What should be done first: window sills or slopes?

Installing window sills and slopes on windows is hard work, which requires special knowledge and skills, as well as the availability of specialized tools.

In combination with all the above factors, it is possible to achieve the desired results.

It should be noted that window sills and slopes are those objects without which plastic windows cannot be imagined.

The key purpose of slopes is to decorate window openings, hide traces of installation and enhance the insulation of the window opening, as well as its tightness.

Window sills, along with slopes, are a hot topic. They reached their peak of popularity during the construction of houses in the second half of the 20th century. They were made from laminated laminated wood, which was painted with oil-based paint and water emulsion, or from a sanded asbestos cement board.

Often similar window sills are now installed in new houses. They are nailed with nails to wooden plugs that are installed in the wall - this, of course, does not have an ideal appearance. The disadvantages of this design are that it requires constant maintenance and repair work.

There is also a variety of stone window sills made from artificial or natural material. This design, despite its beauty and originality, is affordable due to its price criterion. Another disadvantage is that installation of such material is not always possible due to its heavy weight.

The main advantage of the material is its strength, durability and practicality.

At the same time as the rapid introduction of PVC windows into the modern market, sales of plastic window sills also started. Around the same time, society also learned about laminated window sills made of chipboard and MDF. But only plastic products expressed the best properties and captured the main market share.

Plastic windows form an excellent combination with PVC window sills and slopes. This combination creates a unified style and a high level of practicality, as well as efficiency. Installation of plastic products takes a small part of working time and guarantees a high-quality result.

The installation specialist, as well as the window manufacturer, recommend installing window sills and slopes in the following order: first the window sills, and then the slopes. This recommendation will be necessary for everyone, regardless of the material you choose.

The most popular materials are:

- Plastic . The most popular material for plastic windows is PVC slopes. Their advantages are expressed in light weight, favorable price, durability, and ease of maintenance. Thanks to these qualities, plastic is the most popular material in the construction of new houses and in the renovation of houses that have already been put into operation.

- Plaster . Decorative decoration of window sills can be done using plaster and putty, followed by painting. This material is used quite rarely due to the labor-intensive installation process. As a rule, when installing slopes, the walls are covered with plaster, this makes them more reliable and more resistant to various types of damage. Moisture-resistant wallpaper can also be applied to a plaster slope.

- Mosaic and tiles. The facing of the opening is often made of tiles or mosaic tiles. Such decoration looks impressive and original, which explains the popularity of this material in interior decoration.

- Drywall . An excellent combination in renovation is considered to be a composition of plasterboard and PVC windows; this design, due to its favorable cost, helps to save money on the purchase of plastic. It should be noted that these products are difficult to install due to the different materials.

Advice from a specialist

- According to the established rule, the window sill must extend into the side walls by at least 3 cm. Using a tool, it is necessary to make special recesses at the level where the surface will be located. If a new window is being installed, the window sill can be ordered from the same manufacturer. If they are installed separately after a long period of time, or it was decided to replace the old version with a new one, then it will have to be found in specialized stores or made to order. To measure the product, it is best to invite a specialist - he will accurately set the parameters of the product and will be responsible for this.

It is important to make sure that after installing the metal-plastic window, the putty, mounting solution and foam are completely dry. After this, you can begin to prepare the working surface - it should be clean, free of foreign protrusions, dust and construction debris, as smooth as possible

All hard protrusions are carefully knocked down with a chisel or drill, dust is removed with a broom or construction vacuum cleaner, and polyurethane foam is removed with a sharp knife. Even if the finished window sill was made exactly according to the specified parameters, situations may arise when in some place it does not fit as it should. To solve this problem, sandpaper and a hacksaw are useful - in the right places, the finished blade is adjusted to the position being installed. If it is possible to start fitting the window sill from the side of the wall, it is better to start there, using a hammer and chisel or a strong screwdriver. As a result, the window sill should confidently fit into its intended place, not hang out in the grooves of the side walls, but also not rub in too much.

- You need to spray the prepared work surface with plain water using a broom or mechanical sprayer - the foam will stick much easier to the moisture, which will make working with it much easier. This stage is very important, because It is the polyurethane foam that is the main fixing material. There are three holes for installation in place - two side grooves and a recess in the window itself. The last hole should accept the window sill as clearly as possible - the unsuccessful gap will be visible during the operation of the living space. The most important part of installation is setting the surface according to the level. To measure indicators, a mounting level is used. To adjust the angles of inclination, plastic or wooden plates are placed under it. The slope should be set slightly towards the room so that moisture does not linger in the groove between the horizontal surface and the window and mold and dampness do not grow there.

- After the correct level has been set, you need to press down the new surface with something heavy; bricks wrapped in rags are ideal. They will hold the window sill when the polyurethane foam swells. All empty space underneath is carefully and carefully filled with polyurethane foam. The structures are allowed to stand for at least a day. After the foam has dried, its remains are cut off with a knife - and the window sill is ready for use.

Step-by-step installation of slopes and window sills using plaster

Not in all cases they are installed from scratch. Often people use the service of replacing these two elements of the window space. For example, if the windows in the apartment are in good condition, but the window sills and slopes are in a sad state and restoration will not save them, then you can replace these elements with new ones and install identical or more modern material.

At the final stage of wall finishing, plastic window sills are installed, then the slopes are finished. This sequence is determined by the task of securely fixing the slab under the window and preventing it from moving. When decorating an opening, it is necessary, in accordance with the rules, to attach a board under the opening inside.

The desired effect can be achieved using load-bearing pads, polyurethane foam and adhesives. During the installation process, the window sill must be brought “under zero”, and the opening itself must be equipped with insulating materials. In the case when the slopes are finished first, and not the window sills, the latter have an unacceptable property in this matter - displacement.

Pollination methods

As I found out, there are 2 types of pollination of tomatoes indoors - natural and chemical. I will consider with you how to pollinate tomatoes on the windowsill, and decide which is the most effective method.

Natural pollination

Natural pollination is divided into natural and artificial.

Natural

The natural option is when the breeze sways the branches and pollen moves from one flower to another.

How I organize:

- I open the windows, creating a draft in warm weather.

- If it is below 15 degrees outside, then I place the fan at a distance of 50 cm from the bush.

- In both cases, the branches sway and scatter pollen over all the buds.

Artificial

When the ovaries do not turn out naturally, I do artificial pollination and use mechanical actions to help the bushes pollinate the buds.

How I pollinate:

- I shake the bushes a little or tap the brushes with a stick, the pollen falls and the stamens are pollinated.

- I apply an electric toothbrush to the flower and collect pollen, spreading it to neighboring flowers.

Using a watercolor brush with soft bristles, I collect pollen with rotational movements and transfer it, like a bee, to other inflorescences.

Do you pollinate tomatoes with a toothbrush?

Not really

Chemical pollination

Friends, I am not a supporter of using chemicals when growing, but the results are amazing - the yield increases. I’ll tell you about ways to use ovary stimulants.

Spraying and dipping

During flowering in the morning, I irrigate the buds with a stimulant solution, trying not to get it on the young leaves.

How to dilute:

- I dilute the drug “Ovary” 1 g in 500 ml of warm water. I apply the composition with a sprayer to all flowers and ovaries 2 times: when the tomato bloomed and when it began to bloom.

- In between, I spray boric acid once (1 g + 1 liter of water).

Do you use the “Ovary” preparation for pollination?

Not really

There is a synthetic drug of a new generation of stimulants “Tomato”. I dilute 1 ml of the drug in 0.5 liters of water, add 1 drop of liquid soap to the mug, mix and dip the blossomed buds in the solution.

Author's note

Natalia Papanova

Blog author

I use the “Tomato” stimulator only once a season.

Watch the video on why you should remove the crown flower.

Having decided on pollination on the windowsill, get ready for summer and find out how to pollinate tomatoes on the balcony.

The superiority of plastic window sills and slopes

Advantages of plastic products:

- Installation does not require special physical effort and a lot of time, and there is no need to use professional equipment and this process can be carried out simultaneously with the installation of windows.

- Practicality and wear resistance. The service life of plastic products is up to 25 years, while these elements do not lose their operating properties and appearance.

- Fire safety, the surface is resistant to mechanical stress, ultraviolet rays, unstable temperatures, and high humidity levels.

- Ease of use due to the high-pressure structure of the plastic. This material does not tend to accumulate dirt and dust, and can be easily washed using detergents and cleaning agents.

- Wide variety of colors and structures. Thanks to the use of film material, plastic products can be given any color, taking into account the style of the house or apartment. When changing the interior, the film can be easily removed and replaced with a different color or texture, thereby getting another plus - saving money and physical resources.

Clinker tiles

The clinker casting for the base looks very attractive and aesthetically pleasing. Clinker tiles have undoubted advantages, they are:

- Durable

- Can be used for a long time

- Has excellent protective characteristics

Clinker tiles are a material that can easily be replaced if one fragment is deformed. Installing clinker tile planks requires professional skill, so it is better to entrust the installation to a competent specialist. He will be able to accurately determine the required dimensions of ebbs for the plinth, select the material, calculate the angle and perform the installation correctly.

Do-it-yourself installation of PVC window sills and slopes

There is a window between the cold air of the street and the warm air of the room. If the window frame is not installed, external moisture will enter the cracks of the window, flow along the walls and destroy the entire structure. Installing windows requires the knowledge and skills of specialists, but installing PVC window sills and slopes is easy to do with your own hands.

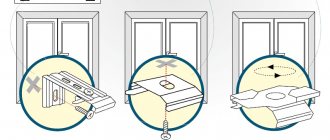

The first step is to install the window sill; for this purpose, it is necessary that several holes are made in the wall near the slopes, after which you can begin finishing them.

Base typology

Below we look at the most common types:

- Sunken. The walls of the house are slightly wider than the part of the base on the ground, and part of the base looks somewhat recessed visually.

- Speakers. The walls of the semi-basement are wider than the facade, providing good thermal protection.

This type of base is needed for a house with a heated basement. A low tide device is needed here. The structure is very susceptible to the influence of moisture that forms as a result of precipitation. As water accumulates in joints over time, it gradually breaks down the concrete. The problem is particularly noticeable as a result of temperature fluctuations. In winter, moisture accumulates and freezes inside the foundation, expands under the influence of low temperatures, and melts with the arrival of spring, eventually cracking the foundation. Result: deformed cladding, bricks falling out, violation of the integrity of the foundation. When moisture penetrates under the basement wall finish, many problems arise. For this reason, the need to install a drip sill on the base of the house is obvious. Slopes and tides play an important role. If you want your house to be attractive not only from the inside, but also from the outside, be sure to pay attention to the ebb and flow strips.

PVC window sill installation

During the installation of a plastic window sill, you need to closely monitor the integrity of its parts. Avoid scratches and other damage. For these purposes, the manufacturer often wraps the window sill in a film covering, which must be removed at the final stage of all work.

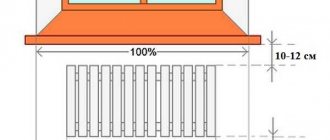

This part is fastened using various construction or adhesive solutions, but sometimes screw materials can also be used. It must be taken into account that the product itself must be 20 cm longer than the window itself. The part that protrudes directly from the wall should be no more than 8 cm.

It should also be remembered that the distance between the radiator and the heating system must be sufficient.

The next stage is installing the window sill. As stated earlier, the product should be slightly longer than the window, because of this, all the recesses are attached directly directly to the wall. The top layer must be cleaned in advance from the previous solution and other products. The window sill can be installed either perpendicular to the loggia or with a slight slope in the other direction from the window structure. In the second solution, water and excess moisture will not be able to linger near the window surface; it will roll down and dry out.

Thus, we need to calculate the length of the window sill, then we need to insert the product into the recesses. After which it is necessary to hold the structure and fill the cracks and voids below with foam, and after complete drying, cut off all excess material.

Afterwards, using slab adhesive, you need to plaster the entire surface of the wall at the bottom of the window. If you need to paste wallpaper or other material, then apply an acrylic solution to the wall in advance, and use putty immediately before painting.

Next, after all the manipulations performed, we remove the film that protects the window sill from damage and attach professional plastic plugs. And only after this you can begin finishing the slopes.

Internal and external finishing of slopes

Installation technology

More often than not, it turns out that the main technical purpose of these products is completely forgotten. They are usually used as a flower stand; especially large and durable versions can be designed as a continuation and expansion of the workspace in the kitchen or office; you can even place a comfortable sofa there for reading books.

In addition to all this, the window sills, with their protrusion, trap the warm air rising from the radiators at a low level, which allows you to warm up the living space much better.

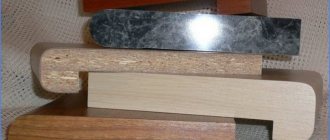

Immediately after installing the metal-plastic window, you need to let it sit for a couple of days, after which the installation of the window sill begins. You need to prepare the tools:

- sharp construction knife;

- hacksaw for metal;

- sandpaper;

- hammer and chisel (if available, an impact drill or hammer drill);

- wooden or plastic pads for leveling the surface;

- building level.

Exterior finishing works

In standard situations, surface work is easier to carry out than internal work. To ensure quality work, you need to clean the walls near the window from various debris generated during construction or repairs. We cut the foam so that the levels of the wall and the foam are the same. We use the same material to fill cracks and voids.

You can also use ceramic tile mortar for this.

Next, you need to use soil for construction on the wall; it is better to treat the walls in several layers to improve the bonding qualities. The following work in finishing this surface is carried out using materials used to decorate the outer wall of the house.

It is also necessary to take into account the fact that all materials used in repairs must be produced specifically for external work, otherwise their service life will be much lower than that regulated by the manufacturer. Next, we level the surfaces, sand them, apply coloring materials or putty for decorations.

Before working with finishing materials, you must carefully study the instructions and, as carefully as possible, the section that indicates the method and frequency of applying layers. Due to the last point and the quality of materials, finishing of external surfaces may take a couple of days.

The most difficult block in exterior finishing is leveling surfaces. In order to reduce this complexity, you need to use a professional reinforced mesh; it is much easier to apply the construction mixture on top of it.

It is necessary to check in detail all surfaces, including walls and coverings, for the presence of lyes and voids; if any are found, they must be covered up immediately. Otherwise, insects and moisture may enter these voids, and they will also be exposed to climatic conditions - this can lead to an unfavorable outcome of the overall repair result.

Concrete casting

Concrete structures demonstrate amazing resistance to temperature fluctuations. Castings for concrete foundation plinths are not subject to deformation; they have a long service life. Concrete is a super-strong material that is resistant to cracking. Concrete casting lends itself well to painting, so it can be decorated in the same style as the exterior decoration. Concrete casting strips will harmonize beautifully with the finishing of the base if it is made of natural stone. Among the disadvantages, it is worth noting the bulkiness of the design and the complexity of restoration work. Concrete remains a very popular option and is very easy to purchase in the market. The structures must be fastened by an experienced craftsman who will correctly measure the angle and correctly select the fasteners.

Interior finishing work

The work on decorating the internal slopes, of course, is more responsible, since it is carried out in the living room, which you see every day. Based on this, you need to very carefully select finishing materials and perform the work as accurately as possible.

The sequence of finishing internal slopes is the same: it is necessary to clean the surface by removing old building materials; If necessary, cut off excess foam and make the slopes yourself. If there are voids in the wall, fill them with mortar, insulating material or another substance that performs a similar function.

Preparing the opening

To properly equip the window sill, the opening must be thoroughly cleaned. This will require a primer and putty. The sequence of actions will look like this:

- If there are deformations on the lower slope, it should be leveled. The putty fits perfectly. To continue preparation, you will need to wait for it to dry completely.

- In order to prevent the formation of fungus on a plastic structure, you can use a primer composition as an antiseptic;

- When replacing a window sill in an old house, you should take care of the waterproofing layer. To do this, special mastic is applied to the slope. It must also be completely dry before installation work can continue.

Window sill installation diagram

Natural stone

Installation of flashing on the base of a stone foundation is carried out mainly using sandstone; granite is used less frequently. The cost of natural material is quite high, so not every owner will be able to afford a device of this type.

Among the advantages it is worth noting:

- Stone is a durable material

- Reliable

- Resistant to wear

- Aesthetically attractive

- Goes well with facade panels.

Stone options, due to their heavy weight, are not suitable for any foundation. Only a foundation that can withstand heavy loads can support such a device. Another disadvantage of natural stone is the complex and labor-intensive installation.

Requirements

The product is manufactured taking into account the requirements that need to be studied before ordering:

Calculation of the width of the ebb is carried out depending on the width of the opening.

This is a dependent quantity. Then you need to add 3-4 cm (protrusion) + a slight slope. As a result, the minimum width of the part should not be less than 90 cm.- The length is calculated based on the distance between the outer side edges of the window opening. To the resulting measurement you need to add 4 cm on each side. In its finished form, the length of the ebb should not be 7-8 cm greater than the original measurement.

- The appearance and parameters of the window sill differ for windows in a frame, panel or brick house. The configuration of the part must correspond to them.

- The optimal color of the shimmer is the same as the color of the frame or a shade darker.

Technical requirements include:

- increased resistance to corrosion;

- resistance to negative natural factors - precipitation, temperature changes, solar activity;

It is necessary that the selected ebb tide option for a plastic window meets all the listed requirements.