then there is no fixed place, it all depends on the position of the side slats.

The frame with the panel and guides are attached to the window/door frame or wall using self-tapping screws according to the diagram in the installation instructions.

It is worth noting that installing a mosquito net of a roller shutter or pleated type with your own hands is more complicated than for frame and swing options, so it is better to place an order for the product immediately with a professional installation service.