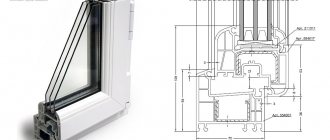

Classic five-chamber profile system

Stable multi-chamber profile system with excellent insulating characteristics.

Special reinforcing profile reinforcements ensure high stability of window structures.

High noise insulation of the profile system ensures peace and quiet of your home.

Smooth profile surface.

High-quality plastic does not require painting or special care. The material is resistant to any environmental influences.

Window profile - width matters

The most common window profile widths are 60 mm and 70 mm systems. The 60 series includes systems from 58 to 62 mm, the 70 series includes systems from 70 to 76 mm.

In Russia, 60 mm systems are more popular due to their lower cost. In Europe, the most common width is 70 mm. Why do Europeans prefer to buy larger systems when living in warmer climates?

A wider window profile has improved heat saving and sound insulation properties, but that’s not all. A wide 70 mm profile creates more opportunities for a safe and comfortable life for the future owner.

Photo: the wider the window profile, the “warmer” it is (on the left - a three-chamber profile of 58 mm, on the right - a five-chamber profile of 70 mm) A plastic profile with a width of 70 mm is “warmer” than 60 mm by approximately 20%. The main indicator that determines the level of heat conservation is the reduced resistance to heat transfer (Ro, m²∙оС/W). For a 60 mm profile with 3-4 chambers (with steel reinforcement) it can be in the range of 0.68-0.70 m²∙оС/W, and for a 70 mm profile with 5-6 chambers (with steel reinforcement) – 0.79 -0.82 m²∙оС/W.

More air chambers

In addition to classification by width, there are differences in the number of air chambers formed by vertical or inclined internal partitions of the systems. For example, a three-chamber profile, a five-chamber profile, etc. The more such chambers, the higher the thermal characteristics. The number of chambers must correspond to the width of the profile: 60 mm should have 3-4 chambers, and 70 mm should have 4-6 chambers. This is the optimal ratio for effective thermal insulation.

A window profile 60 mm wide with 5 chambers does not provide additional benefit to the window, but in terms of heat saving it corresponds to 3-4 chambers.

Double-glazed windows - warmer and quieter

In a 60 mm profile, you can usually install a double-glazed window with a maximum width of 32 mm, and in a 70 mm profile - with a maximum width of 40 mm. The leading Russian manufacturer of PVC profiles, ExProf, produces profile systems that allow the installation of a larger glass unit in a 58 mm profile - up to 36 mm, and in a 70 mm profile - up to 44 mm.

Photo: EXPROF Experta allows you to install a double-glazed window with a thickness of 44 mm *The wider the double-glazed window (subject to the same window configuration), the “warmer” the window. In a wider plastic profile, you can install a double-glazed window with better sound insulation properties

Window profile for residential premises

For residential premises with a moderate continental and extreme continental climate, it is advisable to use 70 mm systems, which, together with a “correctly” selected double-glazed window, allow obtaining high thermal characteristics of the window.

Plastic profile for non-residential premises

In rooms that do not require high levels of heat saving (utility rooms, garden buildings, etc.) you can get by with 60 mm wide systems in any climate. For residential premises in the southern regions, it is also sufficient to use 60 mm, if there is no need for additional safety or sound insulation functions.

When choosing between a 70 mm and 60 mm profile with the same number of chambers, preference should be given to systems with a larger width.

Features of the ULTRA 70 window profile

Physical properties

The given heat transfer resistance corresponds to product class 1 according to GOST 30673-99 and DIN 4108 and EnEV standards. Sound insulation VDI 2719, noise protection classes from II to IV. Anti-burglary characteristics comply with DIN V ENV 1627 - 1630 standards.

Seals

Seam seal. Continuous sealing contour in frame and sash. Special sealing systems made of APTK or silicone. Seals are black, gray or caramel.

Double-glazed window

The installation depth of the double-glazed window is 21 mm. The thickness of the glass unit when installed in the frame and sash: from 4 mm to 40 mm.

Decorative crossbars

The crossbars separating the glass unit can be of width: 48, 64, 85 and 118 mm. Crossbars that do not separate the glass unit can have a width from 25 to 55 mm.

Accessories

All major fitting systems can be used.

Profile system

Five-chamber profiles 70 mm wide. The outer wall thickness of 3 mm complies with RAL standards. Elegant outline. Various sash options: combined, offset, semi-offset. The width of the frame-sash combination in the light opening is from 81 to 158 mm. Special reinforcement according to ULTRA standards.

Additional profiles and accessories

Connecting profiles - extenders - stand profiles - profiles for connecting to the wall - connectors - decorative profiles - profiles for additional reinforcement.

Functionality

Standard windows, windows with increased thermal insulation, windows with improved noise insulation qualities, increased security window systems, balcony doors, facades.

Certificates and licenses

Certificates from leading European institutions, Rostest certificate, hygiene, fire certificates, ISO and RAL certificates.

Main features of VEKA profile systems 70 mm wide

One of the main functions of a modern window is to protect the room from the negative influences of the external environment, including temperature. The choice of plastic as a structural material for the manufacture of window and facade structures was largely due to its excellent thermal insulation characteristics. And although PVC is inferior to wood in terms of basic thermal technical indicators, the plasticity of this material and the ease of its processing make it possible to manufacture elements from it with high energy-saving indicators. And the durability of PVC and the absence of the need for any complex maintenance have provided plastic with a number of significant competitive advantages in comparison with wooden bindings.

If we talk about such a task as creating the warmest possible window, then its solution involves several directions. The first is improving the thermal technology of the window due to changes in the profile design, the second is the use of energy-saving double-glazed windows, and the third is qualified professional installation. VEKA, as a developer and manufacturer of plastic window and door systems, can logically influence the first of the above aspects. How is this done?

From 58 to 70

Traditionally, the market in Russia and the CIS countries was dominated by window profiles with an installation width of 58 – 60 mm. They were offered by all manufacturers - German, Russian, Turkish and Chinese. The standard installation width of 58 mm was not born as a result of speculative calculations, but as the most cost-effective solution to the problem of profile design, especially the frame. At the same time, the constant tightening of energy saving requirements has forced developers of profile systems to take the path of increasing the installation width. The German VEKA was one of the first to develop such a system, introducing a series of SWINGLINE profiles to the construction market. In 2003, VEKA released another 70-mm profile system of classical design - SOFTLINE, which in 2005 the Russian divisions of the concern began to produce in Moscow and Novosibirsk.

From 3 cameras to 5

The second parameter that profile manufacturers can influence is the number of chambers in the frame and sash. The 58 mm wide systems had three chambers. Their number is determined by the functions that these cameras perform. The first chamber provides temperature compensation and organization of drainage of the intra-profile space. It is she who takes the “first blow” of the outside air temperature. The second, or central chamber, serves to accommodate the reinforcing amplifier. And finally, the third chamber is intended for securing the fittings. Thus, technologically, three cameras are quite enough. But increasing the width of the profile allows you to place additional partitions inside the profile, which allows you to increase not just the number of chambers, but also optimize the heat flows inside the profile and, ultimately, reduce the heat loss of the finished structure. The VEKA SWINGLINE system mentioned above had four cameras, and SOFTLINE had five.

Solving the edge zone problem

In the new VEKA systems, such an essential parameter as the installation depth of the double-glazed window has been changed. This parameter determines how deep the glass unit “goes” inside the sash. In profiles with a width of 70 mm, this figure is usually 18 mm. In VEKA systems with increased energy-saving characteristics SWINGLINE and SOFTLINE, the installation depth of the double-glazed window is 21 mm. An insignificant, at first glance, three millimeters can be decisive if the windows are installed in a continental climate with strong temperature fluctuations and increased wind load. The fact is that it is the spacer frame in the double-glazed window that is one of the most significant conductors of cold. And its movement to a warmer zone significantly reduces the risk of lowering the temperature of the edge zones of the glass unit.

42 instead of 32

As mentioned above, manufacturers of profile systems can influence the heat-saving properties of finished plastic windows only to the extent that these properties are related to the design of the profiles. VEKA engineers managed to change another detail that has a direct impact on the thermal technology of the window. A feature of the 70 mm VEKA SWINGLINE and SOFTLINE systems is the expansion of the rebate zone in standard frames and sashes, which makes it possible to install double-glazed windows up to 42 mm wide (in a 58 mm system, the maximum width of a double-glazed window does not exceed 32 mm)

It is clear that all of the above aspects are only one, albeit a very important part of everything that must be done to create a truly warm and reliable window. VEKA's engineering experience has made it possible to create a design that makes life much easier for window manufacturers and builders. And the end consumer is guaranteed a reliable and high-quality product.

Popular VEKA profiles

Euroline (3-chamber profile 58 mm wide)

The VEKA EUROLINE profile system contains 3 chambers inside the profile, has an installation depth of 58 mm and refers to:

- HIGHER class “A” in terms of wall thickness in the profile

- HIGHER class “M” for frost resistance

- Installation depth - 58 mm

- Number of cameras - 3 pcs.

- Maximum glass thickness - 32 mm

- The thickness of the front wall of the profile is 3 mm (class “A”)

- Heat transfer resistance - 0.72 m²•°C/W

- Frost resistance - minus 55 °C (class "M")

Timeless classic - one of the first VEKA profile systems.

WHS 60 (4-chamber profile 60 mm wide)

The WHS-60 profile system contains 4 chambers inside the profile, has an installation depth of 60 mm and belongs to:

- HIGHER class “A” in terms of wall thickness in the profile

- HIGHER class “M” for frost resistance

It is worth noting that WHS is not a budget window - it is not China or Turkey, but a classic English system produced since 2011 by the global holding VEKA, headquartered in Germany. Hence the corresponding requirements for quality and performance characteristics.

- Installation depth - 60 mm

- Number of cameras - 4 pcs.

- Maximum glass thickness - 32 mm

- The thickness of the front wall of the profile is 3 mm (class “A”)

- Heat transfer resistance - 0.75 m²•°C/W

- Frost resistance - minus 55 °C (class "M")

The perfectly smooth, snow-white surface of the profile gives the window a neat and well-groomed appearance.

WHS 72 (5-chamber profile 72 mm wide)

The WHS-72 profile system contains 5 chambers inside the profile, has an installation depth of 72 mm and belongs to:

- HIGHER class “A” in terms of wall thickness in the profile

- HIGHER 1st class for heat transfer resistance

- HIGHER class “M” for frost resistance

- Installation depth - 72 mm

- Number of cameras - 5 pcs.

- Maximum thickness of glass unit - 40 mm

- The thickness of the front wall of the profile is 3 mm (class “A”)

- Heat transfer resistance - 0.83 m²•°С/W (class “1”)

- Frost resistance - minus 55 °C (class "M")

Profile system with an optimal price-quality ratio.