When you need to know how much glass weighs

In some cases, the mass of a finished or future glass product is very important, so certain calculations are required.

Under what conditions is it necessary to find out the weight of glass:

- This is necessary for the correct selection of fasteners and accessories.

- To transport the product without problems, since glass is a rather heavy material and requires special capabilities for transportation.

- The correct choice of installation technology also depends on the mass of the specimen. It is very important to install glass partitions, shower enclosures, and interior doors without errors. For example, glass door panels are hung on the wall or, in the case of sliding structures, from the ceiling or a special track.

It is clear that without an idea of the weight of the specimen, it is impossible to choose a reliable mounting method.

At the same time, calculating the weight of glass is equally important for ordinary and tempered material, multilayer triplex, and colored stemalite.

Actually, you don’t have to solve any particularly complex equations for this; it’s enough to know one universal formula.

Documents establishing requirements

More than 20 GOSTs have been installed on plastic windows, regulating the parameters, characteristics, properties of products, as well as manufacturing and installation processes.

To determine the permissible weight of the product, you will need to refer to the regulatory documents:

- GOST 30674-99. The interstate standard defines all parameters of window blocks made of PVC profiles.

- GOST R 56926. Describes all requirements for window and balcony structures.

- GOST 23166-99. The text is devoted to the general technical characteristics of window units.

- GOST 24866-99. This document contains technical specifications for double-glazed windows for construction purposes.

- GOST 30673-99. Text about technical conditions for polyvinyl chloride profiles.

Each of these documents contains the information necessary to calculate the correct weight of PVC windows.

How to calculate the weight of glass

To obtain the exact mass of a glass structure, you need to use a formula into which two values are substituted - the thickness and area of the glass.

In addition, you need to know one simple mathematical rule. It states that one square meter of glass sheet one millimeter thick has a weight of 2.5 kilograms.

This is a constant value that applies equally to mirrors.

The remaining calculations, depending on the characteristics of your product, will not be difficult.

If your canvas thickness is not one, but 4 mm, then the weight of its square meter will increase four times and will be equal to ten kg.

Double-glazed window design

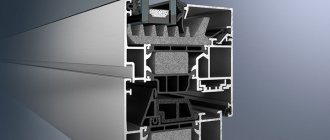

The glass profile can be plastic, aluminum or wood. In addition, the product consists of:

- glasses (their number varies - 2 or 3), forming chambers into which dry air or inert gas is pumped to ensure better heat and sound insulation;

- fittings - mechanisms responsible for opening/closing the entire window structure.

In addition, a double-glazed window cannot do without spacer frames that fix the position of the glass, as well as without a sealant that serves as a means for treating the seams. Thus, the mass of a double-glazed window is the sum of the masses of the glass used, fittings, spacers and sealing compound.

Formula for calculating the mass of glass

M = S x t x 2.5

Here you need to substitute the following indicators:

- The letter S denotes the area of the canvas in square meters. meters.

- t is replaced by the glass thickness in millimeters.

- 2.5 is the same mass coefficient of one square meter. meter of glass 1 millimeter thick.

Finally, M is the desired quantity, that is, the final mass of the glass product, calculated in kilograms. There is an online glass weight calculator that automatically provides the answer if you enter the appropriate data regarding the thickness, width and height of the glass sheet.

Non-standard double-glazed windows

The term “non-standard” refers to a light-transmitting product that differs from the most common one in several components, namely the thickness of the glass, the fittings used, etc. At the same time, non-standard double-glazed windows, with the same dimensions as conventional ones, usually weigh more. From the point of view of the weight of the glass unit, as a non-standard one, we will consider the soundproofing version of the product.

So, how much does a double-glazed window weigh? If we compare soundproofing with standard, then the weight load of the glass used (1 m2) for the first will be approximately 5 kg greater than for the second. This is due to the fact that the soundproof version has built-in glass with a thickness of 6 mm. Accordingly, the weight of 1 m2 of double glazing will have double (compared to standard) weight, equal to 10 kg.

Important! You can learn more about the benefits of soundproofing double-glazed windows here:

It is necessary to note an important point - with the additional weight of the structure itself, the pressure on the individual elements of the window increases, which affects the duration of its trouble-free operation.

For example, excessive weight of the structure affects:

- Accessories . To avoid the appearance of defects in the operation of fitting mechanisms, you should seriously consider selecting a high-quality and reliable model of fittings. The weight of the glass unit in this case plays a decisive role - the more cameras, the thicker the glass, the more reliable the fitting mechanism is required.

- Production of installation . Since the weight of a soundproof double-glazed window is significantly greater than the weight of a standard one, the work associated with installation is very specific and takes longer.

- Operation . It is no secret that with a heavy load on a double-glazed window, the period of trouble-free operation of the sash will be shorter than the period of operation of the sash with a standard load. This is due, first of all, to the distribution of greater load on the hinges and on the rubber seals.

- Price . The additional thickness of the glass, the need to install special fittings designed for operation under conditions of additional weight load - all this affects both the weight and the cost of the final structure. The price of a soundproofing double-glazed window can exceed the price of a budget solution by 1.5-2 times. At the same time, installing a heavy window will also entail additional financial costs.

This article provided data on the weight of each component of a modern double-glazed window. The weight load of a standard double-glazed window was also calculated, and the disadvantages of a non-standard design were given in terms of the influence of the weight load, both on individual window elements and on the ease of installation work.

Discussion: there is 1 comment

- Yana Berlinets:

12/11/2021 at 18:47Good afternoon. How much does a 3-chamber 1.5 by 2 double-glazed window cost: And is there power supply delivery to the regions? Need 3 windows

Answer

What does the glass factory “Omni Vitrum” offer?

If you were unable to independently calculate the weight of the glass, then simply write or call us at the phone number listed on the website in the “Contacts” section. Our specialists will not only help you find out the exact weight of your item, but will also tell you how best to transport and install it.

Within the walls of our production there is a professional production of glass and mirrors of all types and sizes. You can choose products from our catalog or implement a completely new interior design according to a separate project, which will be completed in a single copy.

Problems with the foundation when glazing terraces

Problems with the foundation due to the weight of windows most often arise when glazing terraces. Initially, a platform with a roof is attached to the house, but not on a common strip foundation with the house, but on a lighter one. A year later they decide to glaze it so that it doesn’t get covered with snow - and problems begin. The weight of the extension increases several times, and the foundation is not designed for such a load. The foundation begins to settle, followed by distortions in the windows and doors.

It is not possible to correct the deformation of windows by adjusting them. When deciding to glaze your terrace, make sure that the foundation will support it.

The influence of weight on the delivery, unloading and installation of windows

With heavy structures, additional problems arise - they have to be unloaded, lifted and moved around the site and the house.

A standard window weighs about 100 – 130 kg. Specially trained people - loaders - will remove it from the car and bring it to the apartment.

Photo: a panoramic door leaf can weigh 400 kg, © rotoAnd what to do with panoramic structures? For example, with lift-and-slide doors, in which one leaf can weigh 400 kg? You can't carry it in your arms.

When ordering panoramic glazing, discuss the details of delivery and installation with the window company:

- You need a machine with a manipulator, or you will have to call a crane.

- To move double-glazed windows around the territory you will need a special lift.

- The use of special equipment greatly increases the cost of work.

Select Roto fittings for windows of different weights* |

Light transmittance values

| Type of light-transmitting material | values of τ1 | Type of binding | values of τ2 | Load-bearing structures of coatings | τ3 values |

| Window sheet glass: | Bindings in industrial buildings: | Steel trusses, reinforced concrete and wooden trusses and arches | 0,9 | ||

| single | 0,9 | wooden: | Solid beams and frames with section height: | ||

| double | 0,8 | single | 0,75 | 50 cm or more | 0,8 |

| triple | 0,75 | paired | 0,7 | less than 50 cm | 0,9 |

| Display glass 6-8 mm | 0,8 | double separate | 0,6 | ||

| Reinforced sheet glass | 0,6 | steel: | |||

| Patterned sheet glass | 0,65 | single opening | 0,75 | ||

| Sheet glass with special properties: | single deaf | 0,9 | |||

| sun protection | 0,65 | double opening | 0,6 | ||

| contrasting | 0,75 | double deaf | 0,8 | ||

| Organic glass: | Bindings in residential, public and auxiliary buildings: | ||||

| transparent | 0,9 | wooden: | |||

| dairy | 0,6 | single | 0,8 | ||

| Hollow glass blocks: | paired | 0,75 | |||

| light-scattering | 0,5 | double separate with 3rd glazing | 0,5 | ||

| translucent | 0,55 | metal: | |||

| Double-glazed windows | 0,8 | single | 0,9 | ||

| paired | 0,85 | ||||

| double separate with 3rd glazing | 0,8 | ||||

| Glass-reinforced concrete panels with hollow glass blocks with seam thickness, mm | |||||

| ≤20 | 0,9 | ||||

| >20 | 0,85 |

Thermophysical properties of earthenware

The table shows the thermophysical properties of earthenware at room temperature. The properties of faience are given for the following types: clay, lime faience, feldspathic faience: household, sanitary.

The table shows the following properties of earthenware:

- density of earthenware, kg/m3;

- porosity, %;

- coefficient of thermal expansion (CTE), 1/deg;

- compressive strength, kg/cm2;

- bending strength, kg/cm2;

- thermal conductivity of earthenware, W/(m deg).

Sources:

- Physical quantities. Directory. A. P. Babichev, N. A. Babushkina, A. M. Bratkovsky and others. Ed. I. S. Grigorieva, E. Z. Meilikhova. - M.: Energoatomizdat, 1991. - 1232 p.

- Glass: Directory. Ed. N. M. Pavlushkina. M.: Stroyizdat, 1973.

- Chirkin V.S. Thermophysical properties of nuclear technology materials.

- Sentyurin G. G., Pavlushkin N. M. et al. Workshop on glass and ceramic glass technology - 2nd ed. reworked and additional M.: Stroyizdat, 1970.

- GOST 13569-78 Colorless optical glass Physico-chemical characteristics. Main settings

What does it depend on?

The density of window glass used for the manufacture of translucent structures in civil buildings depends on three basic criteria , which are taken into account by manufacturers:

- The volumetric weight of each individual component of glass - silicon, calcium oxide, sodium oxide, lead, cobalt, magnesium, lead, potassium and other chemical elements.

- The percentage of the above elements in the translucent structure, which are mixed in certain proportions.

- Glass manufacturing technology, as well as its processing after molding in a heated form.

As a rule, each type of glass has its own chemical formula, which determines the amount of a particular component included in its composition. Thus, using a correctly composed chemical formula, you can initially find out the density of the finished structure after its manufacture.