In order to correctly select the desired element and install it correctly, you need to familiarize yourself with the basic requirements for its characteristics.

What is the purpose, technical requirements and characteristics, as well as how to correctly install this part - read on.

Definition

A plastic window consists of many elements, each of which performs a specific function.

Low tide is a very important link that ensures the reliability and longevity of the window structure. It prevents rain moisture from penetrating the window frame or wall of the house.

The part completely covers the lower slope and prevents it from getting wet. To ensure the drainage of water and snow, it is attached obliquely with a slight protrusion beyond the façade. It is made from a profile and installed on the outside of the building at the bottom of the window. It must have a bend that fully matches the design of the window.

Important! Mismatch of parameters leads to incorrect fastening of the element.

The product is equipped with bottom and side bends that ensure rapid drainage of water.

What are they for?

The main function of the element is to protect the structure from precipitation. Moisture is diverted to the side with the help of low tide and drained to the ground. The second meaning of the product is to give the window a finished and harmonious look. It can safely be considered a decorative element if you choose the right material and appearance of the part.

In addition to the walls, the flashing also protects the seams and foam from exposure to sunlight. This prevents premature destruction of the window structure and facade.

If you neglect the installation of the product, then:

- moisture will begin to collect on the windowsill;

- finishing materials will be destroyed;

- the plaster will fall off;

- window frames will become unusable.

Despite this, many owners of PVC windows complain about noise from raindrops at low tide. The question arises: is it possible not to install the product? You can refuse to install a low tide in one case - when the window is mounted flush with the facade without recessing into the wall. Then water does not accumulate on the windowsill, and the protective function is taken over by the canopy above the window.

How to correctly cut the ebb on the plinth Finishing the plinth with facade panels on screw piles

Oynatyshty baskar elementerin corset

Slot machines

- Zhariyaland 2022 5 There.

- How to correctly cut the ebb on the base of the foundation of the facade of a house from screw piles Naro-Fominsk If you want to help the development of our channel, then recommend our videos to your friends who are building a house or want to build one. You can say thank you here: www.donationalerts.ru/r/fasadmontaj #denismontaj #fasadmontaj #siding #house facade #facade panels #fiber cement siding ___ Denchick Life is my second channel kzclip.com/channel/UCUeQYR7_jyt6sew00RlK_7w DOWNLOAD Zello WALKIE TO YOUR PHONE Chat with me live zello .com/denismontaj Contact me !All information is in the VKontakte group VKontakte siding_by My channel goo.gl/4jMyRo I'm in Telegram t.me/FasadMontaj VKontakte group siding_by I'm in Instagram fasadmontaj I'm in Odnoklassniki ok.ru/saydingmo __My affiliate program connect Yoola youpartnerwsp .com/join?110724

Requirements

The product is manufactured taking into account the requirements that need to be studied before ordering:

Calculation of the width of the ebb is carried out depending on the width of the opening.

This is a dependent quantity. Then you need to add 3-4 cm (protrusion) + a slight slope. As a result, the minimum width of the part should not be less than 90 cm.- The length is calculated based on the distance between the outer side edges of the window opening. To the resulting measurement you need to add 4 cm on each side. In its finished form, the length of the ebb should not be 7-8 cm greater than the original measurement.

- The appearance and parameters of the window sill differ for windows in a frame, panel or brick house. The configuration of the part must correspond to them.

- The optimal color of the shimmer is the same as the color of the frame or a shade darker.

Technical requirements include:

- increased resistance to corrosion;

- resistance to negative natural factors - precipitation, temperature changes, solar activity;

It is necessary that the selected ebb tide option for a plastic window meets all the listed requirements.

What types are there for PVC structures?

The main difference between the products is the variety of materials from which they are made. With proper installation and high-quality production, all types of sills can serve for a long time. But, at the same time, each material has its own characteristics.

Cink Steel

This is a material with a whole list of advantages. Manufacturers offer ebb tides of different widths and shapes.

Advantages of the material:

- high corrosion resistance;

- resistance to mechanical damage;

- it is easy to cut and bend, which makes it possible to make a molding for a plastic window yourself;

- ease of care;

- The material can be qualitatively painted in any color.

Minuses:

- the initial shine of steel quickly fades;

- the geometry of the ebb when manufactured independently is much worse than that of a factory one;

- in urban conditions, the service life of the protective zinc layer is much lower - rust appears;

- The noise from raindrops is very loud.

Advice. To reduce the noise effect, it is necessary to use vibration-absorbing materials or carefully fasten the flashing.

Polyester

This is also galvanized steel, only coated with synthetic enamel. The base of the coating is polyester. The coating can be of any shade.

Advantages of the material:

- polyester resists aggressive weather conditions better than galvanized steel;

- the presence of a vibration-absorbing layer on the back side of the ebb.

Minuses:

- low mechanical strength - requires careful installation;

- the material is more expensive.

Note! If there is a protective polyethylene film on the front surface of the part, it is removed immediately after installing the product.

Aluminum

Modern flashings are often made of aluminum.

Pros:

- excellent rigidity;

- durability;

- not afraid of acid rain.

Minuses:

- price;

- impossible to bend without special equipment;

- complex painting technology, limited color range.

Reference. To increase the length of the part, special connecting elements and end caps are required.

Plastic

This material is best combined with plastic windows.

Pros:

- durability;

- weather resistance;

- good noise-absorbing properties;

- versatility - possibility of installation at the bottom of the window and at the top;

- ease of installation.

Minuses:

- high coefficient of thermal expansion;

- price.

Plastic moldings are the “quiest” products for plastic windows. Currently, you can find ebbs made of natural or artificial stone.

Important! It is not recommended to install such products yourself.

Correct installation

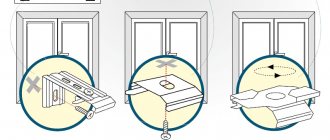

Now let's talk about installation in more detail. This process is not difficult. must be followed:

- The drip sill is supplied with a plastic window to the installation site.

- A waterproofing tape is installed under the product.

- At the junction with the frame, the gap is sealed with polyurethane foam.

- The product is fastened to the stand profile using self-tapping screws. If the building is built of brick, a support profile is not needed, and fastening is carried out to the lower quarter of the opening with screws.

- The area where the ebb comes into contact with the wall is sealed with cement mortar or sealant solution.

- Fixation from below is carried out with polyurethane foam, and it is important to remember its property of secondary expansion, due to which the ebb can rise and lose its slope. Before the foam hardens, the product is rigidly fixed in the desired position.

- Fastening the extreme edges to the slopes and placing them behind the wall ensures that water flows onto the ebb surface. In this regard, it is installed before finishing the street slopes.

Criterias of choice

If you are replacing or installing a plastic window in an apartment building, then you should choose an external sill similar to those already installed.

When the owner of a private home needs a part, the following parameters must be taken into account before purchasing:

Material. For a plastic window, it is recommended to use plastic sills. A galvanized steel part is more suitable for a wooden frame.- Difficult to maintain. It is better to choose low tides that do not require careful maintenance.

During operation, the external ebb becomes dirty, so cleaning will be necessary. The main thing is that this process can be completed with minimal effort and cost. - Light weight. A product that is too heavy will place a heavy load on the façade. And it will need a supporting structure.

- Is there a special coating? It is recommended to choose ebb tides with platisol coating. It increases the strength of the part and improves its appearance.

- Manufacturer's brand. Well-known suppliers value their reputation and supply quality products.

You should also pay attention to the color of the tint. It must be combined with the facade. Technological parameters for choosing a sheet - width, length, possibility of installing special plugs.

Semicircular or figured windows

Not all windows are linear. But what are the best sills for semicircular windows? All the same metals can save you. But just this time, the ideal option is copper shimmer. Copper is a ductile material and a slight curvature can be simply achieved by tapping it with a hammer.

You can make shaped products from copper

If copper is too expensive, there are factories that make radius castings to your measurements. Since this is an individual order, the cost of such a low tide will also be calculated in each specific case.

Radius flashings for windows in bay windows must be ordered

If there is a need to save money, you can make ebbs for figured bay windows from ordinary galvanized ebbs with a polymer coating. In this case, they are cut into pieces, with which you can create the desired bend.

Semi-circular ebbs from standard materials

With this method, one piece should overlap the adjacent one (by 3-5 cm) - this will make leakage less likely. To further reduce the likelihood of water ingress, a layer of sealant is applied to the joint.

Tools and accessories

To work you will need to prepare a set of:

- drills;

- diamond disc;

- roulette;

- hammer;

- scissors for cutting metal;

- self-tapping screws with a special drill tip;

- a screwdriver and a special attachment to work when there is a ledge under the window;

- marker;

- level;

- polyurethane foam;

- tip.

This list is sufficient for professional or self-installation of ebb and flow on a plastic window.

Roof flashing parameters

Installing ebb linings on the roof is the last stage of work; before that, you first need to select and buy them.

Materials

At the moment, buying roof flashings is not a problem; choosing them is more difficult. I’ll tell you about prices later, but now let’s briefly go through the materials.

What are roof drains made of?

Photo

Materials

Cink Steel

The thickness of the sheet here does not exceed 1 mm, so the design is quite light, plus the price of drainage is quite reasonable.

Polymer coated steel

Here the steel sheet is coated with plastisol, polyester and other similar polymers. The stability of such a coating is an order of magnitude higher than that of conventional galvanization.

Aluminum

The main advantage of aluminum gutters is their light weight, plus this metal is not subject to corrosion, so it does not require painting.

Copper

Manufacturers provide a guarantee of 70 years for copper roof gutters, but they last much longer.

Copper is not afraid of aggressive chemicals, corrosion and other troubles, the only problem is that the price of such structures is several times higher than the cost of plastic or galvanized drainage systems.

Plastic

Now every third developer chooses plastic molding. The design is light, elegant, plus modern polymers do not fade in the sun.

Envious people say that plastic gutters are fragile, but if you choose a proper manufacturer and install the roof flashings correctly, they will last for decades.

Gutter shape

The shape of roof drains can be semicircular, rectangular or shaped. Strictly rectangular gutters, frankly speaking, are not for everyone. Their figured counterparts look original, but are much more expensive.

Semicircular types of gutters are considered the most convenient, practical and popular. Their advantage is that such structures do not have internal corners where dirt and debris constantly collect, and cleaning the roof gutter without special equipment is very problematic with your own hands.

As practice shows, semicircular roof flashings are the best option

Gutter calculation

To calculate the amount of material, you need the length of the perimeter and the square of the projection of the roof onto the ground (the square of the area under the house). According to the instructions, the length of one gutter directed into one funnel should not exceed 10 m, but in reality it is better to start from 5, maximum 7 m.

On long spans of roofing, the gutters are cut from the center to the sides, where drain funnels are installed at the corners. The arrangement of funnels and cutting points of straight roof spans depends on the configuration of the structure.

Installation of the drip tide is planned at the rate of 5 - 7 m of straight gutter per 1 drain funnel

- After measuring the roof perimeter, you need to add 10 - 15% to the total footage; they will be used for trimming and overlap at the joining points.

- If possible, a funnel should be installed at each corner of the roof.

- On average, support brackets are installed at 600 mm intervals.

When calculating the width of the gutter, this is the case. According to the rules, for every square meter of the roof plane there is 1.5 mm of width. That is, a 150 mm gutter is installed on a roof of 100 m². But in reality, professionals usually make it simpler.

- On the roofs of residential buildings with a roof area of up to 100 m², a gutter 100 mm wide is installed.

- For a square area of up to 120 m², the gutter width is taken to be 120 mm.

- For a square area of up to 150 m², the gutter width is taken to be 150 mm.

As for drainpipes, brackets and other accessories, stores usually come with it all included. You tell the width of the gutter and they select the entire system for you. When selecting fittings, it is advisable to choose pipes with a large diameter, this way there is less chance of clogging.

Metal roof drains can have several fitting options

Price issues

No matter how beautiful the roof flashings are, their price depends on 2 things. Firstly, brand awareness, and secondly, the price level in the region. I have calculated the average cost of roof drainage; you can use it as a guide, but you should not make final calculations.

Average price of roof casting

Material

Price per 1 m (Russian rubles)

How to install it yourself?

Installing the external part is not considered a difficult task. A diligent beginner can set the low tide correctly. just need to carefully follow some nuances:

First, clean and properly trim the outer window sill.

Both of its edges should overlap the slopes of the window opening by at least 1 cm. During operation, you need to slightly bend the edges upward - this technique will increase the service life and protect against the formation of condensation in winter.- Check the width of the structure. If the value is equal to the width of the slope, then the ebb will not perform a protective function and water will fall on the wall of the building. The width should be 3-4 cm greater than the slope.

- Will prepare the slopes. It is necessary to seal their lower part with vapor-permeable tape. To do this, the tape must be carefully glued to the frame lining with one edge, and to the cleaned end of the opening with the other. If the slopes are finished with mortar, it is necessary to cut the outer window sill into them 1 cm on each side.

- Make a cushion for the low tide on the window. For this purpose, polyurethane foam is used, which must be carefully blown under the external window sill. A cement-sand mortar is considered a more reliable base.

- Attach the ebb with self-tapping screws, but first treat the joints with the frame with sealant. Start fastening from the middle of the window frame. The distance between the screws is 30 cm.

- Check the horizontal line with a level to ensure that rain does not accumulate in one place. The tilt angle is at least 10°.

- Treat all joints with sealant.

Important! In order to maximize the service life of the part, you must strictly follow the installation technology.

Video instructions for installing a low tide with your own hands:

Gutter maintenance

Timely and correct maintenance of the drainage system will increase the efficiency of the system and avoid costly restoration repairs in the event of an accident.

One of the risk factors is clogging the system with debris, including fallen leaves. To prevent them from getting into the gutters, it is recommended to install upper protective grilles.

Grilles protect gutters from debris

The easiest way to clean communications is with water pressure. This can be done at home using a regular flexible hose. After washing, you need to remove debris and dirt from the grates.

Even if you find dirt stuck to the surface of the gutter, you should not use sharp objects to remove it or scrape off any stains or formations that have appeared. In this case, there is a high probability of damage to the coating (polymer or galvanized), which will inevitably lead to corrosion of the area.

Problem areas (joints, corners, connections of gutters with funnels, etc.) require special attention when cleaning. In these places, the flow speed changes, which increases the risk of traffic jams. The unevenness of the surface at the seams also contributes to its increase.

If the installation of a roof drain with your own hands is done with high quality, the diagram is accurately calculated in advance, and during operation the home owners do not neglect the need to carry out preventive measures, the durability of the system will be maximum. In this case, the drain will work effectively throughout its entire service life, requiring virtually no repairs.

And the good condition and performance of the drainage system can largely affect the technical condition and durability of the building itself.

Possible difficulties and errors

Despite the ease of installation of the product, many people make common mistakes:

- Failure to meet installation deadlines. If the installation of the low tide is postponed indefinitely, then the facade will have to be repaired in the future (due to moisture ingress).

This will increase the cost of installation and improvement of the appearance of the window. - Refusal to install a stand profile. This reduces waterproofing and reduces the quality and service life of the window.

- All joints are not sealed. The ebb tide will not perform protective functions, and moisture will begin to penetrate the facade of the building.

- Wrong choice of waterproofing materials. For example, copper or galvanized flashing cannot be tightly attached to brickwork. Therefore, the tightness of the structure will be compromised.

- Incorrect angle setting. Such an error is difficult to correct, and its consequences are serious. Moisture will accumulate on the windowsill or flow inside the window.

Advice. The listed nuances must be monitored during the installation of the ebb tide.

Preparatory work

Usually, ebb and flow sills are installed together with new metal-plastic windows, then the installation is carried out by the same team, and this is already included in the cost of the contract. But the need for installation may be due to several factors, such as replacing an old, damaged sill, installing a metal window sill on a previously installed window (it can be either wooden or metal).

In any case, to independently install an external drip sill, the first thing you need to do is make or buy one. To purchase, you can contact specialized stores if your sizes are typical.

If you are unable to take measurements yourself or require a product of complex shape, then it is best to contact specialists who will competently take the necessary measurements and take into account all the nuances at the installation site.

Immediately before installation you will need:

- ready-made and available low tide;

- hammer drill or impact drill;

- hammer and chisel, sharp construction knife;

- broom or soft brush;

- sandpaper and a hacksaw for metal;

- building level, plastic pads.

Average prices in the Russian Federation

Let's look at the prices in the country for products and their installation.

For the finished product

The pricing policy of manufacturers is quite extensive. The cost of the finished product depends on:

- supplier brand;

- the material from which the part is made;

- water coating;

- the presence of additional elements;

- delivery region;

- product colors.

Estimated prices vary from 480 rubles to 5,000 rubles for one product.

For installation

Approximate installation prices depend on the status of the locality.

For example, installing low tides in Moscow will be more expensive than in Voronezh. Also, the price varies depending on the list of services, the width of the casting and the material. If you need turnkey installation, it will cost from 900 rubles to 1500 rubles.

You can order a ready-made casting with installation. The minimum cost is from 2000 rubles.