Do you need help preparing Plafen windows and doors for winter in St. Petersburg (St. Petersburg) and the Leningrad Region?

Call! +7(812)904-30-42 — We’ll help!

We guarantee a prompt approach, high quality work and affordable prices!

While enjoying our new windows, we often don’t think about the fact that Plafen windows also need care and preparation for winter. Yes, of course, much less care than for wooden ones, but still needed. The design of Plafen windows requires regular (once every six months) cleaning of accumulated dirt, lubricating and adjusting the fittings. The question of preparing Plafen windows for winter arises with the onset of cold weather, but a prudent owner will think about how to adjust Plafen windows for the winter much earlier. After all, prepare the sleigh in the summer and the cart in the winter. Proper preparation of Plafen windows for winter is not a difficult matter, but it is very important and you can most likely handle it yourself. And if you prefer that we do it, we will be happy to help you! Just call and the specialist will prepare your Plafen windows for winter professionally.

So how to properly prepare Plafen windows for winter yourself?

First, think about what bothered you last winter? How are things going with Plafen windows now? Do they open well? Were there any puddles on the windowsill during heavy rain? How does the window handle turn? With or without effort? As expected, does the handle go all the way down? Or not? As they say: cleanliness is the key to health! In our case, regular removal of accumulated dirt and lubrication, plus timely adjustment (adjustment) of windows, significantly increases the service life of the Plafen window mechanisms. The question arises: how to properly wash a Plafen window so that it does not get damaged? You can safely wash the Plafen window with ordinary soapy water and a soft sponge. We soap the glass (glass unit), the Plafen window profile (plafen), the slopes, the window sill, and then wipe it dry with a soft cloth. Check the drainage channels (they are at the bottom of the window frame), maybe they need to be cleaned? It is also important to know how to adjust Plafen windows, but more on that below.

Checking the tightness of the Plafen window (how to check where it is blowing from the Plafen window?)

If in summer the problem of ventilation of Plafen windows (plafen) worries us little, then in winter we don’t want to freeze at home. So, three ways to detect if a Plafen window is blowing. We check the windows for blowing, look for where the wind is blowing from the Plafen window.

The first way to check the tightness of a Plafen window : using a sheet of paper, half an A4 is quite enough. We open the window sash slightly and expose half of the sheet to the street, close the sash, and lower the handle all the way down. Important! The sheet of paper should not fall on the locks that are installed on the window frame, otherwise it will simply be bitten and the experiment will be carried out incorrectly. We pull out the sheet. Three options: the sheet flies out with a whistle, the sheet comes out with difficulty, it feels like the sheet is about to tear. Important! Thus, the entire perimeter of the window sash is checked. If in most places of such a check the sheet comes out freely (flies out with a whistle), the seal needs to be replaced. If the sheet comes out with difficulty in most places of inspection, the problem of window tightness can be solved by adjusting and lubricating the window. If the sheet is about to tear in most places of inspection, you do not need to do anything with the Plafen window. There will be no blowing from this Plafen window!

The second way to check the tightness of a Plafen window : using a soap solution. Do you remember how you were looking for a hole in a bicycle tube?))) We make a soap solution. Apply Plafen around the perimeter of the window. Where the bubbles appear is where it blows.

The third way to check the tightness of a Plafen window : using a candle flame. Carefully move a burning candle around the perimeter of the window. Where the flame fluctuates, that’s where it blows from the Plafen window.

Production of PVC profile Plafen

The first stage is preparing the PVC mixture. The mixture is produced on automated equipment from strictly balanced European components and processed at a temperature of 185-200 °C. Each batch of blending powder is tested for flowability, moisture content and functionality. Samples of the finished mixture are examined and tested daily in the laboratory.

The second stage is the actual production of the PVC profile. Initially it is formed by passing through dry and wet gauges, where it reaches the desired geometric shapes and is sent for automatic stretching, after which it is evenly cut. Afterwards, a special film is applied to the profile, which protects against dust and dirt. Thanks to this film, Plafen profiles are distinguished by their whiteness and gloss.

The finished profile is sent for control, where it is checked for resistance to impact and deformation at high and low temperatures. The finished sample is also tested for deviations along the planes and the strength of welding joints; if a deviation is found, the defect is sent for processing.

Cleaning dirt and lubricating Plafen window fittings

Start insulating your windows for the winter by inspecting the Plafen window fittings. Remove dirt, especially from the top of the window sash. All folds must be cleaned of deposits and dirt, especially cement and plaster residues. Direct exposure of the fittings to moisture and contact with cleaning agents should be avoided. Then lubricate the window fittings with Plafen. Lubrication points for the Plafen window are marked with special markings. How to lubricate a Plafen window? The most common ones are WD-40, machine oil, grease. Do not under any circumstances lubricate with sunflower oil or olive oil or anything else! Edible oils dry quickly into a sticky substance that will break the Plafen window mechanism. After this, rotate the fittings in different modes several times to distribute the lubricant. Wipe off excess oil from the Plafen window.

Methods for adjusting the pressure of the Plafen window sash (plafen) to the frame

There are many manufacturers of window fittings, and each of them has its own way of adjusting the pressure of the window sash, but there are also some general principles on how to tighten Plafen windows. Open the window sash. At the end of the sash, find the eccentric pins. Most often they can be adjusted using a hex or star wrench. Usually, there is a mark on the trunnion - a small strip. By default, it is set up - neutral position. By turning the trunnions to the left or right, you can strengthen or weaken the pressure of the window sash to the frame, i.e. change the winter-summer mode yourself.

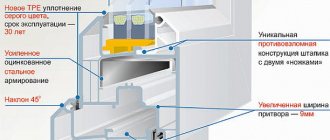

Plafen profile systems

Specialists from the Austrian company Greiner helped develop the design of profile systems, making Plafen windows look modern and elegant. Employees from Europe also took part in the preparation of the PVC mixture. Its balanced composition allows Plafen windows to be used in conditions of prolonged frost for at least 40 years. The best equipment from German and Austrian companies is used for profile extrusion. Thanks to a set of measures, the durability of A-class systems, subject to operating rules, can reach 60 years.

The peculiarity of Plafen systems is that they are all compatible with anti-burglary fittings. This allows, at the customer’s request, to increase the safety class of all windows – economy, standard and premium class models. Profiles can be reinforced with closed or open steel liners, thanks to which buyers independently determine the level of rigidity and weight of the finished structures. Other advantages of the systems include the following:

- reliable fastening of hinges;

- service life 40-60 years (depending on the class of the system);

- Possibility of completing with extended seal;

- high strength of welded joints;

- reliable installation of double-glazed windows.

Plafen is a profile that, regardless of the series, can be laminated on one or both sides. To perform such a complex procedure, Kleiberit adhesive composition and decorative films LG and Hornschuch are used. These components are manufactured in Germany and South Korea. The warehouse program includes the 5 most popular decors - “Mahogany”, “Dark Oak”, “Golden Walnut”, “Gray Brown Oak”, “Golden Oak”. In total, manufacturers have more than 25 colors at their disposal. However, when choosing other decors, window production times increase.

Adjusting the Plafen window sash vertically and horizontally

A shift in the window sash or a slight bevel can be removed by horizontal adjustment. The position of the window sash is adjusted using the upper and lower fastening loops. This can usually be done using a hex wrench. The adjusting screw in the bottom hinge allows you to adjust the window sash from the outside and inside. If you turn the key to the right, the Plafen window sash rises. If you turn it to the left, the angle of the window sash lowers. Also, the top hinge is adjusted when the window sash is open. You need to move the window sash back and forth no more than 2 mm. If the Plafen window does not close tightly from the bottom, then you need to adjust the bottom hinge. If you need to press or move the window sash towards (away from) the lower hinge, then adjust the position of the sash when the Plafen window is open. There is a second adjustment screw on the bottom hinge to lower and raise the sash vertically. If you turn it clockwise, the Plafen window sash will rise. If it's counterclockwise, it will go down.

PVC profile Plafen T-line

The Plafen T-line window profile is a five-chamber PVC profile with a thickness of 70 mm.

Properties:

- Installation width - 70 mm.

- The maximum thickness of the glass unit is 40 mm.

- Number of cameras - 5.

- Heat transfer resistance coefficient, m2°C/W - 0.849 (without steel amplifier) and 0.815 (with steel amplifier)

- Tightness of sealing contours - corresponds to class A

- Number of sealing circuits – 2

- Seal color: gray and black

- Two reinforcement options - closed and open

- The axial size of the fitting groove is 13 mm

- Service life - 60 years

Advantages . At the request of the customer, it is possible to install anti-burglary fittings. The overlap of the sash with additional stiffening elements guarantees the reliability of the hinge on the sash. Increased seating depth of the glass unit.

Design . Classic design of a plastic window.

Sealant for windows Plafen (plafen)

The most popular window seals: Rehau, KBE, Shlegel Q-Lon

In most window designs, two perimeter seals are installed. The first sealing circuit is installed on the window frame - the frame seal. The second contour of the seal is placed on the window sash - the narthex seal. Premium windows have three perimeter seals.

What kind of sealant for Plafen windows is there?

Tips on how to choose a seal for windows Plafen (plafen)

Open the Plafen window. Use a damp cloth to clean the seal from visible dirt. Examine it carefully. On all contours, the seal must be elastic, without visible cracks or tears, and lie flat in the groove without any bumps. Pay attention to the corners. If everything is in order, then lubricate it with silicone grease. If not, then the Plafen window seal needs to be replaced. Otherwise, in winter it will blow from this Plafen window.

PVC profile Plafen C-line

Window profile Plafen C-line is a three-chamber PVC profile 58 mm thick with a classic design.

Properties:

- Installation width - 58 mm.

- The maximum glass thickness is 32 mm.

- Number of cameras - 5.

- Heat transfer resistance coefficient, m2°C/W - 0.727 (without steel amplifier) and 0.640 (with steel amplifier)

- Tightness of sealing contours - corresponds to class A

- Number of sealing circuits – 2

- Seal color: gray and black

- Two reinforcement options - closed and open

- The axial size of the fitting groove is 13 mm

- Service life - 60 years

Advantages . At the request of the customer, it is possible to install anti-burglary fittings. It is possible to manufacture with extended welded seals. The overlap of the sash with additional stiffening elements guarantees the reliability of the hinge on the sash.

Design . The classic design of a plastic window with an increased light opening, due to this, windows from the C-line profile perfectly transmit light.

Sealing the seams of a Plafen window with thermal insulation materials

In case of improper installation, sealing the seams with thermal insulation materials may be the only solution. Sealing installation seams and joints with special heat-insulating materials is one of the most effective ways to insulate Plafen windows.

How can I seal the street seams of a Plafen window?

- polyurethane foam, which must be plastered or covered with strips

- mineral wool, which must be covered with strips

- polystyrene foam, which must be covered with strips

— liquid rubber (STIZ)

How can I seal the internal joining seams of a Plafen window?

- silicone sealant

- acrylic sealant

— cosmofen (liquid plastic)

The described problems with Plafen windows (plafen) can appear due to poor-quality installation of a metal-plastic structure or during a long service life - longer than 10 years. During installation, installers had to familiarize themselves with the design properties of Plafen windows (plafen) and teach owners how to use Plafen windows (plafen).

The end of summer, the beginning of autumn is the time to prepare Plafen windows for winter. If you take care of insulating Plafen windows in advance, you will definitely not freeze at home in winter!

PVC profile Plafen L-line

Plastic windows Plafen L-line

(Light) is intended for the mass consumer and is positioned as an “economy class” system. It is based on the well-proven four-chamber E-line series. Preserving the external contours and geometry of this system, the L-line frame and sash are designed in a three-chamber version. To reinforce the frame and sash, a single reinforcing liner is used, unified with the E-line system. In addition, the possibility of using reinforced reinforcement allows you to create large windows, while providing high resistance to wind loads. The reduced heat transfer resistance of the main profiles of the L-line system with a galvanized steel reinforcing liner 1.5 mm thick is 0.64 m2 °C/W, and without a reinforcing liner 0.73 m2 °C/W.

Profile systems for plastic windows Plafen L-line and E-line are fully compatible in terms of main and auxiliary profiles, which simplifies and speeds up the production process. Energy efficiency with maximum cost-effectiveness is the basis for the design of this system. All PLAFEN PVC profile systems were developed by professionals who have extensive experience in the production of plastic windows, which could not but affect the design and technical properties of the profile systems. This rich experience has made it possible to create unique profiles that are free of virtually all the shortcomings that create difficulties in the production of translucent structures.

The L-line profile system has visually soft shapes that give a more attractive appearance, emphasize the individuality of the owner, and are suitable for any interior. The manufacturer positions this type of profile as “ergonomic and modern design at an affordable price.” 60-year warranty, possibility of installing anti-burglary fittings. The profiles of this line have a glossy surface that does not change shade under the influence of ultraviolet rays and precipitation, and are environmentally friendly. They have a double-chamber double-glazed window - 32 mm with a frame and sash thickness of 60 mm, this ensures high levels of heat saving and sound insulation.

Characteristics of PLAFEN L-LINE windows

- Number of cameras – 3

- Width – 60 mm

- Number of sealing circuits – 2 (color: gray and black)

- Heat saving - 0.730 m2°C/W

- Design: modern

- Frame height: outside – 66 mm, inside – 46 mm

- Frame height with sash - 115 mm

- Service life - 60 years

- Double-glazed window: Thickness - 24, 32 mm, glass - 5 mm

- The reduced heat transfer resistance of plastic profiles without a reinforcing liner is 0.730 m2°C/W, with a reinforcing liner - 0.645 m2°C/W.

- A single reinforcing profile for sashes and frames significantly speeds up the production of windows.

- There are two options for reinforcement - closed and open.

- Universal fastening of the impost to the frame and sash is used. The design of the fastener allows for cross connections.

- The system includes a door group of internal, external and double-leaf opening, as well as an aluminum threshold.

- The ability to install reinforced metal profiles in the sash and frame provides higher resistance to wind loads, allowing you to assemble large windows.

- Production with extended welded seals is possible.

- The overlap of the sash with additional stiffening elements guarantees the reliability of the hinge on the sash.

- In terms of the thickness of the front walls, it belongs to class “B”.

- The axial size of the fitting groove of 13 mm allows the use of anti-burglary fittings, significantly reducing the risk of burglary.

Frequently asked questions about preparing Plafen windows for winter

We have collected here the most popular questions about preparing Plafen windows for winter; we recommend that you read the answers.

Question No. 1

Preparing Plafen windows for winter

How to prepare Plafen windows for winter?

Answer:

Preparing Plafen windows for winter consists of: cleaning plastic windows from dirt, lubricating plastic window fittings and seals, adjusting plastic windows, switching plastic windows to winter mode (adjusting the Plafen window sash pressure), replacing the Plafen window seal ( plafen), if necessary. Call and get a Plafen window repair specialist in St. Petersburg (St. Petersburg) and the Leningrad Region and he will prepare your Plafen windows for winter.

Question No. 2

Adjusting Plafen windows for winter

Do Plafen windows need to be adjusted for winter?

Answer:

Hardware manufacturers recommend adjusting Plafen windows twice a year.

Question #3

Adjusting windows Plafen (plafen) winter-summer

Is it necessary to install a winter-summer mode on Plafen windows?

Answer:

A normally adjusted plastic window does not need to be switched from winter to summer. There is no winter-summer mode, this is a marketing ploy. The winter-summer mode means pressing the window sash to the frame. A stronger pressure is “winter mode”, a weaker pressure is “summer mode”.

Question #4

How much does it cost to prepare Plafen windows for winter in St. Petersburg (St. Petersburg) and the Leningrad Region?

The cost of preparing Plafen windows for winter?

Answer:

The cost of preparing Plafen windows (plafen) for winter (adjustment and lubrication) of a window sash is 600 rubles per sash.

Question #5

Do you provide a guarantee for work on preparing Plafen windows for winter in St. Petersburg (St. Petersburg)?

What is your guarantee for the work on preparing Plafen windows for winter?

Answer:

Yes, we guarantee our work. Work on preparing Plafen windows for winter is guaranteed for one year.

PVC profile Plafen S-line

Plastic windows Plafen S-line

(Superior) is the most advanced system to date, extruded on the latest production line. Initially, the designers were tasked with developing an elite-class profile system, which in terms of its indicators, including aesthetic ones, would become the undisputed leader. Now we can say with confidence that it was a success. Testing of profiles and sales experience show that they can be successfully used throughout Russia - from the Far North to the southernmost point.

The frame is a five-chamber profile with a width of 75 mm, the sash with a width of 86 mm is made in a single-plane design with a frame. The system has the ability to install an internal sealing loop and, due to its characteristics, is recommended for use in the most severe climatic zones with low temperatures and high wind loads. During the development of the system, such successful technical and technological solutions were found that the system received three patents from the Russian Federation for individual elements and connections of the window unit, one of which is a guarantor of the uniqueness of the entire S-line profile system.

Based on the results of 2004, the editors of the Windows and Doors magazine, taking into account the opinions of industry experts and readers, recognized the five-chamber PLAFEN S-line profile system as the winner in the “Best Engineering Development” category. The special configuration of the bead leg greatly simplifies its installation and removal, while at the same time ensuring reliable installation of the glass unit. The co-extruded seal on the bead significantly speeds up the assembly of the window unit. A third sealing circuit with an additional internal chamber shifts the isotherm so that heat loss through the metal is significantly reduced.

The increased depth of the glass unit (29 mm) allows you to install a glass unit with a recess in the profile of 23 mm, as opposed to the traditional 14 mm, which reduces the likelihood of ice formation on the edge of the internal glass and glazing bead. The profiles of the S-line system have the highest reduced heat transfer resistance of 0.87 m2 °C/W, and with a galvanized steel reinforcing liner 1.5 mm thick - 0.84 m2 °C/W.

Minimum heat loss is achieved through the use of a third seal circuit. It should be noted that none of the systems operating in Russia have such indicators.

Profiles for window and door units of the S-line system in terms of thermal protection level (according to GOST 30673-99) belong to class 1 products. The design of S-line profiles is designed for the use of double-glazed windows with a maximum width of 40 mm. In regions with harsh climatic conditions, technical experts recommend using double-glazed windows with low-emissivity glass and filled with inert gas. A universal reinforcing profile that strengthens the frame and sash allows you to optimize the range and volume of warehouse stocks, as well as simplify the processor’s production process.

The solution of the third sealing circuit is unique, which is made in the form of a special removable profile with an additional internal chamber. This design feature of the S-line system significantly expands the technical capabilities of the processor and makes it possible to produce structures with both double-circuit and triple-circuit seals without spending additional money and effort.

The axial size of the fitting groove is 13 mm, which increases the protection of translucent structures from burglary and allows the use of standard anti-burglary fittings. For convenient and quick fastening of double-glazed windows, special wedge corners have been developed, making it possible to adjust the depth of the double-glazed window in a wide range. Developed with the participation of leading European specialists, the S-line profile system completely changes the concept of Russian profiles and surpasses many foreign analogues in its mechanical and thermophysical characteristics. The S-line system is today one of the most successful design and technological solutions in the field of PVC profile systems, the experience of using it in Russian conditions confirms that this system has excellent prospects in the market, since its use opens up unlimited possibilities for processors.

Characteristics of PLAFEN S-LINE windows

- Number of cameras – 5;

- Width – 75 mm;

- Number of sealing contours – 3 (color: gray and black);

- Heat saving - 0.869 m2°C/W;

- Design: modern;

- Frame height: outside – 73 mm, inside – 44 mm;

- The height of the frame with the sash is 122 mm;

- The thickness of the front walls belongs to class “A”;

- The reduced heat transfer resistance of plastic profiles without a reinforcing liner is 0.869 m2°C/W, with a reinforcement liner - 0.841 m2°C/W;

- A single reinforcing profile for sashes and frames significantly speeds up the production of windows;

- Two reinforcement options - closed and open;

- Production with extended welded seals is possible;

- The overlap of the sash with additional rigidity elements guarantees the reliability of the hinge on the sash;

- The axial size of the fitting groove of 13 mm allows the use of anti-burglary fittings, significantly reducing the risk of burglary.

Prices for preparing Plafen windows for winter and other types of window repair work

Make your own calculation of the cost of repair and maintenance of windows and doors

| collapseexpand | ||

| Window/door adjustment | ||

| Adjusting the Plafen window sash (plafen) | 400 rub. | sash |

| Adjusting the plastic balcony door | 600 rub. | door |

| Adjusting the window sash on the loggia (facade glazing) | 400 rub. | sash |

| Adjusting the sash of a wooden window with double glazing | 400 rub. | sash |

| Adjusting the plastic entrance door | 1000 rub. | door |

| Adjusting the plastic entrance door closer | 700 rub. | PC |

| Alignment of window sash geometry (repacking) | 700 rub. | sash |

| Aligning the geometry of the balcony door (repacking) | 900 rub. | door |

| Window/door repair | ||

| Repair of Plafen window sash (plafen) (hardware overhaul) | 1000 rub. | sash |

| Repair of a plastic balcony door (reassembly of fittings) | 1200 rub. | door |

| Repair of façade glazing window sash (refurbishment of fittings) | 1200 rub. | sash |

| Repair of a wooden window sash with double glazed windows (rebuilding fittings) | 1000 rub. | sash |

| Repair of a plastic entrance door (bulkhead fittings) | 1500 rub. | door |

| Replacing window/door seals | ||

| Replacing Plafen window/door seals | from 100 rub. | p.m. |

| Replacing the seal of a wooden window with double glazing | from 200 rub. | p.m. |

| Replacing the façade glazing window seal | from 200 rub. | p.m. |

| Replacing the seal of plastic entrance doors | 150 rub. | p.m. |

| Replacement of window/door fittings | ||

| Replacing the handle of a Plafen window/balcony door | 300 rub. | pen+work |

| Replacing the top hinge of a Plafen window (plafen) | from 1000 rub. | hinge + work (pivot window sash) |

| Replacing the bottom hinge of a Plafen window (plafen) | from 1000 rub. | loop+work |

| Replacing Plafen window scissors (plafen) | from 2000 rub. | scissors+work (tilt-and-turn sash) |

| Replacing the main lock (drive, gearbox) of a window | from 2500 rub. | drive+work |

| Replacing the top hinge of a plastic balcony door | from 1300 rub. | hinge+operation (pivot balcony door) |

| Replacing the bottom hinge of a plastic balcony door | from 1300 rub. | loop+work |

| Replacing the scissors of a plastic balcony door | from 2300 rub. | scissors + work (tilt-and-turn balcony door) |

| Replacing the main lock (drive, gearbox) of a plastic balcony door | from 3000 rub. | drive+work |

| Installation of clamps | from 450 rub. | PC |

| Installation of lock strike plates | from 300 rub. | PC |

| Replacing the hinge of a plastic entrance door | from 2300 rub. | PC |

| Sealing window/door seams | ||

| Sealing the internal seam of windows/doors | from 200 rub. | p.m. |

| Sealing the external seam of windows/doors | from 250 rub. | p.m. |

| Window/door service | ||

| Converting winter/summer mode | 100 rub. | leaf/door |

| Plafen window sash service | 600 rub. | sash |

| Maintenance of plastic balcony doors | 800 rub. | door |

| Maintenance of wooden window sash with double glazing | 600 rub. | sash |

| Service maintenance of façade glazing window sash | 600 rub. | sash |

| Maintenance of a wooden door with double glazed windows | 800 rub. | door |

| Servicing of a plastic entrance door | 1200 rub. | door |

| Cleaning and lubrication of fittings | 200 rub. | leaf/door |

| Window/door opening limiters | ||

| Installing a comb on a window/door | 300 rub. | comb+work |

| Installing a comb on a façade window | 600 rub. | comb+work |

| Installing a handle with a key on a window/door | from 700 rub. | pen+work |

| Installing a child lock on a window | from 900 rub. | lock+work |

| Installing an opening limiter with a cable | 1300 rub. | lock+work |

| Installing a latch on a balcony door “smoker’s kit” | 900 rub. | latch+work |

| Installation of the petal handle | from 100 rub. | pen+work |

| Installing a double-sided handle on a balcony door | 2000 rub. | pen+work |

| Finishing of Plafen windows/doors | ||

| Reinstallation of drainage system with foaming | from 500 rub. | PC |

| Installation of drainage systems | from 1000 rub. | Job |

| Installation of window sills | from 1000 rub. | Job |

| Installation of slopes | from 300 rub. | m.p. |

| Replacement of glass unit | ||

| Replacing a single-chamber double-glazed window | 2000 rub. | sq.m. |

| Replacing double-glazed windows | 2500 rub. | sq.m. |

PVC profile Plafen E-line

Plastic windows Plafen E-line

(Elegance), like the S-Line, were developed jointly by specialists and Greiner. The system fully meets the expectations of customers who want to see the most advanced technologies in their home. positions E-line as an “interior” system, the soft, elegant forms of which are perfectly combined with any style of decoration.

In terms of technical characteristics, the system is ahead of many similar systems present on the Russian market. The main goal in its development was to achieve high strength and thermophysical characteristics and at the same time relatively low cost. The difficulty of the task was that when installing a reinforcing profile of a small cross-section, it is quite difficult to provide the required safety margin, while an increase in the cross-sectional area can lead to a decrease in the thermophysical parameters of the system. The developers of the E-line system have proposed an optimal solution in the form of a four-chamber system with the possibility of installing a reinforced reinforcing profile (with a structural thickness of 60 mm). At the same time, the main profiles of the system, which have four chambers, significantly exceed standard requirements for thermal insulation. The reduced heat transfer resistance of the main profiles of the E-line system with a galvanized steel reinforcing liner 1.5 mm thick is 0.71 m2 °C/W, and without a reinforcing liner 0.78 m2 °C/W.

Profiles for window and door units of the E-line system in terms of thermal protection level (according to GOST 30673-99) belong to class 2 products. The profile design is designed for the installation of glass, single-chamber double-glazed windows with a width of 24 mm and double-chamber double-glazed windows with a maximum width of 32 mm. The axial size of the fitting groove is 13 mm, as in all PLAFEN profile systems. The reinforcing inserts in the frame and sash are identical. This engineering solution simplifies the production process and reduces the processor's warehouse inventory. The E-line system uses universal fasteners for the impost in the frame and sash, which makes it possible to make cross connections. The form of fastening of the bead in the E-line system is the same as in the S-line system. For convenient and quick fastening of double-glazed windows, wedge linings have been developed, consisting of three elements (angle and wedges) and allowing the installation of double-glazed windows without additional components.

The S-line and E-line systems are complementary and, thanks to the use of universal auxiliary profiles, can be used in one design.

Characteristics of PLAFEN E-LINE windows

- With a profile thickness of 60 mm, the four-chamber system provides thermal insulation that significantly exceeds standard requirements.

- The 13-mm fitting groove allows the windows to be equipped with additional anti-burglary systems.

- The sash and frame are reinforced with a single metal profile, which simplifies and speeds up the production process.

- Number of cameras – 4

- Width – 60 mm

- Number of sealing circuits – 2 (color: gray and black)

- Heat saving - 0.782 m2°C/W

- Frame height: outside – 66 mm, inside – 46 mm

- Frame height with sash - 115 mm

- The thickness of the front walls belongs to class “A”

- Double-glazed window: Thickness - 24, 32 mm, glass - 5 mm

- The reduced heat transfer resistance of plastic profiles without a reinforcing liner is 0.782 m2°C/W, with a reinforcing liner - 0.738 m2°C/W.

- A single reinforcing profile for sashes and frames significantly speeds up the production of windows.

- There are two options for reinforcement - closed and open.

- Universal fastening of the impost to the frame and sash is used. The design of the fastener allows for cross connections.

- The frame is increased to 46 mm, thanks to which the sash opens wider than a standard window.

- The system includes a door group of internal, external and double-leaf opening, as well as an aluminum threshold.

- The ability to install reinforced metal profiles in the sash and frame provides higher resistance to wind loads, allowing you to assemble large windows.

- Production with extended welded seals is possible.

- The overlap of the sash with additional stiffening elements guarantees the reliability of the hinge on the sash.